In the world of heavy machinery, a comprehensive understanding of its various elements is essential for optimal performance and maintenance. Each component plays a crucial role in the functionality of these powerful machines, enabling them to operate efficiently in demanding environments.

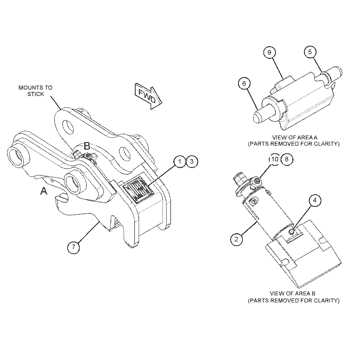

Visual representations of these intricate systems can provide invaluable insights. By examining the arrangement and interconnection of these essential elements, operators and technicians can more effectively troubleshoot issues and enhance the machinery’s longevity.

Delving into these visual guides not only aids in identifying individual components but also offers a broader perspective on how they work together to achieve the ultimate performance. Whether for training or repair purposes, a clear illustration serves as a foundational resource for anyone involved in the operation and upkeep of heavy equipment.

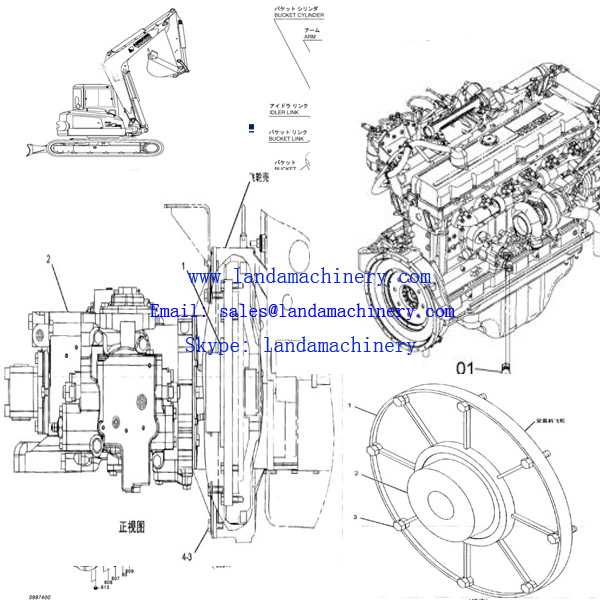

Caterpillar Excavator Parts Overview

This section provides an insightful look into the various components essential for the operation of heavy machinery designed for digging and earthmoving tasks. Understanding the arrangement and functionality of these elements is crucial for efficient maintenance and optimal performance.

Key Components: The machinery comprises several critical elements, each contributing to its overall effectiveness. These include the engine, which powers the unit, the hydraulic system, responsible for movement and force, and the undercarriage, which ensures stability and mobility.

Maintenance Importance: Regular upkeep of these components not only enhances performance but also prolongs the lifespan of the machine. Awareness of how each part interacts will aid operators in troubleshooting and executing repairs effectively.

Importance of Accurate Diagrams

Clear and precise representations are essential in the maintenance and repair of machinery. They serve as vital tools for technicians, enabling them to understand the intricate relationships between various components. When these visual aids are accurate, they greatly enhance the efficiency of diagnostic processes and repairs.

Moreover, reliable illustrations facilitate better training for new personnel, allowing them to grasp complex systems more quickly. This leads to fewer errors during servicing, ultimately resulting in reduced downtime and improved operational efficiency.

In addition, comprehensive visuals support effective communication among team members, ensuring that everyone is aligned on procedures and expectations. This cohesion is crucial for maintaining high standards of safety and performance in any technical environment.

Common Components of Excavators

Understanding the essential elements of heavy machinery is crucial for effective operation and maintenance. Each component plays a vital role in ensuring optimal functionality and performance during various tasks.

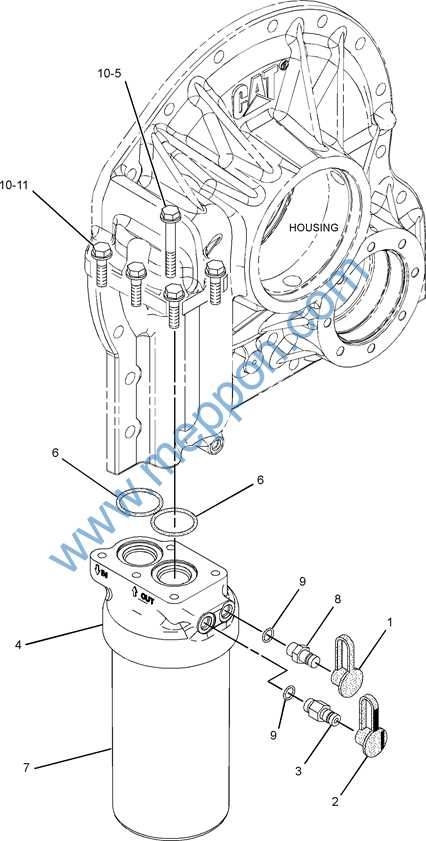

Hydraulic System

The hydraulic system is the powerhouse of the machinery, responsible for moving and lifting heavy loads. It consists of pumps, cylinders, and fluid, working together to generate force and control movement.

Chassis and Undercarriage

The chassis supports the entire structure, while the undercarriage provides stability and mobility. This includes tracks or wheels that facilitate movement across diverse terrains, ensuring that the machine can navigate effectively.

Regular maintenance of these fundamental components is essential for longevity and performance. Understanding their functions allows operators to optimize usage and address potential issues promptly.

Understanding Hydraulic Systems

Hydraulic systems are essential components in various machinery, utilizing fluid power to perform tasks with remarkable efficiency and precision. These systems convert mechanical energy into hydraulic energy, enabling operators to achieve significant lifting and movement capabilities.

Components of Hydraulic Systems

A typical hydraulic setup consists of several key elements, including pumps, cylinders, and valves. The pump generates the necessary pressure, while cylinders facilitate the movement of loads by converting hydraulic energy back into mechanical motion. Valves play a critical role in controlling fluid flow, allowing for precise manipulation of machinery operations.

Benefits of Hydraulic Technology

The use of hydraulic systems offers numerous advantages, such as high power-to-weight ratios and the ability to easily control force and speed. This technology not only enhances operational efficiency but also enables safer handling of heavy loads, making it a preferred choice in many industrial applications.

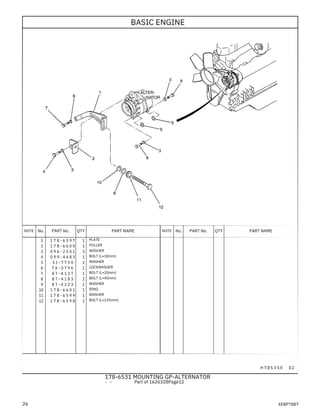

Key Electrical Parts Explained

Understanding the essential components of a heavy machinery’s electrical system is crucial for effective operation and maintenance. These elements play a vital role in ensuring optimal functionality, safety, and efficiency. Each component contributes to the seamless integration of the overall system, supporting both power delivery and control mechanisms.

One of the primary elements is the battery, which serves as the main energy source, providing the necessary voltage to start the engine and power various systems. Another important component is the alternator, responsible for generating electricity once the engine is running, ensuring that all electrical systems remain functional. Additionally, the starter motor is critical for initiating engine operation by converting electrical energy into mechanical energy.

Wiring harnesses are also significant, as they organize and protect electrical circuits, ensuring reliable connections throughout the machine. Moreover, sensors play a pivotal role in monitoring various parameters, sending real-time data to the control unit to optimize performance and safety. Finally, the control unit acts as the brain of the system, processing information and commanding other components to respond accordingly.

Transmission and Engine Connections

This section delves into the intricate relationship between the power generation unit and the drive mechanism in heavy machinery. Understanding these linkages is crucial for optimal performance and efficiency in various operations.

The connection between the propulsion system and the motor involves several critical components:

- Couplings: These elements facilitate the transfer of power from the engine to the transmission.

- Drive Shafts: Essential for transmitting rotational energy, ensuring smooth operation between systems.

- Clutch Mechanisms: Allow for the engagement and disengagement of the power flow, enabling control during operation.

- Gear Assemblies: These convert engine speed into usable torque for the drive system.

Proper maintenance of these connections is vital for enhancing reliability and extending the lifespan of the machinery. Regular inspections and timely replacements can prevent costly breakdowns and ensure seamless functionality.

- Inspect couplings for wear and misalignment.

- Check drive shafts for any signs of damage or imbalance.

- Evaluate clutch performance to ensure effective engagement.

- Monitor gear assemblies for proper lubrication and wear levels.

In summary, a thorough understanding of these connections will not only improve operational efficiency but also contribute to the longevity of the equipment.

How to Read Diagrams Effectively

Understanding visual representations is crucial for interpreting complex information accurately. By mastering the skills to analyze these illustrations, you can enhance your ability to grasp intricate systems and their components.

Key Strategies

- Familiarize Yourself with Symbols: Recognize common icons and their meanings.

- Identify the Layout: Understand how elements are arranged and their relationships.

- Follow Flow: Trace the pathways to see how processes unfold.

Practice and Application

- Start with simple visuals before moving to more complex ones.

- Practice interpreting diagrams in various contexts to build confidence.

- Engage with hands-on tasks to reinforce your understanding of the visuals.

Maintenance Tips for Excavator Parts

Regular upkeep is essential for ensuring optimal performance and longevity of machinery components. By following a few simple strategies, operators can minimize wear and prevent costly breakdowns.

- Conduct frequent inspections to identify signs of wear or damage.

- Keep components clean and free from debris to avoid unnecessary strain.

- Lubricate moving elements according to the manufacturer’s recommendations.

- Monitor fluid levels regularly and replace filters as needed.

- Stay updated with any recall notices or technical bulletins.

Implementing these practices will ultimately enhance reliability and efficiency.

Identifying Wear and Tear

Recognizing signs of deterioration is crucial for maintaining optimal performance and longevity of heavy machinery. Regular inspections can help detect issues before they lead to more significant problems, ensuring safe and efficient operation. Understanding the typical indicators of wear allows operators and technicians to address concerns promptly.

Common symptoms include unusual noises, vibrations, and decreased efficiency during operation. For instance, if components exhibit excessive movement or looseness, it may signal impending failure. Additionally, visual inspections should focus on areas where friction occurs, as well as any signs of corrosion or cracking that could compromise structural integrity.

Monitoring fluid levels and conditions can also provide valuable insights into the health of the equipment. Contaminated or degraded fluids may indicate underlying issues that need to be addressed immediately. Keeping detailed maintenance logs helps track performance over time, making it easier to identify trends that suggest wear and tear.

Replacement Parts: What to Consider

When it comes to maintaining heavy machinery, choosing the right components is crucial for ensuring optimal performance and longevity. Various factors play a significant role in selecting substitutes, impacting not only efficiency but also overall operational costs.

Quality and Compatibility

One of the primary considerations is the quality of the replacements. It’s essential to assess whether the substitutes meet the necessary standards and specifications. Here are some points to keep in mind:

- Verify manufacturer certifications and quality guarantees.

- Ensure compatibility with the existing machinery to avoid functional issues.

- Consider using OEM (Original Equipment Manufacturer) options for optimal performance.

Cost and Availability

Budget constraints are inevitable when managing machinery upkeep. Therefore, evaluating costs alongside availability is key:

- Compare prices from multiple suppliers to find the best deal.

- Check for lead times and stock availability to prevent downtime.

- Consider long-term savings versus initial investment for each option.

Aftermarket vs. OEM Components

The choice between original and alternative components is a critical consideration for machinery maintenance and performance. Each option offers distinct advantages and potential drawbacks that can impact both operational efficiency and long-term costs.

Quality and Reliability

Original components are typically designed and manufactured by the equipment’s original maker, ensuring a high level of quality and compatibility. They undergo rigorous testing, which often translates to enhanced durability and reliability. On the other hand, alternative options can vary significantly in quality. While some aftermarket items may match or even exceed the original specifications, others might compromise on materials or construction, leading to potential issues down the line.

Cost Considerations

One of the primary motivations for choosing alternative components is the potential for cost savings. OEM products often come with a premium price tag, which can be a deterrent for budget-conscious operators. However, it’s essential to weigh these savings against the possibility of increased maintenance needs or shorter lifespans associated with some aftermarket options. In the long run, investing in higher-quality original items may prove to be more economical, reducing the frequency of replacements and repairs.

Safety Measures During Repairs

Ensuring a secure environment during maintenance is crucial to prevent accidents and injuries. Proper precautions not only protect the individual performing the task but also contribute to the longevity and efficiency of the machinery. Adhering to established safety protocols is essential in maintaining a safe workspace.

Personal Protective Equipment

Utilizing appropriate personal protective gear is vital. This includes hard hats, gloves, safety glasses, and steel-toed boots. Each piece of equipment plays a significant role in safeguarding the worker from potential hazards associated with repair activities.

Workspace Organization

A tidy and organized workspace minimizes the risk of accidents. Ensuring that tools and materials are stored properly, and that the area is free from clutter, helps maintain a safe working environment. Additionally, clear pathways should be established to allow for easy movement around the site.

Resources for Further Learning

This section provides valuable materials for those looking to enhance their understanding of heavy machinery components and their configurations. Engaging with these resources will deepen your knowledge and assist in practical applications.

| Resource Type | Description | Link |

|---|---|---|

| Books | Comprehensive guides on machinery and its functions. | Explore Books |

| Online Courses | Interactive courses covering maintenance and repair techniques. | Find Courses |

| Forums | Community discussions for troubleshooting and advice. | Join Forums |

| Videos | Tutorials demonstrating assembly and disassembly processes. | Watch Videos |