Understanding the internal structure and the specific layout of equipment elements is crucial for efficient maintenance and repair. Proper knowledge of the configuration ensures that each section of the machinery is correctly identified and serviced, leading to smoother operation and longer equipment lifespan.

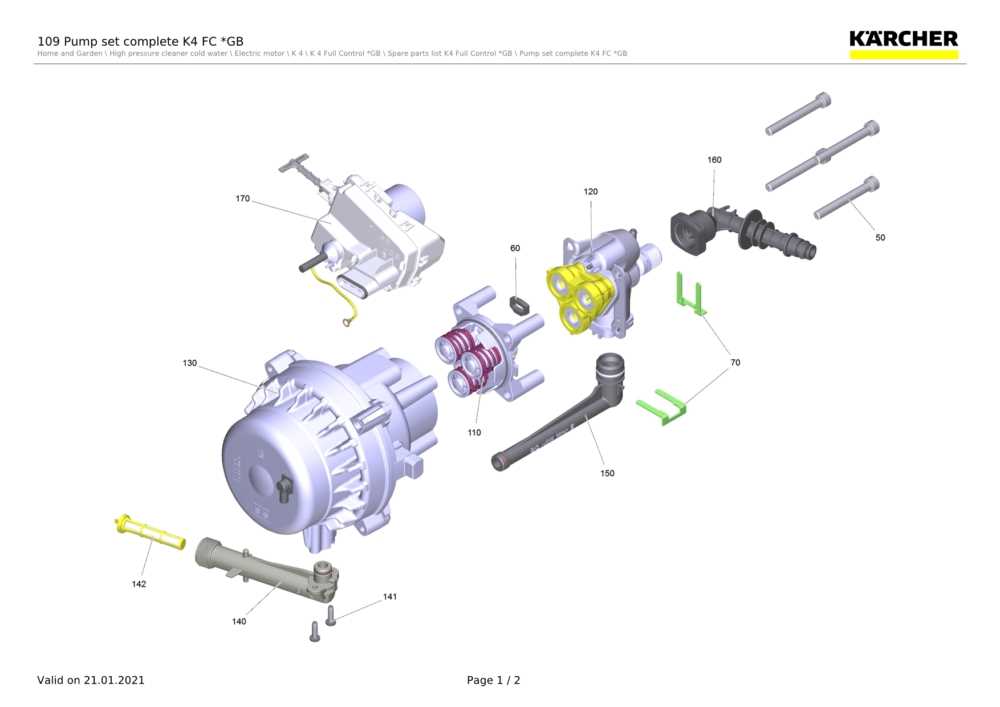

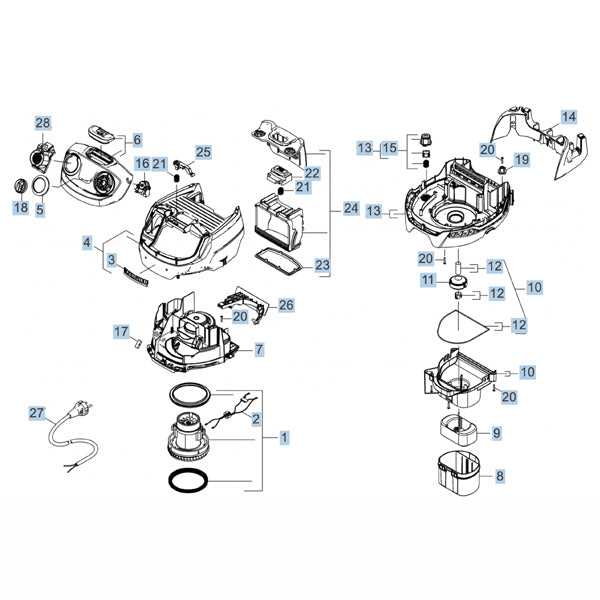

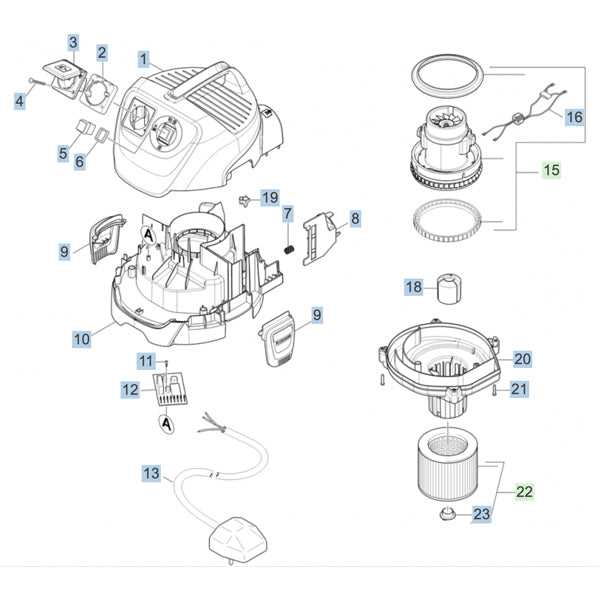

Each mechanical unit consists of various interconnected segments, all playing a vital role in the overall functionality. Having a clear view of these interconnections can greatly simplify troubleshooting and make upgrades more efficient.

In this guide, we will explore the structural composition of these devices, offering a clear breakdown of their essential elements. This will help you not only identify key components but also streamline your repair and optimization efforts.

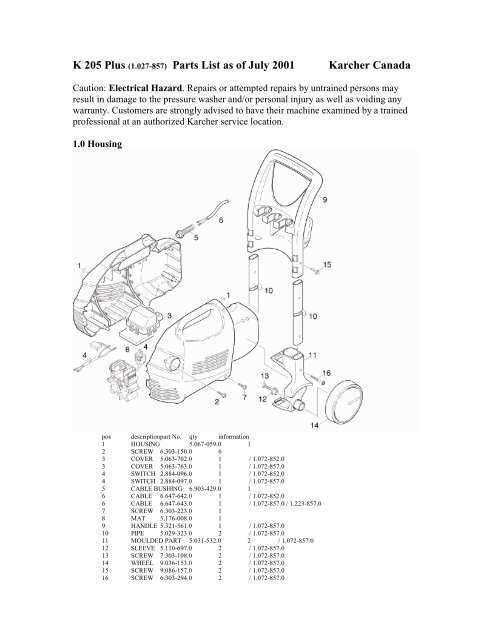

Comprehensive Overview of Karcher Components

Understanding the intricate design and functionality of various cleaning equipment requires a thorough exploration of their individual elements. This section offers a detailed insight into the diverse mechanisms and how each contributes to the overall performance and efficiency of the system. By familiarizing yourself with these elements, you can gain a deeper appreciation of how they work together to achieve optimal results.

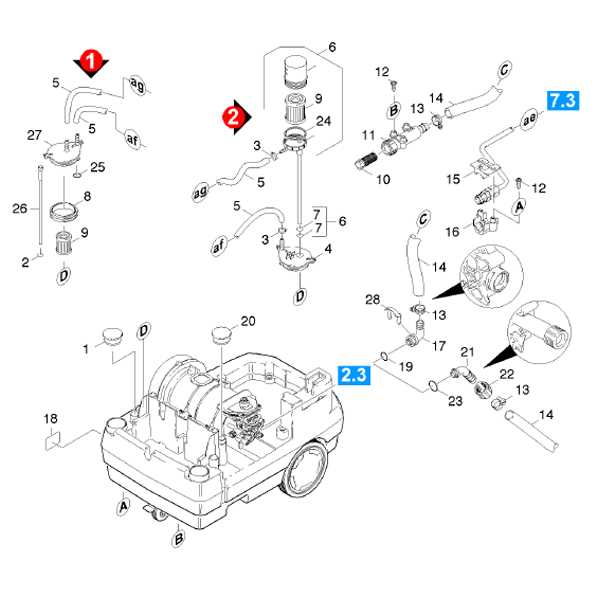

Key Functional Units

Each unit within the cleaning system plays a critical role in ensuring smooth operation. From the fluid handling modules to the pressure control units, these components work in harmony to maintain the required flow and pressure levels. Regular maintenance of these units can significantly extend the lifespan of the equipment and prevent unexpected breakdowns.

Interconnecting Mechanisms

The various connectors and fittings ensure seamless integration between different parts, allowing the equipment to function as a cohesive whole. These interconnections not only support the transfer of power and fluids but also enhance the durability and reliability of the system. Identifying the correct components during replacements en

Identifying Essential Parts for Maintenance

Regular upkeep of cleaning equipment requires a clear understanding of the key components involved. Ensuring smooth operation and prolonging the lifespan of any machine begins with knowing which elements are critical for routine checks and replacements. By focusing on these, you can maintain efficiency and avoid potential issues during usage.

Filters and Seals are crucial for preventing debris and moisture from affecting the machine’s internal mechanisms. Regular inspection and timely replacement of these components can significantly improve performance and reduce the likelihood of malfunctions.

Nozzles and Hoses play a vital role in delivering precise water flow. Keeping these in top condition not only ensures effective cleaning but also prevents unnecessary wear on other parts of the system, helping maintain overall operational efficiency.

Exploring Commonly Replaced Components

Over time, various systems and mechanisms tend to experience wear and tear, leading to the need for regular maintenance. Understanding which elements require frequent attention allows for a more efficient upkeep of machinery, helping to avoid unexpected breakdowns. Below, we will examine some of the key components that are often subject to replacement in a wide range of equipment.

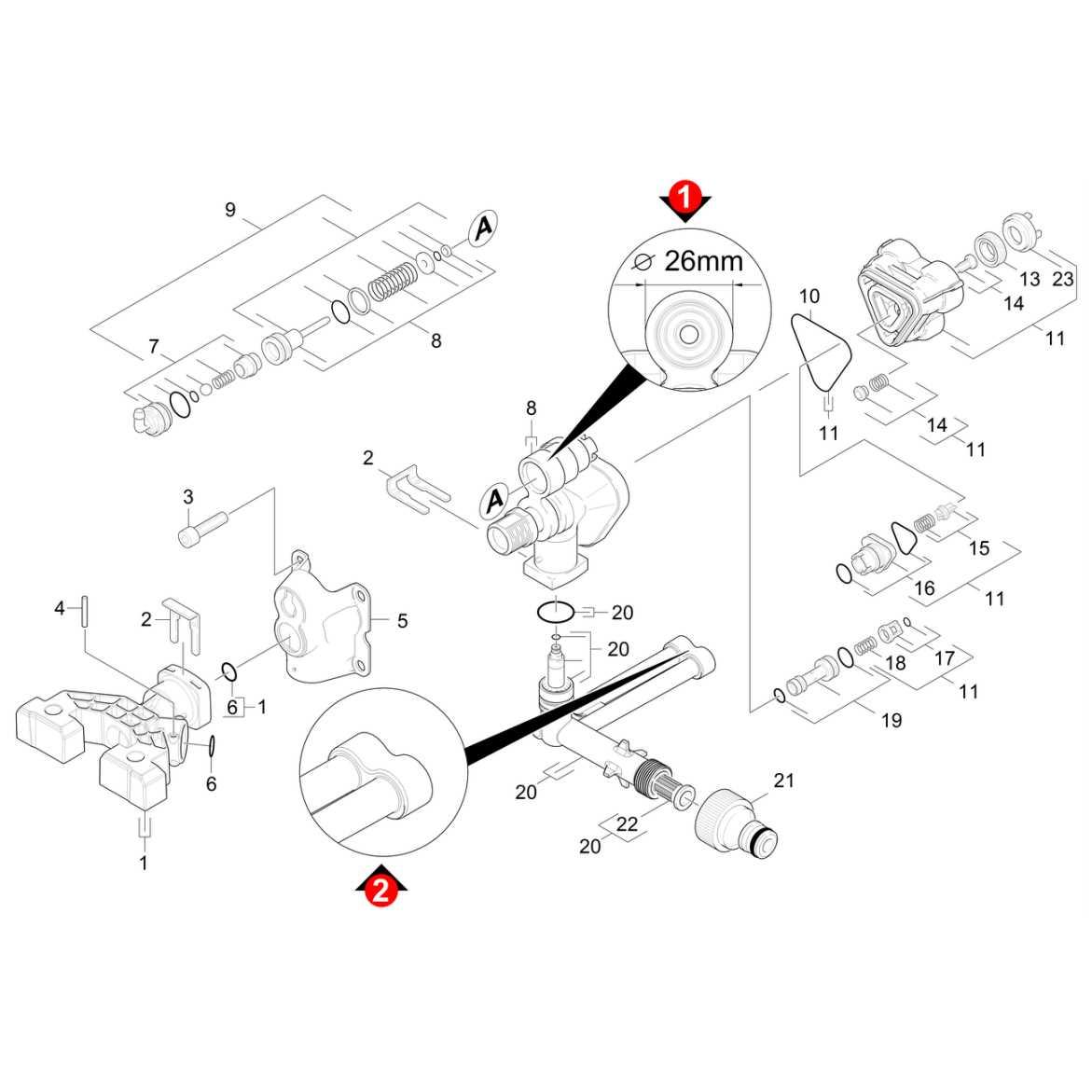

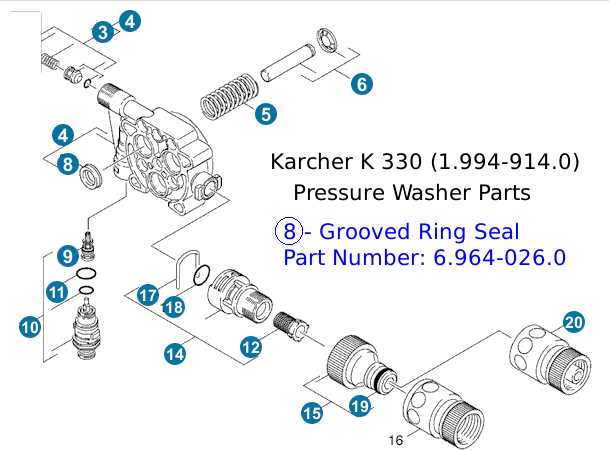

Seals and Gaskets: These flexible elements play a critical role in preventing leaks and maintaining pressure. Due to continuous exposure to various substances, they tend to degrade and lose their effectiveness over time.

O-Rings: Often found in connections and joints, these small yet crucial items ensure that liquid or air-tight seals are maintained. However, they are prone to hardening and cracking, necessitating periodic replacement.

Nozzles: Exposure to different materials and conditions can gradually wear out nozzles, reducing their performance. Replacing them restores the system’s efficiency and ensures optimal operation.

Understanding Key Functions of Karcher Elements

Recognizing the main roles of various components in cleaning equipment helps in ensuring efficient operation and maintenance. Each element within the device serves a specific purpose, contributing to the overall functionality and effectiveness of the system.

Primary Mechanisms

The core mechanisms are responsible for generating the necessary pressure and water flow to achieve thorough cleaning. These parts include pumps and valves, which regulate the performance and ensure optimal force is applied during usage.

Control and Adjustment Features

Control elements allow for the adjustment of power and flow, ensuring the user can customize the settings based on the surface or task at hand. These features are crucial for precision and adaptability, ensuring that the equipment can tackle a wide variety of cleaning scenarios.

Guide to Selecting Replacement Items

When maintaining your equipment, it’s crucial to identify and choose the correct components for replacement. Ensuring compatibility with the system is essential for optimal performance. A well-thought-out approach to selecting substitutes can prevent potential malfunctions and extend the lifespan of your device.

Begin by identifying the key features of the item that needs to be replaced. Look for specifications such as size, material, and any other important attributes that match the original component. This will help you avoid mismatches that could lead to operational issues.

Next, check the availability of compatible alternatives from reliable sources. Ensure that the manufacturer or supplier provides detailed information about the product to guarantee that it meets your system’s requirements. Doing so will help you make an informed decision, ensuring that the selected replacement maintains the functionality and durability of your equipment.

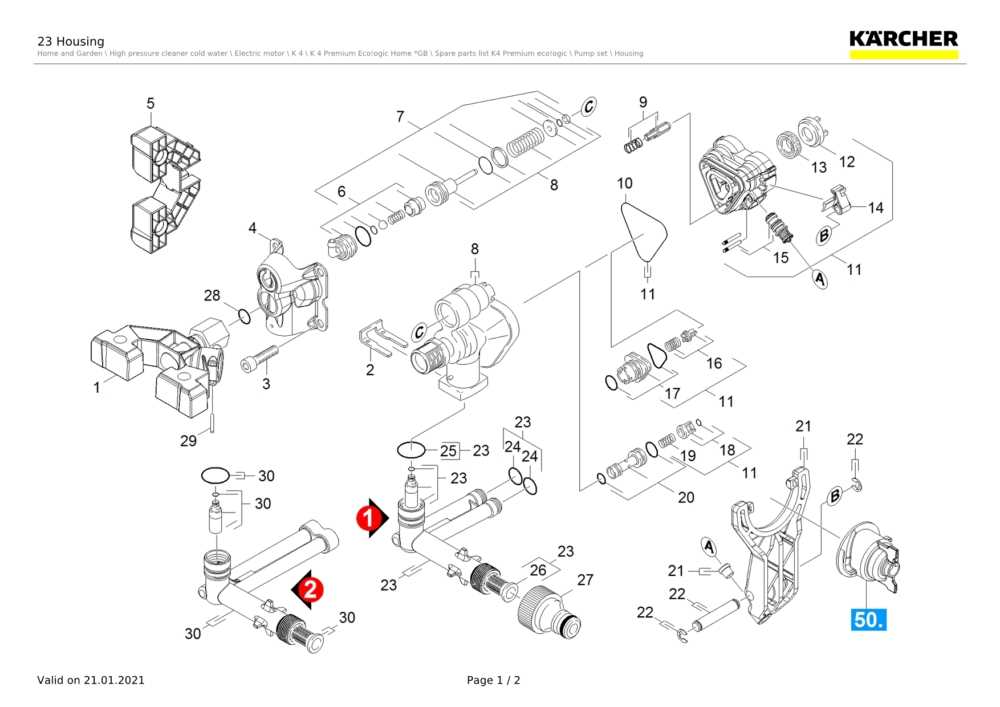

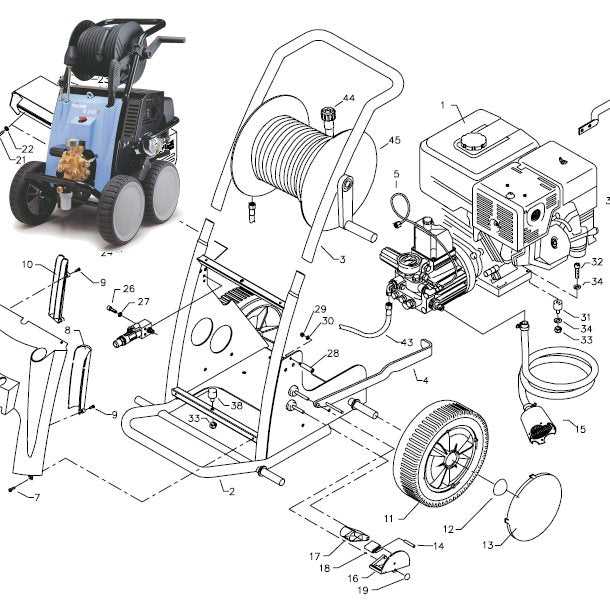

Troubleshooting with Karcher Equipment Diagrams

Understanding equipment schematics can significantly enhance the troubleshooting process for cleaning machines. These visual representations provide essential insights into the components and their interconnections, aiding in the identification of potential issues. By consulting these diagrams, users can quickly diagnose problems and implement effective solutions.

Here are some common troubleshooting steps that can be facilitated by utilizing equipment schematics:

- Identify Components: Recognize each part’s function within the system to understand where potential faults may occur.

- Follow Circuits: Trace the flow of operation to pinpoint disruptions or failures in electrical or mechanical pathways.

- Cross-Reference Issues: Compare symptoms of malfunction with the information presented in the schematic to isolate the faulty component.

- Plan Repairs: Use the layout to strategize repairs by determining the necessary tools and parts required for replacement.

By leveraging these resources, users can enhance their problem-solving skills and reduce downtime, ultimately improving the efficiency of their cleaning operations.

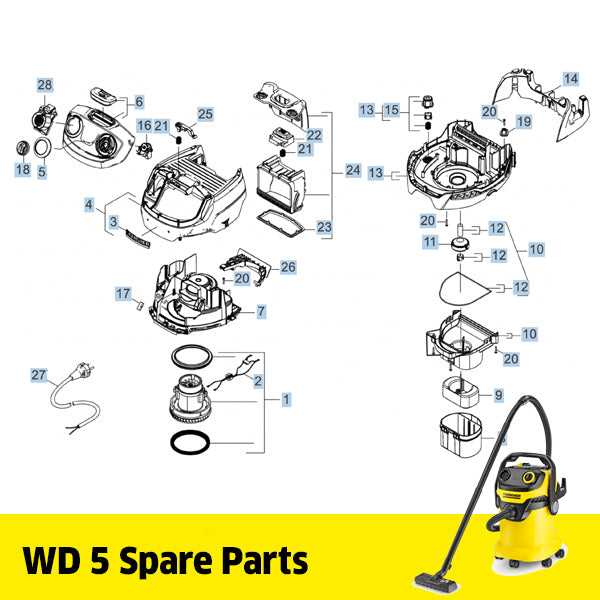

Recognizing Wear and Tear in Karcher Units

Identifying signs of deterioration in cleaning equipment is crucial for maintaining optimal performance and extending its lifespan. Regular inspection helps ensure that all components function smoothly, preventing costly repairs and enhancing efficiency. This section focuses on common indicators of wear and how to address them effectively.

Common Signs of Deterioration

Several visible and operational cues can signify that your cleaning device is experiencing wear. These may include unusual noises during operation, reduced water pressure, or visible leaks. Additionally, a thorough examination of the housing and connectors can reveal cracks or corrosion that may impact functionality.

Maintenance and Solutions

To mitigate wear and tear, it is essential to perform routine maintenance, including cleaning filters and checking seals. Addressing minor issues promptly can prevent them from escalating into significant problems. Below is a table summarizing common issues and their solutions:

| Issue | Possible Causes | Recommended Actions |

|---|---|---|

| Reduced Pressure | Clogged filter, worn pump | Clean or replace filter, inspect pump |

| Unusual Noises | Loose parts, damaged bearings | Tighten components, replace bearings |

| Leaks | Worn seals, cracked hoses | Inspect and replace seals, repair or replace hoses |

Locating Spare Parts for Efficient Repair

Efficient maintenance relies heavily on the ability to find the right components. Whether for routine servicing or unexpected breakdowns, knowing where to source necessary items can significantly reduce downtime and enhance the repair process.

Here are some strategies for effectively locating components:

- Manufacturer’s Website: Begin your search on the official website of the equipment’s manufacturer. They often provide a comprehensive catalog of available components along with detailed specifications.

- Authorized Dealers: Reach out to certified retailers who specialize in the brand. These dealers can offer expert advice and ensure you receive genuine items.

- Online Marketplaces: Explore popular e-commerce platforms that feature a wide range of components. Always check reviews and seller ratings to ensure quality.

- Local Repair Shops: Visit nearby service centers. They may have a stock of commonly needed items and can also provide installation assistance.

Additionally, consider the following tips to streamline your search:

- Maintain a list of model numbers and specifications for easy reference.

- Utilize forums and online communities dedicated to maintenance and repair; these can be valuable resources for finding specific components.

- Set up alerts on e-commerce websites for specific items to be notified when they become available.

By utilizing these approaches, you can ensure a smooth repair experience, minimizing interruptions and enhancing the longevity of your equipment.

Best Practices for Parts Installation

Ensuring optimal functionality and longevity of equipment relies heavily on proper installation techniques. By adhering to specific guidelines during the assembly process, users can avoid common pitfalls and enhance overall performance. This section outlines essential recommendations for achieving a successful setup.

Before commencing the installation, it is vital to gather all necessary tools and components. A well-organized workspace contributes to efficiency and minimizes the risk of errors. Always consult the manufacturer’s manual for guidance on each element’s specifications and compatibility.

Proper alignment and secure fastening are crucial steps in the installation process. Avoid overtightening, as it can lead to damage or misalignment. Instead, follow torque specifications as indicated in the documentation. Additionally, use appropriate lubricants where necessary to ensure smooth operation and reduce wear.

After completing the assembly, it is advisable to perform thorough testing. This allows for the identification of any potential issues early on, ensuring everything functions as intended. Routine maintenance checks should be scheduled to prolong the lifespan of the components.

| Step | Recommendation |

|---|---|

| 1 | Gather necessary tools and components. |

| 2 | Consult the manual for specifications. |

| 3 | Ensure proper alignment and secure fastening. |

| 4 | Perform thorough testing after installation. |

| 5 | Schedule routine maintenance checks. |

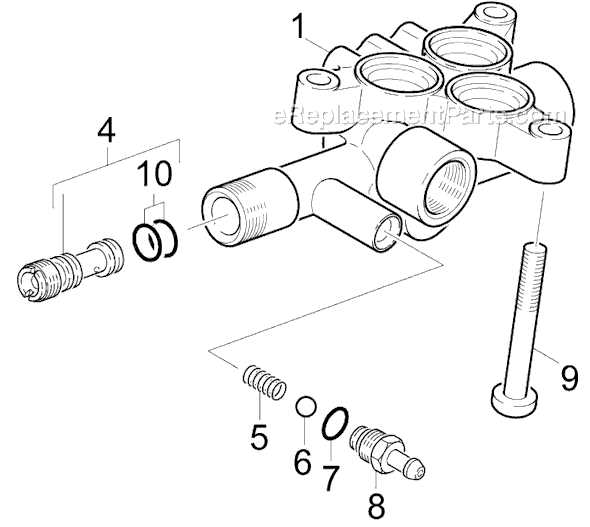

Matching Components to Specific Models

Identifying the correct elements for various equipment is crucial for ensuring optimal performance and longevity. Each model has unique specifications that dictate which components are compatible. Understanding these relationships allows users to maintain and repair their devices effectively, minimizing downtime and maximizing efficiency.

Importance of Compatibility

Utilizing appropriate components enhances the functionality of the device and prevents potential damage. Mismatched parts can lead to operational failures and increased repair costs. Therefore, recognizing which components align with specific models is essential for effective maintenance and operation.

Component Identification Table

| Model | Compatible Component | Part Number |

|---|---|---|

| Model A | Element Type 1 | 123456 |

| Model B | Element Type 2 | 789012 |

| Model C | Element Type 3 | 345678 |

Finding Quality Parts for Long-Term Use

When it comes to maintaining equipment, selecting high-quality components is crucial for ensuring durability and optimal performance. Reliable elements contribute significantly to the longevity of your devices, helping to prevent frequent breakdowns and costly repairs. This section explores effective strategies for sourcing dependable materials that can withstand regular use.

Researching Trusted Suppliers

Identifying reputable vendors is essential for acquiring top-notch components. Start by checking online reviews and testimonials to gauge the reliability of different suppliers. Look for companies with a solid track record in delivering quality products and excellent customer service. Building relationships with trusted distributors can also provide you with valuable insights and recommendations.

Evaluating Quality Standards

Before making a purchase, it’s important to assess the quality standards of the items. Look for certifications or guarantees that indicate compliance with industry benchmarks. Components that meet rigorous testing protocols are often more reliable and perform better in the long run. Consider comparing specifications and performance ratings to ensure you choose the most suitable options for your needs.

| Criteria | Importance | Example |

|---|---|---|

| Supplier Reputation | High | Established companies with positive reviews |

| Quality Certifications | Medium | ISO certification, compliance with standards |

| Warranty Options | High | Products with extended warranties |

| Customer Support | Medium | Availability of assistance and guidance |

Optimizing Equipment Performance with New Parts

Upgrading components can significantly enhance the efficiency and longevity of any machine. By incorporating fresh elements, users can restore optimal functionality and prevent unexpected breakdowns. This process not only improves performance but also contributes to more effective operation and reduced energy consumption.

When considering the replacement of essential components, several factors should be taken into account:

- Compatibility with existing equipment

- Quality of materials used in manufacturing

- Warranty and support offered by the manufacturer

Implementing new elements in your machinery can lead to a variety of benefits, including:

- Enhanced Efficiency: Fresh components often operate more smoothly, resulting in improved performance.

- Reduced Maintenance Costs: New parts can decrease the frequency of repairs and associated expenses.

- Increased Lifespan: By ensuring that all components are in good condition, the overall lifespan of the equipment can be extended.

Investing in quality replacements is essential for achieving the best results. Regular maintenance and timely upgrades can ensure that machinery operates at peak performance for years to come.

Maintaining Your Karcher Machine for Longevity

Proper upkeep of your cleaning equipment is essential for ensuring its durability and optimal performance. By following a few simple practices, you can extend the lifespan of your device and enhance its efficiency, making your cleaning tasks easier and more effective.

Regular inspections are crucial. Check the various components for wear and tear, and replace any damaged parts promptly. This proactive approach prevents minor issues from escalating into major repairs. Additionally, keeping the exterior clean and free from debris helps maintain its overall condition.

Another important aspect is the proper storage of your equipment. When not in use, ensure it is stored in a dry and sheltered environment to protect it from moisture and temperature fluctuations. This will significantly reduce the risk of rust and other environmental damage.

Lastly, follow the manufacturer’s guidelines for routine maintenance. This includes tasks such as changing filters, checking hoses, and ensuring connections are secure. Adhering to these recommendations will contribute to the longevity and reliable performance of your machine.