The intricacies of mechanical devices can often be overwhelming, yet they are vital to ensuring optimal performance and functionality. This section delves into the essential elements that constitute these systems, highlighting their significance and interconnectivity.

By exploring the various components and their arrangement, readers can gain insights into the operational mechanisms at play. Such knowledge not only aids in better comprehension but also enhances troubleshooting abilities and maintenance practices.

Equipped with an understanding of these elements, users can confidently navigate the complexities of their machinery, ensuring longevity and efficiency in their operations. This exploration serves as a guide for those seeking to familiarize themselves with the underlying structure of these essential tools.

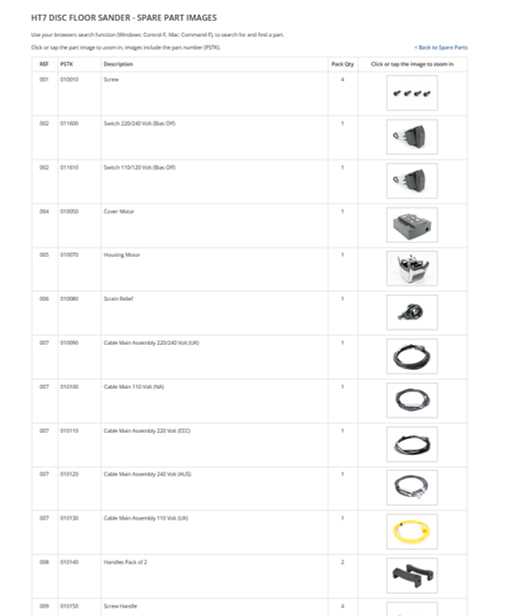

Understanding Hiretech HT7 Components

This section delves into the essential elements that comprise a specific piece of equipment used in various applications. Each component plays a vital role in ensuring optimal functionality and performance, contributing to the overall efficiency of the machine. A thorough comprehension of these elements is crucial for effective operation and maintenance.

Key Elements of the Equipment

Familiarity with the main parts can enhance the understanding of how the machinery operates. Here are some critical components:

| Component | Description |

|---|---|

| Motor | Drives the equipment, providing necessary power for operation. |

| Chassis | The main structure that supports all other components and ensures stability. |

| Control Panel | Allows the operator to manage settings and monitor performance. |

| Wheels | Facilitates mobility and ease of movement across different surfaces. |

Importance of Each Component

Understanding the significance of each part is essential for maintenance and troubleshooting. Each element contributes uniquely to the functionality, and recognizing their roles can aid in identifying issues and ensuring optimal performance.

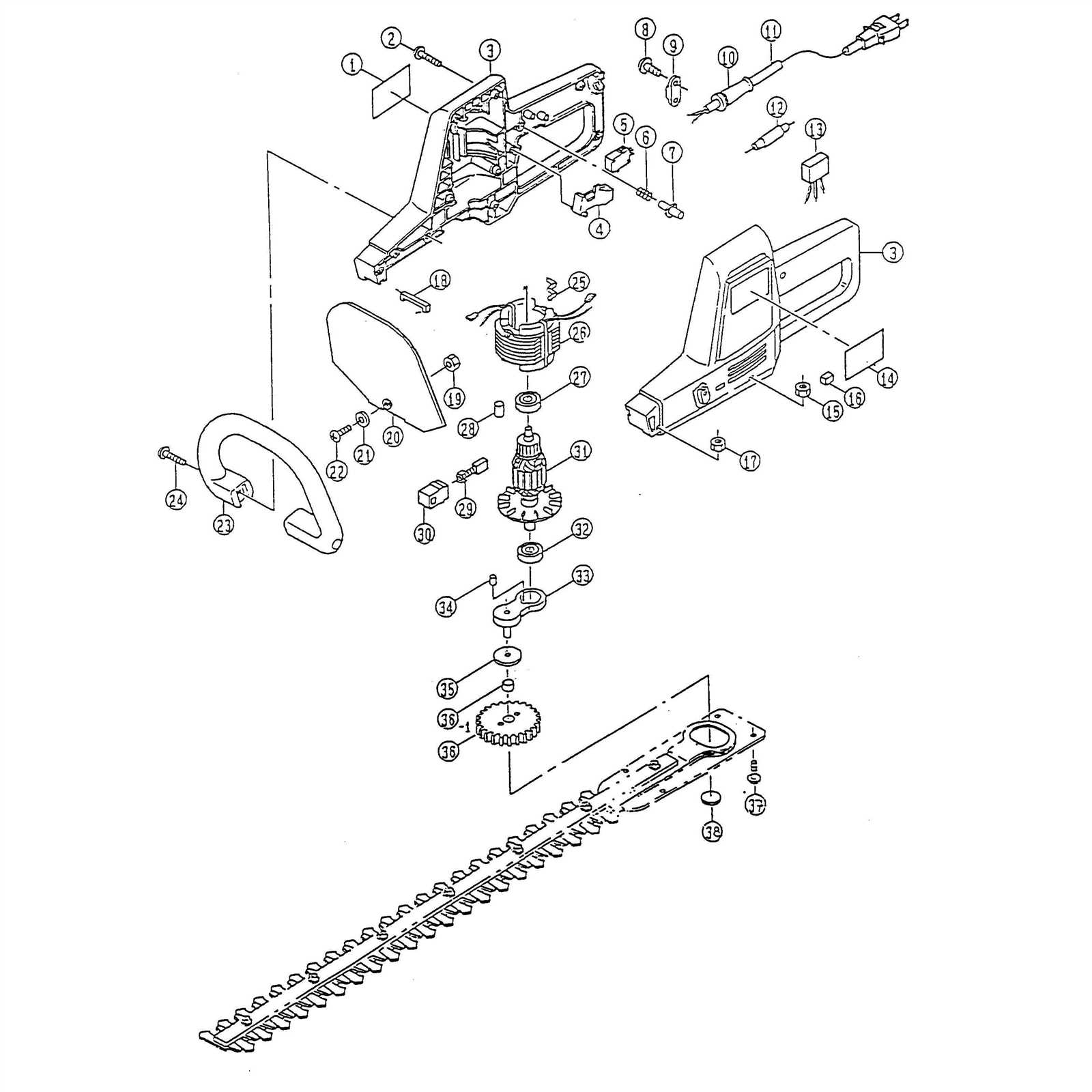

Importance of Parts Diagrams

Understanding the components of any mechanical device is crucial for effective maintenance and repair. Visual representations that outline the individual elements of equipment serve as essential tools for technicians and users alike. These illustrations not only enhance comprehension but also facilitate efficient troubleshooting and assembly.

Utilizing visual aids offers numerous advantages:

- Clarity: Clear depictions provide a straightforward understanding of how various elements interconnect.

- Efficiency: Quickly identifying specific components reduces the time spent on repairs or maintenance tasks.

- Reference: Serving as reliable guides, these visuals help in locating parts and understanding their functions.

- Training: They are invaluable resources for educating new personnel about equipment structure and operation.

In summary, these visual resources are fundamental for anyone involved in the upkeep of machinery, ensuring that repairs are conducted accurately and efficiently.

Common Issues with Hiretech HT7

This section addresses typical challenges encountered with a specific type of equipment, focusing on operational and mechanical aspects. Understanding these common difficulties can enhance user experience and prolong the lifespan of the machinery.

Performance Fluctuations

Users often report inconsistencies in performance, which may stem from various factors, including improper maintenance, environmental conditions, or component wear. Regular checks can help identify underlying issues early on.

Maintenance Concerns

Maintenance plays a crucial role in ensuring optimal function. Neglecting routine upkeep can lead to increased wear and potential failures. Following manufacturer guidelines for service intervals is advisable.

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Inconsistent Performance | Environmental factors, Lack of maintenance | Regular maintenance checks, Environmental adjustments |

| Wear and Tear | Prolonged usage, Inadequate servicing | Scheduled servicing, Replacement of worn parts |

| Overheating | Clogged filters, Low fluid levels | Regular cleaning, Fluid checks and replenishment |

How to Read Diagrams Effectively

Understanding visual representations is crucial for grasping complex information quickly and accurately. These illustrations can convey intricate details about a system, making them invaluable tools for anyone working with machinery or technical equipment. By familiarizing oneself with the symbols and layouts used in these graphics, individuals can enhance their comprehension and problem-solving abilities.

Identify Key Symbols and Elements

Start by recognizing the essential symbols that frequently appear in these visuals. Each symbol typically represents a specific component or function. Familiarizing yourself with these icons will allow for a quicker interpretation of the information presented. Take time to refer to a legend or key, as it often clarifies the meaning behind each symbol.

Follow the Flow of Information

As you study the visual representation, pay attention to the pathways connecting various elements. These lines and arrows indicate how different components interact and function together. Understanding the flow of information can provide insight into the operation and maintenance of the equipment. Take notes on relationships between elements to reinforce your understanding.

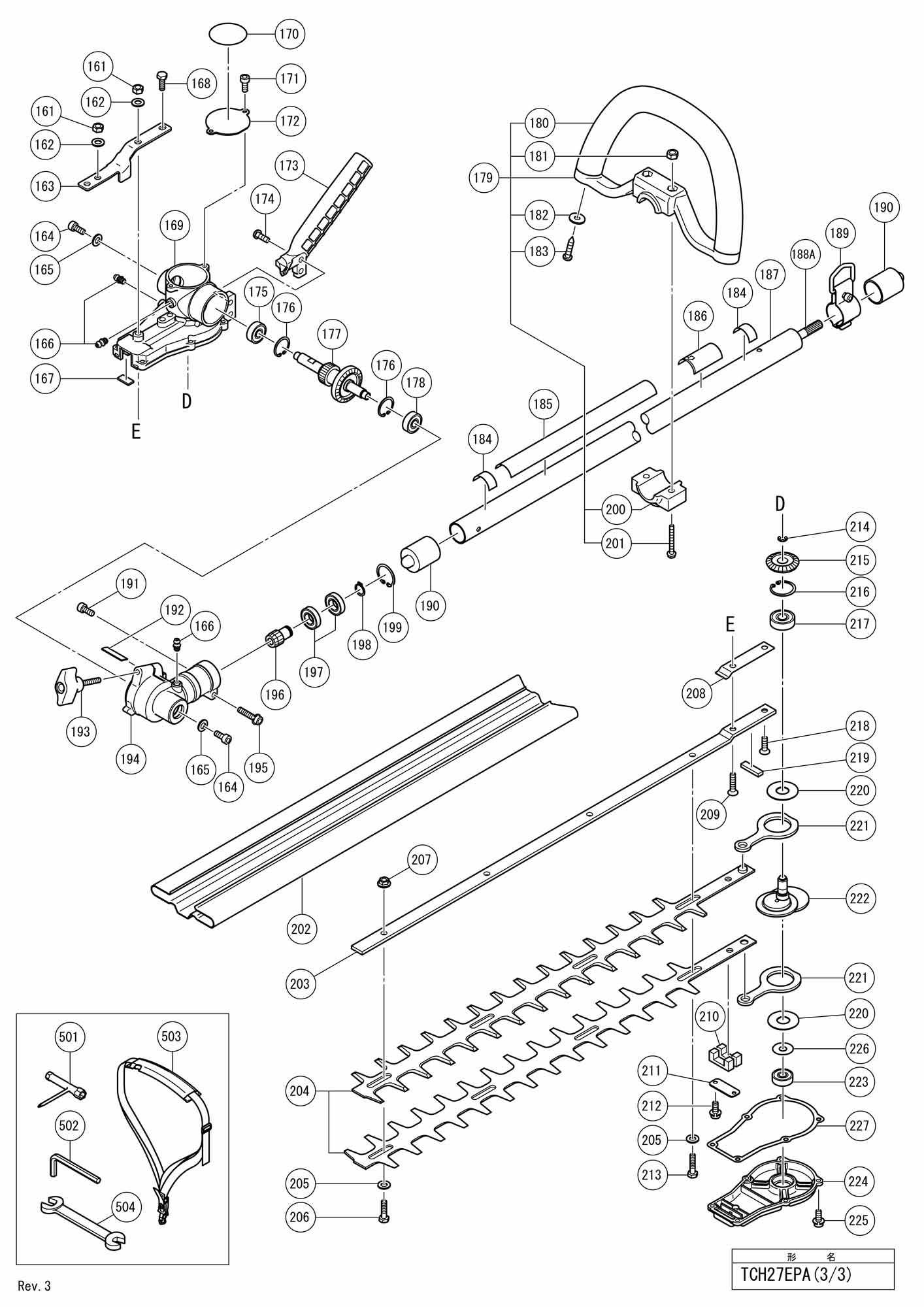

Key Parts and Their Functions

This section delves into the essential components of the equipment, highlighting their roles in ensuring optimal performance. Understanding these elements is crucial for efficient operation and maintenance.

Primary Components

Several key elements play vital roles in the machinery’s functionality:

- Engine: Powers the equipment and drives its operational capabilities.

- Frame: Provides structural support and stability during use.

- Controls: Allow the operator to manage various functions and settings.

- Wheels: Facilitate mobility, enabling easy transportation across different terrains.

Supporting Elements

In addition to the primary components, several supporting elements enhance overall efficiency:

- Hydraulic System: Ensures smooth movement and control of the machinery.

- Electrical Components: Supply power to various systems and controls.

- Safety Features: Include mechanisms designed to protect the operator and equipment from potential hazards.

Maintenance Tips for HT7

Ensuring the longevity and optimal performance of your equipment requires regular upkeep and attention. By following a few essential maintenance practices, you can enhance the functionality and reliability of your device. Here are some key strategies to keep in mind.

Regular Cleaning

Maintaining a clean environment for your machinery is crucial. Dust and debris can affect performance and lead to premature wear. Consider the following:

- Use a soft cloth to wipe down surfaces regularly.

- Inspect and clean filters to prevent clogging.

- Remove any accumulated dirt or grime from moving parts.

Inspection and Lubrication

Routine checks can help identify potential issues before they escalate. Lubrication is equally important to ensure smooth operation. Focus on these areas:

- Check belts and hoses for signs of wear.

- Apply appropriate lubricants to bearings and joints.

- Inspect electrical connections for corrosion or damage.

Where to Find Replacement Parts

Locating suitable components for machinery can often be a challenging task. However, understanding where to search can significantly simplify the process. Various avenues are available to obtain high-quality substitutes that ensure optimal performance and longevity.

Here are some effective options to consider:

- Authorized Dealers: Visiting authorized retailers or distributors is a reliable way to find genuine components. They usually carry a comprehensive range of items specifically designed for various equipment.

- Online Marketplaces: Websites that specialize in industrial equipment often provide a wide selection of alternatives. Searching these platforms can yield competitive prices and extensive inventory.

- Local Hardware Stores: Some local shops stock essential components for popular machinery. This option is convenient for those who need items quickly and prefer in-person shopping.

- Manufacturer’s Website: Checking the official website of the equipment’s manufacturer can lead to direct purchases of necessary components. Many manufacturers offer online ordering options.

- Forums and Community Groups: Engaging with online communities or forums related to machinery can be beneficial. Members often share insights on where to find specific items and may recommend trustworthy sources.

By exploring these avenues, one can effectively locate the required components to keep machinery running smoothly.

Upgrading Hiretech HT7 Equipment

Enhancing your machinery can significantly improve performance and efficiency. By implementing various enhancements, users can achieve better results and extend the lifespan of their equipment. This section explores several key upgrades that can optimize the functionality of your device.

One of the most effective ways to improve overall performance is by replacing worn components with high-quality alternatives. Investing in durable and efficient parts ensures that the machinery operates smoothly and reduces the likelihood of unexpected breakdowns. Regularly assessing the condition of these elements is crucial for maintaining peak operational capacity.

Additionally, integrating advanced technology can offer substantial benefits. Upgrading to more modern systems enhances control and monitoring capabilities, allowing for real-time adjustments and greater precision during operations. These innovations not only streamline workflows but also contribute to better resource management.

Finally, enhancing safety features should never be overlooked. Implementing the latest safety advancements not only protects the operator but also safeguards the equipment from potential hazards. Prioritizing safety not only complies with regulations but also fosters a more productive working environment.

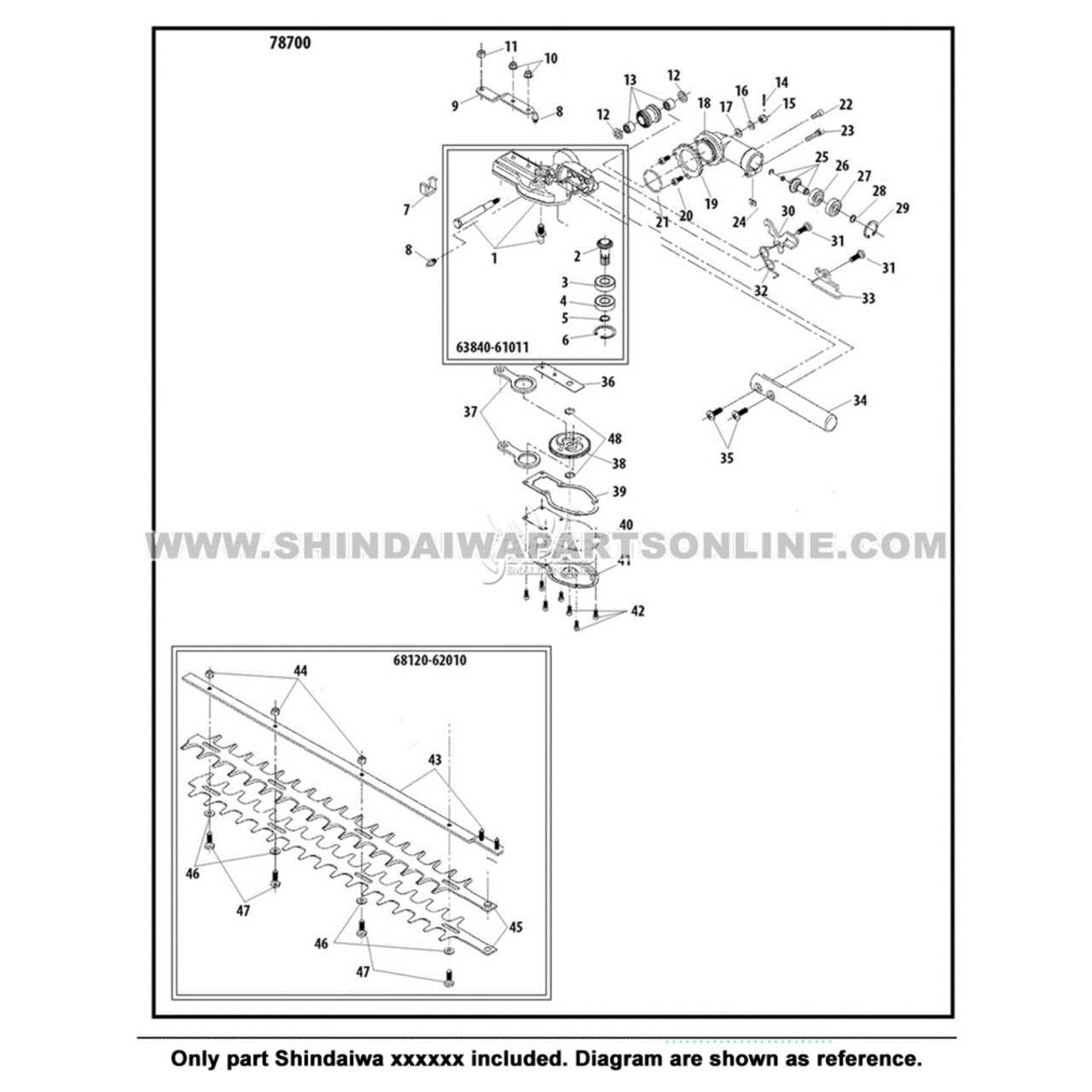

DIY Repairs for HT7 Owners

For those who own this versatile piece of equipment, understanding basic repair techniques can greatly enhance your experience and extend its lifespan. Engaging in self-repairs not only saves time and money but also empowers you with the knowledge to troubleshoot common issues that may arise during use.

Common Issues and Solutions

Here are some frequent problems encountered and how you can address them:

- Electrical Faults: Inspect wiring for damage and ensure all connections are secure. Replace any frayed wires to restore functionality.

- Fluid Leaks: Check for leaks in hoses and seals. Tightening connections or replacing worn parts can prevent further leakage.

- Performance Drops: Regularly clean filters and check the air intake for blockages to maintain optimal performance.

Tools You Might Need

Before starting any repairs, make sure you have the following tools at hand:

- Wrenches and sockets for loosening and tightening bolts

- Screwdrivers for adjusting various components

- Replacement seals and hoses to address common leaks

- Multimeter for diagnosing electrical issues

By following these guidelines, you can effectively manage minor repairs and keep your equipment in prime condition.

Safety Precautions During Repairs

Ensuring a secure environment during maintenance tasks is essential for preventing accidents and injuries. By adhering to specific safety measures, individuals can mitigate risks and enhance their overall protection while working with machinery. It is crucial to prioritize safety to achieve effective and secure repair procedures.

Personal Protective Equipment

The use of appropriate personal protective equipment (PPE) is vital. Items such as gloves, goggles, and steel-toed boots help shield against potential hazards. Make sure to inspect PPE regularly for any damage to maintain their effectiveness during repairs.

Workspace Safety

Maintaining an organized workspace contributes to a safer repair environment. Keep tools and materials neatly stored to avoid tripping hazards and ensure adequate lighting to improve visibility. Additionally, be mindful of your surroundings and ensure that emergency exits are clear and accessible at all times.

Resources for Further Learning

Expanding your knowledge on equipment maintenance and troubleshooting can greatly enhance your operational efficiency. Various sources are available to provide insights into effective practices, technical specifications, and innovative techniques to ensure optimal performance.

Online Tutorials and Courses

Many platforms offer comprehensive online tutorials and courses tailored to different skill levels. These resources often include video demonstrations, interactive sessions, and detailed guides that cover various aspects of equipment handling and care.

Community Forums and Support Groups

Engaging with online communities can be invaluable for sharing experiences and seeking advice. Forums dedicated to machinery enthusiasts and professionals allow users to ask questions, share solutions, and learn from one another, fostering a collaborative learning environment.