In many modern fixtures, the blend of hot and cold water is controlled by a complex mechanism designed for smooth temperature adjustment. These systems ensure that water is delivered at the desired warmth, providing comfort and efficiency in various environments. Understanding the internal elements of such systems can help in identifying potential issues and maintaining optimal performance.

Each of these assemblies consists of various elements that work together to control water flow and balance. From valves that regulate pressure to cartridges that adjust the mix, these units require precise interaction between components. Knowing the role of each part within the system allows for easier troubleshooting and replacement when needed.

Exploring the detailed layout of these mechanisms offers valuable insights into how they function. By studying the design and

Overview of American Standard Ultramix System

The mixing solution offers a convenient and efficient way to manage water temperature in residential and commercial settings. This system provides precise control, ensuring that water temperature remains consistent and comfortable for users. It combines modern technology with traditional design, offering an intuitive interface for adjusting water flow and heat levels.

Key Features of the Mixing System

One of the main benefits of this setup is its ability to regulate temperature quickly and efficiently. The system is equipped with thermal control mechanisms that prevent fluctuations in water temperature, even during simultaneous use in multiple locations. Its design emphasizes ease of use, allowing for seamless adjustments to water temperature with minimal effort.

Installation and Maintenance

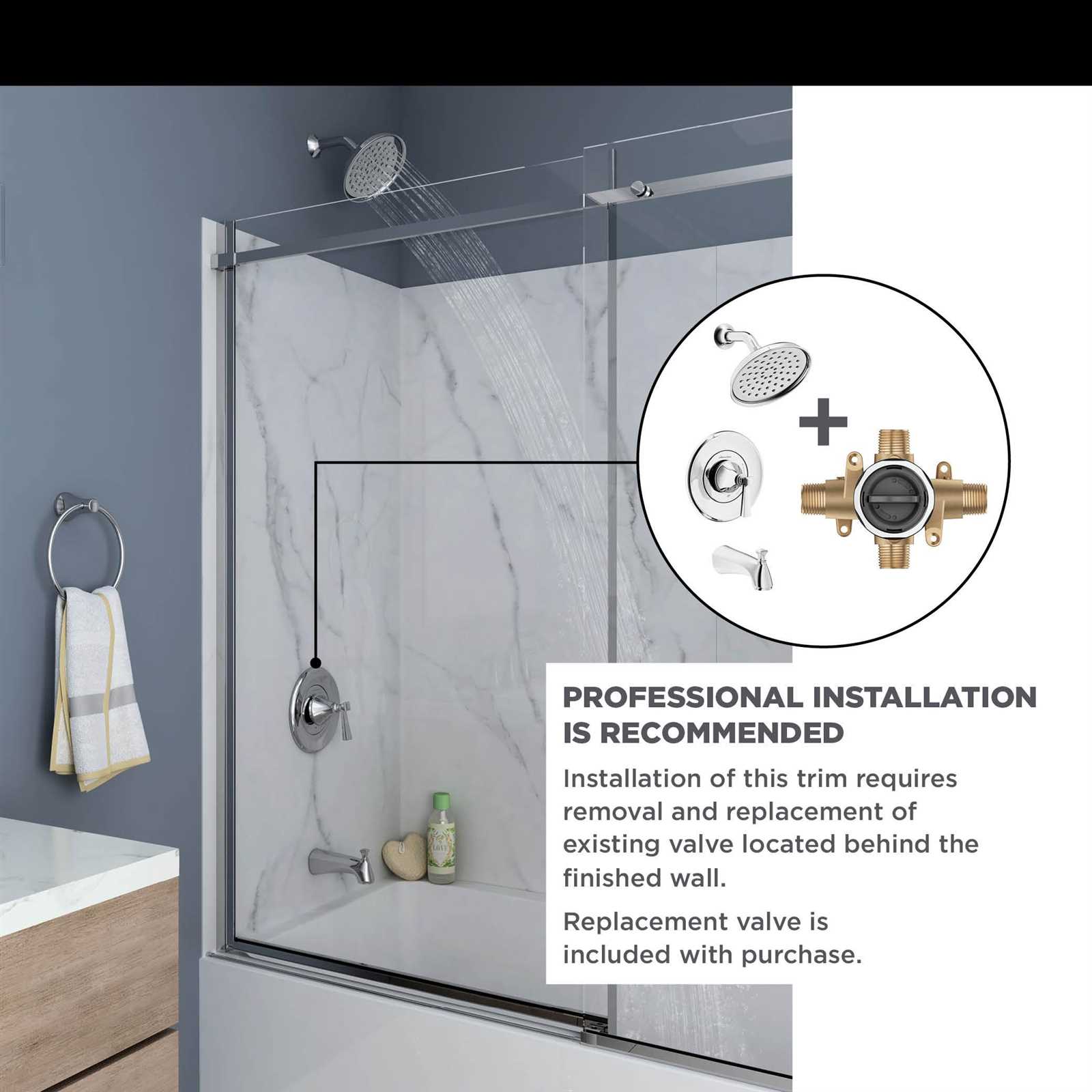

Installing this

Key Components of the Ultramix Mechanism

The internal system responsible for controlling the mixing process consists of several critical elements that ensure smooth water regulation. These elements work together to balance temperature and pressure, providing a reliable and consistent flow. The following sections highlight the essential components that make this process efficient and effective.

| Component | Description |

|---|---|

| Control Valve | This component regulates the flow of water, allowing the user to adjust the temperature and pressure to desired levels. It is designed for precise control and durability. |

| Component | Function |

|---|---|

| Temperature Sensor | Monitors the current thermal state of the mixture. |

| Heating Element | Provides necessary heat to achieve desired temperatures. |

| Control Unit | Processes data from sensors and adjusts heating accordingly. |

Replacing the Cartridge in

Changing the cartridge in your fixture is essential for maintaining optimal performance and ensuring a smooth flow. Over time, cartridges can wear out due to regular use, leading to leaks or reduced functionality. This guide outlines the steps to effectively replace the cartridge, enhancing the longevity and efficiency of your setup.

Tools Required

Before beginning the replacement process, gather the necessary tools. Having everything ready will streamline the task and minimize interruptions.

| Tool | Description |

|---|---|

| Adjustable Wrench | Used to loosen and tighten fittings. |

| Screwdriver | Required for removing screws holding the handle or cover. |

| Replacement Cartridge | Ensure compatibility with your specific fixture model. |

| Towel | To catch any water that may spill during the process. |

Steps for Replacement

Follow these steps to successfully replace the cartridge:

- Turn off the water supply to avoid any leaks during the process.

- Remove the handle by loosening the screws and lifting it off.

- Take out the old cartridge carefully, noting its orientation for proper installation of the new one.

- Insert the new cartridge, ensuring it is aligned correctly.

- Reattach the handle and secure it with screws.

- Turn the water supply back on and test for leaks.

Regularly replacing the cartridge can help maintain the efficiency and functionality of your fixture, ensuring a reliable experience.