Maintaining outdoor machinery is crucial for optimal performance and longevity. A thorough comprehension of the individual elements that make up these machines can significantly enhance their functionality. Whether for residential or commercial use, knowing how to identify and replace specific components is vital for ensuring a smooth operation.

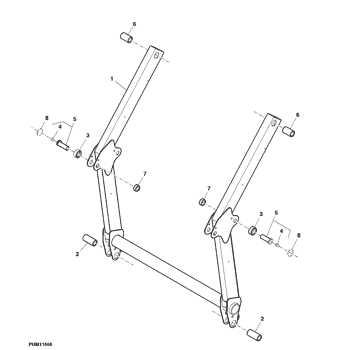

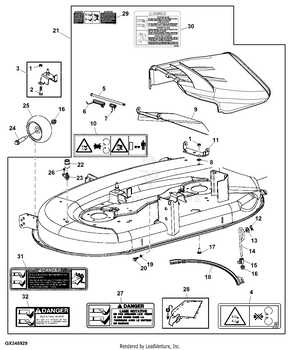

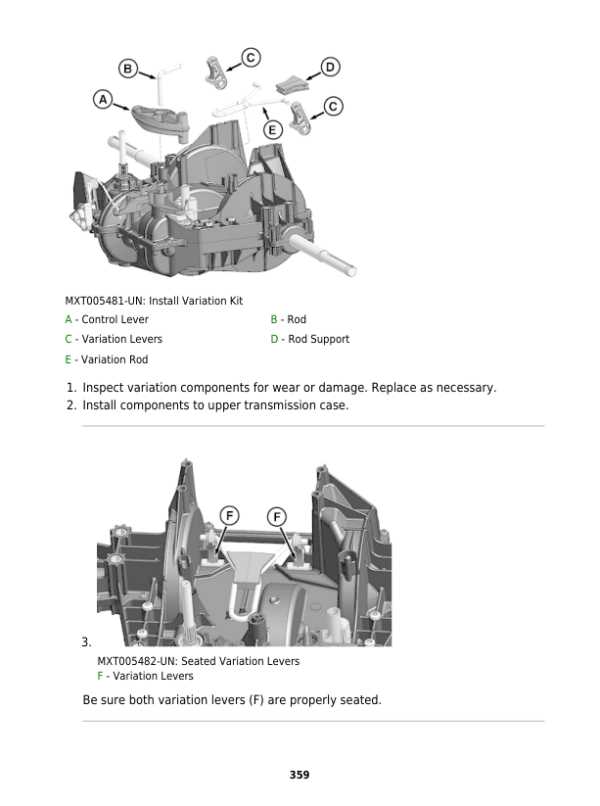

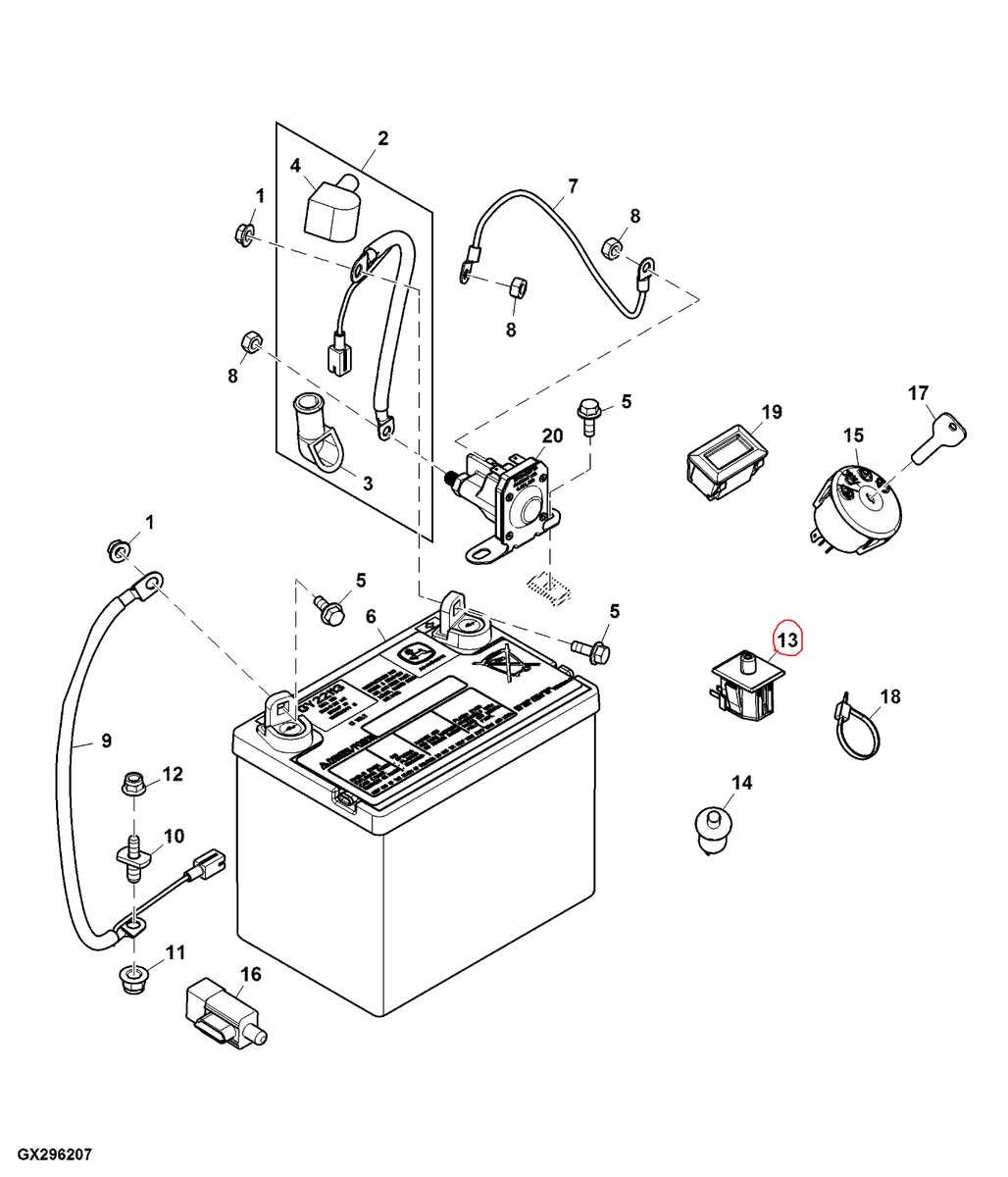

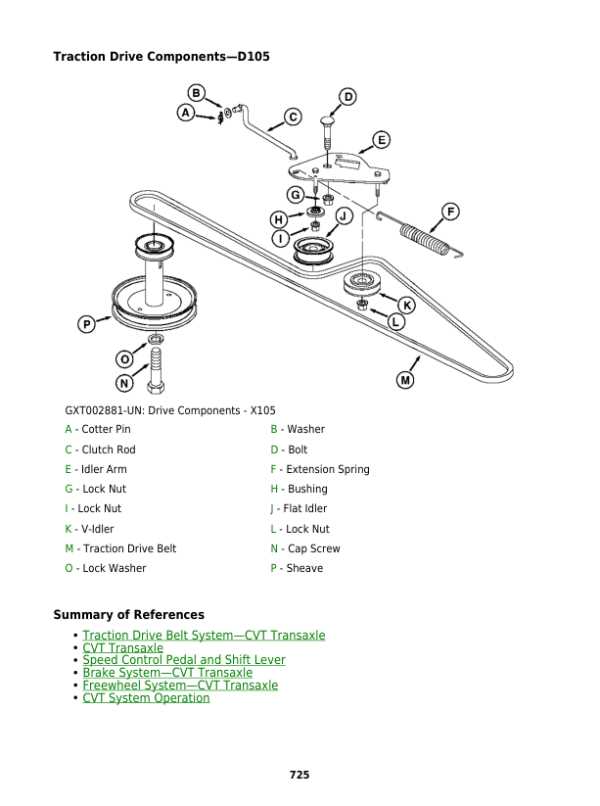

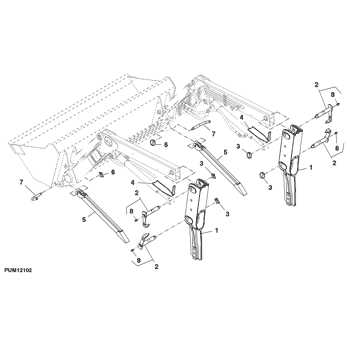

Visual aids can be particularly beneficial when navigating the intricate network of parts within any model. These illustrative representations provide clarity and assist users in recognizing various elements, simplifying the maintenance process. Having access to such resources empowers users to take control of their equipment’s upkeep.

Furthermore, understanding the relationship between different components can lead to more efficient repairs and improved overall performance. By familiarizing oneself with the arrangement and function of each section, operators can address issues proactively, reducing downtime and enhancing productivity in outdoor tasks.

Understanding John Deere D120 Parts

In the realm of machinery maintenance, comprehending the various components that contribute to a machine’s functionality is crucial. Each element plays a specific role, ensuring that the equipment operates efficiently. This section delves into the essential features of a well-known lawn care model, providing insight into its mechanical structure.

Key Components

Familiarity with the main elements can enhance maintenance efforts. Here are some critical features:

- Engine Assembly

- Transmission System

- Deck Structure

- Control Mechanisms

- Wheels and Axles

Maintenance Tips

Regular upkeep is vital for longevity and performance. Consider the following recommendations:

- Inspect and replace air filters regularly.

- Check oil levels and change as needed.

- Keep blades sharp for effective cutting.

- Examine belts and cables for wear and tear.

- Clean the undercarriage to prevent buildup.

By understanding these elements, operators can ensure their machinery remains in top condition, providing reliable performance for years to come.

Importance of Parts Diagrams

Understanding the layout of components within a machine is crucial for efficient maintenance and repair. Visual representations of these elements serve as valuable resources, guiding users through the intricacies of assembly and disassembly. They not only enhance comprehension but also minimize the risk of errors during the repair process.

Enhanced Clarity

Detailed illustrations provide a clear view of how various elements interact, making it easier to identify potential issues. Users can quickly locate specific sections, ensuring that they focus on the right components. This clarity leads to quicker diagnostics and streamlined repairs.

Efficiency in Maintenance

Having a visual guide simplifies the process of upkeep, allowing for systematic inspection of each segment. Users can efficiently track wear and tear, planning replacements before failures occur. This proactive approach ultimately prolongs the lifespan of the equipment and improves overall performance.

Key Components of the D120

Understanding the essential elements of this model is crucial for maintenance and repair. Each component plays a significant role in ensuring optimal performance and efficiency, contributing to the overall functionality of the machine.

| Component | Description |

|---|---|

| Engine | Powers the machine, providing the necessary energy for operation. |

| Transmission | Facilitates the transfer of power from the engine to the wheels, allowing for controlled movement. |

| Deck | Houses the cutting blades, essential for grass trimming and maintenance. |

| Wheels | Provide mobility and stability, enabling maneuverability across various terrains. |

| Battery | Supplies electrical energy to start the engine and power electrical components. |

| Control Panel | Enables user interaction, allowing for adjustments and monitoring of the machine’s functions. |

How to Read the Diagram

Understanding a schematic can significantly enhance your ability to maintain and repair machinery. These visual representations provide a wealth of information, helping you identify components and their interconnections. By familiarizing yourself with the layout and symbols used, you can streamline your repair process and ensure accurate replacements.

Begin by examining the overall layout. Each section typically corresponds to a specific function or area of the machine, making it easier to locate the parts you need. Take note of the labels and numbers that accompany each element; these often serve as references to detailed lists or catalogs.

Symbols are crucial in interpreting the illustration. Different shapes and lines denote various types of components and connections, such as electrical links or mechanical joints. It’s essential to familiarize yourself with these representations, as they form the foundation of your understanding.

Additionally, color coding can play a significant role in conveying information. Some schematics use different colors to distinguish between types of systems, such as hydraulic versus electrical. Recognizing these color cues will assist you in quickly identifying relevant sections of the schematic.

Finally, don’t hesitate to refer to the accompanying documentation or manuals. These resources often provide insights into the schematic’s design and usage, offering tips and guidance for successful navigation. With practice, reading these illustrations will become an invaluable skill in your maintenance toolkit.

Identifying Common Issues

Recognizing typical challenges in machinery operation can significantly enhance maintenance efficiency and longevity. Many users encounter similar problems that can often be traced back to a few common sources. By understanding these frequent issues, operators can take proactive steps to mitigate potential failures.

One prevalent concern is engine performance. Symptoms such as reduced power or difficulty starting may indicate underlying mechanical faults or fuel system issues. Regular inspections of these components are essential to ensure optimal functioning.

Another area to monitor is the transmission system. Slipping gears or unusual noises can signal wear and tear that requires immediate attention. Early diagnosis can prevent more extensive damage and costly repairs.

Additionally, electrical problems often arise, manifesting as flickering lights or unresponsive controls. Ensuring connections are secure and wiring is intact can help avoid these complications.

Finally, wear on moving parts can lead to decreased efficiency and operational safety. Regular lubrication and part replacements based on usage can extend the lifespan of critical components.

By staying vigilant about these common issues, operators can ensure their equipment remains reliable and effective over time.

Maintenance Tips for D120 Parts

Ensuring the longevity and performance of your equipment requires regular upkeep and attention to detail. Following a few essential practices can help maintain efficiency and prevent premature wear and tear.

- Regular Inspections: Routinely check all components for signs of damage or wear. Early detection can save time and money.

- Lubrication: Keep moving parts well-lubricated to reduce friction and wear. Use the recommended lubricants for best results.

- Cleaning: Remove dirt and debris from all surfaces to prevent build-up that can hinder performance.

- Replace Worn Components: Stay proactive about replacing any parts that show signs of significant wear to avoid more extensive repairs.

- Consult the Manual: Refer to the manufacturer’s manual for specific maintenance schedules and guidelines tailored to your model.

By following these guidelines, you can ensure your equipment operates smoothly and remains in optimal condition for years to come.

Where to Find Replacement Parts

Locating suitable components for your machinery is crucial for maintaining its functionality and longevity. Various sources offer an array of options, ensuring you find what you need efficiently.

| Source | Description |

|---|---|

| Official Retailers | Authorized dealers provide original components, ensuring compatibility and quality. |

| Online Marketplaces | Platforms like eBay and Amazon feature numerous listings from different sellers, often at competitive prices. |

| Local Repair Shops | Local technicians may have access to quality items and can offer personalized advice. |

| Aftermarket Suppliers | These vendors specialize in producing alternative options, often at lower prices, while maintaining reasonable quality. |

Cost Factors for D120 Components

When evaluating the expenses associated with various machine elements, several critical aspects come into play. Understanding these factors can aid in making informed decisions about maintenance and repairs, ensuring longevity and optimal performance.

Quality of Materials: The grade of materials used in manufacturing components significantly impacts pricing. Higher-quality materials often result in enhanced durability and performance, which can justify a higher initial investment.

Brand Reputation: Established manufacturers typically charge more for their products due to a proven track record of reliability and customer support. Investing in reputable brands can offer peace of mind, but it may also raise overall costs.

Availability and Demand: Market dynamics play a crucial role in determining component costs. Items that are in high demand or limited supply may command higher prices, especially during peak seasons for repairs or maintenance.

Complexity of Design: Components with intricate designs or advanced technology often entail higher production costs. This complexity can also lead to increased labor expenses during installation or repair, further affecting the overall cost.

Shipping and Handling: Logistics can influence the final price of machine elements. Costs associated with transportation and handling may vary based on the supplier’s location and the delivery method, impacting the overall budget.

Comparing OEM and Aftermarket Parts

When considering components for machinery, it’s essential to evaluate the differences between original and alternative offerings. Each option presents unique advantages and potential drawbacks that can impact performance, durability, and cost-effectiveness.

Original components are typically produced by the manufacturer, ensuring compatibility and reliability. Conversely, alternative options can offer:

- Cost savings, often being more affordable than their original counterparts.

- Availability, with many suppliers providing a wider range of choices.

- Variety, allowing for customization based on specific needs.

However, some drawbacks of aftermarket items include:

- Potential quality inconsistencies, which can affect performance.

- Warranty issues, as using non-original components may void existing guarantees.

- Compatibility risks, where fit and function may not meet the required standards.

Ultimately, the decision should be informed by thorough research, weighing both reliability and budgetary considerations. Understanding these differences is crucial for maintaining optimal machinery performance.

Popular Upgrades for the D120

Enhancing the functionality and performance of your lawn tractor can significantly improve your mowing experience. Whether you’re looking to increase efficiency, boost power, or add convenience, several popular enhancements can elevate your machine to meet your specific needs. Below are some of the most sought-after upgrades that enthusiasts often consider.

| Upgrade | Description | Benefits |

|---|---|---|

| Improved Mower Blades | High-performance blades designed for a cleaner cut. | Better grass health and reduced clumping. |

| Mulching Kit | Accessory that chops clippings into fine pieces. | Enhances nutrient recycling and reduces waste. |

| Sunshade | Canopy attachment for protection from the sun. | Increases comfort during long mowing sessions. |

| LED Headlights | Bright lighting for enhanced visibility at dusk. | Extends mowing time and improves safety. |

| Comfort Seat | Upgraded seating for better ergonomics. | Reduces fatigue and enhances the overall experience. |

Common Tools for D120 Maintenance

Proper upkeep of your equipment requires a selection of essential instruments to ensure efficiency and longevity. Familiarity with these tools will enhance your maintenance routine and prevent unnecessary issues.

- Wrenches: Various sizes are necessary for tightening or loosening bolts.

- Screwdrivers: Both flathead and Phillips for adjusting and securing components.

- Socket Set: Ideal for quick access to fasteners in tight spaces.

- Oil Filter Wrench: Facilitates easy replacement of the oil filter.

- Grease Gun: Essential for lubrication of moving parts.

Utilizing the right tools can significantly simplify the maintenance process and improve the overall performance of your machinery.

Resources for Further Research

This section provides valuable materials and references for those seeking to deepen their understanding of equipment components and their functionalities. Exploring these resources will enhance knowledge and facilitate efficient maintenance and repairs.

Online Platforms

- Manufacturer’s Official Website

- Online Repair Manuals

- Parts Retailer Websites

Community Forums

- Machinery Discussion Boards

- Social Media Groups

- DIY Repair Communities