The exploration of firearm mechanisms unveils a world of intricate engineering and design. Each element plays a vital role in the overall functionality, contributing to the reliability and performance of the weapon. Grasping the structure and layout of these components is essential for enthusiasts, historians, and professionals alike.

In this section, we delve into the specifics of a renowned model, shedding light on its individual elements and their interrelationships. By examining the arrangement and characteristics of these essential features, one gains a deeper appreciation for the craftsmanship involved in its creation. This knowledge not only enhances the understanding of how the firearm operates but also highlights the significance of precision in weapon design.

As we navigate through this detailed analysis, we aim to provide clarity on the mechanical intricacies and the importance of each section. Recognizing how these components work together can improve maintenance practices and support informed discussions about historical advancements in firearm technology.

The development of a certain automatic firearm in the early 20th century marked a significant evolution in military technology. Its design and functionality not only reflected the needs of contemporary warfare but also set a precedent for future weapon systems. The historical context surrounding this innovation is pivotal in understanding its impact and legacy in military history.

This firearm was conceived in the interwar period, a time characterized by rapid advancements in weaponry and the changing dynamics of armed conflict. Several factors contributed to its creation:

- Technological Advancements: The innovations in materials and engineering allowed for more reliable and effective weapon designs.

- Military Doctrine Changes: Evolving strategies emphasized the need for rapid fire and increased mobility on the battlefield.

- Political Context: The geopolitical tensions of the time spurred nations to enhance their military capabilities, leading to increased investments in firearms research.

The resulting weapon featured a combination of versatility and firepower, appealing to various military forces. Its design facilitated easy integration into different operational environments, whether in infantry units or mounted on vehicles.

Throughout its service, the firearm underwent several modifications, enhancing its effectiveness and adaptability. The variations included adjustments to its caliber, ammunition types, and operational components, ensuring it remained relevant through various conflicts.

In summary, the historical development of this automatic firearm illustrates the intersection of technology, military strategy, and geopolitical realities, shaping its role in modern warfare and influencing future designs.

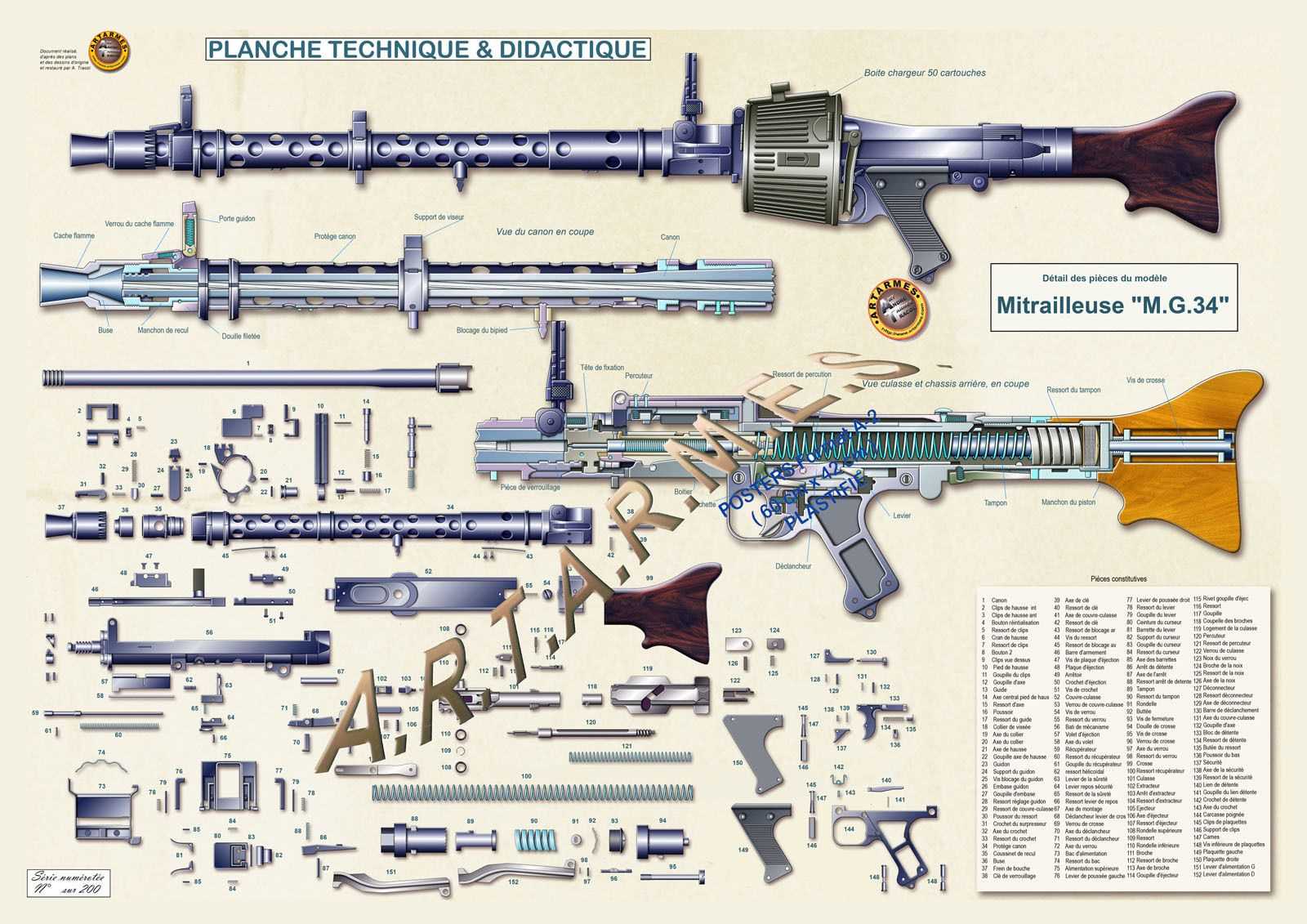

Key Features of Mg34 Design

The design of this iconic firearm embodies a blend of functionality, durability, and innovation. Its engineering reflects a careful consideration of both performance and user experience, making it a noteworthy example in the realm of weaponry. This section explores the distinctive characteristics that contribute to its effectiveness on the battlefield.

Robust Construction

Durability is a hallmark of this firearm’s design. Constructed from high-quality materials, it can withstand harsh conditions and prolonged use. The precision engineering ensures that all components fit seamlessly, reducing the likelihood of malfunctions during critical moments.

Ergonomic Features

Designed with the operator in mind, this weapon incorporates ergonomic features that enhance usability. The layout of controls and grips allows for easy handling and quick access, enabling rapid response in dynamic situations. This thoughtful approach not only improves performance but also minimizes fatigue during extended engagements.

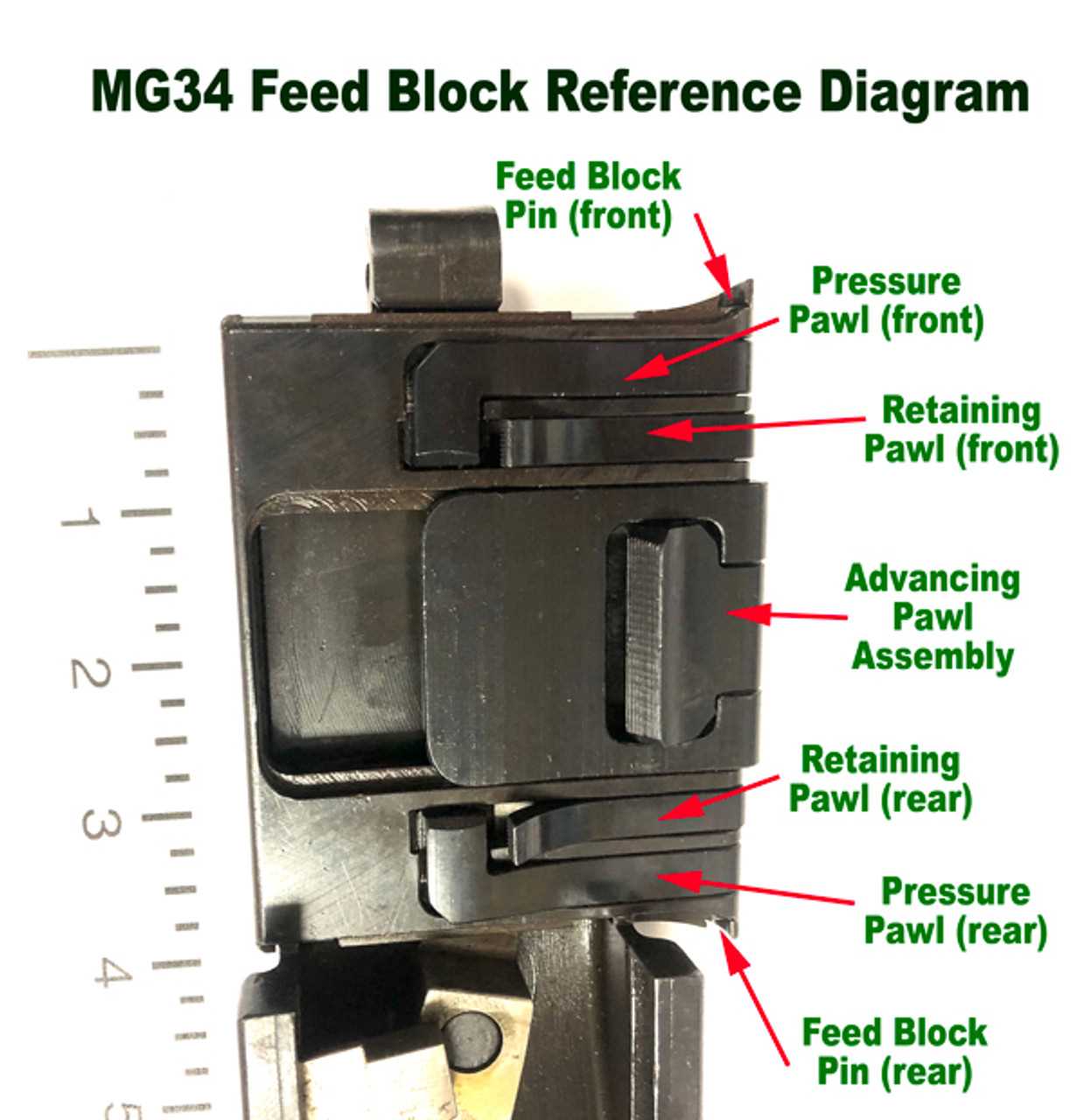

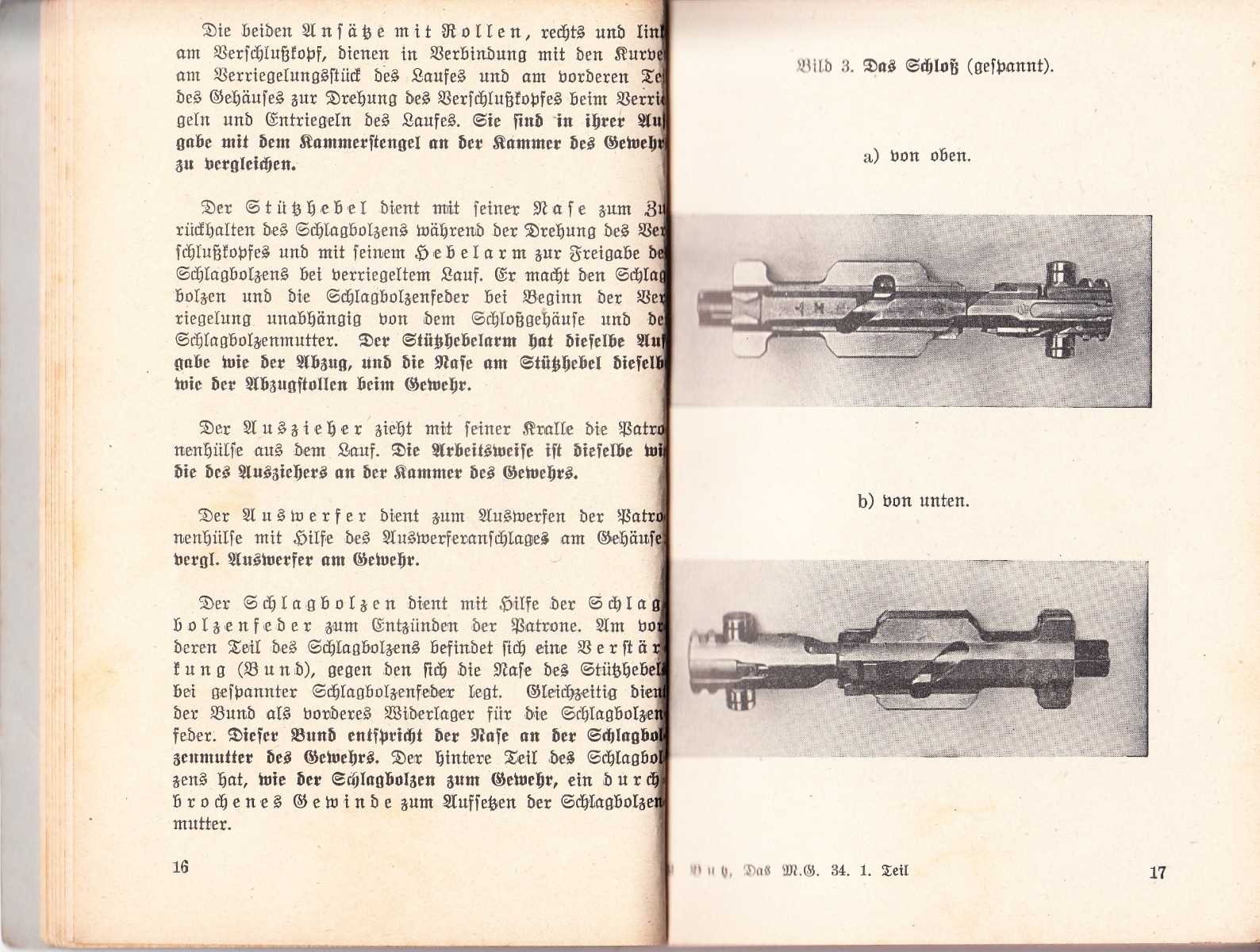

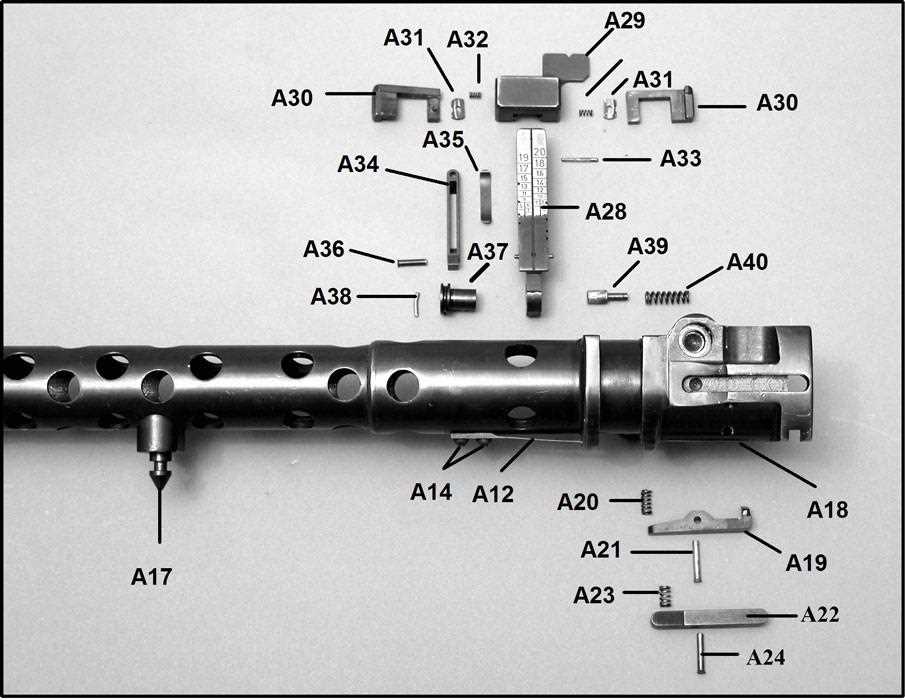

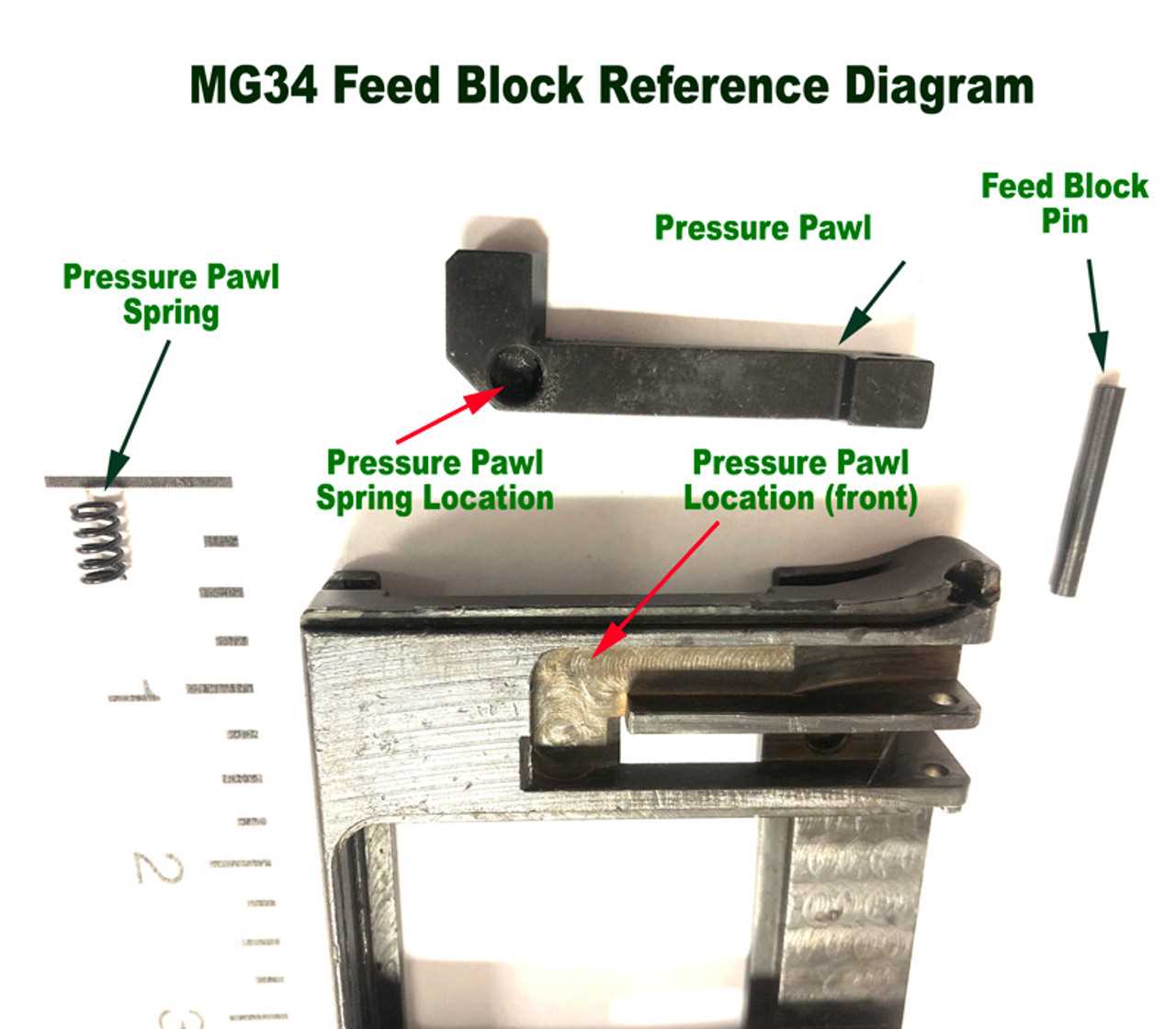

Essential Parts and Their Functions

The functionality of any complex mechanism relies on various integral components, each playing a specific role in ensuring the system operates smoothly and efficiently. Understanding these elements is crucial for anyone interested in the intricacies of such equipment.

One key component is the assembly responsible for controlling the firing sequence. This part ensures that each discharge occurs in rapid succession, maintaining a consistent rate of fire. Additionally, the system includes a mechanism that facilitates the feeding of ammunition, allowing for continuous operation without interruption.

Another vital element is the barrel, which guides the projectile during its exit, significantly impacting accuracy and range. Coupled with this is the recoil system, designed to manage the forces generated during firing, thus enhancing user control and stability.

The housing protects internal mechanisms from external damage while providing a stable platform for operation. Lastly, the sighting apparatus is essential for targeting, offering adjustments for elevation and windage to improve precision during use.

Common Maintenance Practices for Mg34

Proper upkeep of any complex mechanism is crucial for its longevity and optimal performance. Regular maintenance not only enhances reliability but also prevents unexpected malfunctions. By adhering to systematic practices, users can ensure that their equipment operates smoothly and efficiently.

Here are some essential practices that should be routinely performed:

| Maintenance Task | Description | Frequency |

|---|---|---|

| Cleaning | Remove debris and contaminants from external and internal components to prevent wear. | After each use |

| Lubrication | Apply appropriate lubricants to moving parts to reduce friction and wear. | Monthly |

| Inspection | Examine all elements for signs of damage or excessive wear and replace if necessary. | Quarterly |

| Calibration | Ensure that all settings and adjustments are within specified parameters for accurate operation. | Annually |

| Storage | Keep the equipment in a controlled environment to protect it from moisture and extreme temperatures. | Always |

Implementing these practices can significantly prolong the lifespan and reliability of the equipment, ensuring that it remains in excellent working condition throughout its service life.

Comparison with Other Firearms

The analysis of historical and modern weaponry often reveals intriguing insights into design philosophy, functionality, and overall performance. By examining a specific automatic firearm alongside its contemporaries, one can appreciate the unique engineering choices that set it apart, as well as common trends that may influence operational efficiency and user experience.

When comparing various automatic systems, several key aspects such as rate of fire, weight, caliber, and versatility come into play. Below is a comparison table highlighting these elements among several renowned firearms.

| Firearm Model | Rate of Fire (RPM) | Weight (kg) | Caliber | Versatility |

|---|---|---|---|---|

| Weapon A | 800 | 8.0 | 7.62mm | High |

| Weapon B | 1200 | 9.5 | 5.56mm | Medium |

| Weapon C | 600 | 7.5 | 7.92mm | High |

| Weapon D | 1000 | 10.0 | 7.62mm | Low |

Through such comparisons, enthusiasts and professionals alike can draw conclusions about the evolution of automatic systems, reflecting advancements in technology and changes in tactical requirements over time.

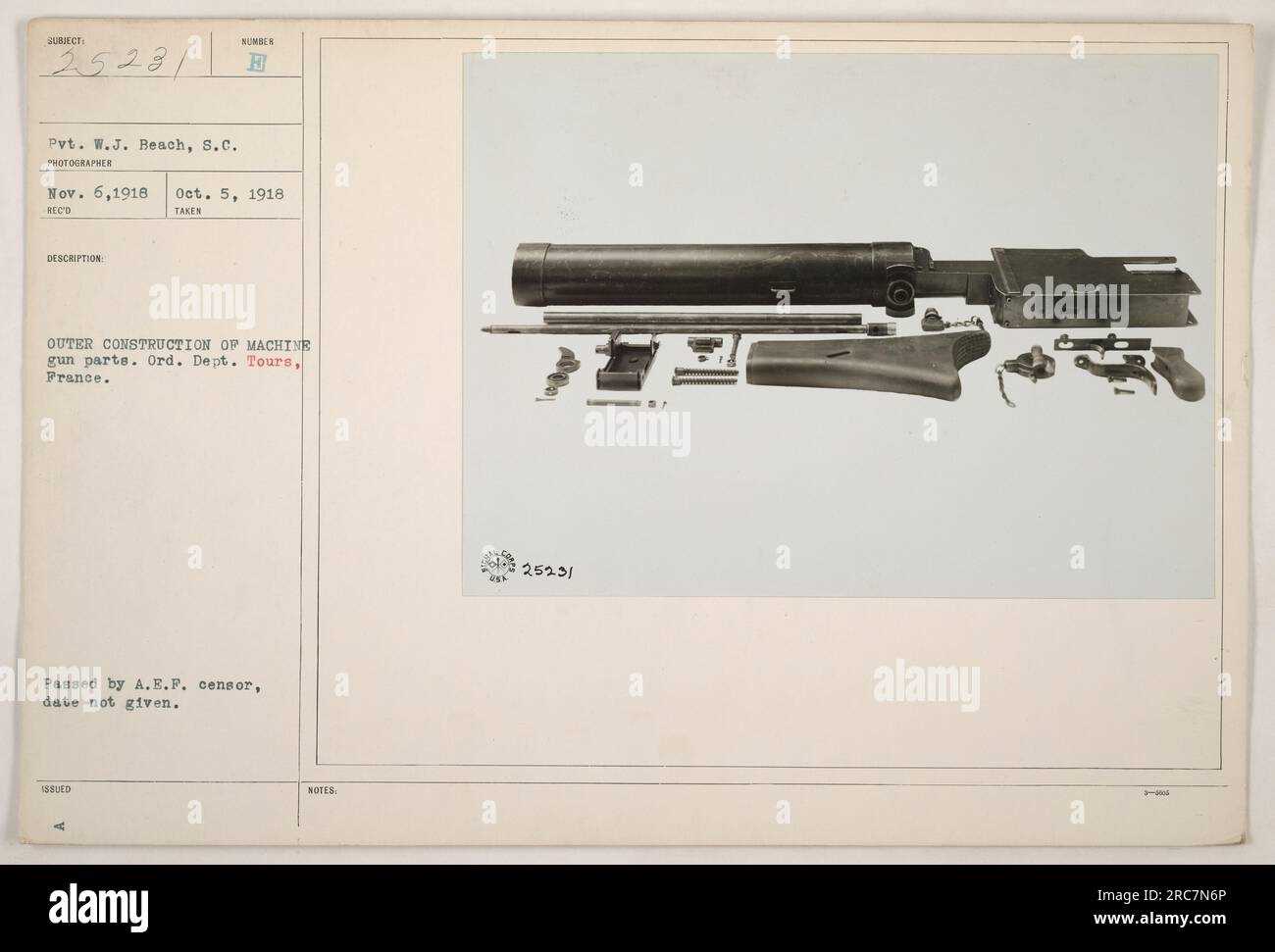

Assembly and Disassembly Guidelines

This section provides essential instructions for the proper assembly and disassembly of the firearm components, ensuring safety and efficiency throughout the process. Adhering to these guidelines will help maintain the integrity of the mechanism and enhance the overall functionality of the weapon.

Preparation

Before beginning the assembly or disassembly, it is crucial to gather all necessary tools and ensure a clean workspace. Follow these steps:

- Ensure the firearm is unloaded and the chamber is clear.

- Gather appropriate tools, such as screwdrivers, wrenches, and cleaning supplies.

- Work in a well-lit area to improve visibility and reduce the risk of error.

Assembly Steps

- Start with the main components, aligning them carefully.

- Secure each part using screws or fasteners, ensuring they are tightened adequately but not overtightened.

- Install additional components sequentially, following the recommended order in the user manual.

- Once assembled, conduct a thorough inspection to confirm that all parts are securely in place and functioning correctly.

Disassembly Steps

- Begin by removing any accessories attached to the firearm.

- Carefully unscrew and detach each component, starting from the rear and moving forward.

- Organize the removed parts systematically to facilitate easier reassembly.

- Clean each component as you disassemble, checking for wear or damage.

Identifying Worn Components

Recognizing deteriorated elements in any mechanical assembly is crucial for maintaining optimal performance and safety. Over time, various components may exhibit signs of wear due to repeated use and environmental factors. Understanding how to identify these worn elements can prevent further damage and ensure the reliability of the entire system.

When assessing the condition of components, look for common indicators of wear. These may include visible damage, changes in dimensions, or impaired functionality. Early detection of such issues is essential to avoid costly repairs and downtime.

| Indicator | Description | Recommended Action |

|---|---|---|

| Cracks or Fractures | Visible breaks or fissures on the surface. | Replace immediately to prevent failure. |

| Corrosion | Oxidation leading to a rough or pitted surface. | Clean and treat; consider replacement if severe. |

| Wear Marks | Shiny areas indicating excessive friction. | Inspect closely; replace if tolerance is exceeded. |

| Play or Excessive Movement | Unusual looseness or instability when assembled. | Tighten or replace as necessary. |

| Discoloration | Color changes that indicate overheating or chemical exposure. | Assess function; replace if performance is compromised. |

Aftermarket Parts and Accessories

Exploring the realm of replacement components and enhancements can significantly improve performance and aesthetics. Many enthusiasts seek alternatives that not only match the quality of original equipment but also provide unique features or improved specifications. This section delves into the various offerings available in the aftermarket sector, focusing on their benefits and considerations.

Benefits of Aftermarket Options

- Cost-effectiveness: Often, alternative components are available at lower prices compared to factory originals, making upgrades more accessible.

- Diverse selection: A wide range of choices allows customization to meet personal preferences and needs.

- Enhanced performance: Many aftermarket enhancements are designed to improve efficiency, power, or handling.

- Improved aesthetics: Custom designs can elevate the visual appeal of the vehicle, offering a unique touch that sets it apart.

Considerations When Choosing Alternatives

- Quality assurance: It’s essential to research manufacturers and read reviews to ensure the reliability of the components.

- Compatibility: Verify that selected enhancements fit seamlessly with the existing system to avoid any issues.

- Warranty implications: Understand how installing alternative components may affect any existing warranties.

- Legal regulations: Some enhancements may not comply with local regulations, impacting vehicle legality on public roads.

Importance of Proper Lubrication

Effective lubrication plays a crucial role in the optimal performance and longevity of mechanical systems. It serves to minimize friction between moving components, which in turn reduces wear and tear, preventing premature failure. By maintaining a consistent application of lubricants, one can ensure that machinery operates smoothly and efficiently, thereby enhancing overall productivity.

Benefits of Adequate Lubrication

Proper application of lubricants not only extends the lifespan of components but also enhances operational efficiency. Reduced friction leads to lower energy consumption, which is vital for cost-effective performance. Additionally, lubricants help to dissipate heat generated during operation, further protecting vital parts from damage due to excessive temperatures.

Consequences of Neglecting Lubrication

Failure to maintain appropriate lubrication levels can lead to severe consequences, including increased friction, overheating, and eventual breakdown of machinery. Such neglect can result in costly repairs and downtime, ultimately impacting productivity and financial resources. It is imperative to prioritize regular lubrication schedules to ensure optimal function and prevent mechanical failures.

Resources for Further Learning

For enthusiasts and professionals looking to deepen their understanding of firearm mechanics, a wealth of resources is available. These materials can enhance knowledge about historical and modern weaponry, focusing on design, operation, and maintenance. Whether you’re seeking books, online courses, or communities of like-minded individuals, there are numerous avenues to explore.

Books and Publications

- Historical Analyses: Look for comprehensive texts that cover the evolution of firearms, focusing on specific models and their operational contexts.

- Technical Manuals: Seek out detailed guides that provide insights into assembly, disassembly, and troubleshooting techniques.

- Military History: Explore works that delve into the use of various firearms in historical conflicts to understand their impact and significance.

Online Resources

- Educational Websites: Numerous platforms offer free courses and tutorials covering the mechanics and history of firearms.

- Forums and Discussion Groups: Engage with communities where experts and hobbyists share their knowledge, experiences, and advice.

- YouTube Channels: Watch informative videos that showcase maintenance tips, historical overviews, and live demonstrations.

By leveraging these resources, individuals can expand their expertise and appreciation for firearms, gaining insights that go beyond basic understanding.