In the realm of protective gear, comprehending the intricate details of its components is vital for ensuring reliability and performance. Each element plays a significant role in the overall functionality, contributing to the user’s safety in hazardous environments. This exploration will highlight key features and the relationships between various parts, providing clarity for both users and technicians.

By examining the assembly and function of these crucial elements, one can appreciate the sophisticated engineering behind modern safety apparatuses. Whether you’re a professional or an enthusiast, understanding how each segment interacts can enhance your expertise and confidence in handling the equipment.

Ultimately, gaining insights into these fundamental aspects will empower individuals to maintain, repair, or upgrade their gear effectively. With this knowledge, users can ensure optimal performance and longevity of their essential safety tools.

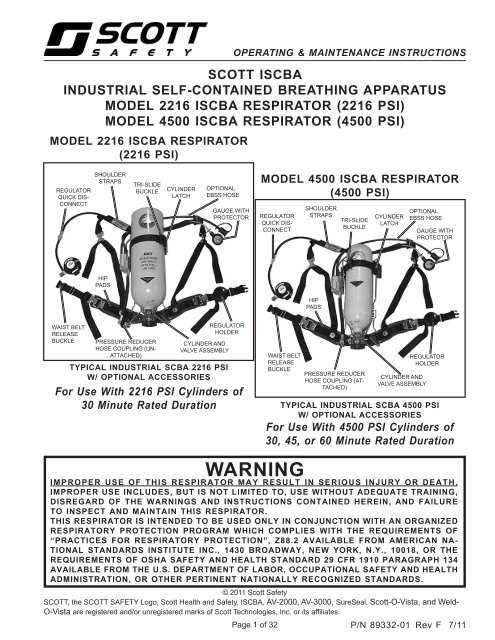

Understanding Scott Air Pak 4.5

This section aims to provide insight into a specific type of breathing apparatus designed for use in hazardous environments. The focus will be on its functionality, key components, and the overall benefits it offers to users, particularly in emergency situations. By exploring these aspects, we can appreciate the importance of this equipment in ensuring safety and efficiency during critical operations.

Key Components and Functionality

The device is comprised of several essential elements that work together to deliver clean air to the user. Each component plays a vital role in maintaining performance and reliability. The system typically includes a high-pressure cylinder, a regulator, and a facepiece. These features ensure that the individual can breathe comfortably while minimizing the risks associated with toxic atmospheres.

Benefits of Usage

Utilizing this type of respiratory equipment offers numerous advantages, especially in emergency response scenarios. It enhances the safety of the user by providing a reliable source of breathable air, allowing them to operate effectively in dangerous conditions. Additionally, the design promotes ease of use, ensuring quick deployment when time is of the essence. Overall, this equipment is indispensable for professionals who face life-threatening environments regularly.

Key Components of Scott Air Pak

This section explores the essential elements that comprise a modern breathing apparatus, focusing on their functions and interrelationships. Understanding these components is crucial for effective use and maintenance in various environments.

Breathing System

The breathing system is the heart of the apparatus, designed to deliver a consistent flow of air. It typically includes a high-pressure cylinder, regulators, and a harness system, ensuring safety and comfort for the user.

Communication and Safety Features

Integrated communication devices and safety alarms enhance situational awareness. These features allow for seamless interaction among team members and provide alerts in emergencies, contributing to overall operational effectiveness.

Benefits of Using Scott Air Pak

The utilization of advanced respiratory equipment brings numerous advantages, enhancing safety and performance in hazardous environments. This innovative apparatus is designed to support individuals in challenging situations, ensuring they can operate efficiently while minimizing risks.

Enhanced Safety Features

- Reliable breathing support during emergencies.

- Robust construction for durability in tough conditions.

- Comprehensive monitoring systems to alert users to potential hazards.

Improved Operational Efficiency

- Lightweight design facilitates mobility.

- Intuitive controls allow for quick adjustments.

- Extended operational time enables longer missions without interruption.

Maintenance Tips for Air Pak

Ensuring the longevity and efficiency of your respiratory equipment is crucial for safety and performance. Regular maintenance not only enhances the reliability of the gear but also helps in identifying potential issues before they escalate. Here are some essential tips to keep your apparatus in optimal condition.

Regular Inspections

- Conduct visual checks for wear and tear, paying close attention to seals and connections.

- Inspect the straps and harness for any signs of fraying or damage.

- Ensure that all gauges are functioning properly and display accurate readings.

Cleaning Procedures

- Wipe down the exterior surfaces with a damp cloth to remove dust and contaminants.

- Use mild soap and water for deeper cleaning of components, avoiding harsh chemicals.

- Allow all parts to dry completely before reassembly to prevent mold and mildew.

By following these guidelines, users can maintain their equipment effectively, ensuring it remains reliable when needed most.

Common Issues with Scott Air Pak

Understanding the frequent challenges encountered with personal protective breathing systems is crucial for ensuring safety and efficiency in hazardous environments. Many users face specific difficulties that can impact performance and reliability.

Frequent Problems

- Pressure leaks due to damaged seals or connections.

- Malfunctioning pressure gauges leading to inaccurate readings.

- Obstruction in airflow from dirt or moisture accumulation.

- Battery issues affecting the electronic components.

Maintenance Tips

- Regularly inspect seals and connections for wear and tear.

- Calibrate pressure gauges periodically to ensure accuracy.

- Clean and dry components to prevent airflow blockages.

- Check batteries and replace them as needed to maintain functionality.

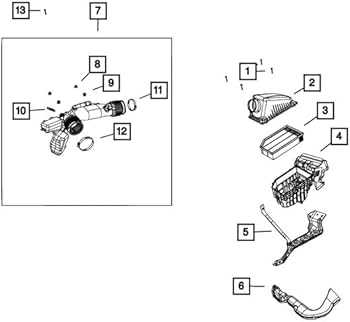

Parts Identification for Air Pak

This section focuses on the essential components that make up the breathing apparatus, highlighting their roles and importance in ensuring safety and functionality. Understanding these elements is crucial for effective maintenance and operation, providing users with the knowledge necessary to identify and manage each segment effectively.

Each component plays a specific role in the overall system, from the harness that secures the unit to the regulators that control airflow. Familiarity with these elements enhances operational efficiency and safety during use.

Users are encouraged to familiarize themselves with the layout and function of each component, which can significantly aid in troubleshooting and servicing. Proper identification ensures that any issues can be promptly addressed, ultimately leading to improved reliability during critical situations.

Assembly Instructions for Scott Air Pak

This section provides a comprehensive guide to assembling essential respiratory equipment, ensuring all components are correctly fitted for optimal performance and safety. Follow these step-by-step instructions carefully to achieve a successful assembly.

Preparation Steps

- Gather all necessary components and tools.

- Inspect each part for any signs of damage or wear.

- Ensure you have a clean, organized workspace.

Assembly Procedure

- Start by connecting the main harness to the frame.

- Secure the regulator assembly into place, ensuring a tight fit.

- Attach the air cylinder to the designated bracket, following safety guidelines.

- Connect the hoses, ensuring there are no twists or kinks.

- Double-check all connections for security and integrity.

- Conduct a final inspection before use to confirm everything is in order.

Following these guidelines will help ensure that the assembly is carried out correctly, providing reliable functionality when needed.

Safety Features of Air Pak 4.5

This section explores the crucial safety mechanisms integrated into the equipment designed for first responders. These features aim to ensure the highest level of protection and functionality in hazardous environments.

Key Safety Mechanisms

- Durable Construction: Designed to withstand extreme conditions and impacts.

- Automatic Alarm: Activates when a user becomes inactive for a specified period.

- Pressure Gauge: Provides real-time monitoring of remaining air supply.

- Clear Communication System: Facilitates reliable communication among team members.

Enhanced User Protection

- Adjustable Harness: Ensures a secure fit, minimizing movement during use.

- Integrated Safety Lights: Increases visibility in low-light situations.

- Emergency Escape Features: Includes systems for rapid exit in emergencies.

Repairing Scott Air Pak Components

Maintaining vital equipment is essential for ensuring safety and performance in critical situations. Properly addressing issues with various components can extend the lifespan of your gear and enhance its reliability. This section will explore effective methods for diagnosing and repairing essential elements to keep them in optimal condition.

Begin by identifying the specific issues that may arise with the equipment. Common problems include leaks, worn-out seals, or malfunctioning valves. Conduct a thorough inspection to pinpoint the source of any malfunction. Once identified, gather the necessary tools and replacement materials to facilitate the repair process.

When replacing components, always ensure compatibility with the existing system. Follow manufacturer guidelines for installation to guarantee proper function and safety. Additionally, regular maintenance checks can help prevent future issues and improve overall performance.

Lastly, documenting the repairs made and any parts replaced is crucial for tracking the equipment’s history. This practice not only aids in future maintenance but also ensures that the gear remains compliant with safety standards.

Upgrading Scott Air Pak Parts

Enhancing the performance and safety of respiratory equipment is essential for ensuring optimal functionality during critical operations. Upgrades can involve various components that significantly improve the user experience and reliability of the gear. By focusing on modern advancements and maintaining high standards, users can maximize the effectiveness of their respiratory systems.

When considering upgrades, it’s important to evaluate each component’s role in overall performance. Below is a comparison table highlighting key upgrade options and their benefits:

| Component | Upgrade Option | Benefits |

|---|---|---|

| Regulator | High-Flow Design | Improved air delivery, reduced work of breathing |

| Facepiece | Advanced Seal Technology | Enhanced fit, better comfort, reduced leakage |

| Harness | Ergonomic Padding | Increased comfort during extended use, better weight distribution |

| Filter | HEPA Filtration | Superior protection against airborne contaminants |

Each upgrade contributes to a more efficient and secure environment for users. Prioritizing the most critical components based on individual needs will lead to a significant enhancement in operational readiness and safety.

Compatibility with Other Equipment

Understanding how one device interacts with various tools and systems is crucial for ensuring optimal performance and safety. Compatibility not only enhances functionality but also streamlines operations across different environments.

Interoperability Features

Many modern systems are designed to work seamlessly with a range of equipment, facilitating efficient use. Key features that enhance interoperability include standardized connections and adaptable designs, allowing for flexible integration in diverse settings.

Compatibility Table

| Equipment Type | Compatibility Level | Notes |

|---|---|---|

| Respiratory Protection | High | Most devices can connect without modifications. |

| Monitoring Systems | Medium | Requires specific adapters for optimal function. |

| Storage Solutions | Low | Limited integration; check specifications. |

FAQs About Scott Air Pak 4.5

This section addresses common inquiries regarding a specific breathing apparatus widely used in various industries. Understanding its features, maintenance, and operational guidelines can enhance user experience and safety.

General Inquiries

- What is the purpose of this breathing apparatus?

It is designed to provide breathable air in hazardous environments, ensuring user safety during emergency situations. - Who can operate this device?

Typically, it is used by professionals in firefighting, rescue operations, and industrial settings, requiring proper training. - How often should it be inspected?

Regular inspections are recommended, ideally before each use, to ensure functionality and safety.

Maintenance and Care

- What are the key maintenance tasks?

- Check for any visible damage or wear.

- Test the pressure and functionality of the components.

- Clean and store properly after each use.

- How can I extend the lifespan of the device?

Regular maintenance and following manufacturer guidelines can significantly enhance durability and performance.

Real-World Applications of Air Pak

In various high-risk environments, specialized breathing apparatuses play a crucial role in ensuring the safety and efficiency of responders. These systems are designed to provide a continuous supply of breathable air, enabling personnel to operate effectively in hazardous conditions.

Emergency Services: Firefighters and rescue teams utilize these devices during operations in smoke-filled or toxic environments. The ability to maintain oxygen supply allows them to perform their duties without compromising their safety.

Industrial Settings: In sectors such as construction and chemical manufacturing, workers rely on this technology to safeguard against airborne contaminants. This ensures compliance with safety regulations while enhancing productivity.

Military Operations: Armed forces depend on these systems for mission success in hostile environments. The durability and reliability of the equipment are vital for the well-being of personnel during critical operations.

Training Scenarios: Training facilities incorporate these tools to prepare responders for real-life emergencies. Simulations using such equipment help build confidence and proficiency in handling various situations.

Overall, the integration of this technology in diverse fields underscores its ultimate significance in enhancing safety and operational effectiveness.