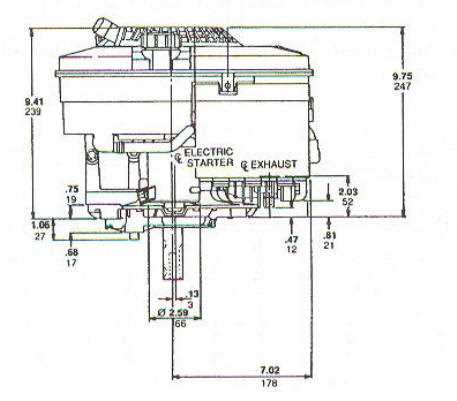

This section delves into the intricate design of a compact power source commonly found in various outdoor machinery. Analyzing the structure helps users recognize the essential elements that contribute to the overall functionality and performance of these reliable machines. Familiarity with these components enables better maintenance and optimization.

By exploring the configuration of a specific model, enthusiasts and technicians can gain insights into the interrelation of individual components. This knowledge is crucial for troubleshooting issues, enhancing efficiency, and ensuring longevity. A comprehensive understanding of these units fosters confidence in making informed decisions regarding repairs and upgrades.

Whether you are a seasoned professional or a novice, having access to a detailed representation of the unit’s layout will facilitate a more profound grasp of its operation. As users engage with the various features, they will appreciate the engineering that goes into crafting these powerful devices.

This section aims to explore the essential elements that make up a specific power unit, highlighting their functions and interrelationships. By understanding these components, users can better appreciate how each part contributes to the overall performance and efficiency of the machine.

Key Components Overview

- Power Source: The fundamental unit that generates mechanical energy.

- Fuel System: Responsible for delivering energy-rich fuel to the combustion chamber.

- Ignition System: Initiates the combustion process by producing a spark at the correct time.

- Cooling Mechanism: Maintains optimal temperature by dissipating heat during operation.

- Lubrication System: Ensures smooth movement of internal parts by reducing friction.

Functions of Individual Elements

- Power Source: Converts fuel into mechanical energy, driving the device’s functions.

- Fuel System: Optimizes fuel mixture for efficient combustion and performance.

- Ignition System: Ensures timely ignition for reliable operation.

- Cooling Mechanism: Prevents overheating, ensuring longevity and safety.

- Lubrication System: Extends the lifespan of the power unit by minimizing wear.

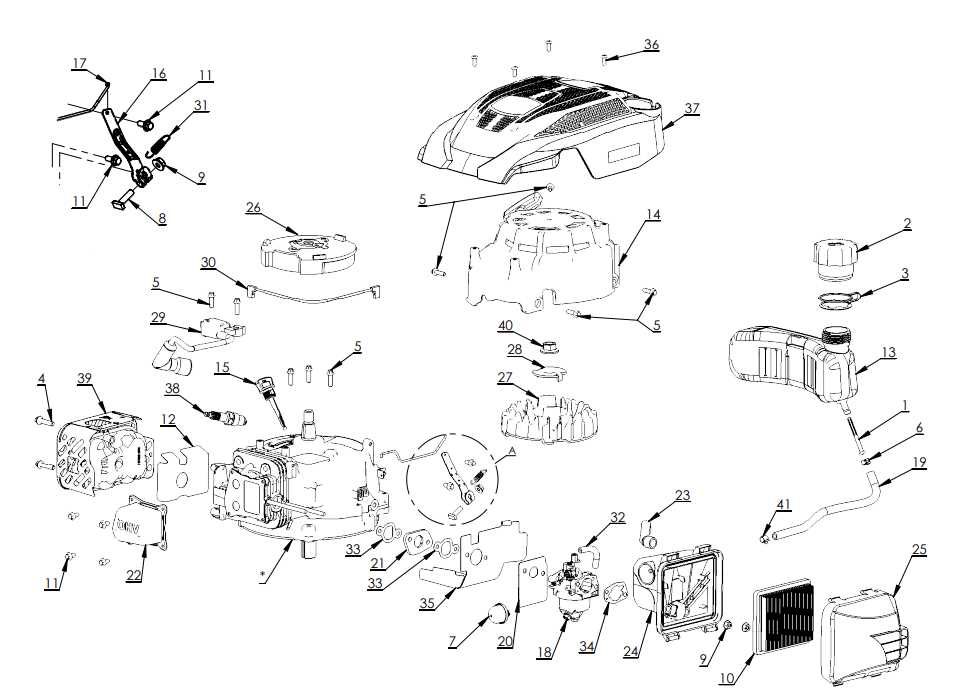

Overview of Engine Functionality

The operation of a power unit relies on a series of interconnected components that work in harmony to convert fuel into mechanical energy. Understanding the fundamental processes involved is essential for anyone looking to maintain or repair such machinery. Each component plays a vital role in ensuring smooth performance and optimal efficiency.

Key Components and Their Roles

At the heart of the power unit is the combustion chamber, where fuel is ignited, generating the necessary energy. The piston then converts this energy into motion, driving the crankshaft. This rotational movement is what ultimately powers the attached devices. Additionally, the cooling system prevents overheating, ensuring longevity and reliability during operation.

Importance of Maintenance

Regular upkeep is crucial for the longevity of the machinery. Routine checks on essential elements, such as the air filter and spark plug, can significantly impact performance. Timely maintenance not only enhances efficiency but also minimizes the risk of costly repairs, allowing for uninterrupted usage.

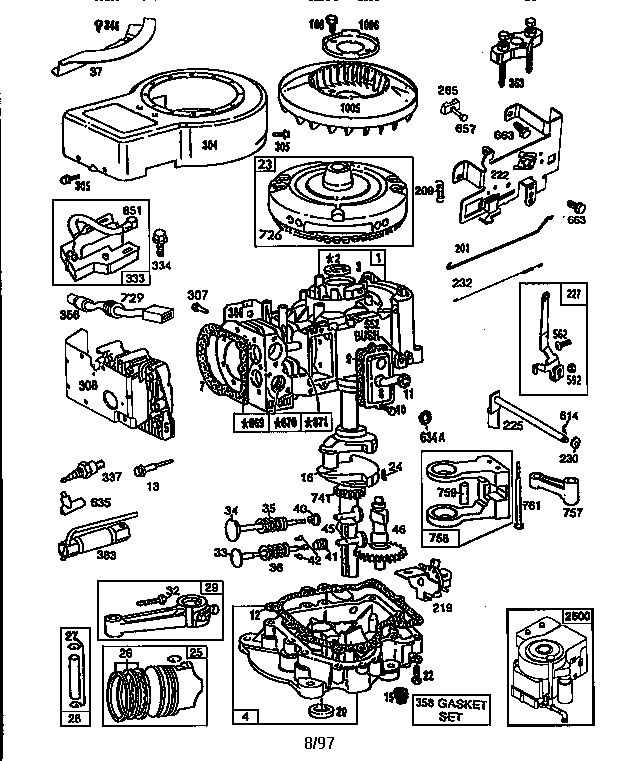

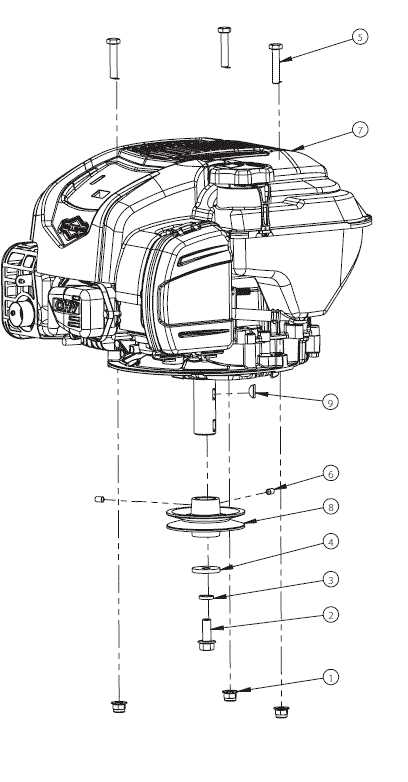

Key Parts of the Engine

This section explores the essential components that contribute to the functionality of a small power unit. Each element plays a crucial role in ensuring optimal performance and reliability, making understanding these components vital for maintenance and repair.

Essential Components

- Fuel Tank: Stores the fuel necessary for operation, ensuring a steady supply to the combustion chamber.

- Piston: Moves within the cylinder, converting fuel energy into mechanical power.

- Crankshaft: Translates the up-and-down motion of the piston into rotational motion.

- Spark Plug: Ignites the air-fuel mixture, initiating the combustion process.

- Carburetor: Mixes air with fuel in the proper ratio for efficient combustion.

Additional Important Elements

- Governor: Regulates the engine speed by controlling the amount of fuel entering the carburetor.

- Air Filter: Prevents dirt and debris from entering the combustion chamber, protecting internal components.

- Exhaust System: Directs exhaust gases away from the unit, ensuring efficient operation.

- Cooling System: Maintains an optimal temperature to prevent overheating during operation.

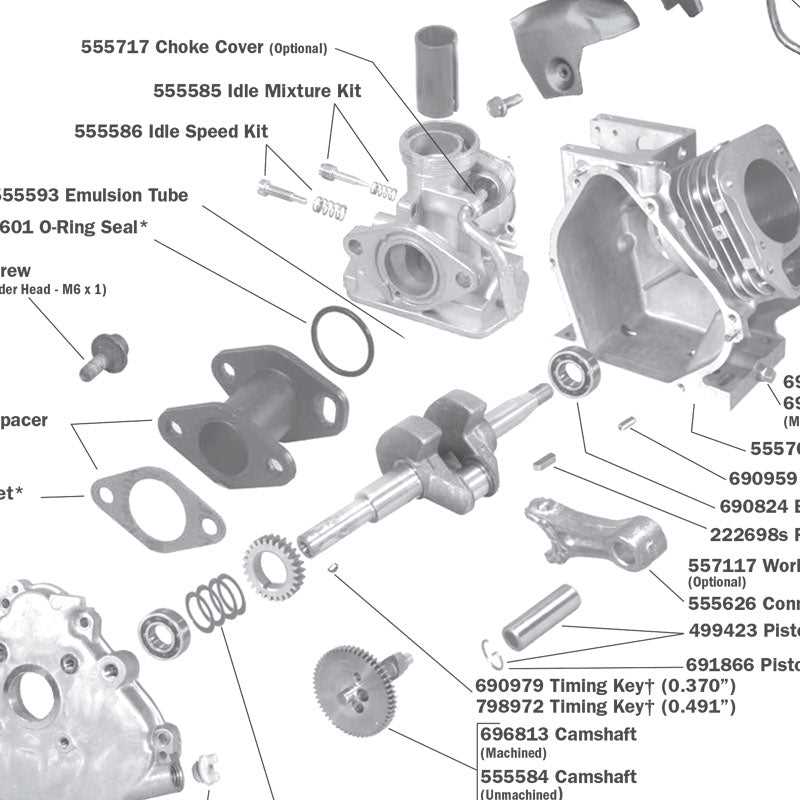

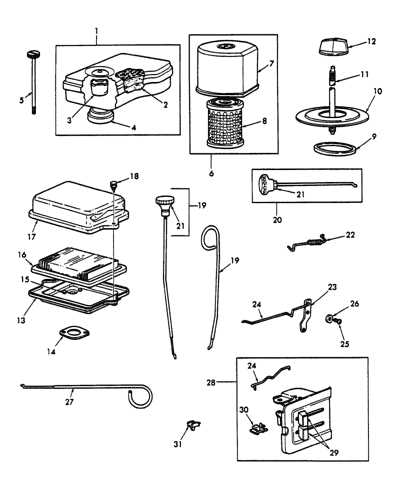

Exploring the Fuel System

The fuel mechanism plays a crucial role in ensuring optimal performance and efficiency in small power units. Understanding its components and their functions is essential for effective maintenance and troubleshooting.

Key elements of the fuel mechanism include:

- Fuel Tank: Stores the liquid fuel required for operation.

- Fuel Filter: Prevents contaminants from entering the fuel line and damaging internal components.

- Fuel Line: A conduit that transports fuel from the tank to the combustion chamber.

- Carburetor: Mixes air and fuel in the correct proportions for combustion.

- Fuel Pump: Moves fuel from the tank to the carburetor, ensuring a steady supply during operation.

Regular inspection and maintenance of these components can enhance the longevity of the unit and improve its overall functionality. Proper care will ensure that the fuel system operates smoothly, preventing common issues such as fuel starvation or excessive consumption.

Maintenance and Care Tips

Regular upkeep is essential for ensuring optimal performance and longevity of your machinery. Proper attention to routine maintenance tasks can prevent potential issues and enhance efficiency. Adopting a systematic approach to care can significantly extend the lifespan of your unit.

Routine Inspections

Frequent assessments are crucial for identifying wear and tear before they escalate into significant problems. Check for signs of damage or excessive wear on various components, including the fuel system and ignition elements. A proactive approach allows for timely replacements, reducing downtime.

Fluid Management

Maintaining the right levels of fluids is vital for optimal operation. Ensure that the oil is changed regularly and at the recommended intervals to keep internal parts lubricated and functioning smoothly. Additionally, monitoring fuel quality and replacing it as necessary can prevent complications and improve efficiency.

Common Issues with 6.5 HP Engines

Power units of this size often encounter a range of typical problems that can impact their performance and longevity. Identifying these issues early can lead to effective solutions and maintenance strategies.

- Starting Difficulties:

Many users report challenges when attempting to initiate operation. This may stem from:

- Insufficient fuel supply

- Dirty spark plug

- Weak battery

- Overheating:

Excessive temperatures can arise due to:

- Blocked air intake

- Low oil levels

- Faulty cooling system

- Loss of Power:

A noticeable decrease in output may occur due to:

- Clogged fuel filter

- Worn piston rings

- Improper fuel mixture

- Excessive Vibration:

Unusual movement and noise can indicate:

- Loose mounting bolts

- Imbalanced components

- Worn bearings

- Fuel Leakage:

Fuel escaping from the system can be a serious concern. Common causes include:

- Cracked fuel lines

- Faulty carburetor gasket

- Worn seals

By staying vigilant and addressing these frequent complications promptly, users can enhance the reliability and functionality of their power units.

Replacement Parts Availability

Access to high-quality components is essential for maintaining optimal performance in small machinery. Users often seek reliable sources to acquire necessary items, ensuring their equipment operates efficiently and effectively. Understanding where to find these crucial elements can enhance the longevity and functionality of your machinery.

Common Sources for Components

Several avenues exist for acquiring the necessary elements, including local retailers, online marketplaces, and authorized dealers. Each option provides varying benefits in terms of availability, pricing, and delivery time. Exploring multiple sources can lead to better choices for specific needs.

Recommended Component Suppliers

| Supplier Name | Type of Supply | Website |

|---|---|---|

| Local Hardware Store | In-Store Sales | localhardwarestore.com |

| Online Retailer A | Wide Selection | onlineretailera.com |

| Official Distributor | Genuine Items | officialdistributor.com |

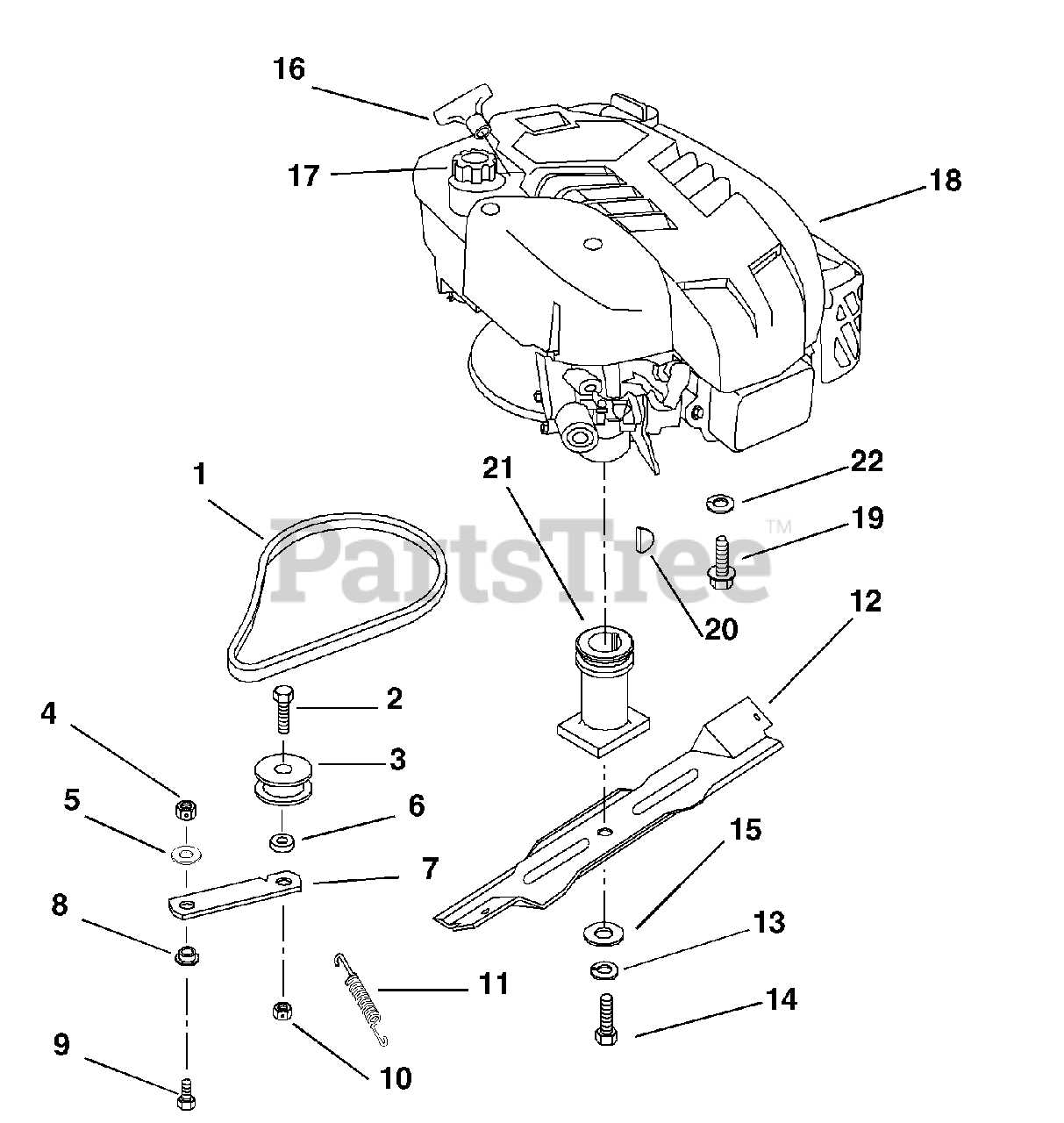

Step-by-Step Disassembly Guide

This section provides a comprehensive approach to carefully dismantling the specified machinery for maintenance or repair. Following a structured process ensures that each component is handled with care, reducing the risk of damage and facilitating a smooth reassembly.

Step 1: Begin by ensuring the unit is disconnected from any power source to avoid accidental starts. Prepare a clean workspace to keep all components organized.

Step 2: Remove any coverings or housings that protect the internal mechanisms. Use appropriate tools to prevent stripping screws or damaging parts.

Step 3: Carefully take out the primary components, such as the fuel tank and air filter, noting their positions for later reference. Use a container to keep small items together.

Step 4: Gradually detach remaining sections, paying attention to the order of disassembly. If any components are particularly resistant, apply gentle pressure or consult the manual for guidance.

Step 5: Once all elements are removed, examine each piece for wear or damage. Cleaning them before reassembly will enhance performance and longevity.

By adhering to this methodical approach, you will facilitate efficient troubleshooting and repairs, ensuring that the equipment functions optimally once reassembled.

Identifying Wear and Tear

Recognizing signs of deterioration is crucial for maintaining optimal performance of small machinery. Regular inspections can help identify components that may be suffering from excessive use or environmental factors. This proactive approach can extend the lifespan of the machinery and prevent more significant issues from developing.

Common indicators of wear include visible damage, unusual noises, and changes in performance. It is essential to pay attention to these warning signs to ensure the effective operation of the equipment. Below is a table that outlines various symptoms and their potential causes:

| Symptom | Potential Cause |

|---|---|

| Excessive vibrations | Worn bearings or misalignment |

| Difficulty starting | Faulty ignition or fuel delivery issues |

| Reduced power output | Clogged air filter or exhaust |

| Overheating | Insufficient lubrication or coolant |

| Leaks | Worn seals or gaskets |

Regular maintenance, including cleaning and timely replacement of worn components, can significantly mitigate these issues. Monitoring these factors will contribute to the reliable operation of the machinery over time.

Tools Required for Repairs

Undertaking maintenance or fixes on small power machinery necessitates a selection of specific implements. Having the right tools ensures that tasks are completed efficiently and effectively, minimizing the risk of damage to the equipment. This section outlines essential tools to keep on hand for successful repairs.

Basic Hand Tools

Basic hand tools are indispensable for any repair job. They allow for precise adjustments and are often necessary for disassembly and reassembly processes.

| Tool | Description |

|---|---|

| Wrench Set | Used for loosening and tightening various bolts and nuts. |

| Screwdriver Set | Essential for handling screws of different sizes and types. |

| Pliers | Useful for gripping, twisting, and cutting wire. |

| Socket Set | Provides versatility for fastening fasteners in confined spaces. |

Specialized Tools

In addition to basic tools, certain specialized instruments may be required for specific tasks. These tools can enhance efficiency and accuracy during repairs.

| Tool | Description |

|---|---|

| Torque Wrench | Ensures bolts are tightened to the correct specifications. |

| Compression Tester | Measures the compression pressure of the unit for diagnostics. |

| Feeler Gauge | Used to measure gaps between parts, ensuring proper clearance. |

| Fuel Line Cutter | Facilitates precise cuts on fuel lines without causing damage. |

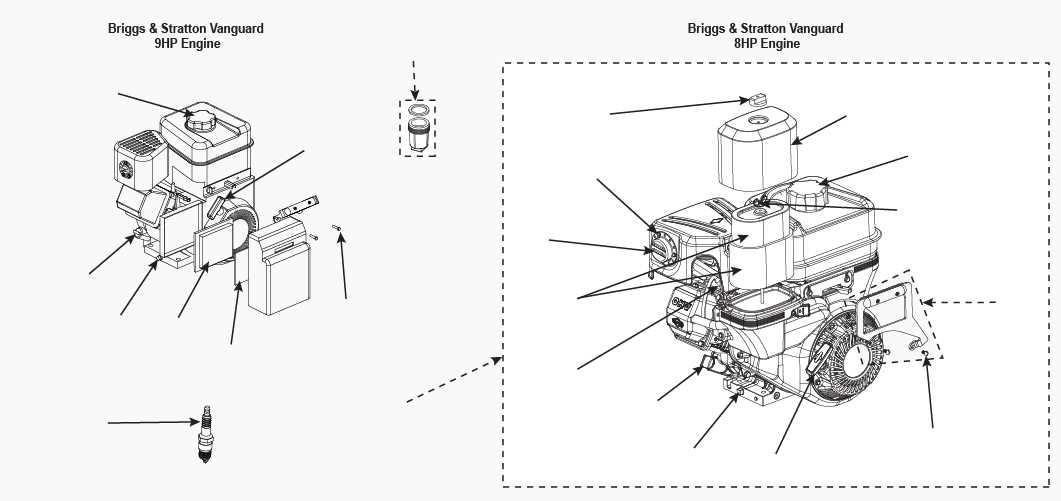

Improving Engine Performance

Enhancing the functionality and efficiency of a small power unit can significantly impact its overall performance. By focusing on several key aspects, you can optimize the operation of the machinery, leading to increased power output and improved fuel efficiency. Understanding the essential components and their roles is crucial for achieving the desired results.

Regular Maintenance and Upgrades

Conducting routine maintenance, such as changing filters and fluids, is vital for sustaining optimal operation. Upgrading specific components, like the carburetor or exhaust system, can also contribute to better airflow and fuel mixture, enhancing power delivery. Regular checks can prevent issues that may hinder performance and extend the lifespan of the machinery.

Fuel Quality and Mixture

The quality of the fuel used plays a significant role in the performance of any power unit. Utilizing high-grade fuel and ensuring the correct mixture can lead to smoother operation and improved efficiency. Additionally, considering fuel additives may help in cleaning the combustion chamber and optimizing fuel combustion.

Resources for Troubleshooting

When dealing with mechanical issues, having access to the right information can significantly aid in diagnosing and resolving problems. Utilizing various tools and sources can help identify symptoms and effective solutions, ensuring optimal performance of your equipment.

Online Manuals and Guides

Consulting comprehensive manuals and user guides is an excellent starting point. These documents often include troubleshooting tips, maintenance schedules, and detailed explanations of the components involved. Many manufacturers provide downloadable resources directly from their websites.

Community Forums and Support Groups

Engaging with online communities can provide valuable insights from other users who have experienced similar challenges. These forums often feature discussions, solutions, and advice from enthusiasts and experts.

| Resource Type | Description | Link |

|---|---|---|

| User Manual | Detailed instructions and troubleshooting tips | Download Manual |

| Community Forum | Discussion platform for sharing experiences and solutions | Visit Forum |

| Video Tutorials | Step-by-step visual guides for common issues | Watch Tutorials |