When exploring the structure of a vintage agricultural vehicle, it’s essential to have a clear understanding of how its various components fit together. The layout provides valuable insights into the organization of mechanical elements, allowing for easier maintenance and restoration of these classic machines.

Each element in the assembly serves a crucial role in the overall function of the vehicle. From the engine to the transmission system, recognizing how they connect helps enthusiasts and mechanics alike in identifying potential

Understanding the Structure of the Ford 8N

The design of this well-known agricultural machine is a remarkable blend of simplicity and durability, ensuring its longevity and ease of maintenance. Its layout reflects an intuitive approach to engineering, making it accessible for both experienced users and those new to machinery. Each section of the vehicle is carefully positioned to promote smooth functionality and performance.

Chassis and Frame form the backbone of the machine, providing stability and a solid foundation for all other components. This sturdy base is designed to handle tough conditions, offering both strength and reliability in various tasks.

Engine and Powertrain are at the

Main Components of the Ford 8N

The structure of this classic model is built from several essential elements that work together to ensure its functionality. Understanding the core units will help maintain its performance and reliability.

- Engine – The heart of the machine, providing the necessary power for various operations.

- Transmission – This system controls the speed and torque, allowing smooth movement and handling.

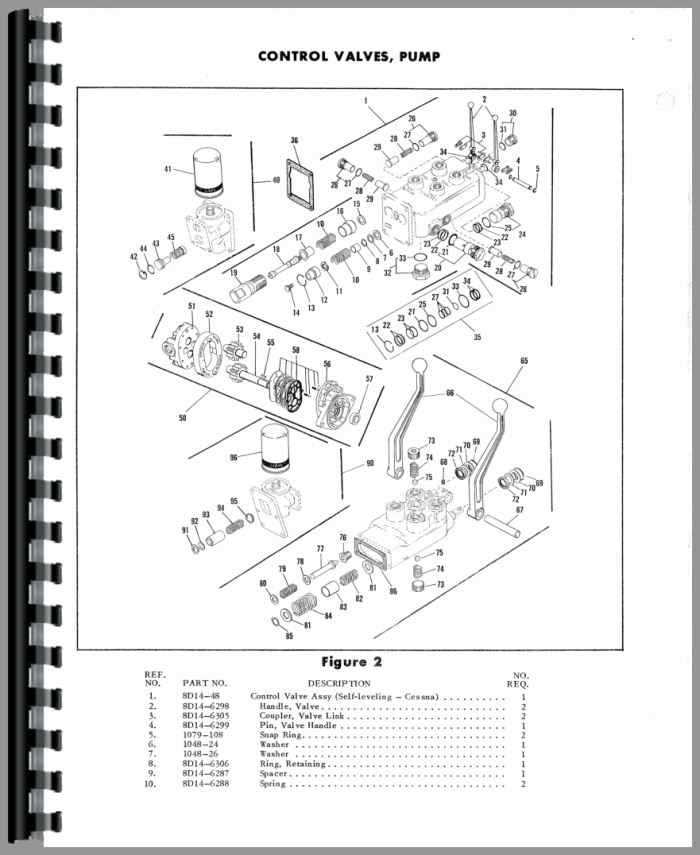

- Hydraulic System – Vital for operating attachments, offering precise control and strength.

- Pump – responsible for generating the necessary pressure to move the fluid through the system.

- Reservoir – stores the hydraulic fluid and helps maintain

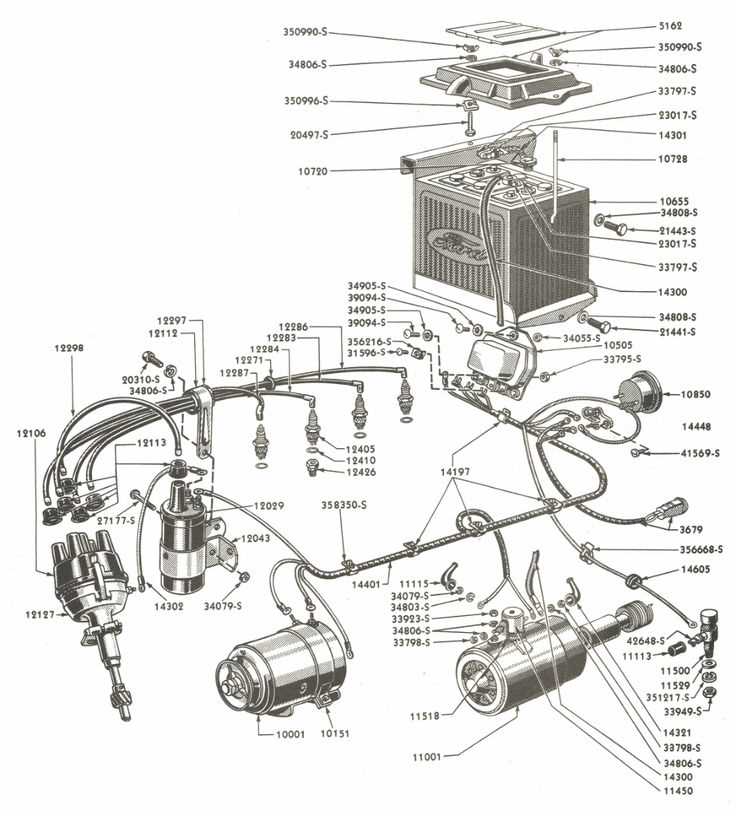

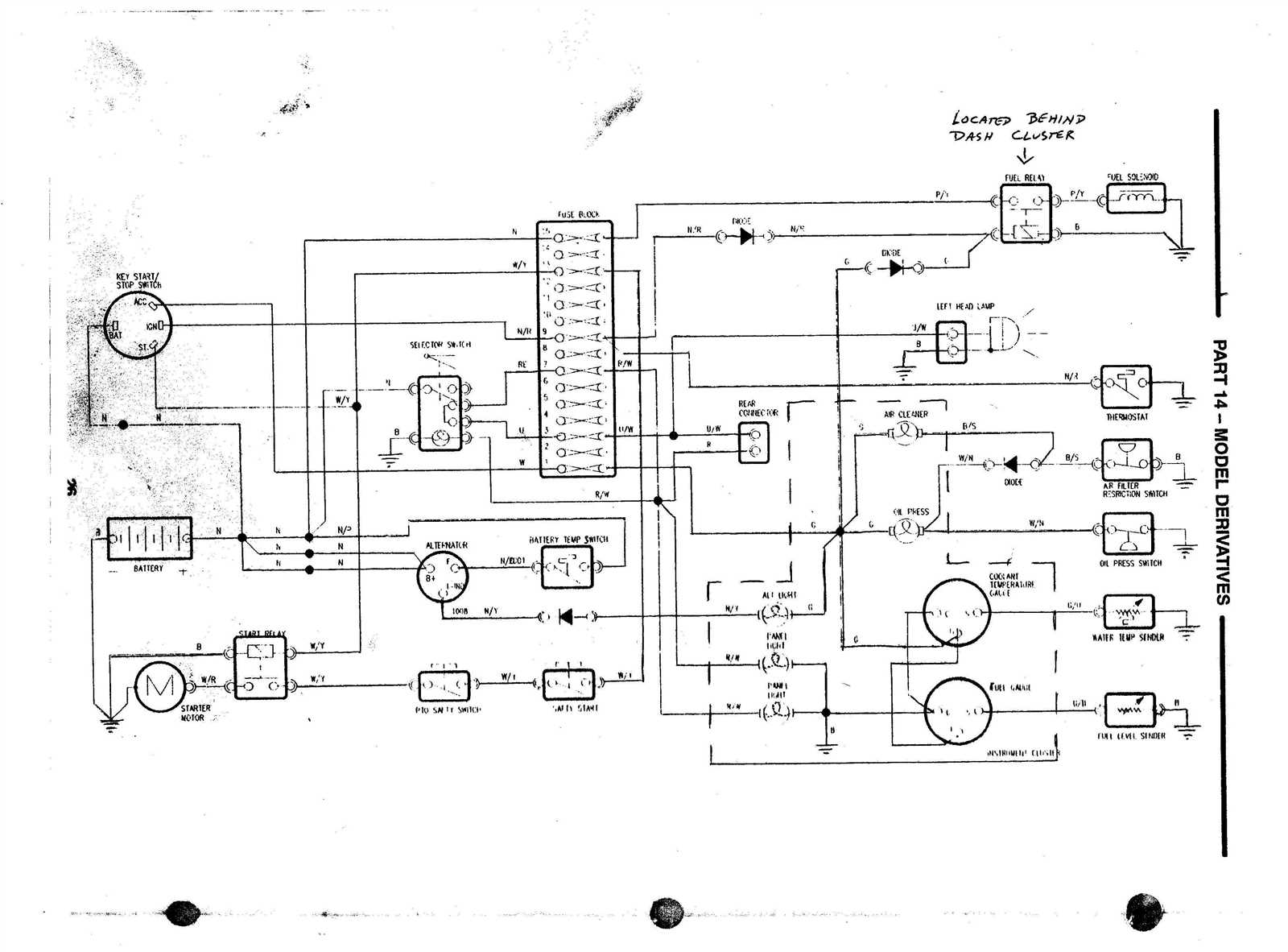

Electrical System Layout

The electrical framework of a tractor is crucial for its efficient operation, ensuring that all components function harmoniously. Understanding the arrangement of this system helps in troubleshooting issues and performing maintenance effectively. This section provides an overview of the main elements within the electrical setup.

Main Components

- Battery: Supplies electrical energy for starting the engine and powering accessories.

- Alternator: Charges the battery and provides power to the electrical systems when the engine is running.

- Wiring Harness: Connects various electrical parts and ensures proper transmission of electrical signals.

- Starter Motor: Initiates the engine’s operation by turning the flywheel.

- Fuse Box: Protects electrical circuits by preventing overloads.

Functionality Overview

- The battery provides the necessary voltage to the starter motor, enabling the engine to start.

- Once the engine is running, the alternator generates electricity to power the electrical systems.

- The wiring harness facilitates the distribution of electrical signals to different components, ensuring efficient communication.

- The fuse box acts as a safeguard, disconnecting power in case of a fault, protecting the electrical system from damage.

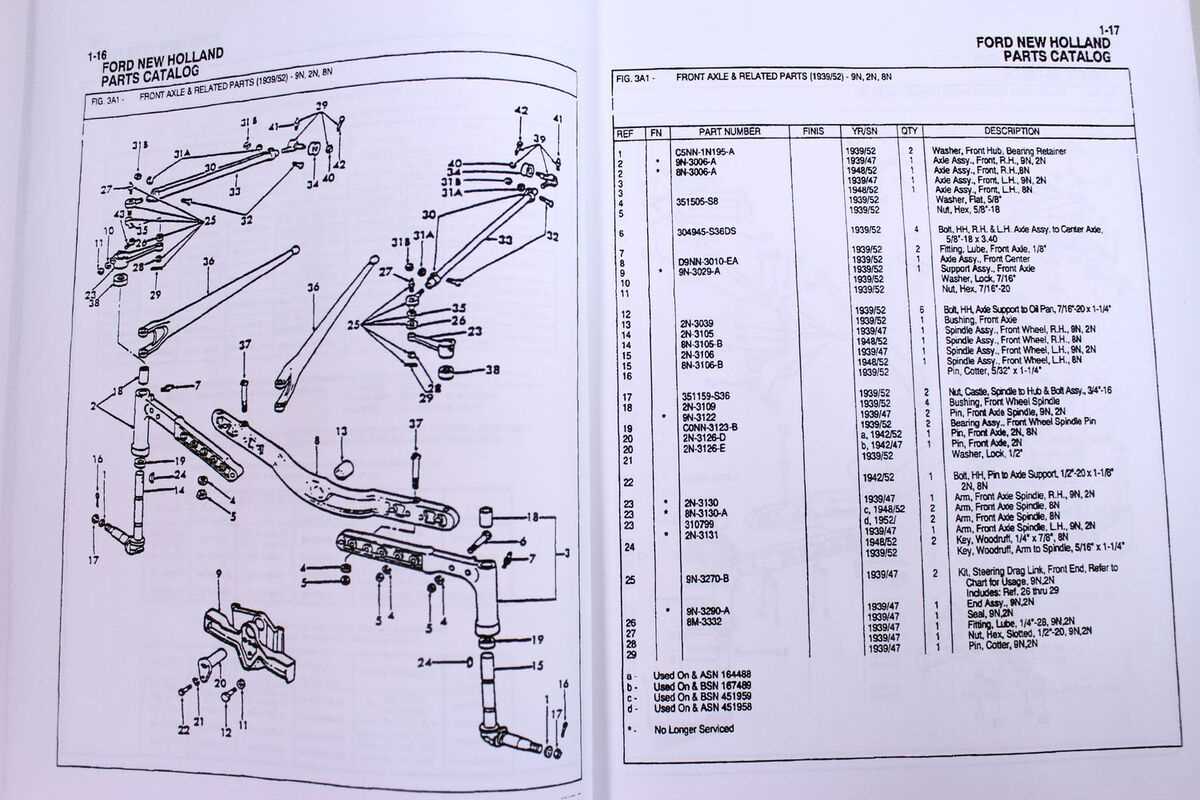

Brake and Steering System Diagram

The braking and steering mechanisms are essential components that contribute to the overall functionality and safety of agricultural machinery. Understanding the configuration and interplay of these systems is crucial for effective maintenance and troubleshooting.

Key features of these systems include:

- Braking System: Designed to provide effective stopping power, ensuring the operator can control the machine’s speed and direction safely.

- Steering Assembly: Facilitates maneuverability, allowing for precise navigation through various terrains.

Proper maintenance of these systems is vital for optimal performance. Regular inspections can help identify potential issues before they escalate into more significant problems. The following aspects should be considered during maintenance:

- Check for wear and tear on brake components.

- Inspect steering linkages for signs of damage.

- Ensure fluid levels are adequate in hydraulic systems.

In summary, maintaining the integrity of the braking and steering systems enhances safety and functionality, ensuring the equipment operates efficiently in the field.

Fuel System Components

The fuel system of a tractor plays a vital role in ensuring efficient engine performance and reliability. It comprises various elements that work together to store, filter, and deliver fuel to the engine, ultimately supporting its operation. Understanding these components is essential for maintenance and troubleshooting.

Component Function Fuel Tank Stores the fuel required for engine operation. Fuel Filter Cleans the fuel by removing impurities before it reaches the engine. Fuel Pump Transfers fuel from the tank to the engine, maintaining necessary pressure. Fuel Lines Conduits that transport fuel between the tank, filter, pump, and engine. Injectors Atomize the fuel, allowing it to mix efficiently with air in the combustion chamber. Cooling System Overview

The cooling mechanism in machinery is essential for maintaining optimal operational temperatures. It ensures that the engine does not overheat, promoting longevity and efficient performance. This system circulates a fluid that absorbs heat from the engine components and dissipates it through radiators or coolers, thus preventing damage from excessive heat buildup.

Key Components

Understanding the main elements of the cooling mechanism can help in maintaining its effectiveness. Each component plays a critical role in the overall functionality of the system.

Functionality

The operation of the cooling system involves various processes, including fluid circulation and temperature regulation. These processes are vital for efficient engine operation and preventing overheating.

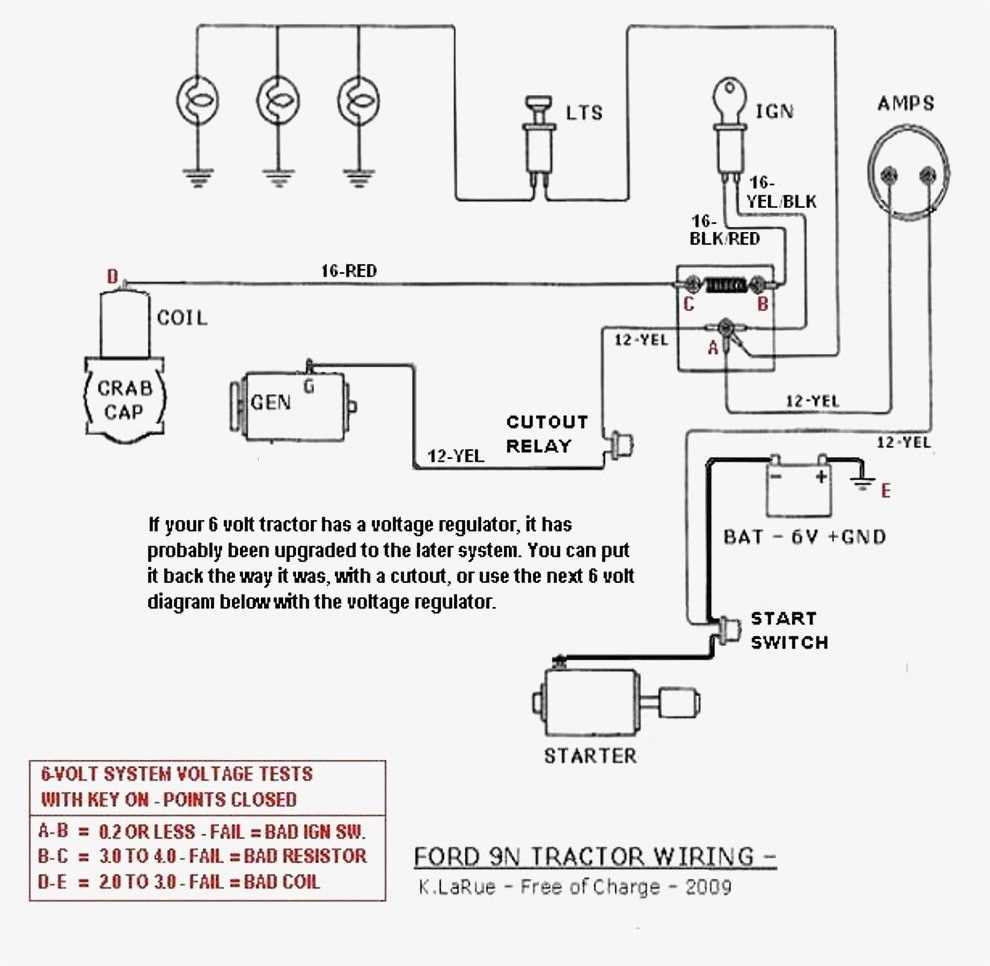

Component Function Radiator Dissipates heat from the coolant Water Pump Circulates coolant throughout the system Thermostat Regulates coolant flow based on temperature Coolant Absorbs heat from the engine Wiring Diagram for Ford 8

The electrical configuration of a tractor is essential for its optimal performance and reliability. Understanding how the various components are interconnected can help troubleshoot issues and ensure proper functioning. This section provides an overview of the electrical layout specific to the 8N model.

Key components involved in the electrical setup include:

- Battery

- Starter motor

- Ignition system

- Lights

- Charging system

To gain a comprehensive understanding of the electrical configuration, consider the following aspects:

- Power Sources: The battery serves as the primary power source, supplying energy to start the engine and operate electrical accessories.

- Connection Points: Each component is connected via wires, creating a network that allows electricity to flow efficiently.

- Grounding: Proper grounding is crucial for safety and functionality, helping to prevent electrical faults.

- Fuse Protection: Fuses are integrated into the system to protect against overloads and shorts, safeguarding the electrical components.

By familiarizing yourself with this electrical configuration, you can ensure better maintenance and troubleshooting for your tractor.

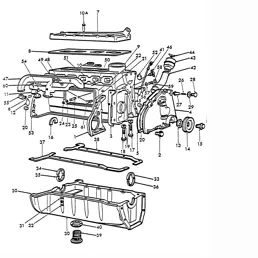

Engine Parts Breakdown

The core of any mechanical system is the intricate set of components that work together to generate power and ensure smooth operation. Understanding the individual sections of the power unit helps to maintain and troubleshoot issues more effectively. Each piece plays a crucial role in the overall performance and durability of the machine.

Starting from the combustion chamber to the pistons, each element contributes to converting energy into mechanical force. The internal setup includes various moving parts that interact to keep the machine running efficiently. This interaction is vital for achieving optimal performance

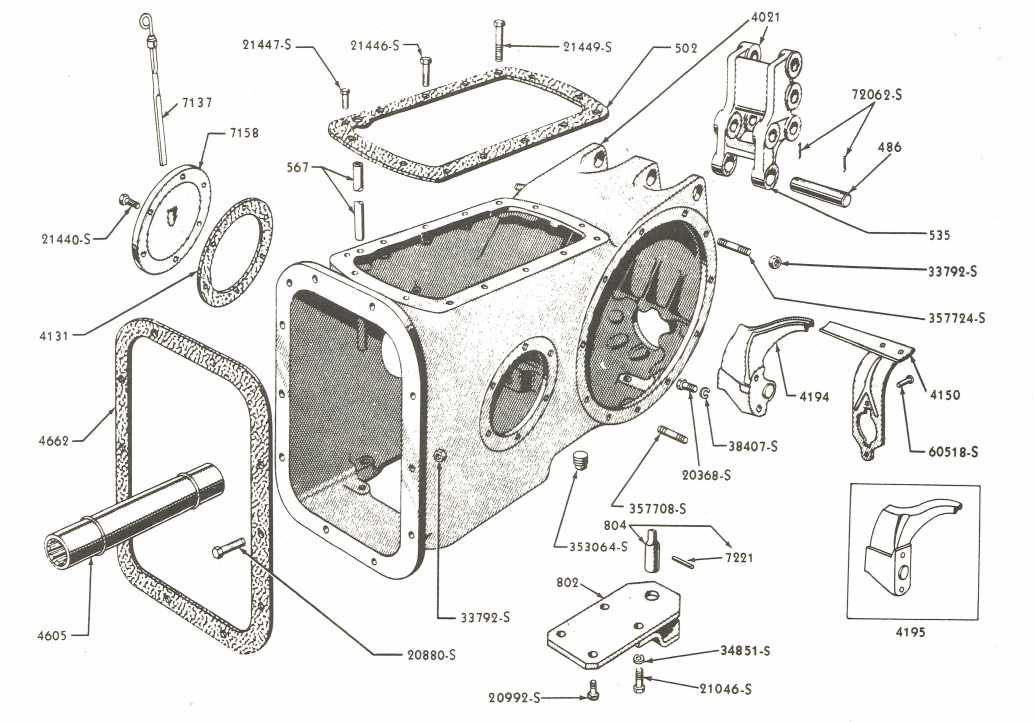

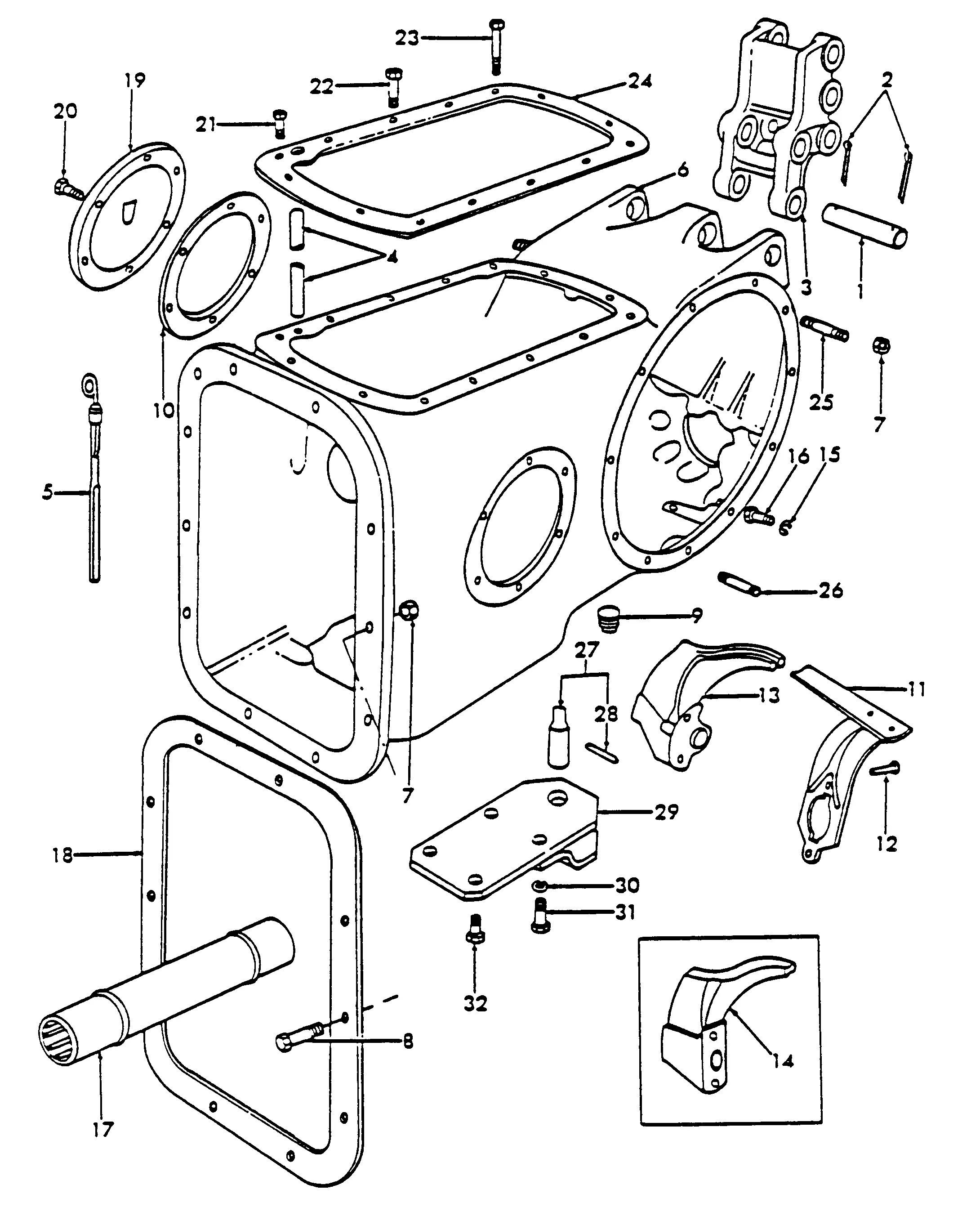

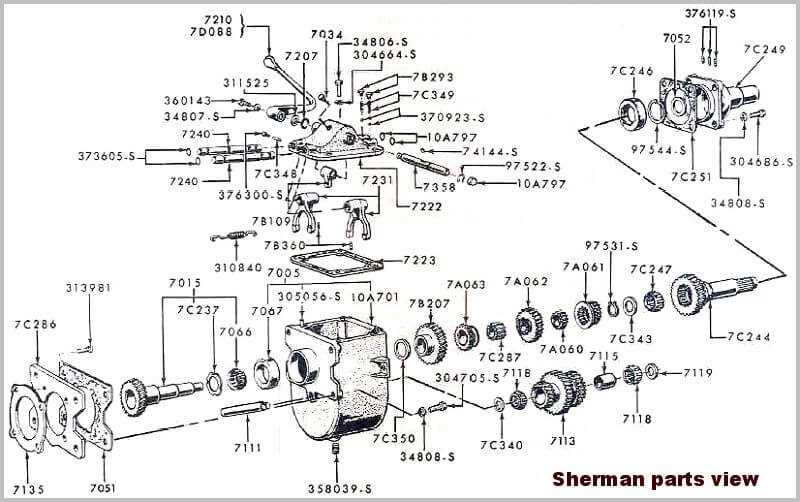

Transmission Assembly Overview

The transmission system is a crucial component responsible for managing the power generated by the engine, ensuring smooth transitions between various speeds. This section provides an outline of the key elements involved in the functioning of the transmission, highlighting its role in the overall operation of the machine.

| Component | Function |

|---|---|

| Gearbox | Facilitates the selection of different speeds and direction

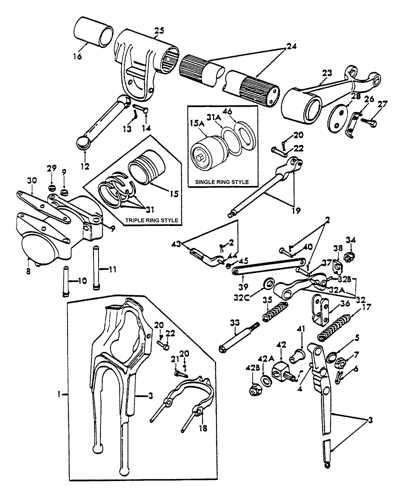

Hydraulic System and Its Elements

The hydraulic system plays a crucial role in ensuring smooth and efficient operation by transmitting power through fluid under pressure. It relies on various components working together to generate, control, and apply this power. Each element has its own function in maintaining the proper flow and pressure of the hydraulic fluid. |