When it comes to maintaining and repairing machinery, having a clear visual representation of its elements is essential. Such illustrations provide valuable insights into the arrangement and functionality of various components, ensuring that users can efficiently troubleshoot and perform necessary upgrades.

By examining these visual guides, users can easily identify each segment’s role within the system, leading to more informed decision-making during repairs or replacements. This understanding not only enhances the operational efficiency of the equipment but also extends its lifespan.

Overall, a detailed overview of the individual components empowers operators and technicians alike to approach maintenance tasks with confidence, ultimately fostering a deeper appreciation for the intricate workings of their equipment.

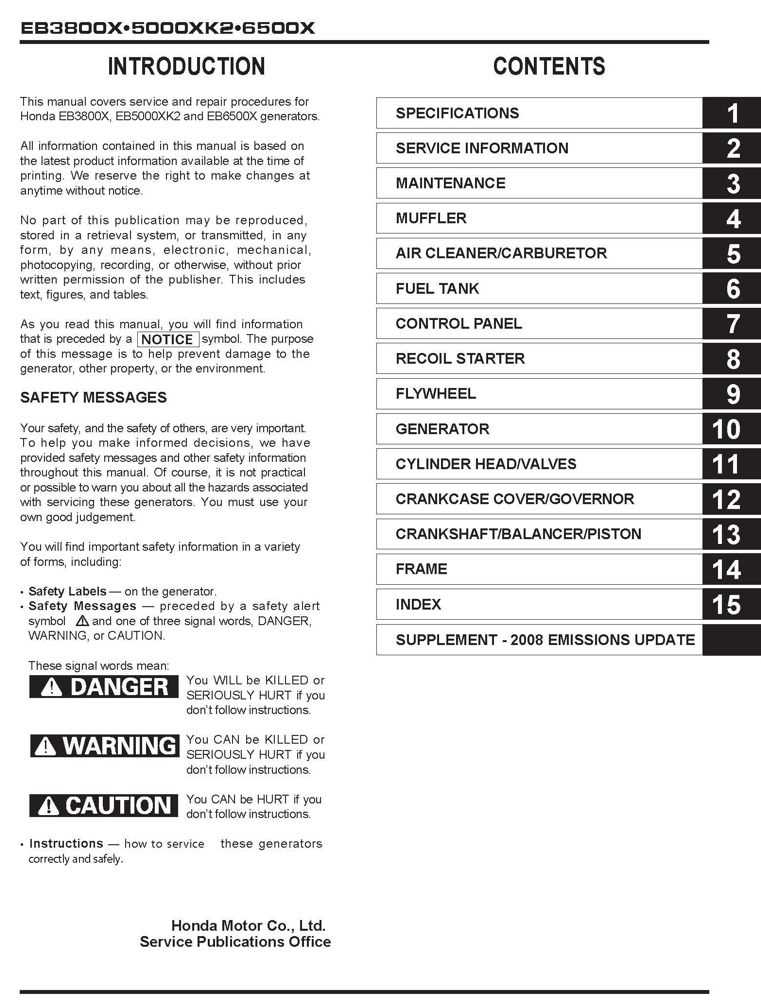

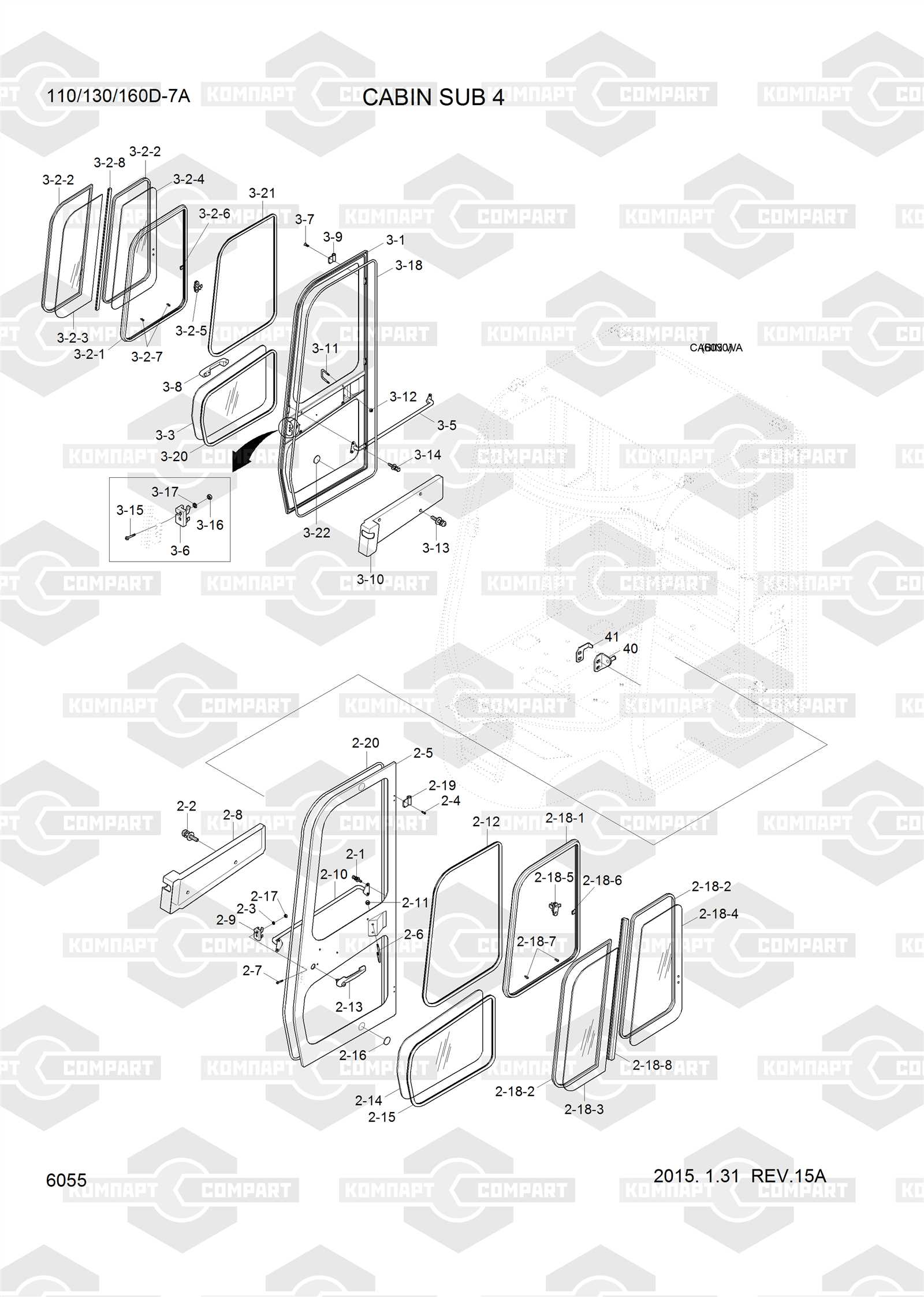

Importance of Parts Diagram

A comprehensive visual representation of components plays a crucial role in understanding the assembly and functionality of equipment. It aids users in identifying various elements, their arrangement, and how they interact within the overall system. This clarity enhances maintenance, repairs, and troubleshooting, leading to more efficient operation.

Enhanced Understanding

Having a clear visual guide allows individuals to:

- Quickly locate specific elements within the machinery.

- Understand the relationship between different components.

- Facilitate the learning process for new users or technicians.

Efficient Maintenance and Repair

Utilizing an illustrative reference provides significant advantages:

- Streamlined identification of worn or damaged parts.

- Reduction of errors during reassembly after repairs.

- Improved accuracy in ordering replacements, minimizing downtime.

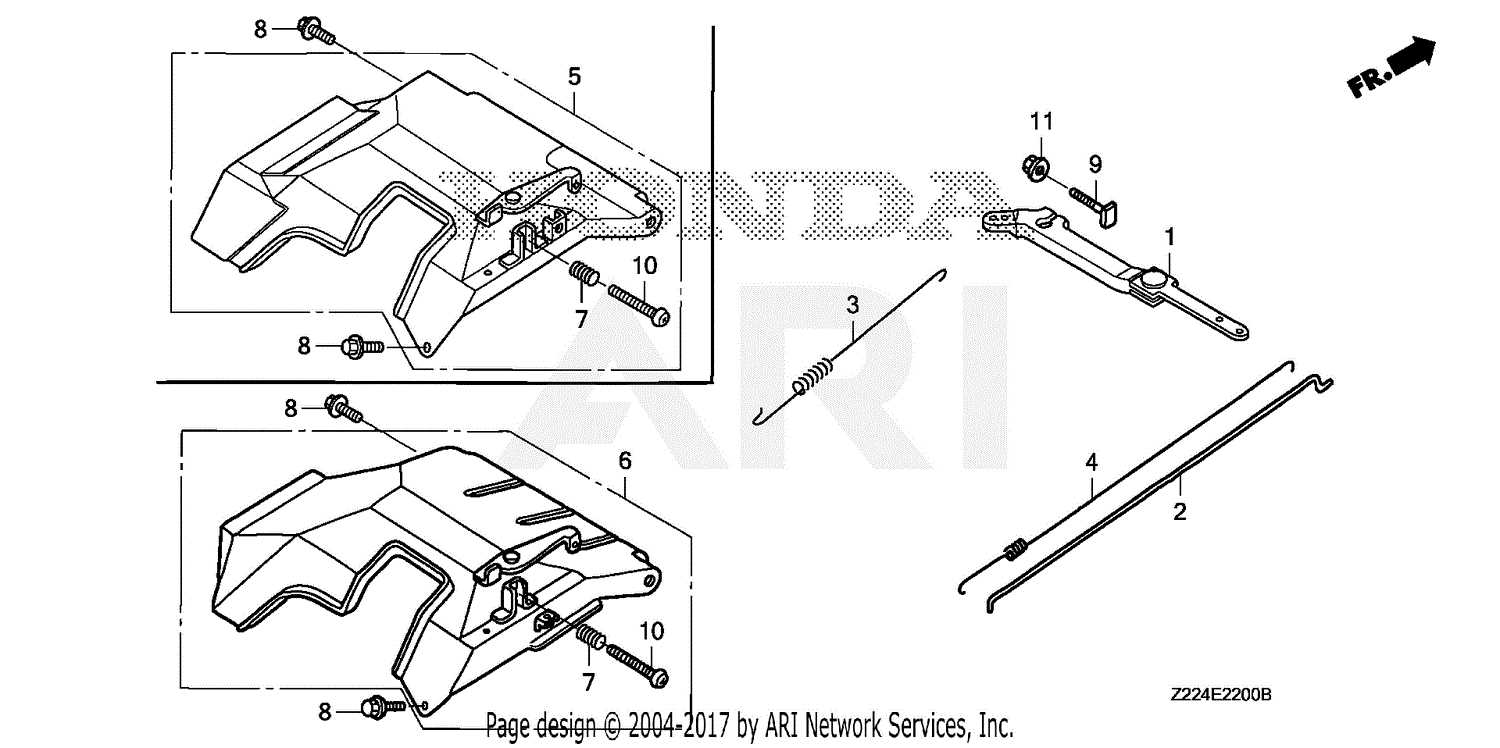

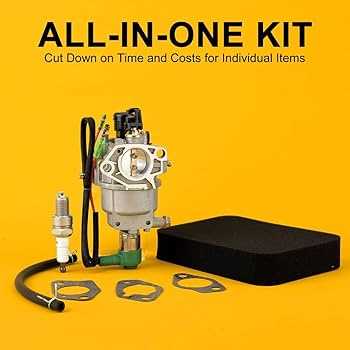

Key Components of the Generator

The functioning of a power generator relies on several essential elements that work in harmony to produce electricity. Each component plays a vital role, contributing to the overall efficiency and reliability of the machine.

The engine serves as the heart of the generator, providing the necessary power to drive the alternator. The alternator is responsible for converting mechanical energy into electrical energy, making it a crucial part of the system. Additionally, a robust fuel system ensures a steady supply of energy, while the control panel allows users to monitor performance and manage settings effectively.

Other significant parts include the cooling system, which prevents overheating during operation, and the frame that provides structural integrity. Understanding these key components helps in maintaining the generator and ensuring it operates smoothly.

Identifying Replacement Parts

Understanding the components of your equipment is essential for maintaining its functionality and longevity. Knowing how to recognize the various elements can greatly simplify the process of sourcing new or replacement items when needed.

Common Components to Look For

- Engine elements

- Fuel system components

- Electrical parts

- Cooling mechanisms

- Support structures

Tips for Identifying Elements

- Consult the user manual for a detailed overview of each component.

- Take note of any part numbers or identifying marks on the items.

- Utilize online resources and forums for advice and recommendations from other users.

- Contact local retailers or service centers for assistance in identifying specific elements.

Understanding Engine Specifications

When it comes to engines, comprehending their specifications is crucial for optimal performance and efficiency. These details provide insight into how an engine operates, its capabilities, and what makes it unique. By delving into these characteristics, users can make informed decisions about maintenance, upgrades, and repairs.

Key elements to consider include engine displacement, power output, and torque ratings. Engine displacement refers to the total volume of all the cylinders combined, influencing the power potential. Meanwhile, power output indicates the engine’s ability to produce energy, while torque ratings reflect its efficiency in performing work, particularly at lower RPMs.

Furthermore, understanding fuel type requirements and cooling systems enhances overall engine management. Each specification plays a vital role in ensuring that the engine operates smoothly and effectively, leading to improved longevity and reliability.

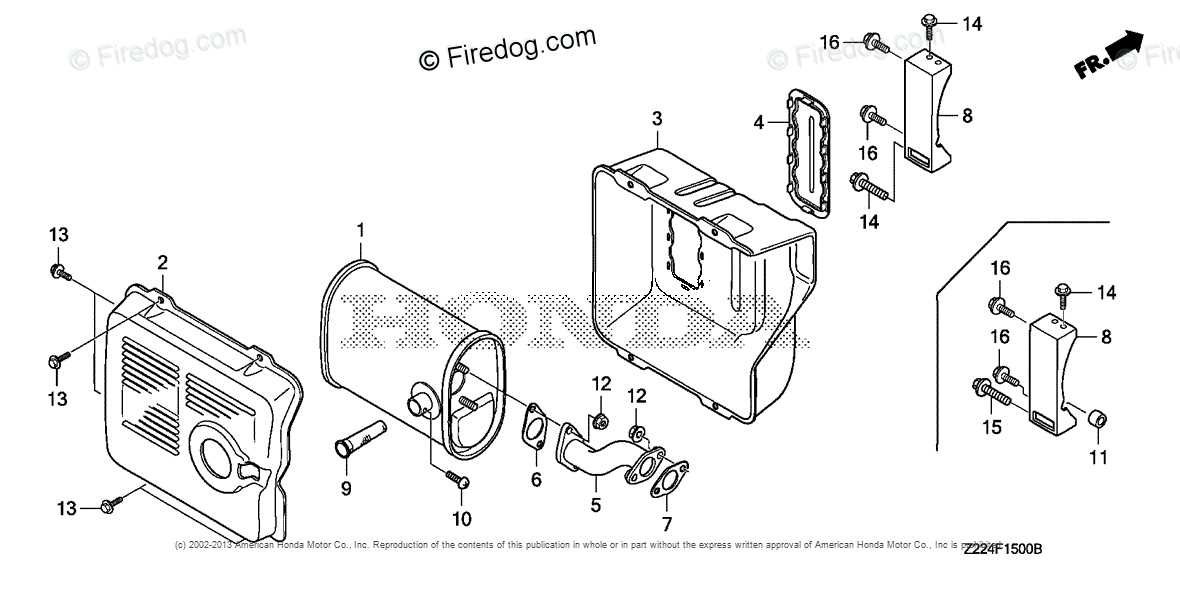

Assembly Instructions for Components

Properly assembling components is crucial for ensuring the efficient operation of your device. Following a systematic approach can help you achieve optimal performance and longevity. This section provides detailed guidance on how to put together various parts effectively.

Step 1: Gather Necessary Tools

Before starting the assembly, ensure you have all the required tools at hand. This may include screwdrivers, wrenches, and other essential equipment. Having everything ready will streamline the process and prevent interruptions.

Step 2: Organize Components

Arrange all components in a logical order. This not only simplifies the assembly process but also helps you verify that you have all necessary items. Check for any damage or defects before proceeding.

Step 3: Follow the Sequence

Adhere to the specified sequence for assembling the parts. This is critical, as certain components may need to be installed before others to ensure proper alignment and functionality. Refer to the accompanying documentation for guidance.

Step 4: Secure Connections

Ensure that all connections are tight and secure. Loose connections can lead to inefficiencies and potential damage. Use the appropriate fastening methods, whether screws, bolts, or clips, to achieve a sturdy assembly.

Step 5: Final Inspection

Once all components are assembled, conduct a thorough inspection. Look for any misalignments or loose parts. Ensuring everything is in its correct place is essential for safe and effective operation.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires consistent care and attention. By following a few fundamental maintenance practices, you can keep your machine operating smoothly and efficiently over time.

Regularly check and replace filters to prevent dust and debris from causing damage. Keeping the air intake clean is vital for optimal performance. Additionally, monitor fluid levels, including oil and fuel, to ensure your equipment runs without strain.

Routine inspections of components can help identify potential issues before they escalate. Tightening loose screws and bolts can prevent operational disruptions, while checking for signs of wear can save you from costly repairs down the line.

Finally, store your equipment in a dry, sheltered area when not in use. This protects it from harsh weather conditions and extends its overall life. By adopting these simple yet effective practices, you can significantly enhance the durability and reliability of your machine.

Troubleshooting Common Issues

When operating machinery, it’s common to encounter various challenges that can hinder performance. Identifying and resolving these issues promptly can significantly enhance efficiency and prolong the lifespan of the equipment. This section offers guidance on recognizing typical problems and implementing effective solutions.

Identifying Performance Problems

Performance issues often manifest through unusual noises, reduced power output, or inconsistent operation. These symptoms may indicate mechanical wear or misalignment. Conducting regular inspections can help detect early signs of malfunction, enabling timely interventions. Check all connections and ensure that components are securely fastened to prevent further complications.

Electrical Failures and Solutions

Electrical failures can disrupt functionality, leading to complete shutdowns. Common causes include faulty wiring, blown fuses, or drained batteries. To address these issues, inspect wiring for any signs of damage or corrosion. Replacing blown fuses and ensuring the battery is charged can restore normal operation. Always prioritize safety by disconnecting power before performing any electrical repairs.

Where to Find Genuine Parts

Locating authentic components for your machinery can significantly enhance its performance and longevity. It is essential to ensure that the replacement elements meet the manufacturer’s standards for quality and reliability.

One of the most effective approaches is to visit authorized dealers or service centers. These establishments often stock original equipment and can provide expert advice on installation and maintenance. Additionally, online platforms dedicated to equipment sales frequently offer a wide selection of genuine components, ensuring that you have access to the latest versions.

Another valuable resource is manufacturer websites, where you can often find lists of certified suppliers. These suppliers are trusted to sell only high-quality products, giving you peace of mind when making a purchase. Engaging with forums or community groups focused on machinery can also lead to recommendations for reputable sources.

Comparison with Other Models

When evaluating different generators, it’s essential to consider various models to determine which one best suits your needs. Each generator comes with its unique specifications and features, making the comparison process critical for informed decision-making.

Here are some key aspects to consider when comparing this generator with others:

- Power Output: Examine the wattage capacity of each model to ensure it meets your power requirements.

- Fuel Efficiency: Consider how much fuel each generator consumes relative to the power it produces.

- Noise Level: Assess the sound output, as quieter models may be more suitable for residential areas.

- Portability: Look at the weight and design for ease of transport, especially if you need to move the generator frequently.

- Durability: Investigate the build quality and materials used to ensure longevity and reliability.

By analyzing these features, potential users can make a more informed choice that aligns with their specific requirements and preferences.

Customer Reviews and Experiences

This section highlights the feedback and insights shared by users regarding their experiences with the generator. Their thoughts can provide valuable information for potential buyers, helping them make informed decisions.

Positive Feedback

Many users have praised the reliability and performance of the unit. Key aspects mentioned in their reviews include:

- Durability in various weather conditions

- Ease of use and setup

- Fuel efficiency and runtime

- Quiet operation during use

Constructive Criticism

While there are numerous positive remarks, some users have noted areas for improvement:

- Weight and portability challenges

- Limited power output for larger appliances

- Availability of replacement components

Understanding both the strengths and weaknesses shared by users can help potential customers gauge whether this generator meets their needs.