Keeping your yard in top condition requires the right equipment. Knowing how various pieces of your landscaping tool function ensures longevity and optimal performance. When it comes to maintaining large green spaces, understanding the individual elements of your device can make all the difference. From routine maintenance to unexpected repairs, having a clear understanding of each component is essential for smooth operation.

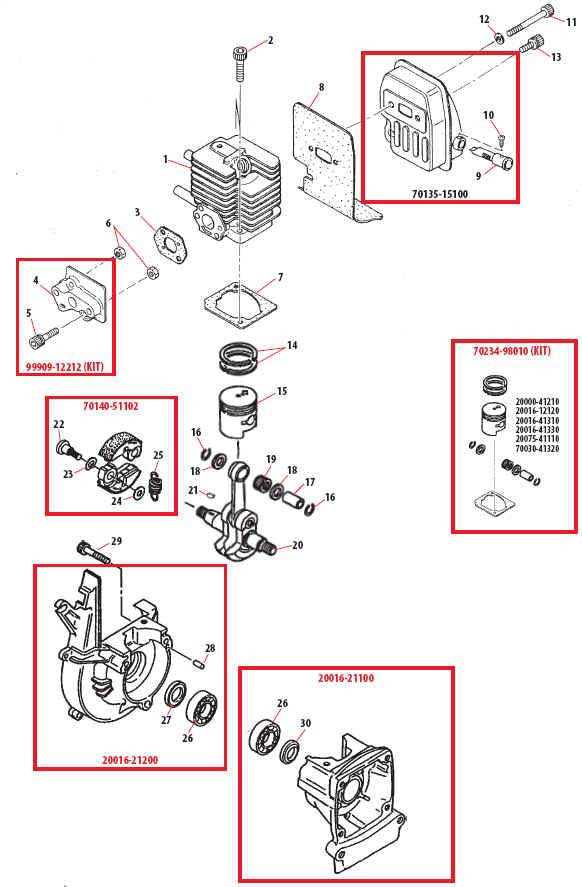

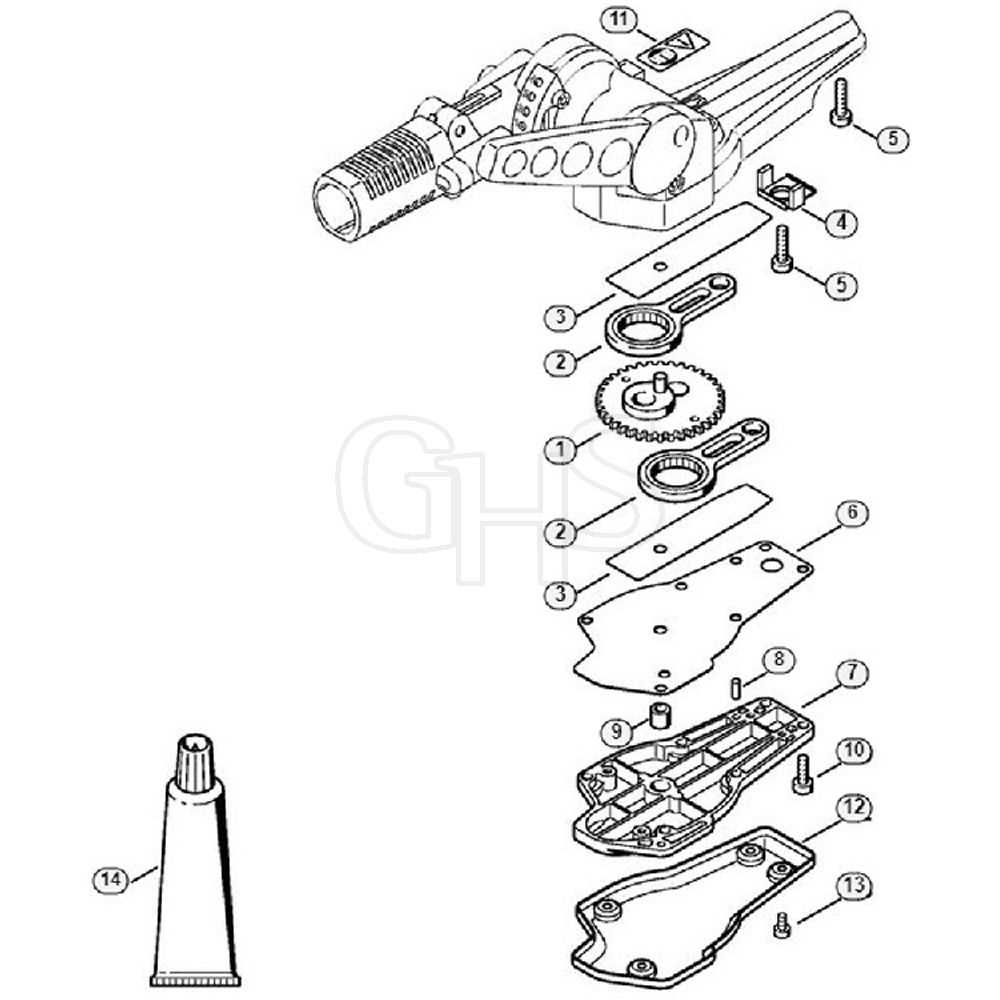

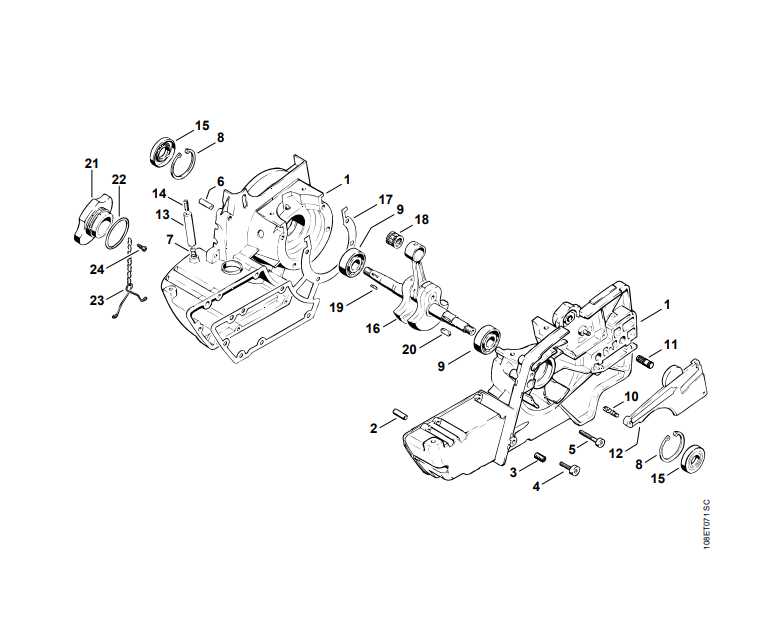

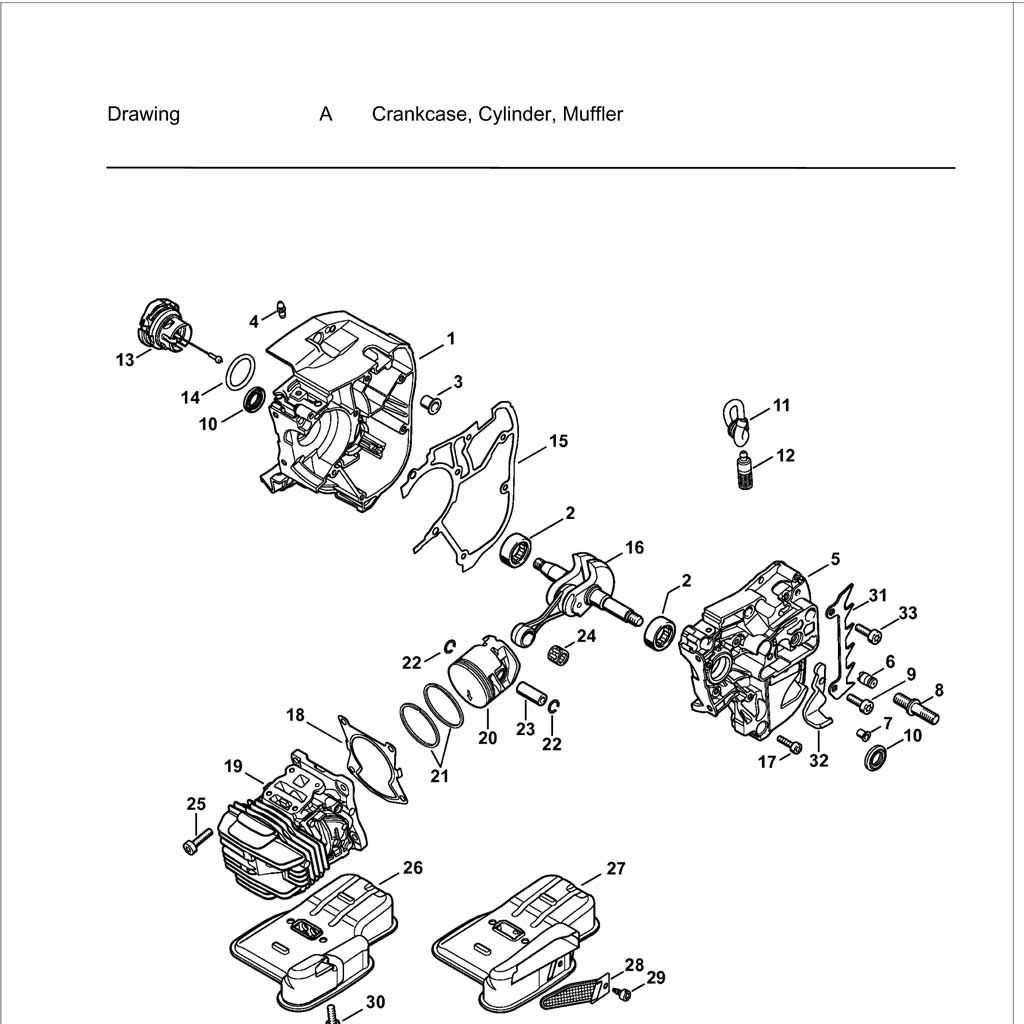

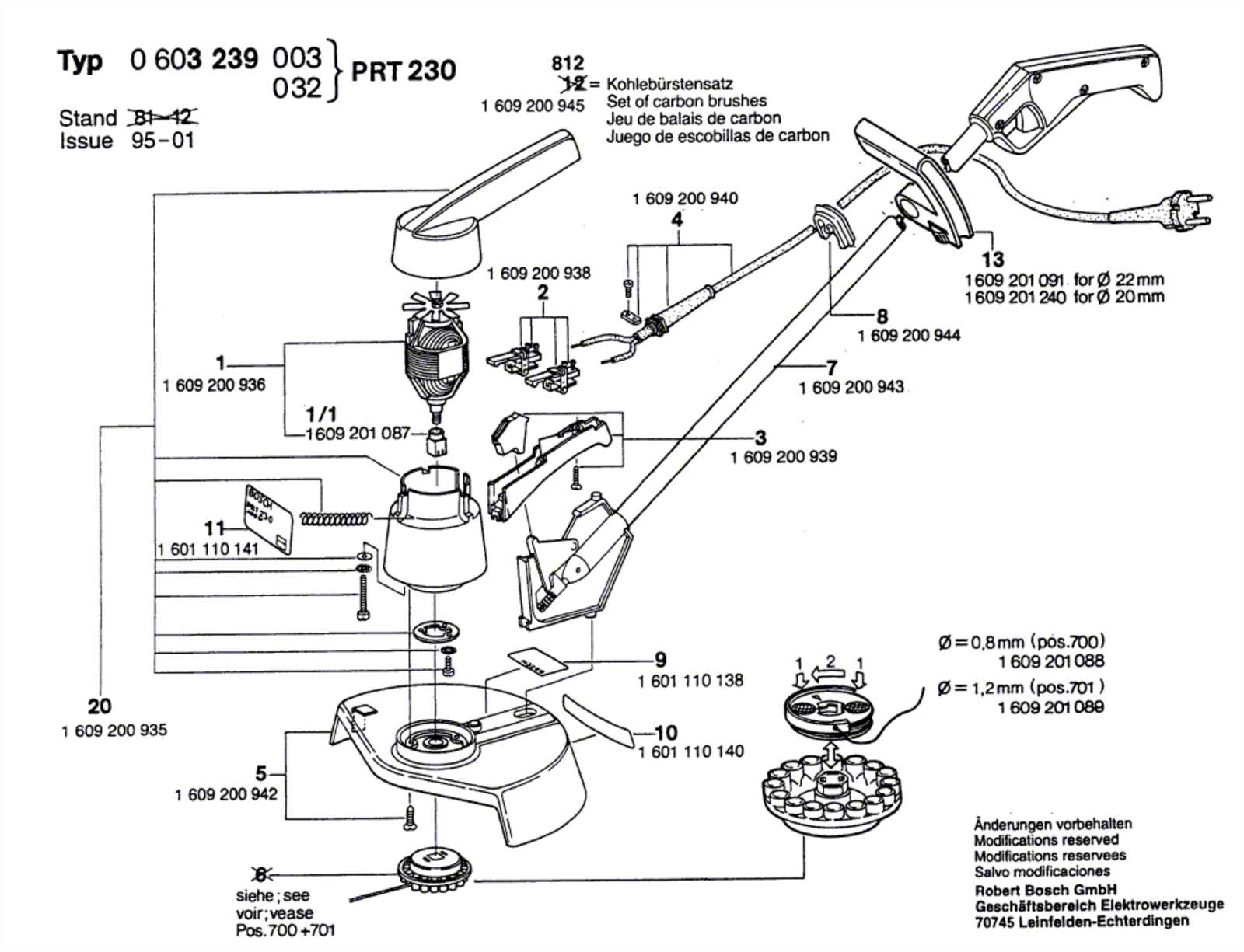

Detailed illustrations of tool assemblies provide an invaluable resource for owners looking to troubleshoot or replace worn elements. These visual aids break down the complex system into manageable sections,

Understanding the Components of a Stihl Weed Eater

The efficient operation of any outdoor trimming tool relies on its various interconnected parts working seamlessly. Each element plays a crucial role in ensuring the device delivers precise and powerful performance. By gaining an understanding of these key components, users can maintain and troubleshoot their equipment effectively, ensuring longer service life and optimal functionality.

Engine and Drive Mechanism

The heart of the machine

Exploring the Function of the Engine

The core component of any small machinery is its engine, which provides the necessary power for the device to operate. Understanding how this mechanism works is key to maintaining and optimizing the performance of the equipment. Below, we will break down the main functions of the engine and how its parts interact to generate the needed output.

| Component | Function | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cylinder | Houses the combustion process, where fuel and air mix to create energy through controlled explosions. |

| Type of Shaft |

|---|

| Function | Consequences of Neglect |

|---|---|

| Prevents debris entry | Increased engine wear |

| Enhances airflow | Reduced power output |

| Improves fuel efficiency | Higher fuel consumption |

| Supports engine longevity | Frequent repairs and replacements |

In conclusion, the importance of the air filtration system cannot be overstated. By prioritizing its upkeep, users can ensure their equipment operates at peak performance while minimizing long-term costs associated with repairs and replacements.

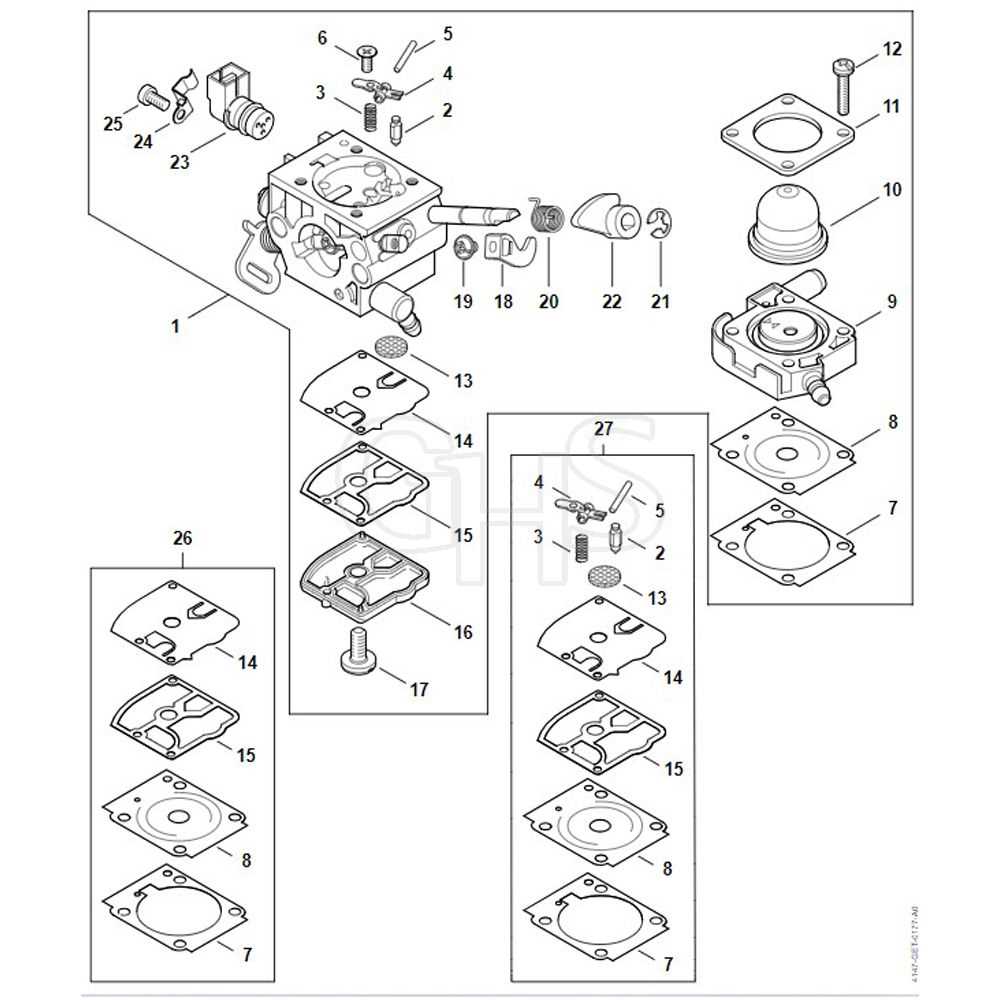

What You Need to Know About the Carburetor

The carburetor is a vital component of many engine systems, playing a crucial role in the mixture of air and fuel that powers the machinery. Understanding its function and maintenance is essential for ensuring optimal performance and longevity of your equipment.

Functionality: The primary job of the carburetor is to regulate the ratio of air to fuel that enters the engine. By adjusting this mixture, it ensures that the engine runs smoothly and efficiently. A well-tuned carburetor contributes to better fuel economy and reduced emissions, making it an important aspect of engine care.

Common Issues: Over time, carburetors can become clogged with debris or suffer from wear and tear. Symptoms of a malfunctioning unit may include poor starting, stalling, or uneven acceleration. Regular inspection and cleaning can help prevent these issues, allowing for reliable operation.

Maintenance Tips: To keep the carburetor in good condition, it is advisable to clean it regularly and replace any worn components. Ensure that the air filter is free from dirt and blockages, as a clean filter supports the carburetor’s ability to function properly. Additionally, using high-quality fuel can help reduce the likelihood of deposits forming within the system.

Conclusion: Understanding the role of the carburetor and performing routine maintenance can greatly enhance the performance of your engine. Taking proactive steps to care for this component will lead to more efficient operation and a longer lifespan for your equipment.

Different Types of Stihl Weed Eater Blades

When it comes to maintaining your outdoor space, the choice of cutting implements can significantly impact efficiency and performance. Various options exist, each designed for specific tasks and vegetation types. Understanding the differences between these implements can help users select the right tool for their needs, enhancing the overall mowing or trimming experience.

Metal Blades

Metal cutting tools are ideal for tackling tougher vegetation, such as thick grass, brush, and small saplings. These durable implements provide a clean cut and can withstand wear over time. They come in different shapes and sizes, including circular and multi-tooth designs, allowing users to adapt to various landscaping challenges.

Plastic Blades

Plastic cutting tools are lightweight and flexible, making them suitable for lighter tasks and soft vegetation. They are typically used for trimming grass in delicate areas, ensuring that surrounding plants remain undisturbed. These implements are often easier to handle and less likely to cause damage to hard surfaces.

Troubleshooting the Ignition Coil in Your Garden Tool

The ignition coil plays a crucial role in the proper functioning of your outdoor equipment, ensuring that the engine starts and runs smoothly. When issues arise, it can lead to poor performance or failure to start. This section will guide you through the process of diagnosing and addressing problems related to the ignition coil.

Here are some common symptoms of ignition coil failure:

- Difficulty starting the engine

- Engine misfiring or running unevenly

- Loss of power during operation

- Excessive fuel consumption

To troubleshoot the ignition coil effectively, follow these steps:

- Visual Inspection: Examine the ignition coil for signs of damage, such as cracks or corrosion.

- Check the Connections: Ensure that all electrical connections are secure and free from dirt or moisture.

- Testing the Coil: Use a multimeter to measure the resistance of the ignition coil. Compare the readings to the manufacturer’s specifications.

- Inspect the Spark Plug: A faulty spark plug can mimic ignition coil issues. Replace the spark plug if it shows signs of wear or damage.

- Replace the Coil: If the ignition coil is determined to be faulty after testing, replace it with a new component.

By systematically following these troubleshooting steps, you can effectively diagnose and resolve ignition coil issues in your equipment, ensuring reliable performance for all your gardening tasks.