Understanding the various elements that contribute to a vehicle’s functionality is essential for enthusiasts and mechanics alike. This section delves into the intricate arrangement of these components, providing insight into their relationships and operations.

Visual aids play a crucial role in grasping complex systems. By examining a representation of these crucial elements, one can appreciate how each part interacts with others, ensuring optimal performance.

Whether you are performing maintenance or seeking to enhance your knowledge, familiarity with these intricacies enhances your appreciation for automotive engineering. This exploration invites readers to engage with the inner workings of their favorite vehicles.

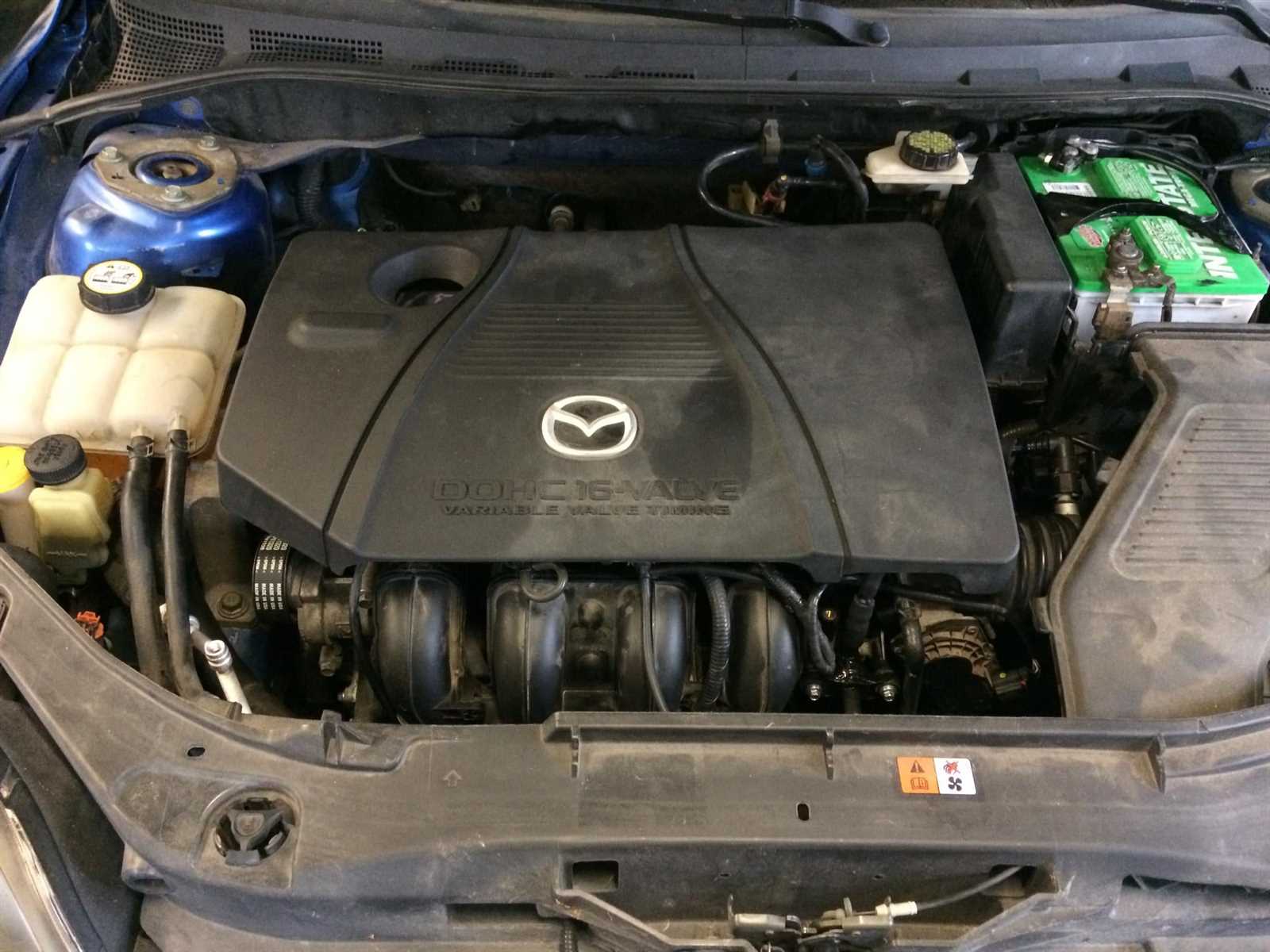

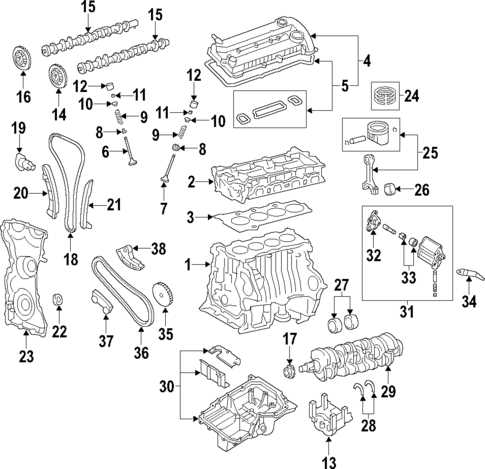

Overview of the Powertrain

This section provides a comprehensive look at the components that make up the performance unit of the vehicle, highlighting their roles and functions. Understanding these elements is essential for appreciating how they work together to ensure smooth operation and reliability.

| Component | Description |

|---|---|

| Block | The main structure that houses various internal components. |

| Cylinder Head | Covers the top of the block, containing intake and exhaust passages. |

| Pistons | Move up and down within the cylinders, creating the power needed to propel the vehicle. |

| Crankshaft | Transforms linear motion from the pistons into rotational motion. |

| Camshaft | Controls the timing of the opening and closing of the intake and exhaust valves. |

Key Components of Mazda 3 Engine

This section explores the essential elements that contribute to the functionality and performance of a vehicle’s powertrain. Understanding these components is crucial for anyone interested in automotive mechanics or maintenance.

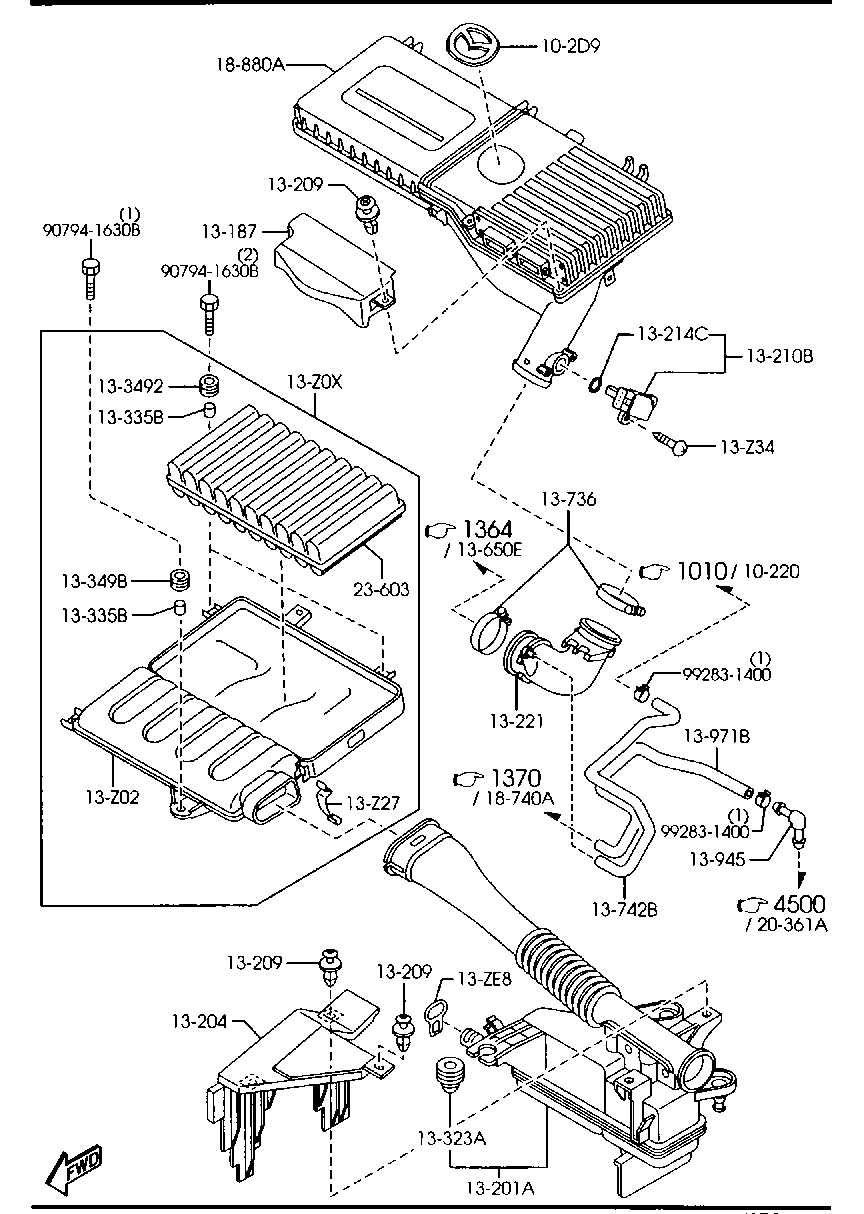

- Fuel Delivery System: This system is responsible for supplying the necessary fuel to the combustion chamber, ensuring optimal performance.

- Ignition System: The ignition components work together to ignite the fuel-air mixture, enabling the engine to produce power.

- Cooling System: This system prevents overheating by regulating the temperature of the internal components, ensuring efficient operation.

- Exhaust System: The exhaust components help in the expulsion of gases produced during combustion, maintaining the performance and efficiency of the vehicle.

- Lubrication System: This system minimizes friction between moving parts, ensuring smooth operation and prolonging the life of the components.

Each of these elements plays a vital role in maintaining the overall efficiency and effectiveness of the vehicle’s performance. Proper understanding and maintenance of these components can significantly enhance longevity and reliability.

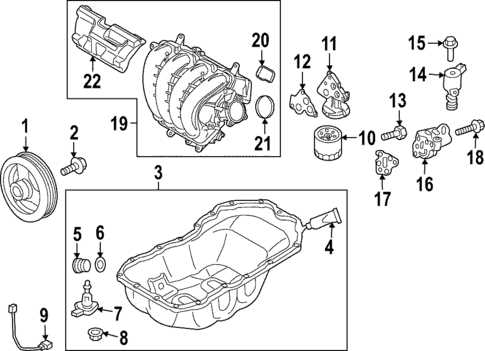

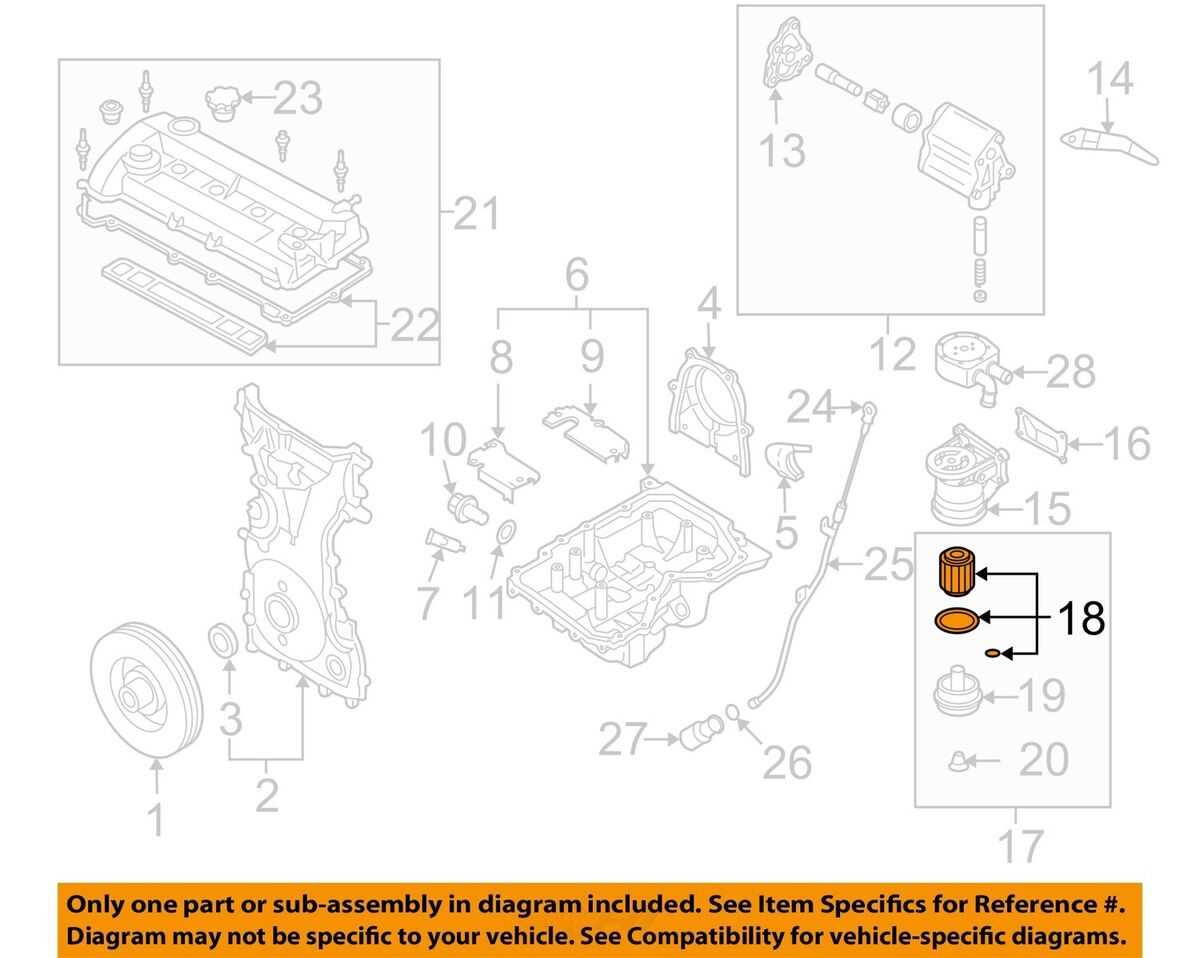

Function of Each Engine Part

The components of a motor play crucial roles in its overall performance and efficiency. Understanding the function of each element helps in diagnosing issues and optimizing operations. Each segment contributes uniquely, ensuring smooth running and reliability of the vehicle.

Core Components

Key elements like the pistons and crankshaft are essential for converting fuel into motion. The pistons move within the cylinders, creating pressure that drives the crankshaft, which then translates linear movement into rotational energy, powering the wheels.

Supporting Systems

Supporting elements, such as the cooling system and lubrication mechanisms, ensure that the motor operates within safe temperature ranges while reducing friction. Effective cooling prevents overheating, while proper lubrication minimizes wear and tear on moving components, enhancing longevity.

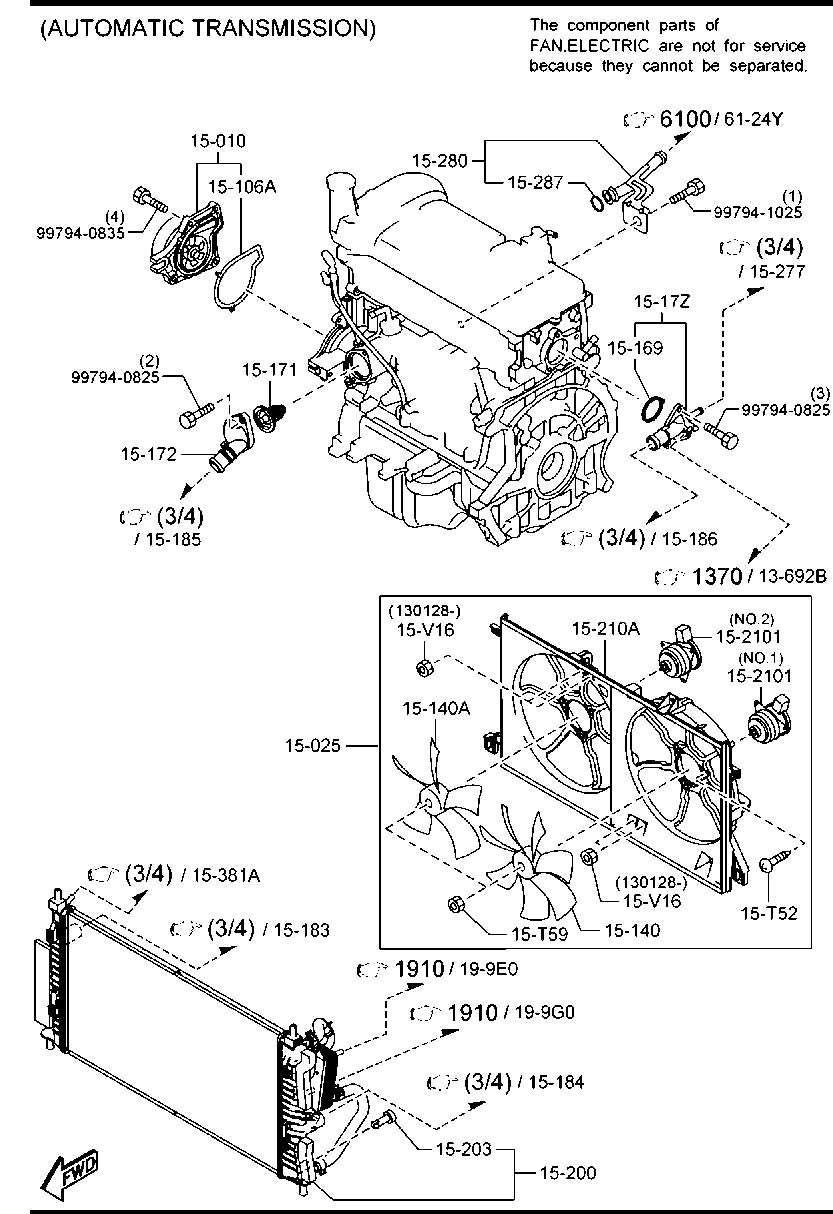

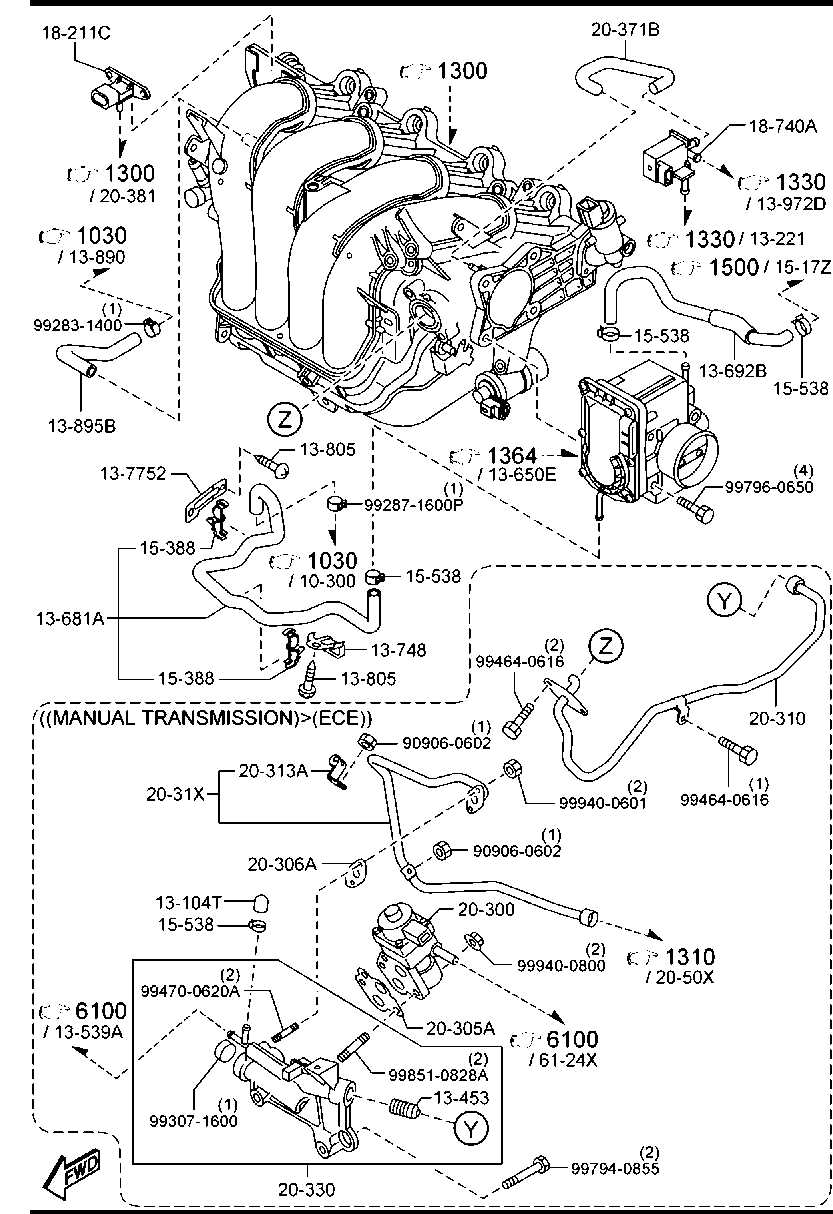

Understanding Engine Diagrams

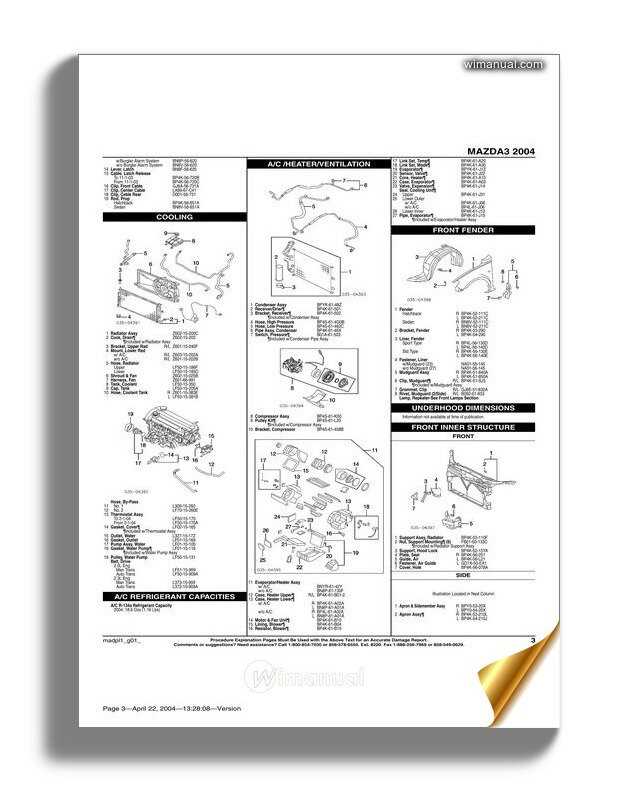

Comprehending the structure of a vehicle’s internal components is crucial for both enthusiasts and professionals. These illustrations serve as visual guides, detailing how various elements interact within the power system. By breaking down complex arrangements into simpler representations, one can easily grasp the functionality and significance of each segment.

These visual aids can enhance diagnostics, maintenance, and repair efforts. Recognizing the layout of each section allows for a better understanding of how to address potential issues. Moreover, familiarization with these representations can foster a deeper appreciation for automotive engineering and design.

Common Issues with Engine Parts

When it comes to automotive components, various challenges can arise, impacting overall performance and reliability. Understanding these common issues helps in maintaining functionality and preventing significant breakdowns.

Wear and Tear

Over time, components can experience natural degradation due to regular use. Friction and exposure to harsh conditions contribute to this wear, leading to decreased efficiency. Regular inspections are crucial to identify these signs early and avoid further complications.

Improper Installation

Another prevalent issue is the result of incorrect assembly during maintenance or repairs. This can cause misalignment or inadequate sealing, leading to leaks and performance problems. Ensuring proper installation techniques and following guidelines is essential for optimal operation.

Maintenance Tips for Engine Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your vehicle’s core components. Regular maintenance not only enhances performance but also extends the lifespan of critical systems, allowing for a smoother and more reliable driving experience.

Regular Fluid Checks

Monitoring and replacing vital fluids is crucial for optimal function. Ensure that all liquids are at appropriate levels, as deficiencies can lead to severe issues.

| Fluid Type | Frequency of Check | Notes |

|---|---|---|

| Oil | Every 3,000 miles | Change if dirty or low |

| Coolant | Every 6 months | Check for leaks and concentration |

| Brake Fluid | Every year | Replace if discolored |

Scheduled Inspections

Conducting routine evaluations of essential systems helps identify potential problems before they escalate. Regularly scheduled inspections by a professional ensure that every aspect is functioning correctly.

Upgrading Mazda 3 Engine Components

Enhancing the performance of your vehicle involves a strategic approach to improving various internal mechanisms. By focusing on critical components, drivers can experience better efficiency, increased power output, and an overall refined driving experience.

One of the primary areas to consider is the intake system. Upgrading to a high-performance air filter or a complete intake kit can significantly improve airflow, allowing the engine to breathe better and enhancing combustion efficiency.

Additionally, exhaust modifications play a crucial role in performance upgrades. Installing a performance exhaust system can reduce back pressure and improve exhaust flow, leading to a noticeable boost in power and a more aggressive sound profile.

Finally, focusing on the suspension and tuning components can elevate the handling characteristics of your vehicle. Aftermarket options can provide better stability, improved responsiveness, and a more engaging driving experience, ensuring that the power generated is effectively transferred to the road.

Aftermarket Parts vs. OEM Options

When considering replacements for vehicle components, two primary categories emerge: aftermarket alternatives and original manufacturer selections. Each option presents unique advantages and challenges that can significantly influence maintenance decisions.

Benefits of Aftermarket Alternatives

Aftermarket selections often provide cost-effective solutions, appealing to budget-conscious consumers. Additionally, these options may offer a wider variety of features and enhancements that can improve vehicle performance or aesthetics. However, it’s crucial to ensure that quality standards are met to avoid potential issues.

Advantages of Original Manufacturer Selections

Choosing original components typically guarantees compatibility and reliability, as these parts are designed specifically for the vehicle’s specifications. Moreover, they often come with warranties that can provide peace of mind. Nevertheless, this option may come at a premium price, which can be a significant consideration for many owners.

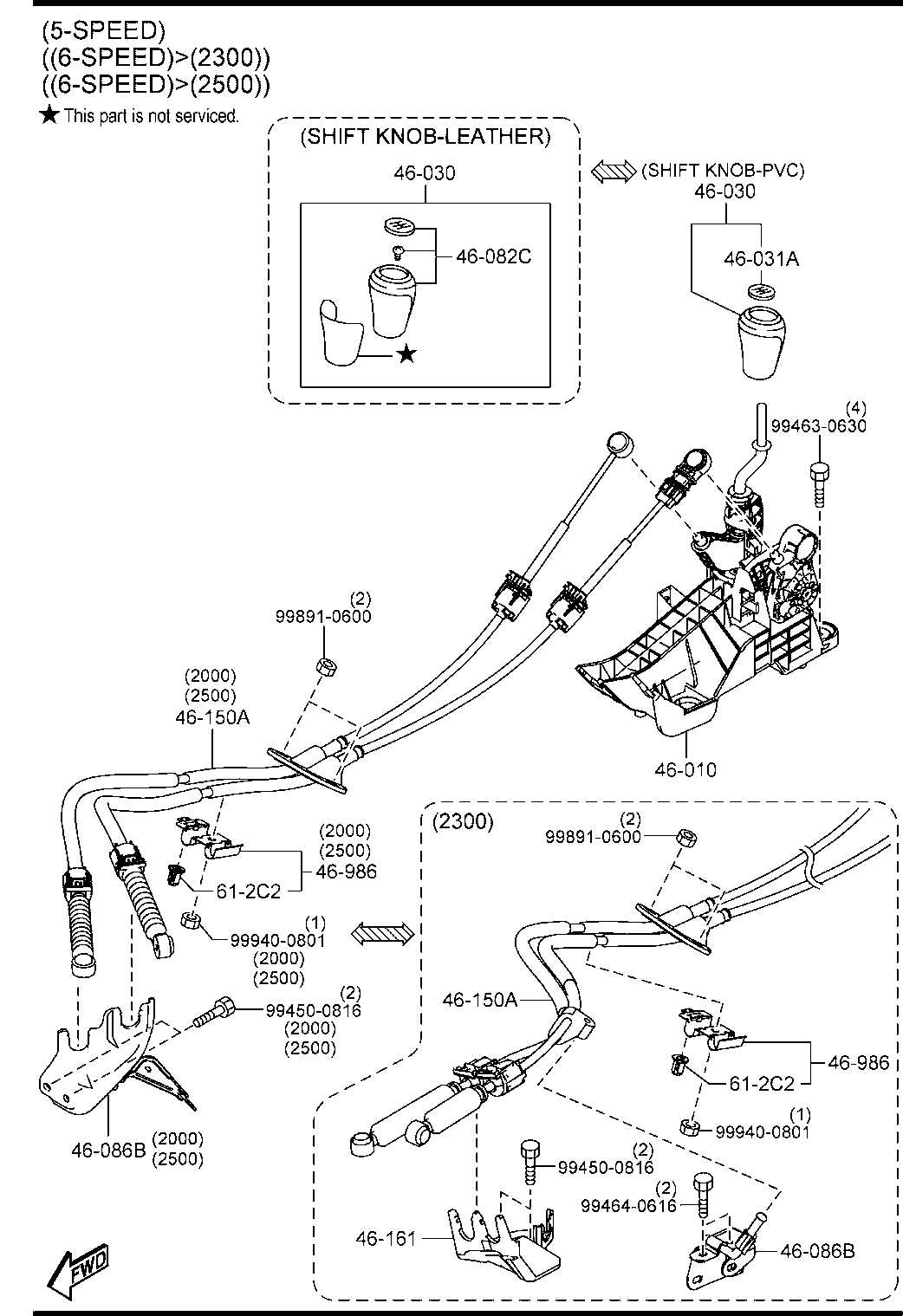

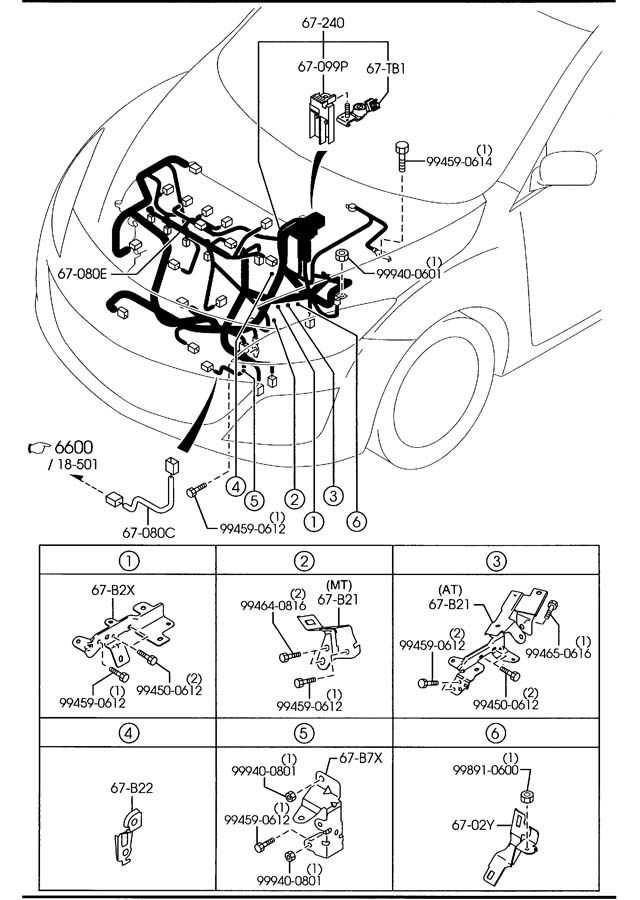

How to Read Engine Diagrams

Understanding technical illustrations related to mechanical systems can greatly enhance your comprehension of their functionality. These visuals serve as a guide to identify various components and their interrelations, providing insights into the overall mechanism.

Familiarize with Symbols

Different representations are used to denote specific elements. Familiarizing yourself with these symbols will enable you to navigate the visual effectively. Each symbol typically corresponds to a particular function or part, facilitating a clearer understanding of the system.

Follow Flow Directions

Most illustrations include directional indicators that show the flow of operations. Recognizing these pathways is crucial for grasping how different components interact within the assembly. This approach allows you to see how energy or motion travels through the system.

Importance of Proper Engine Assembly

Ensuring the correct assembly of mechanical components is vital for optimal performance and longevity of any vehicle. Proper integration of each element contributes to the overall efficiency and reliability of the system.

A meticulous approach to assembling mechanical structures offers numerous advantages:

- Enhanced performance: Each component functions harmoniously, leading to better responsiveness and power delivery.

- Increased durability: A well-assembled system is less prone to wear and tear, extending its lifespan.

- Reduced maintenance costs: Fewer breakdowns and repairs translate into significant savings over time.

- Improved safety: Proper alignment and integration of parts minimize the risk of malfunctions that could compromise safety.

Attention to detail during the assembly process is essential. Following manufacturer specifications and guidelines ensures that each component fits precisely and operates as intended.

In conclusion, the significance of careful assembly cannot be overstated. It is a fundamental aspect that influences the functionality and dependability of mechanical systems.