When it comes to operating heavy-duty equipment, having a comprehensive grasp of its internal structures is essential. Each element contributes to the overall functionality, enabling users to achieve their tasks efficiently. Knowing these components not only enhances performance but also aids in maintenance and repairs.

In this section, we will explore the intricate arrangement of a specific high-performance tool. By examining its various segments, users can gain valuable insights into how to optimize their usage and troubleshoot common issues. A clear visualization of the assembly is crucial for both novices and seasoned professionals alike.

Through a detailed exploration of these mechanisms, we aim to deepen your understanding. Whether you’re looking to enhance your skills or simply seek knowledge, this examination will serve as an ultimate guide to mastering your equipment.

Understanding Milwaukee Hammer Drill Components

This section aims to explore the various elements that comprise a powerful tool designed for drilling and chiseling tasks. By examining each component, users can gain insights into how they function together to achieve optimal performance in diverse applications.

| Component | Description |

|---|---|

| Motor | Drives the tool and provides the necessary power for operation. |

| Chuck | Holds the bit securely, allowing for quick changes between different attachments. |

| Gearbox | Regulates speed and torque, adapting to various drilling requirements. |

| Handle | Offers grip and control, enhancing user comfort during operation. |

| Clutch | Prevents over-tightening by disengaging the motor at a preset torque. |

Essential Parts of Hammer Drills

Understanding the key components of these powerful tools is crucial for effective operation and maintenance. Each element plays a significant role in the overall functionality, ensuring precision and efficiency during usage. Familiarity with these fundamental segments can enhance both performance and longevity.

The motor is the heart, providing the necessary power. The gear system allows for torque adjustment, enabling various tasks to be executed seamlessly. The chuck secures the bit, ensuring stability and accuracy during operation. A robust casing protects internal mechanisms from damage, while the handle design contributes to user comfort and control.

Additionally, the impact mechanism is vital, delivering rapid blows to facilitate drilling into hard surfaces. Lastly, an efficient cooling system prevents overheating, promoting durability. Mastery of these essentials equips users with the knowledge to optimize their tool’s capabilities.

Functionality of Each Component

This section explores the essential roles of various elements within a powerful tool designed for effective drilling. Each component contributes uniquely to the overall performance, ensuring efficiency and precision during operation.

Power Source

The energy provider is crucial, delivering the necessary force for the device to function optimally. It converts electrical energy into mechanical power, enabling robust performance across different materials.

Chucking Mechanism

The clamping system holds the bit securely in place, allowing for seamless bit changes. This component is vital for maintaining stability and control during operation, ensuring that the tool performs its ultimate task without any slippage.

Common Issues with Hammer Drill Parts

Tools designed for intense applications often encounter a variety of challenges that can hinder their performance. Understanding these common problems can aid in effective maintenance and prolong the lifespan of the equipment.

Several factors contribute to malfunctions, ranging from wear and tear to improper usage. Below is a table outlining some frequent issues along with their potential causes and solutions.

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| Insufficient Power | Battery depletion, motor failure | Recharge or replace battery, inspect motor components |

| Excessive Vibration | Worn components, unbalanced attachments | Check for wear, ensure attachments are secured |

| Overheating | Prolonged use, blocked vents | Allow cooling time, clean ventilation areas |

| Chuck Issues | Debris buildup, wear | Clean and lubricate chuck, replace if necessary |

| Difficulty in Operation | Faulty trigger, electrical issues | Inspect trigger mechanism, check wiring |

Regular inspections and maintenance can significantly mitigate these issues, ensuring the tool operates efficiently and reliably for various tasks.

Identifying Replacement Parts Easily

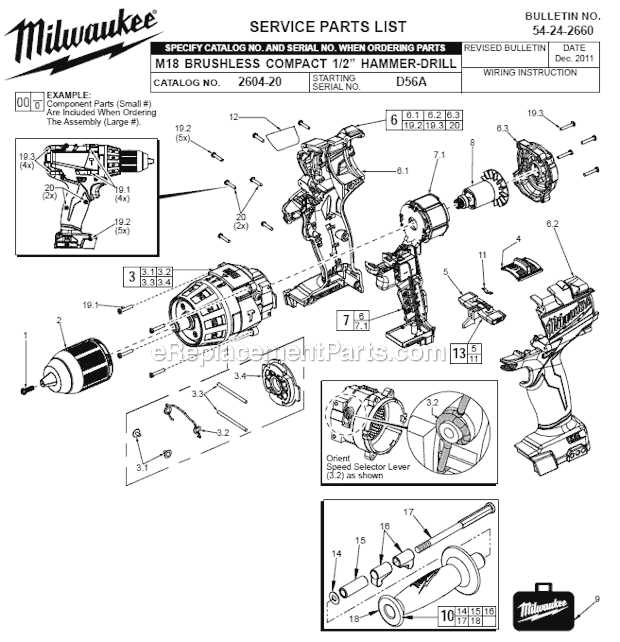

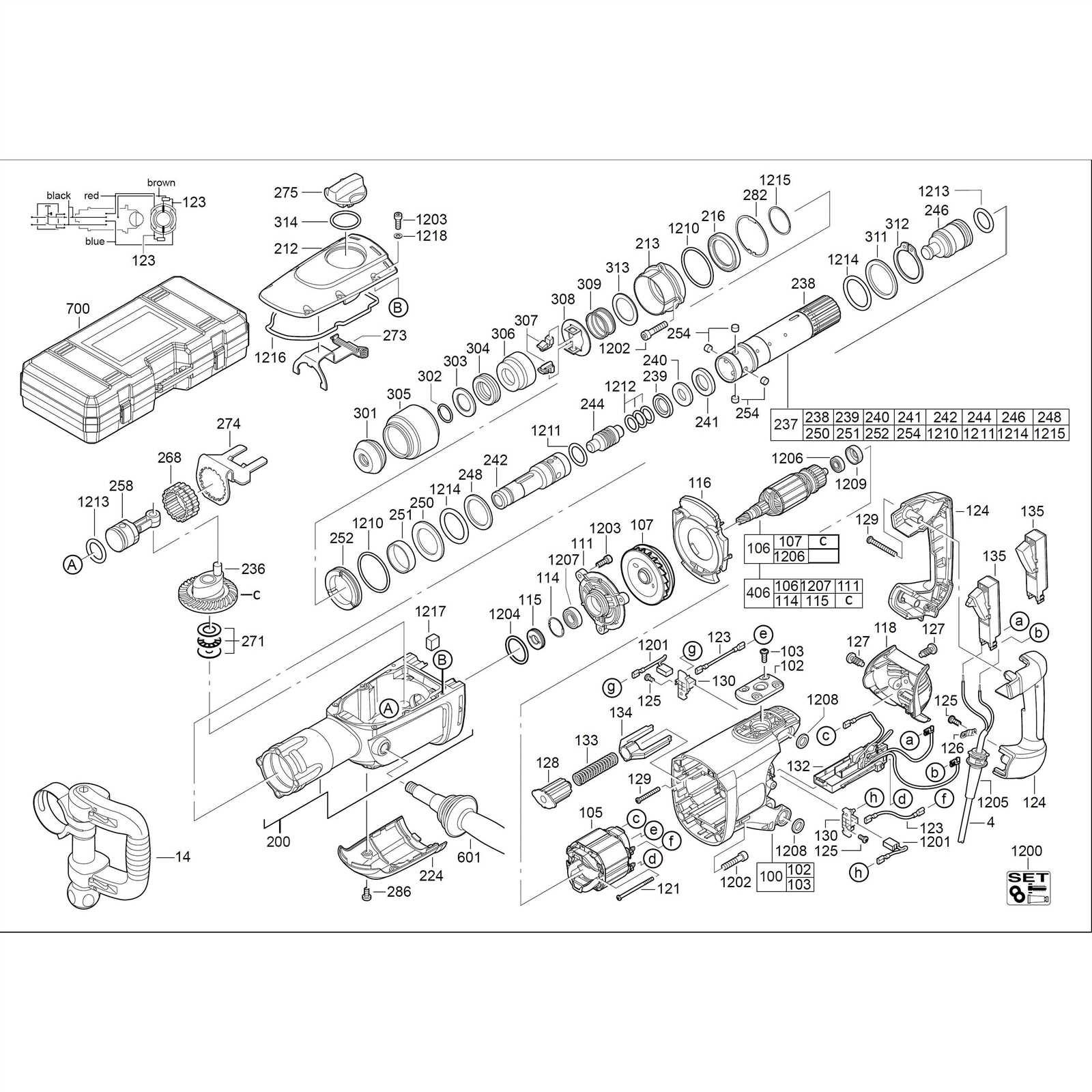

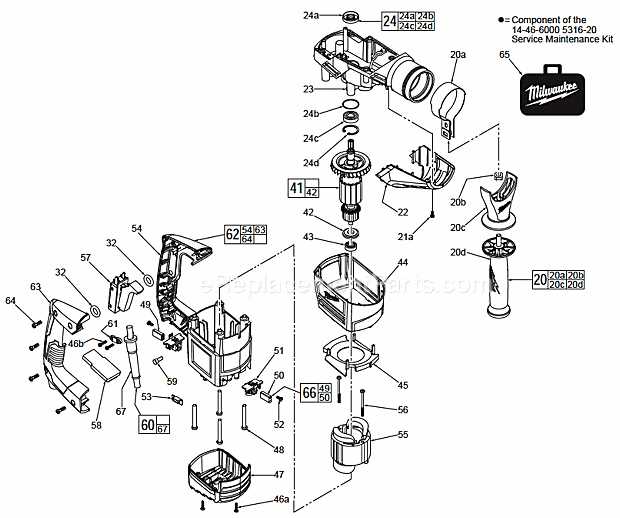

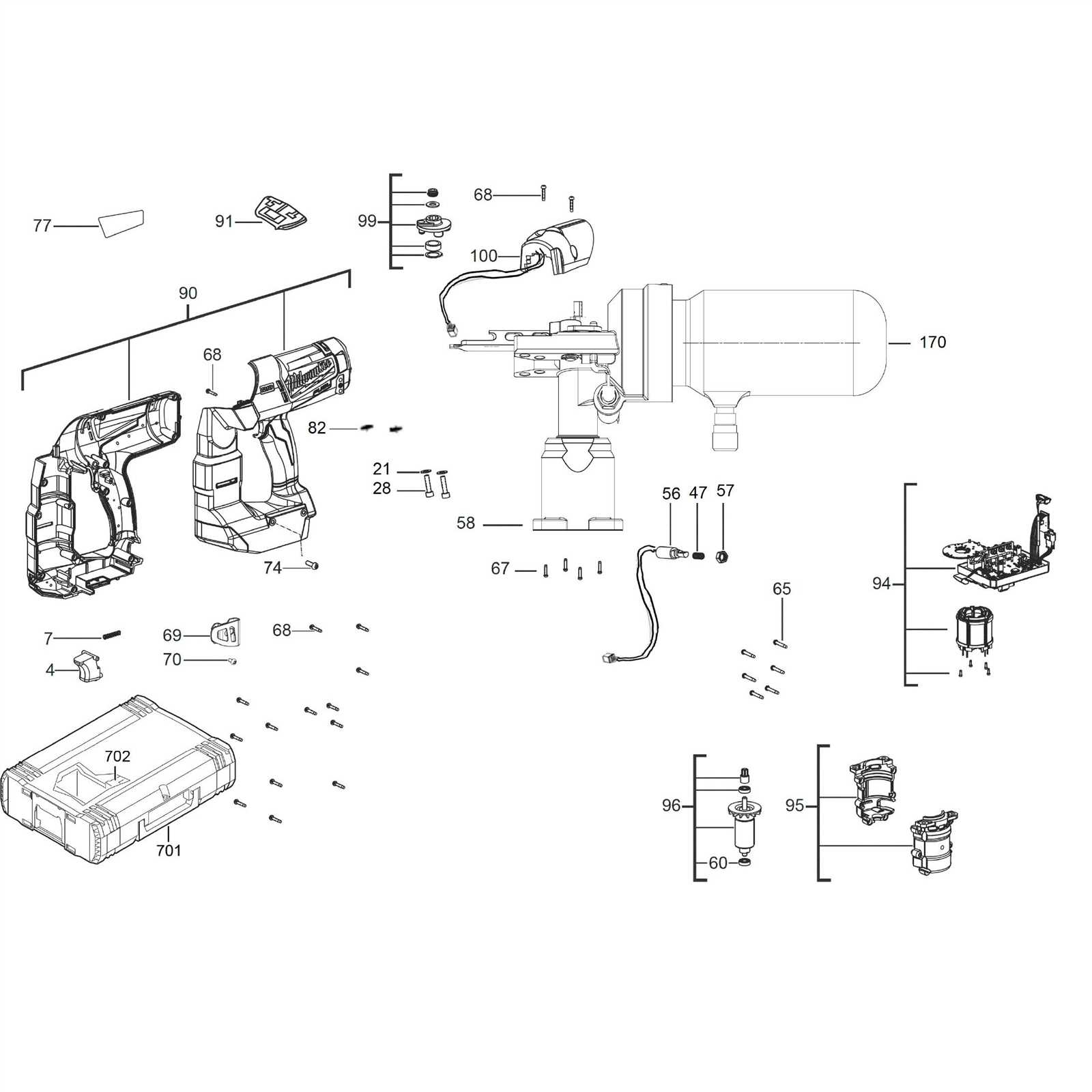

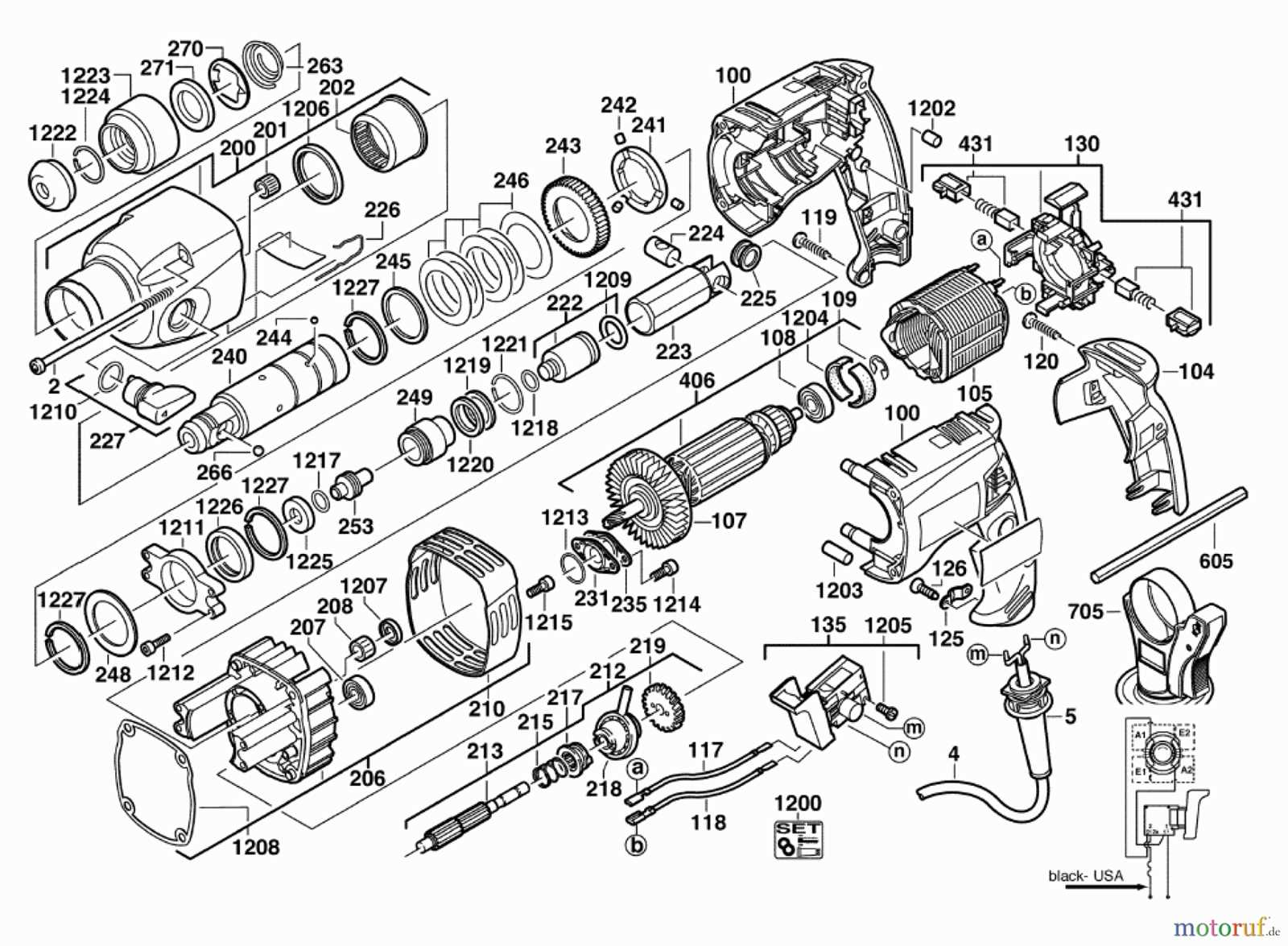

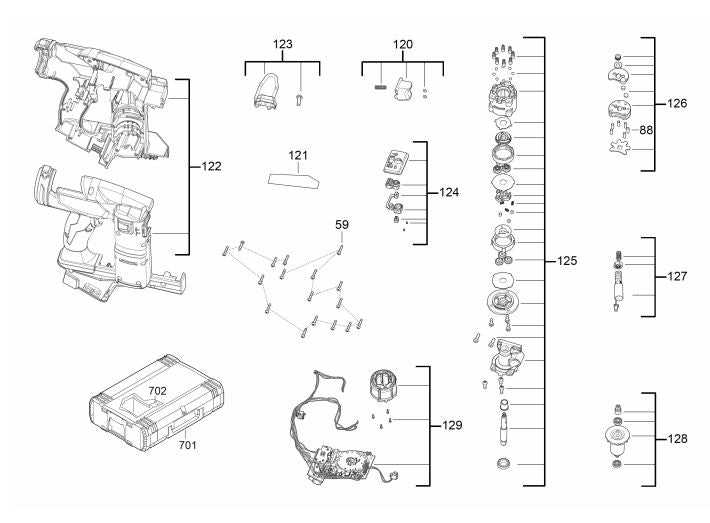

Understanding the components of your power tool is crucial for maintenance and repair. When parts wear out or break, knowing how to identify and source replacements can save time and money. This section provides insights on how to navigate this process effectively.

First, familiarize yourself with the essential components of your equipment. Having a basic knowledge of each part’s function will enable you to pinpoint the exact item that needs replacement. Make use of resources like user manuals and online guides that offer detailed descriptions and images.

Next, consider using part identification tools available on various websites. These tools often allow you to enter the model number of your equipment, displaying a comprehensive list of compatible components. Visual aids, such as exploded views, can also significantly enhance your understanding by showing how different pieces fit together.

Additionally, engaging with online forums or communities dedicated to tool repair can provide valuable insights. Experienced users often share their tips on identifying and acquiring necessary components, helping you avoid common pitfalls. Collaboration and shared knowledge in these platforms can lead to quicker solutions and better understanding.

Finally, keep a record of the parts you replace. Documenting the brand, model, and specifications of each component will streamline future repairs and ensure you have the right information at hand when needed. This proactive approach can enhance your overall experience and efficiency in tool maintenance.

Importance of Proper Maintenance

Ensuring the longevity and efficiency of power tools relies heavily on routine upkeep. Proper care not only enhances performance but also minimizes the risk of unexpected breakdowns. A well-maintained tool can significantly improve productivity and ensure safety during operation.

Benefits of Regular Care

Regular maintenance offers numerous advantages, including:

| Benefit | Description |

|---|---|

| Increased Lifespan | Consistent maintenance can extend the operational life of tools, reducing the need for replacements. |

| Enhanced Performance | Routine checks and adjustments ensure that tools function at their peak efficiency. |

| Safety Improvements | Maintaining equipment reduces the likelihood of accidents caused by faulty machinery. |

| Cost Savings | Investing in regular upkeep can prevent costly repairs and downtime. |

Key Maintenance Practices

To ensure optimal functioning, consider the following essential practices:

- Regularly inspect components for wear and tear.

- Clean tools after each use to prevent buildup of debris.

- Lubricate moving parts to reduce friction.

- Store tools in a dry, safe place to prevent damage.

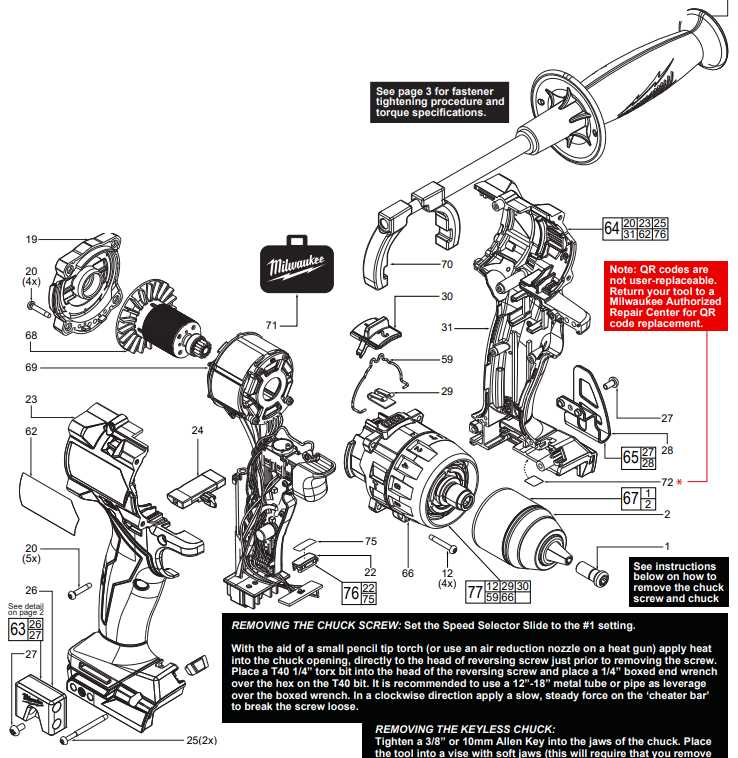

Tools Needed for Disassembly

When embarking on the journey of taking apart your tool, having the right instruments is essential for a smooth process. The selection of proper equipment not only ensures safety but also aids in efficient and effective disassembly.

Here are some key items you will need:

- Screwdrivers: A variety of sizes, including both flathead and Phillips, to handle different types of fasteners.

- Wrenches: Adjustable and socket wrenches will help with bolts and nuts.

- Pliers: Needle-nose and slip-joint pliers can be invaluable for gripping and twisting.

- Safety Gear: Gloves and goggles to protect yourself from potential hazards during the process.

- Container: A small bin or tray to organize screws and small components as you remove them.

Gathering these tools will empower you to delve into the disassembly confidently and with ease.

Visual Guide to Hammer Drill Parts

This section provides an overview of the essential components that comprise a powerful tool, enabling users to enhance their understanding and maintenance of their equipment. Familiarity with these elements can lead to more efficient use and troubleshooting.

Key Components Overview

At the heart of the device are several crucial elements, including the motor, which drives the mechanism, and the gearbox that regulates speed and torque. Understanding how these interact is vital for optimal performance.

Additional Features and Accessories

Various attachments and enhancements can elevate functionality, such as specific chucks and bits tailored for diverse tasks. Recognizing these accessories allows users to expand the ultimate potential of their tools.

Comparing Milwaukee with Other Brands

When it comes to power tools, the landscape is filled with a variety of manufacturers, each offering unique features and technologies. Understanding the differences among these brands can help consumers make informed decisions when selecting tools for their projects.

Durability is often a key factor in assessing quality. Many brands boast rugged designs and materials, yet not all achieve the same longevity under heavy use. Some companies may prioritize weight reduction, which can sometimes compromise the tool’s resilience.

Performance also varies widely. While one manufacturer may excel in delivering higher torque, another might focus on speed. Users should consider their specific needs; for instance, professionals might prioritize efficiency over versatility, while hobbyists may seek a balance of both.

Ergonomics plays a crucial role in user experience. Certain brands invest heavily in creating comfortable grips and lightweight designs, making prolonged use less taxing. This attention to detail can significantly enhance productivity and reduce fatigue.

Finally, innovation remains a vital aspect of comparison. Some brands continuously introduce cutting-edge technology, such as advanced battery systems and smart features, while others may stick to tried-and-true designs. Evaluating how these innovations align with personal or professional needs can lead to better tool choices.

Upgrading Your Hammer Drill Components

Enhancing the efficiency and performance of your power tool can significantly impact your projects. By focusing on improving specific elements, you can achieve better results and extend the lifespan of your equipment. This section explores various upgrades that can transform your tool into a more reliable and effective companion in your tasks.

One of the first areas to consider is the motor. Opting for a higher torque motor can provide increased power and speed, enabling you to tackle tougher materials with ease. Additionally, switching to a more advanced battery system can offer longer runtime and faster charging, allowing for uninterrupted work sessions.

Another crucial component to evaluate is the chuck. Upgrading to a more durable or quick-release design can enhance bit retention and reduce downtime during bit changes. Furthermore, incorporating advanced vibration reduction features can lead to a more comfortable experience, minimizing fatigue during prolonged use.

Lastly, consider the accessory options available. Investing in high-quality drill bits and specialized attachments can expand your tool’s versatility and improve its capability to handle various tasks. By strategically upgrading these elements, you will not only enhance your tool’s performance but also elevate the overall quality of your work.

Safety Tips for Handling Drills

When working with power tools, ensuring safety should always be a top priority. Proper precautions not only protect the user but also enhance the efficiency of the task at hand. Understanding how to handle these tools safely can prevent accidents and injuries, making your work environment more secure.

Always wear appropriate personal protective equipment, including safety glasses and gloves, to shield yourself from debris and potential hazards. Additionally, ensure your workspace is well-lit and free of clutter to reduce the risk of tripping or distractions.

Before starting, inspect the equipment for any signs of wear or damage. Make sure that all components are securely fastened and functioning properly. If something appears faulty, refrain from using the tool until it has been repaired or replaced.

Maintain a firm grip on the tool, keeping both hands on it whenever possible. This not only improves control but also minimizes the risk of losing grip during operation. Always position yourself in a stable stance to prevent slips or falls.

Be aware of your surroundings, ensuring that others are at a safe distance while you work. Communicate clearly if someone is nearby, and use caution when working in tight spaces or on ladders.

Finally, always follow the manufacturer’s instructions for safe usage and maintenance. Staying informed and vigilant can lead to a safer and more productive experience.

Where to Buy Replacement Parts

Finding suitable components for your tool is essential for maintaining its efficiency and longevity. Various options are available to source these items, ensuring you can keep your equipment in top condition.

Online Retailers

- Check large e-commerce platforms for a wide selection.

- Specialized websites often offer competitive prices and detailed descriptions.

- Manufacturer’s official site may have specific items and warranty information.

Local Stores

- Home improvement centers usually stock popular replacements.

- Tool supply shops can provide expert advice and assistance.

- Pawn shops or second-hand stores may have unique finds.

DIY Repairs for Hammer Drills

Maintaining your power tools can enhance their longevity and performance. Understanding common issues and how to resolve them empowers users to tackle repairs with confidence. This guide provides insights into essential components and offers practical tips for effective restoration.

Identifying Problems: Begin by observing any unusual sounds or performance drops. These signs often indicate specific areas needing attention. Regular inspection can prevent minor issues from escalating into major failures.

Basic Maintenance: Cleaning is crucial; accumulated dust and debris can hinder functionality. Regularly check and replace worn-out components to ensure optimal operation. Keeping your equipment lubricated can also reduce wear and extend its life.

Repair Techniques: For simple fixes, consult user manuals to identify compatible replacement items. Utilizing the correct tools will make the process smoother. When disassembling, take care to document the arrangement of components for easier reassembly.

Safety First: Always prioritize safety by disconnecting power sources before starting any repairs. Wearing appropriate protective gear can prevent injuries during maintenance tasks.