The efficiency and longevity of any equipment heavily rely on the proper functioning of its various elements. Identifying and understanding how different mechanisms work together can significantly enhance maintenance efforts and prevent malfunctions. Knowing what makes up these tools is crucial for both professionals and those using them occasionally.

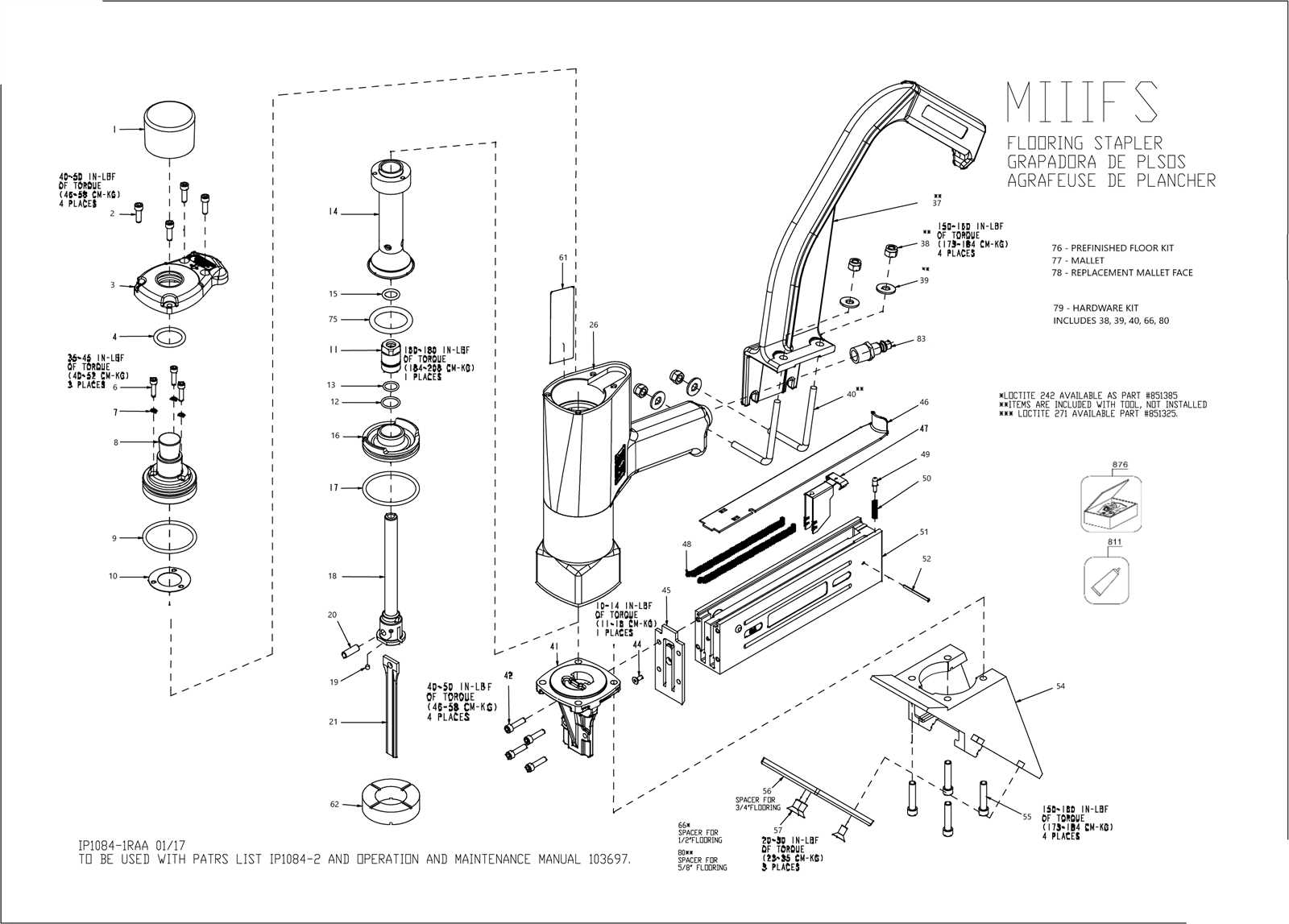

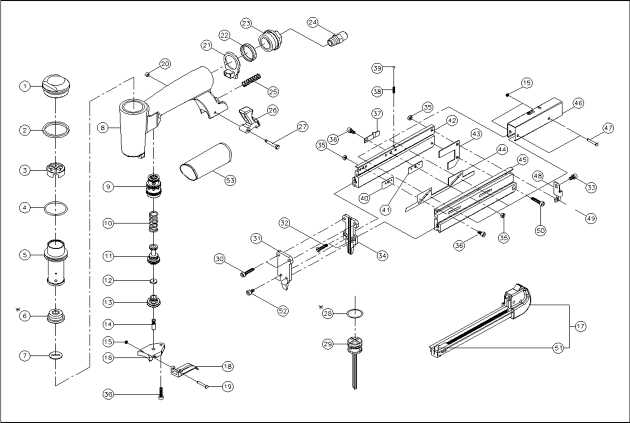

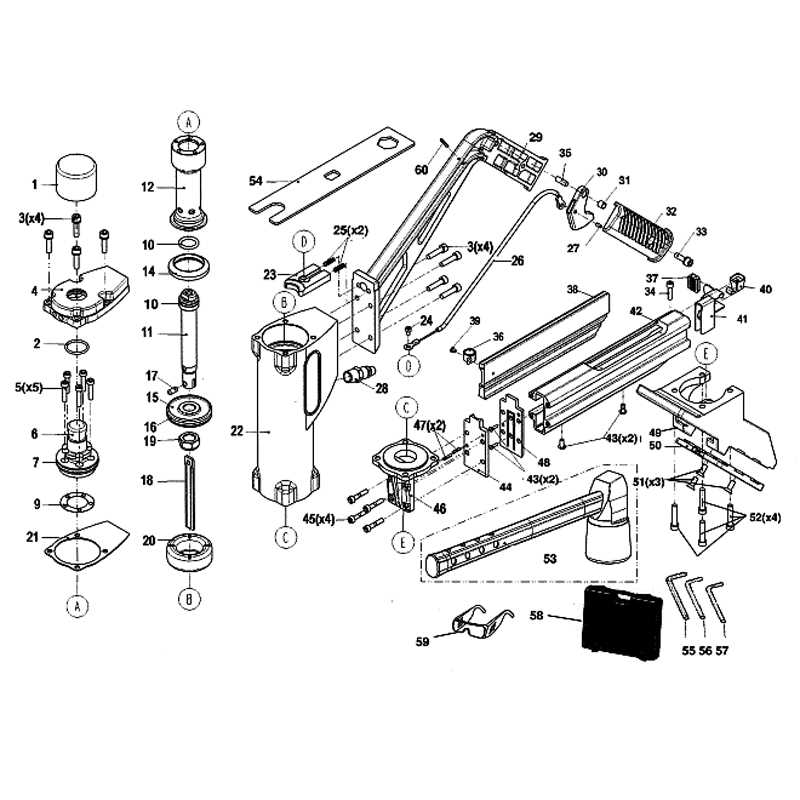

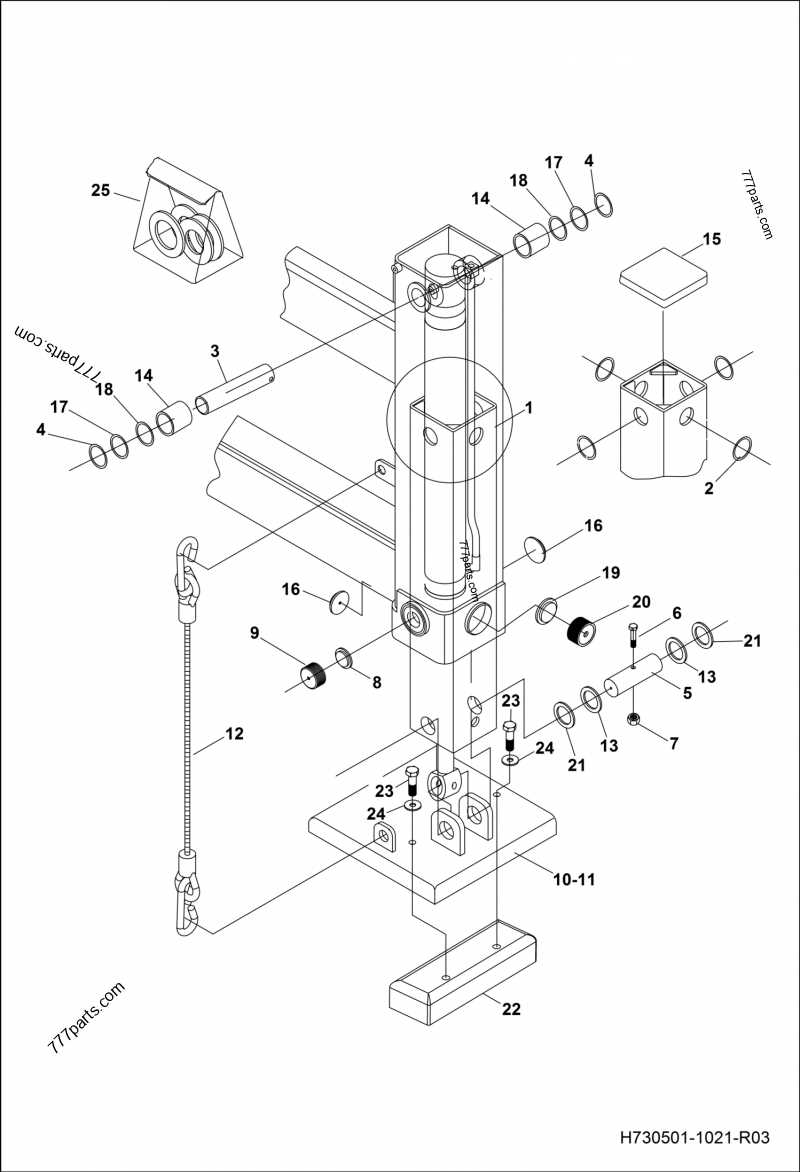

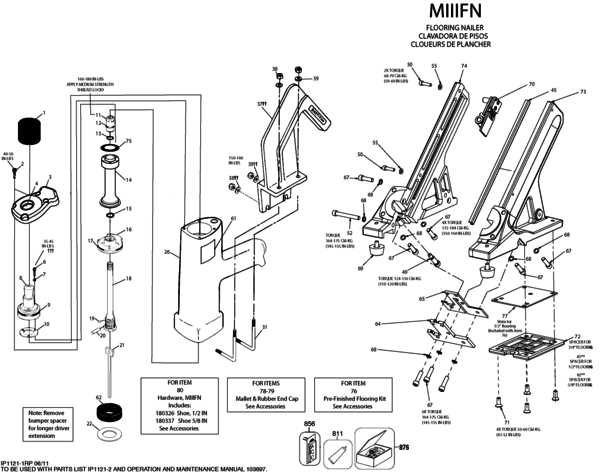

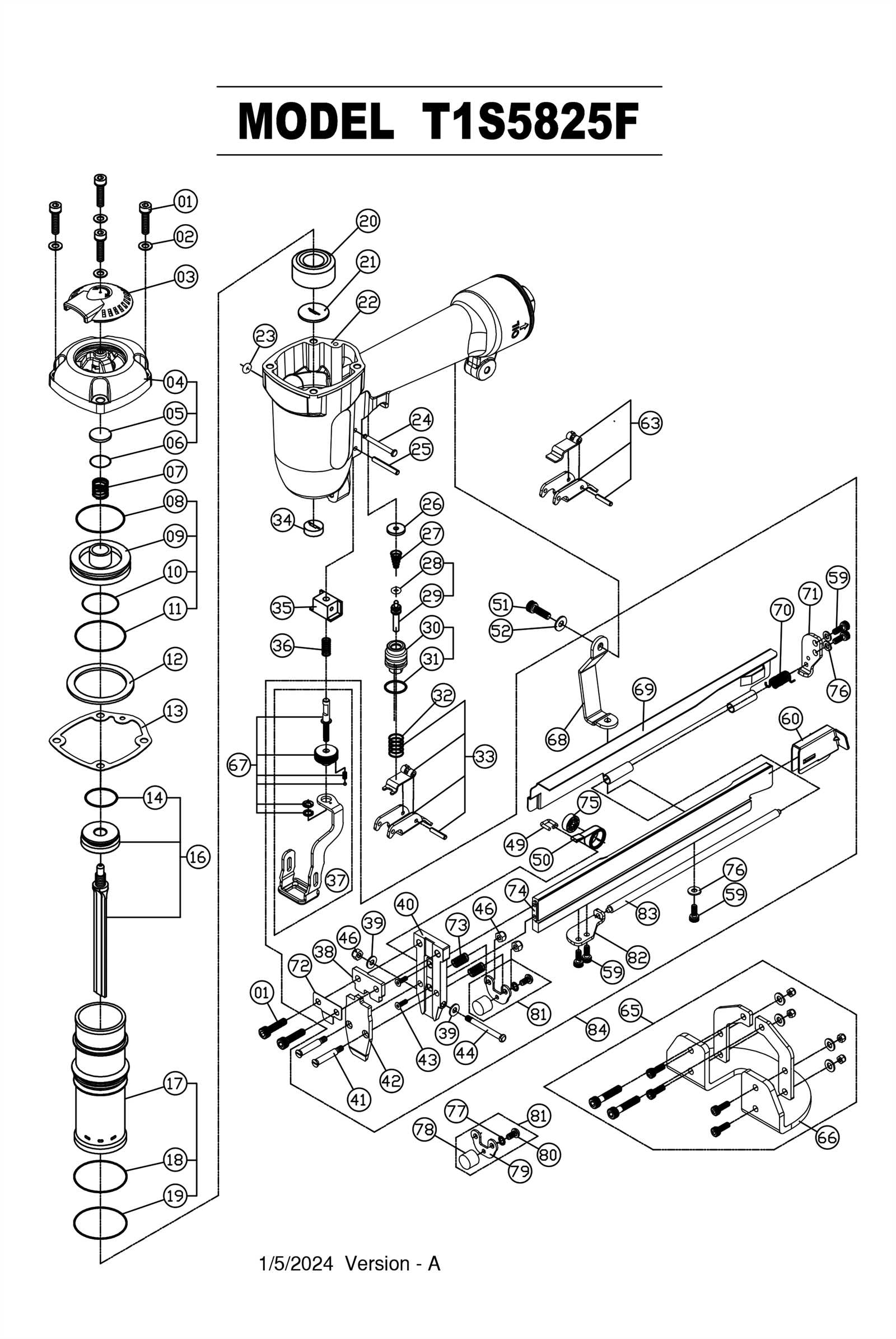

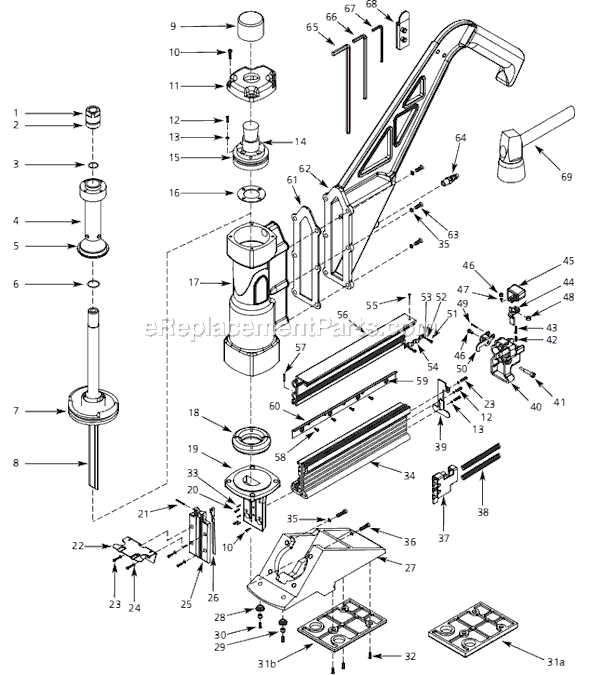

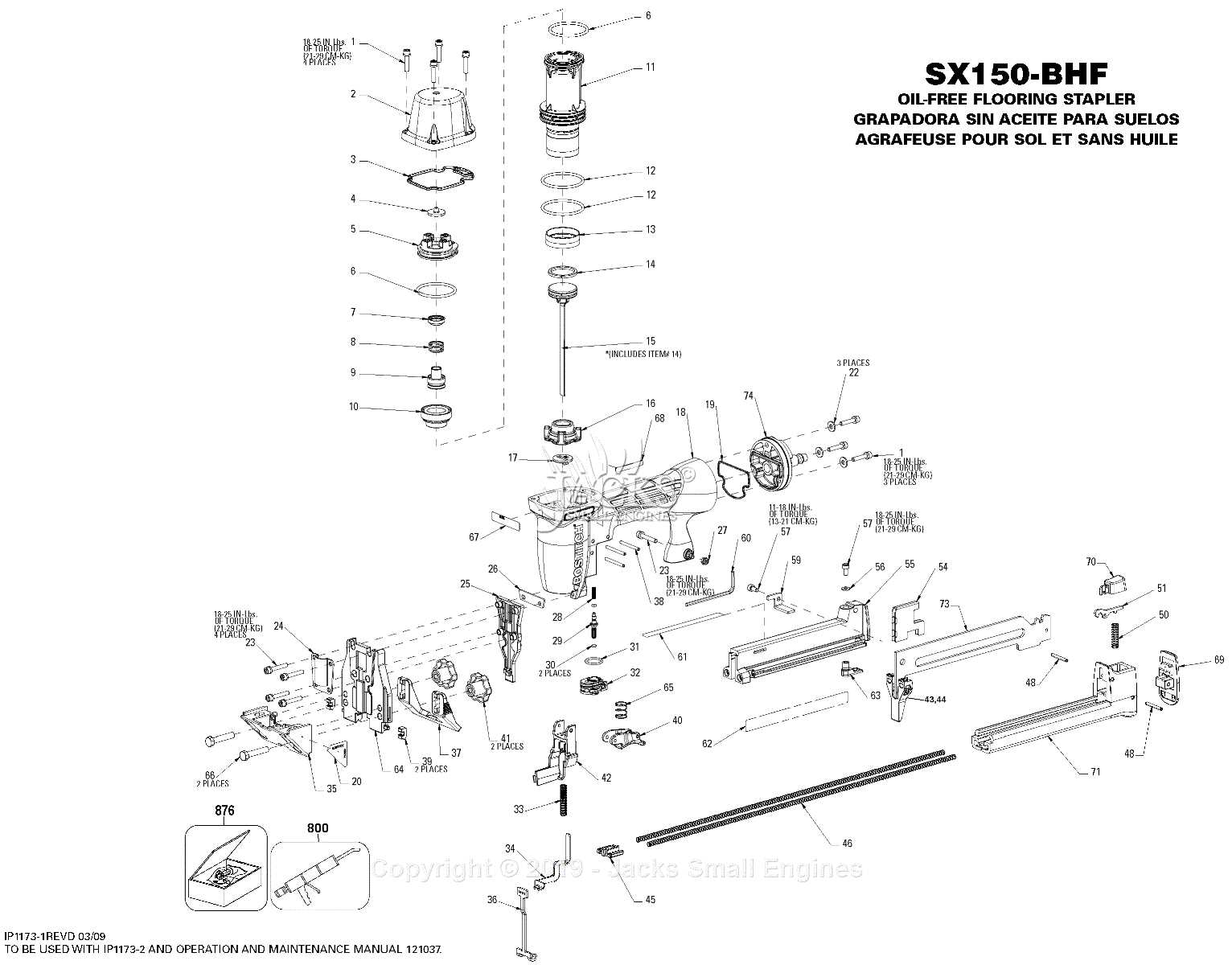

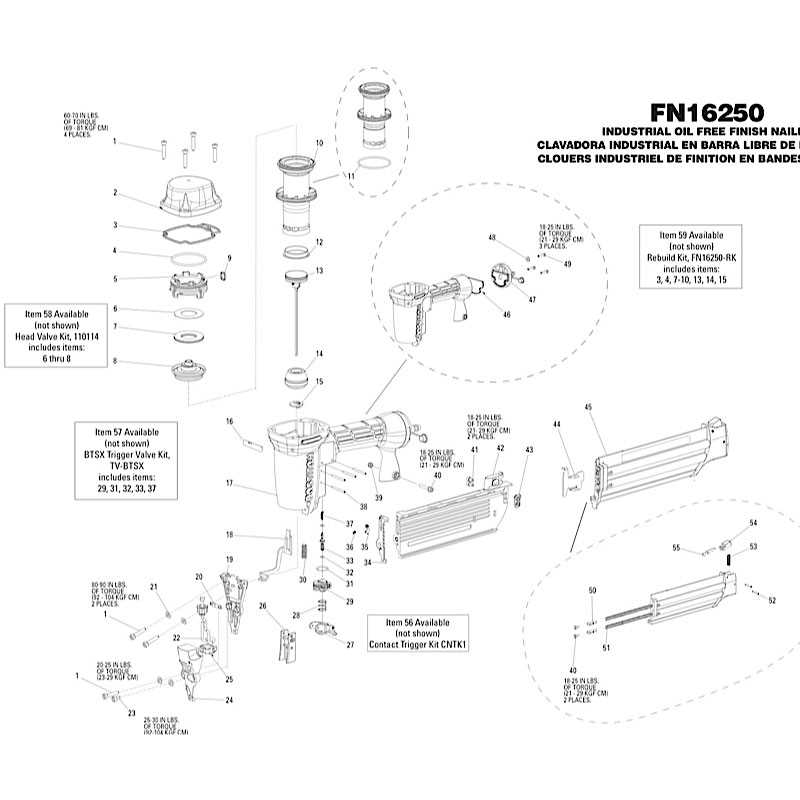

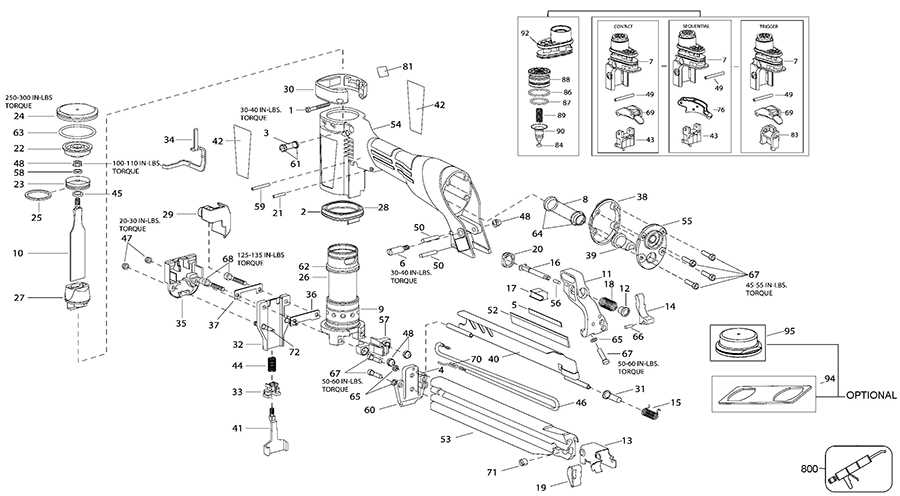

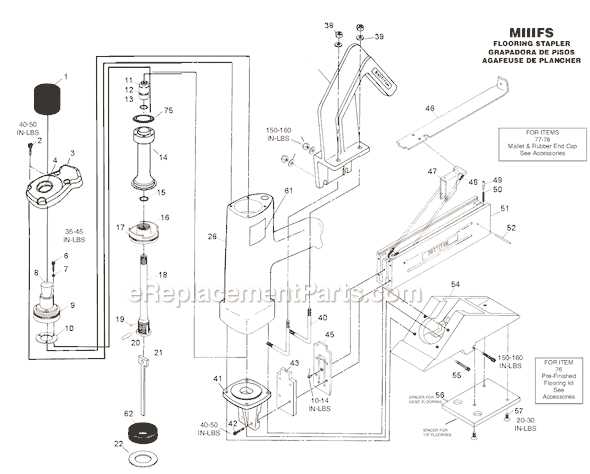

Detailed schematics and illustrations often serve as invaluable resources when trying to navigate the intricate connections within a device. These depictions allow users to visualize the internal structure, ensuring easier identification of potential issues and enabling quick replacements when needed.

Recognizing the importance of each component can empower users to approach repairs and adjustments with greater confidence. Whether tackling routine maintenance or solving more complex issues, a solid grasp of how all parts fit together is key to smooth operation.

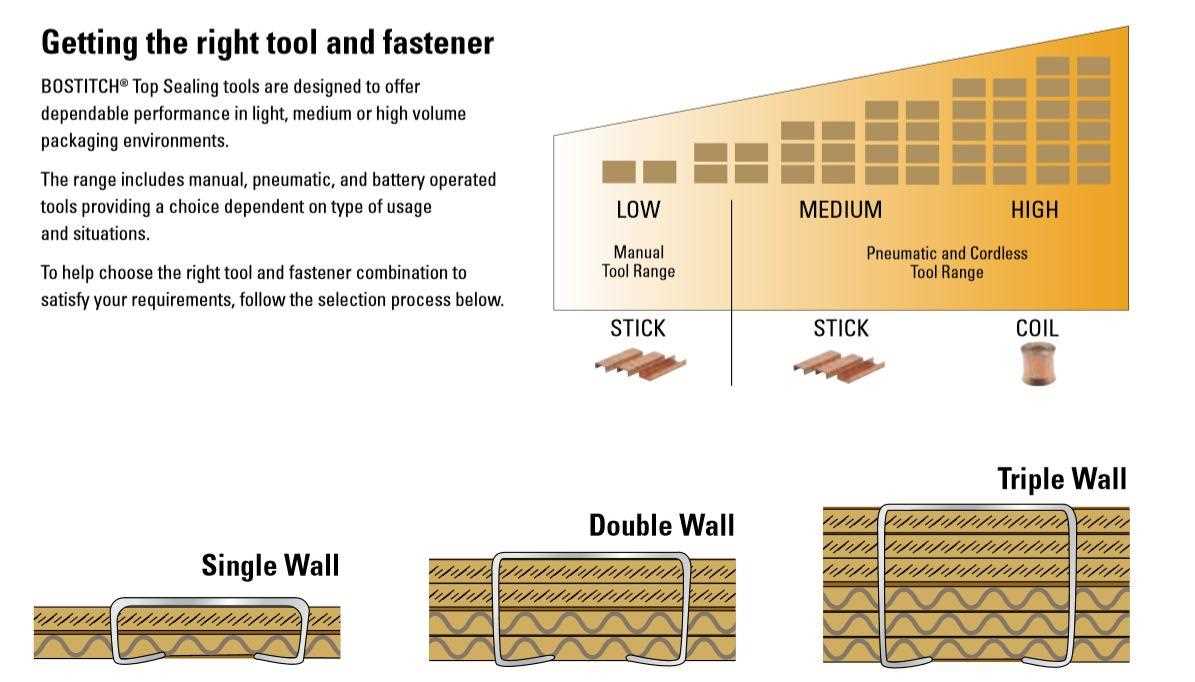

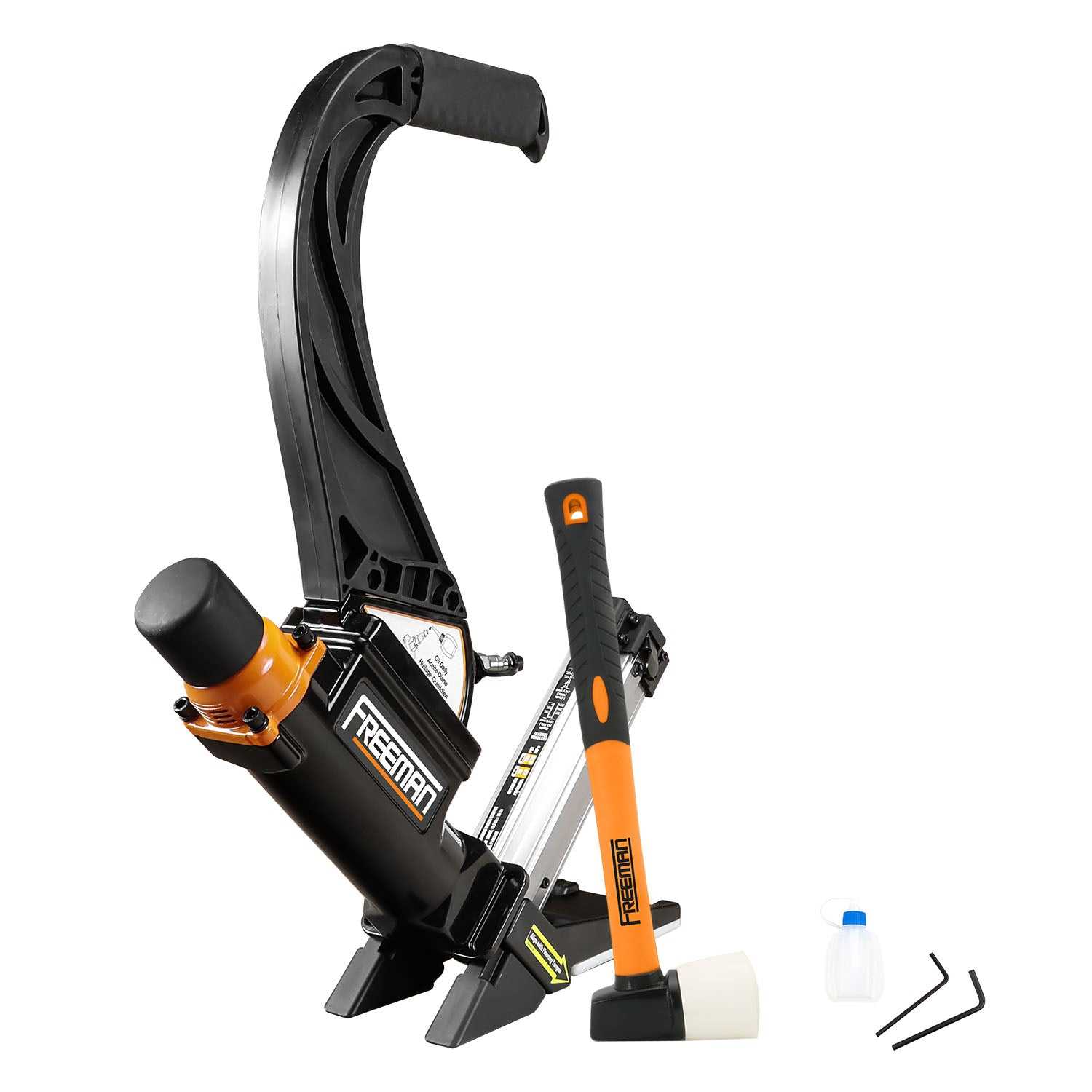

Bostitch Floor Stapler Overview

Designed for precise installation of various materials, this tool ensures consistent performance in demanding tasks. It is engineered to provide efficiency and reliability, making it suitable for both professionals and DIY enthusiasts. The robust construction allows for extended use, while its ergonomic design reduces fatigue during operation.

Main Features

The device incorporates advanced mechanisms to optimize user experience. Key elements include adjustable settings for different materials and an easy-to-use handle for smooth operation. The efficient fastening system ensures secure attachment, enhancing productivity and accuracy in every project.

Applications and Benefits

This equipment excels in applications requiring strong, durable connections. Its versatility makes it ideal for various surfaces, allowing for seamless integration into multiple projects. Users can expect long-lasting performance and minimal maintenance, which contribute to an overall smooth workflow.

Key Features of the Stapler

This device is designed to handle demanding tasks, making it a valuable tool in various assembly processes. Its robust construction ensures durability, while the specialized mechanics contribute to efficient performance, reducing the effort required from the user. Below are some of the essential characteristics that enhance its functionality.

Ergonomic Design

The tool’s handle is engineered to provide comfort during extended use. With a focus on minimizing strain, the design promotes a natural grip, allowing for more precise control. This ensures that the user can operate the device effectively without experiencing fatigue.

High Precision Mechanism

- Accurate alignment of materials for consistent results

- Minimal recoil, ensuring smoother operation

- Adjustable settings to accommodate various project requirements

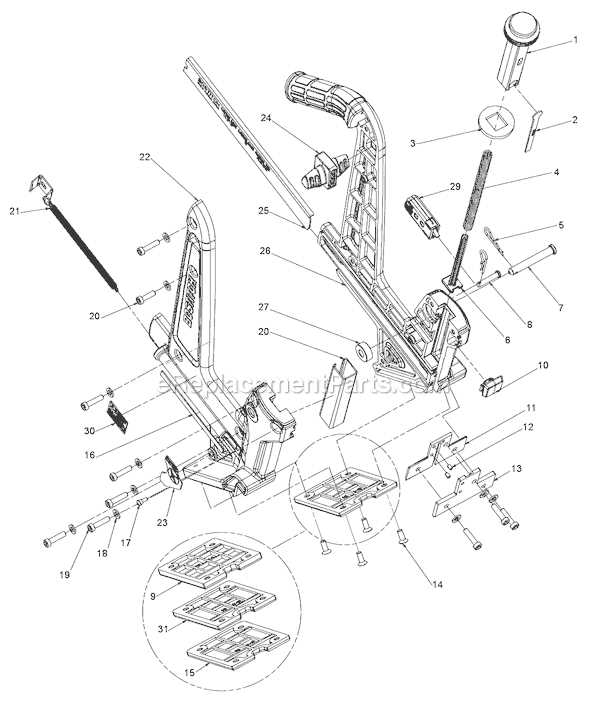

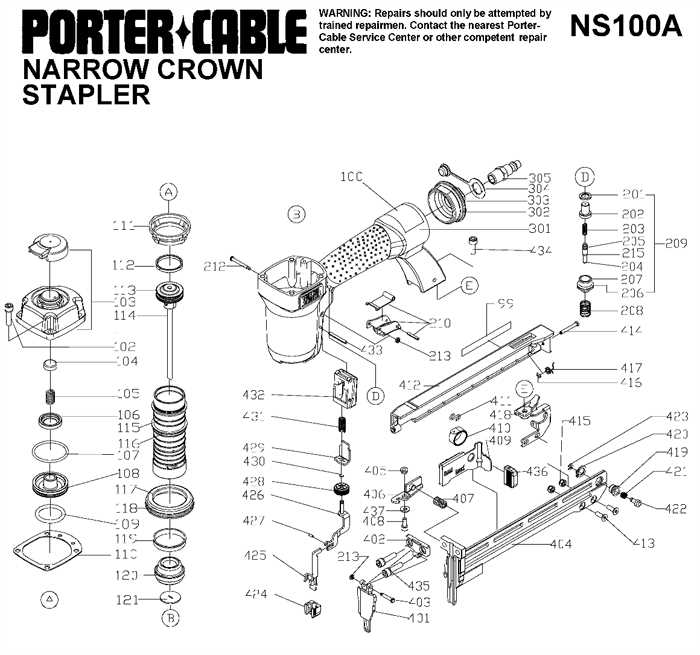

Exploring the Internal Components

The internal mechanisms of this tool consist of multiple elements working together to ensure efficient operation. Understanding how each piece contributes to the overall functionality can provide insights into its design and performance. By examining these key components, users can gain a deeper appreciation for the precision involved in its construction.

Main Structural Elements

The primary components include several key sections responsible for stability and power transmission. These sections are essential for maintaining alignment during use, and their careful arrangement ensures smooth functionality under various conditions.

Mechanism Breakdown

The operational mechanics involve several interconnected parts, each playing a crucial role in the device’s performance. This section dissects the movement of these components and highlights how they work together to produce consistent results.

| Component | Function |

|---|---|

| Driving Mechanism | Delivers force to activate the device. |

| Guide Assembly | Maintains alignment and precision during operation. |

| Return Spring | Resets the system after each activation for continuous use. |

Understanding the Mechanism

Comprehending how the device operates requires a basic grasp of its internal structure and function. The mechanism is driven by several key components working together in sync, creating a smooth and efficient operation. Each element plays a crucial role in the overall functionality, ensuring reliable performance.

Core Components

The system is built around interconnected parts that rely on both mechanical and pneumatic principles. The primary element triggers a sequence of movements, which results in the activation of the tool. These movements are precisely calibrated, allowing for consistent operation during usage.

Sequential Process

When engaged, the mechanism initiates a controlled process, starting with the compression of air or force, followed by a release that drives the action forward. This sequence is designed to optimize energy transfer, ensuring minimal effort is required from the operator while achieving powerful results.

Main Parts of the Stapler

The device consists of several essential elements that work together to ensure smooth and efficient operation. Each component plays a crucial role in the functionality, contributing to the overall performance and durability of the tool.

Key Components

- Handle: Provides the user with the grip needed to apply force during operation.

- Magazine: Holds the fasteners in place, ready for use in the driving mechanism.

- Driver Blade: Responsible for pushing the fasteners into the material.

Supporting Elements

- Base Plate: Ensures stability and precise alignment during use.

- Trigger Mechanism: Controls the release of the fasteners at the right moment.

- Fastener Guide: Directs the fasteners accurately toward the surface being worked on.

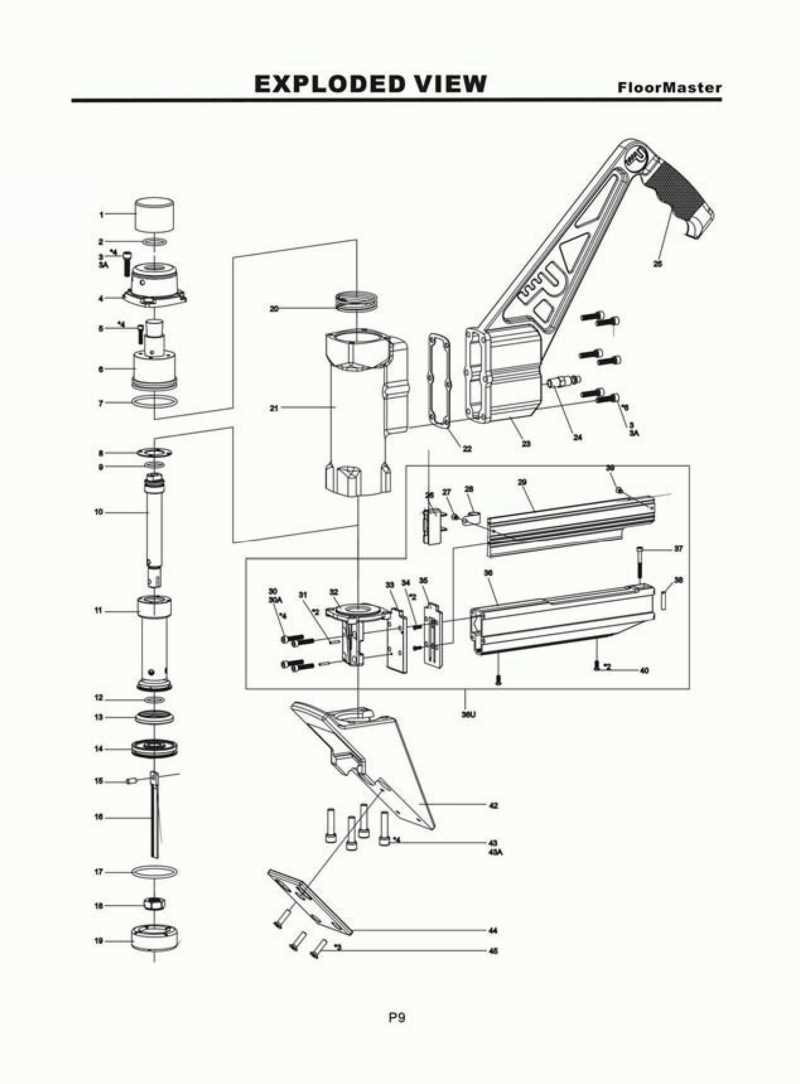

Diagram Breakdown of Components

This section offers an in-depth examination of the various elements that contribute to the functionality of the equipment. Understanding each component’s role is essential for effective operation and maintenance. The following overview highlights the key parts and their respective functions, enabling users to navigate the assembly with confidence.

| Component | Description |

|---|---|

| Housing | The outer shell that provides protection and stability to the inner mechanisms. |

| Piston | A vital part responsible for driving the fasteners into the material. |

| Trigger | The control mechanism that initiates the fastening process. |

| Magazine | Holds and feeds the fasteners into the operational area. |

| Air Inlet | Allows compressed air to enter the tool, powering its functions. |

Essential Maintenance Tips

Regular upkeep is crucial for ensuring optimal performance and longevity of your equipment. By adhering to a few fundamental guidelines, you can minimize wear and enhance efficiency, ultimately saving time and resources.

Routine Cleaning

Keeping the machinery free from dust and debris is essential. Regularly inspect and clean the various components to prevent build-up that could hinder performance. Use a soft brush or cloth to gently remove any residue from the surfaces.

Lubrication and Adjustment

Proper lubrication of moving parts is vital for smooth operation. Check the manufacturer’s recommendations for suitable lubricants and application intervals. Additionally, periodically assess the alignment and tension of any adjustable elements to maintain functionality.

| Maintenance Task | Frequency |

|---|---|

| Clean components | Weekly |

| Lubricate moving parts | Monthly |

| Inspect for wear | Every three months |

| Adjust settings | As needed |

Preserving Stapler Performance

Maintaining optimal functionality of a fastening tool is essential for achieving efficient results in various projects. Proper care and regular maintenance can significantly extend the lifespan and reliability of the device.

To ensure long-lasting performance, consider the following practices:

- Regular Cleaning: Frequently remove dust and debris from the tool to prevent clogging and ensure smooth operation.

- Lubrication: Apply appropriate lubricants to moving parts to minimize friction and wear. Follow manufacturer guidelines for suitable products.

- Inspection: Routinely check for any signs of damage or wear. Addressing minor issues promptly can prevent more significant problems.

- Proper Storage: Store the device in a dry environment, away from extreme temperatures, to prevent deterioration of materials.

By incorporating these strategies into your maintenance routine, you can enhance the durability and efficiency of your fastening equipment, ensuring it performs at its best for years to come.

Common Stapler Issues and Solutions

Issues with fastening devices can arise from various factors, often leading to frustrating interruptions during use. Understanding these challenges and their remedies can enhance efficiency and prolong the lifespan of the equipment. This section outlines frequent problems encountered with these tools and suggests effective solutions to address them.

Jammed Fasteners

A common issue involves the occurrence of jammed fasteners, which can hinder functionality and require immediate attention. To resolve this, it is advisable to turn off the device and carefully remove any obstructing materials. Regular maintenance, including cleaning the feeding mechanism, can help prevent future occurrences.

Inconsistent Fastening

Inconsistent fastening results in unreliable performance, often due to worn components or incorrect settings. Ensuring that the device is set to the appropriate pressure and that all parts are in good condition is essential. Replacing any damaged components and adjusting the pressure settings can significantly improve performance.

Troubleshooting Part Failures

Addressing component malfunctions is crucial for maintaining optimal performance and longevity of any equipment. Understanding the common issues that may arise can help users effectively diagnose and resolve problems, ensuring efficient operation.

One frequent issue involves jamming, which can occur when materials are not loaded correctly or if there is a buildup of debris. To remedy this, check the loading mechanism and clear any obstructions. Regular cleaning of the equipment can prevent such occurrences.

Another common failure is related to power loss, often caused by a depleted energy source or a faulty connection. Users should inspect the power supply and all connections to ensure they are secure and functioning. If the power source is adequate, yet issues persist, further investigation into the internal circuitry may be necessary.

Additionally, users may experience inconsistent performance, where the mechanism fails to operate smoothly. This could stem from worn or damaged components. Periodic inspection of all moving parts and replacing any that show signs of wear can significantly enhance reliability.

By systematically addressing these common challenges, users can effectively troubleshoot and maintain their equipment, ensuring it operates at peak efficiency.

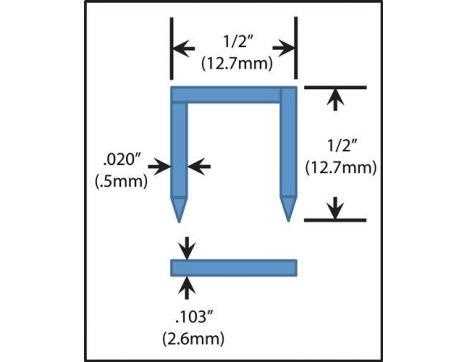

Choosing Replacement Parts

When it comes to maintaining and enhancing the functionality of your equipment, selecting the right components is crucial. Understanding the various elements that make up your tool can help you identify which replacements are necessary for optimal performance. Ensuring compatibility and quality can prolong the lifespan of your device and improve its efficiency.

Identifying Necessary Components

Before purchasing any replacements, assess the current state of your tool. Look for signs of wear and tear, such as reduced performance or physical damage. It’s essential to determine which components are faulty or inefficient. This assessment will guide you in making informed choices about what to replace.

Quality Considerations

Opting for high-quality components is vital for maintaining the integrity of your equipment. Consider reputable manufacturers known for their durable products. While it may be tempting to choose cheaper options, investing in reliable components can save you money in the long run by reducing the need for frequent replacements.

Finding Compatible Components

When working with specialized equipment, ensuring the compatibility of various elements is crucial for optimal performance. Identifying suitable accessories and replacements can significantly enhance functionality and longevity. It is important to understand the specifications and requirements of each component to achieve seamless integration.

Researching Specifications

Before making a purchase, it is essential to investigate the technical details of the items you need. Look for information regarding size, material, and intended usage. This knowledge will help you select components that not only fit but also function effectively within your setup.

Consulting Manufacturer Resources

Utilizing official resources, such as manuals and guides from the manufacturer, can provide valuable insights into compatible components. These documents often include detailed information about suitable alternatives, ensuring that you make informed decisions that align with your project requirements.

Stapler Assembly Guide

This section provides an overview of the assembly process for a fastening tool, ensuring optimal performance and durability. Proper assembly is crucial for achieving consistent results and extending the lifespan of the equipment. Each component plays a vital role in the functionality, so understanding their placement and interaction is essential for effective operation.

Essential Components

The assembly consists of various key elements, including the main housing, trigger mechanism, and driving blade. Each part should be examined for signs of wear before assembly. Ensure that all components are clean and free from debris to facilitate smooth operation. Proper alignment is critical, as misaligned parts can lead to malfunction and reduce efficiency.

Assembly Steps

Begin by securing the main housing and carefully installing the trigger mechanism. Follow this by attaching the driving blade, ensuring it fits snugly within its designated slot. Tighten any screws or fasteners as necessary, but avoid overtightening, which could damage the components. Once assembled, conduct a thorough inspection to confirm that all parts are securely in place and functioning correctly before use.