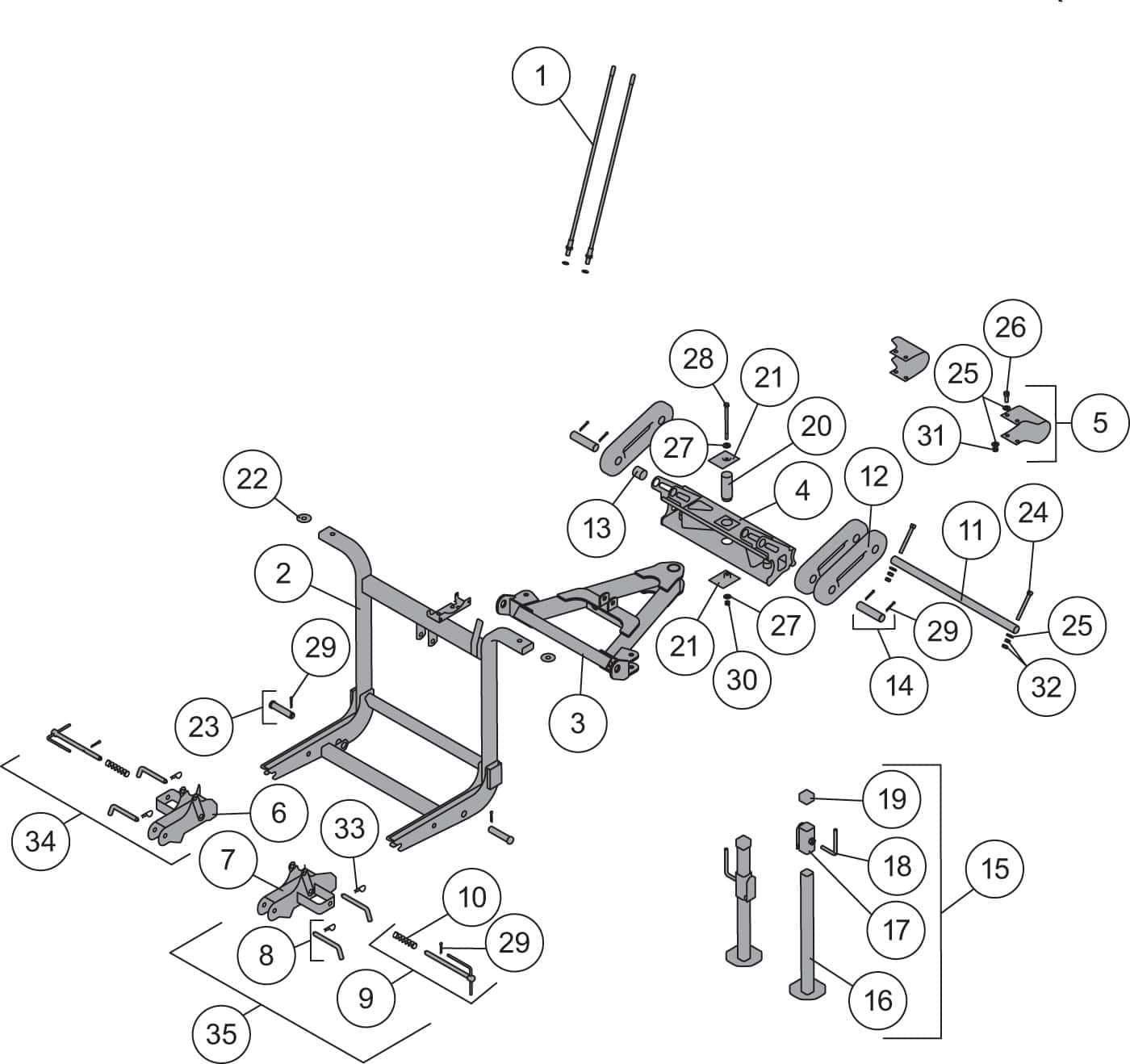

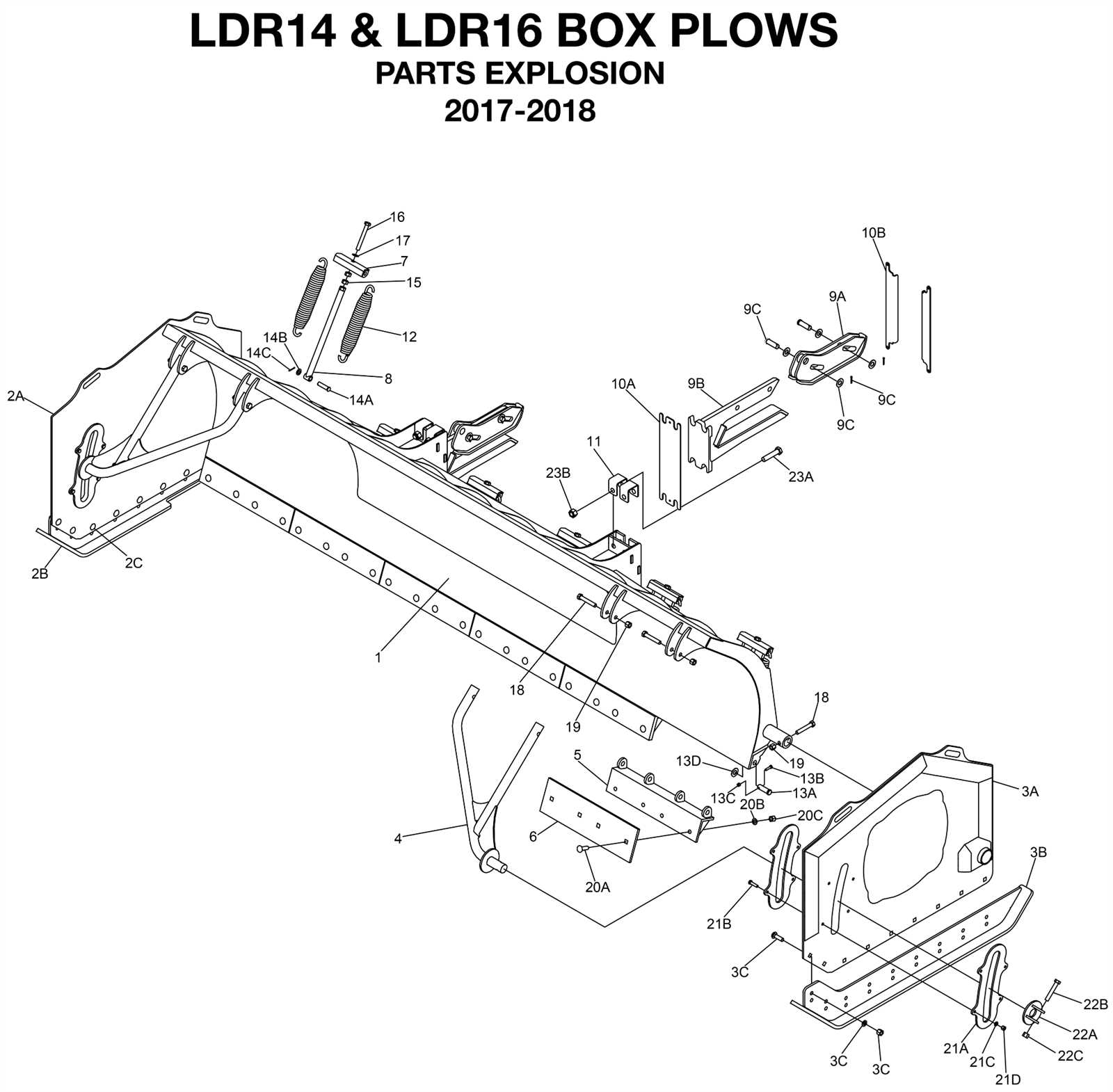

The intricacies of heavy-duty machinery require a thorough comprehension of their individual elements and functionalities. A well-structured reference can greatly enhance one’s ability to identify and utilize these essential components effectively. This knowledge not only aids in maintenance but also fosters a deeper appreciation for the engineering behind such robust devices.

By delving into the specific configurations and arrangements of these elements, users can optimize performance and ensure longevity. Each component plays a vital role in the overall operation, and recognizing their functions can lead to improved efficiency and reduced downtime. The ability to visualize how these parts interact is invaluable for both novice and seasoned operators alike.

Understanding the components of a hydraulic system is crucial for ensuring efficient operation and maintenance. These systems rely on fluid movement to transmit power, making the identification of each element essential for troubleshooting and repairs. Below are some key components commonly found in hydraulic setups.

- Pump: This device generates hydraulic pressure by moving fluid through the system.

- Reservoir: A container that holds hydraulic fluid, allowing for storage and heat dissipation.

- Actuator: Converts hydraulic energy into mechanical movement, often found in cylinders or motors.

- Valves: Control the flow and direction of fluid, regulating pressure and speed within the system.

- Filters: Remove contaminants from the hydraulic fluid, ensuring smooth operation and longevity of components.

Each component plays a vital role in the overall functionality of the hydraulic mechanism. Regular inspection and maintenance can prevent system failures and enhance performance.

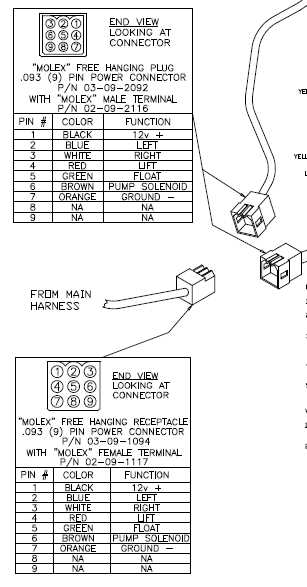

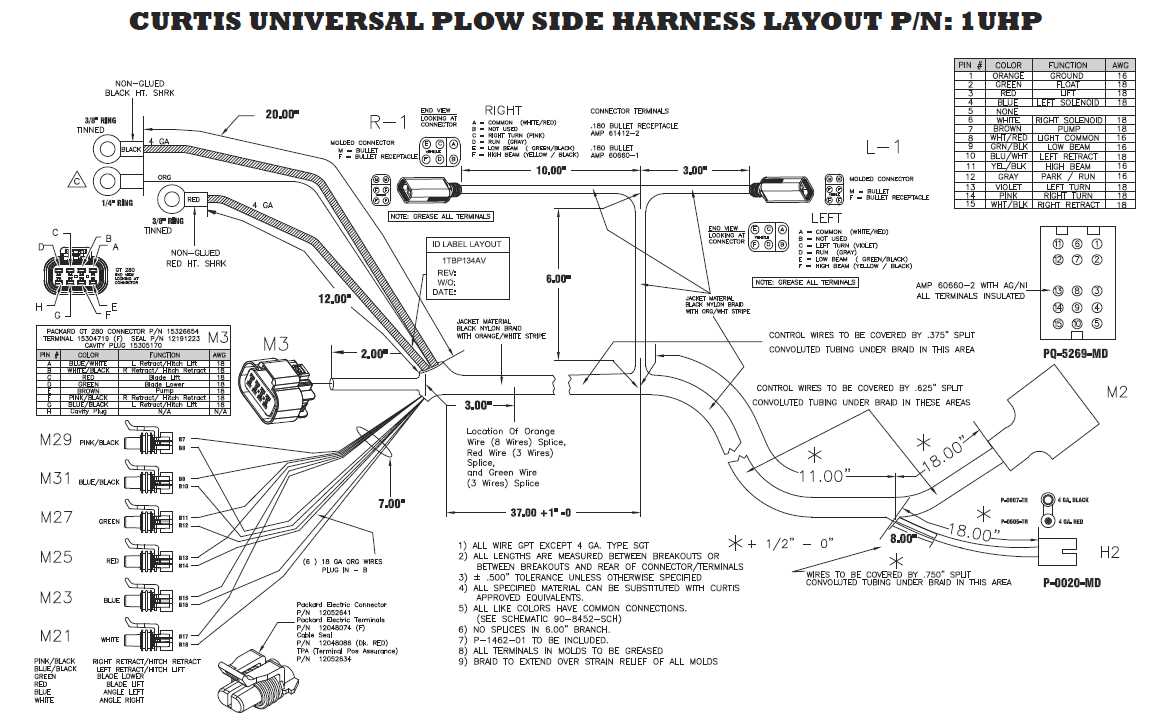

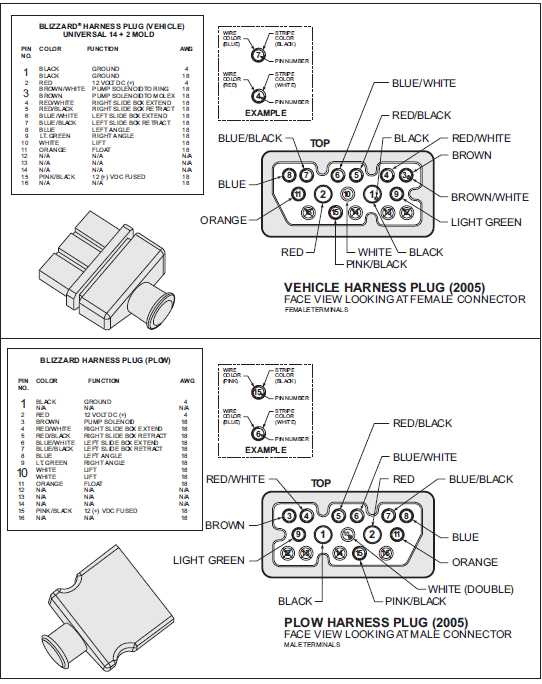

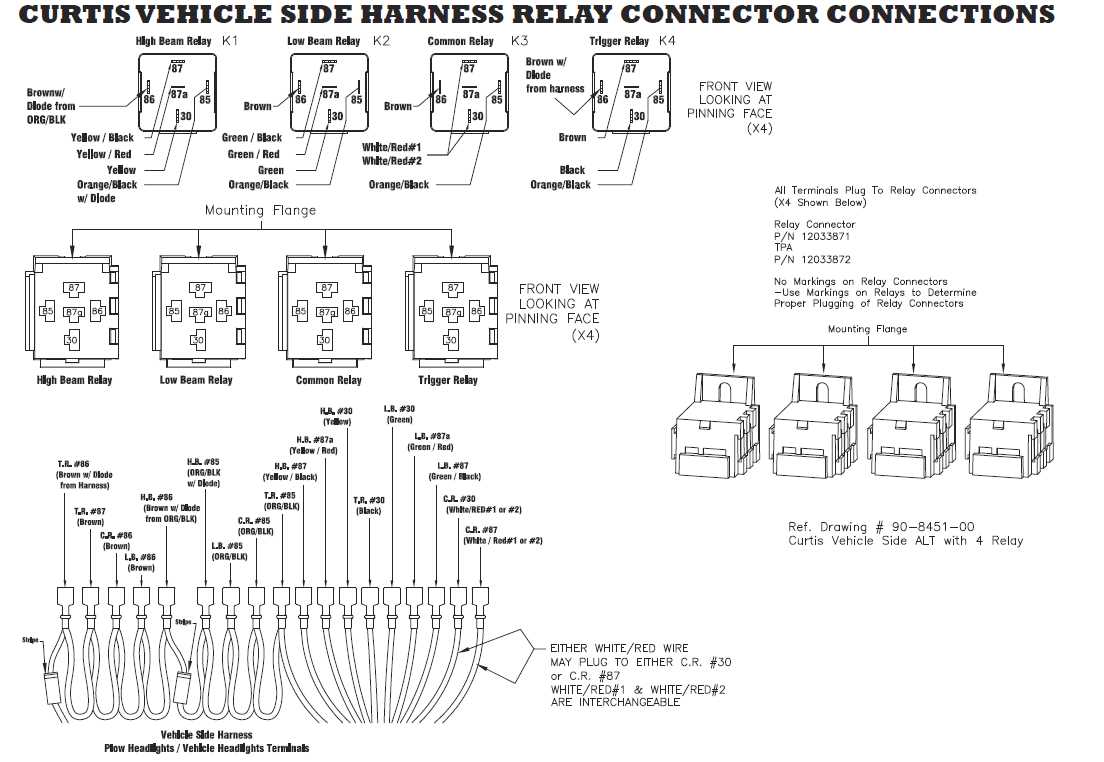

Electrical Components in Snow Removal

Effective winter maintenance relies heavily on various electrical systems that facilitate operational efficiency. These systems ensure that equipment functions seamlessly in adverse weather conditions, providing reliable performance when it matters most. Understanding the roles of these electrical elements is crucial for anyone involved in winter service activities.

Control Systems and Sensors

At the heart of any winter maintenance machine are the control systems and sensors. These components are responsible for regulating the equipment’s functions and providing feedback to the operator. Sensors detect changes in environmental conditions, while control units enable precise adjustments, ensuring optimal performance throughout the operation.

Power Supply and Distribution

Another essential aspect is the power supply and distribution network. This setup delivers the necessary energy to various systems, allowing them to operate efficiently. Proper management of power distribution ensures that all components receive adequate energy, preventing interruptions and enhancing overall functionality during demanding tasks.

Maintenance Tips for Snow Plow Parts

Ensuring the longevity and efficiency of your equipment involves regular care and attention. Routine upkeep not only enhances performance but also reduces the likelihood of unexpected failures. Implementing effective strategies can significantly improve the reliability of your machinery.

Here are some essential maintenance practices to consider:

| Maintenance Activity | Frequency | Tips |

|---|---|---|

| Inspection of Components | Monthly | Check for wear and damage. Replace any worn items promptly. |

| Lubrication | Every 100 hours of use | Use appropriate lubricants to ensure smooth operation. |

| Cleaning | After each use | Remove debris and dirt to prevent corrosion and buildup. |

| Fluid Levels Check | Weekly | Ensure all fluids are at the recommended levels for optimal function. |

By following these practices, you can enhance the performance and lifespan of your equipment, ensuring it operates efficiently throughout the season.

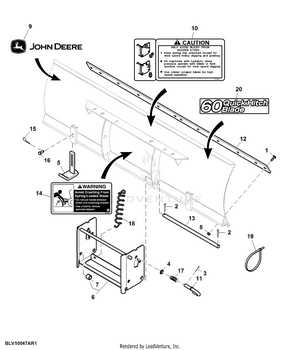

Common Replacement Parts Explained

When maintaining equipment designed for clearing surfaces, understanding essential components is crucial for optimal performance. These elements often require replacement due to wear or damage, and being familiar with them ensures seamless operation and longevity of the machinery.

Key Components Overview

Several critical components play a role in the functionality of surface-clearing devices. These include mechanisms responsible for lifting and angling the attachment, as well as elements that ensure proper engagement with the terrain. Knowledge of these parts aids in timely replacements and efficient repairs.

Identification of Common Elements

The following table highlights some frequently replaced components and their functions:

| Component | Function |

|---|---|

| Lift Cylinder | Raises and lowers the attachment. |

| Angle Cylinder | Allows adjustment of the attachment’s angle. |

| Control Switch | Engages and disengages the lifting mechanism. |

| Mounting Bracket | Secures the attachment to the vehicle. |

Impact of Quality on Performance

The significance of excellence in components cannot be overstated, as it directly influences the overall functionality and efficiency of any system. High-quality materials and precision engineering lead to enhanced reliability, which is essential for optimal operation. When the integrity of elements is compromised, performance suffers, potentially resulting in increased downtime and maintenance costs.

Moreover, the durability of high-grade components ensures that systems can withstand harsh conditions and prolonged usage, thereby extending their lifespan. This reliability translates to consistent performance and user satisfaction. In contrast, inferior components may lead to frequent malfunctions and repairs, adversely affecting productivity and operational costs.

| Quality Level | Performance Impact | Longevity |

|---|---|---|

| High | Optimal functionality, reliability | Extended lifespan |

| Medium | Variable performance, occasional issues | Moderate lifespan |

| Low | Frequent malfunctions, reduced efficiency | Short lifespan |

Installation Process for New Components

Successfully integrating new elements into your system requires careful planning and execution. This process ensures that all components function harmoniously, enhancing the overall efficiency and effectiveness of the setup. Following a structured approach can simplify the installation, allowing for a smooth transition and minimizing potential issues.

Preparation and Safety Measures

Before commencing the installation, ensure that all necessary tools and components are readily available. It’s crucial to familiarize yourself with the specifications of each element. Always prioritize safety by wearing appropriate protective gear and working in a well-ventilated area. Disconnecting the power source is essential to prevent accidents during the setup.

Step-by-Step Installation Guidelines

Begin by carefully removing any existing components that may interfere with the new installations. Follow the manufacturer’s instructions closely, making sure to connect the new elements according to the provided guidelines. Use secure fasteners and ensure that all connections are tight to avoid any operational failures. Once everything is in place, perform a thorough inspection before reactivating the system.

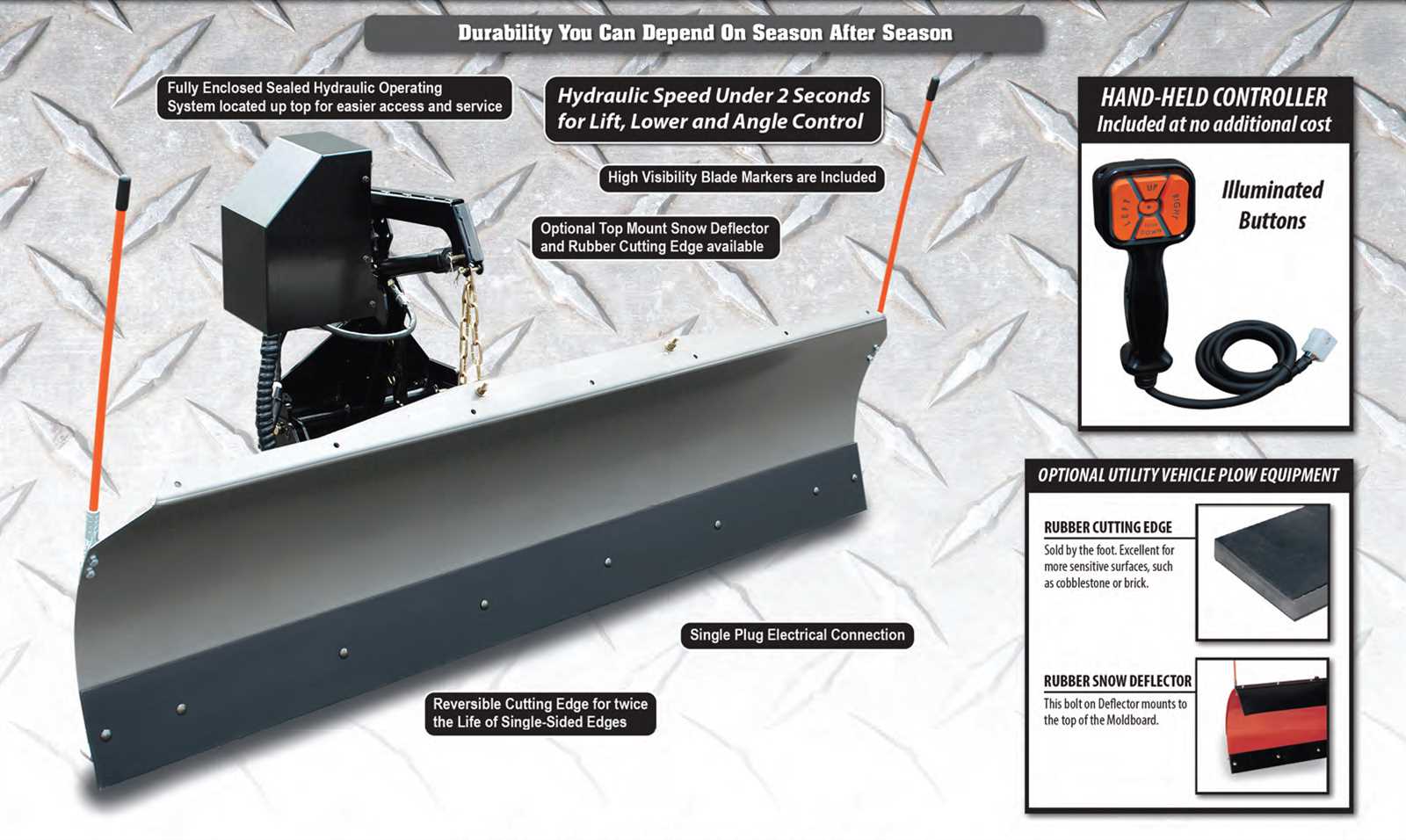

Choosing the Right Accessories

Selecting appropriate enhancements is crucial for optimizing the functionality and performance of equipment. The right add-ons can significantly improve efficiency, ease of use, and overall effectiveness. Understanding various options available allows users to make informed decisions that suit their specific needs.

Assessing Compatibility and Functionality

Before making a selection, it is important to evaluate how each accessory interacts with existing systems. Compatibility ensures that all components work harmoniously together, while functionality determines how well they meet operational demands. Identifying the correct features is essential for achieving desired outcomes.

Considering Durability and Quality

Investing in high-quality enhancements is vital for long-term reliability. Accessories constructed from durable materials can withstand harsh conditions and frequent use. Prioritizing robust designs will not only enhance performance but also reduce the need for frequent replacements, ultimately saving time and resources.

Identifying Wear and Tear Issues

Recognizing signs of deterioration in equipment is crucial for maintaining optimal performance. Regular inspection helps in identifying components that may require repair or replacement, ensuring longevity and reliability. Observing changes in functionality can prevent more significant issues from arising, thus promoting a safe and efficient working environment.

Common Signs of Deterioration

Several indicators can signal the need for attention. Frequent inspections can help in pinpointing these issues early, leading to timely interventions. Here are some typical signs to watch for:

| Indicator | Possible Consequence |

|---|---|

| Unusual Noises | Potential mechanical failure |

| Leaking Fluids | Fluid loss affecting operation |

| Excessive Vibration | Imbalance in moving parts |

| Visible Wear | Compromised efficiency |

Preventative Maintenance Strategies

To mitigate wear and tear, implementing a routine maintenance schedule is advisable. This includes regular lubrication, tightening of loose fittings, and replacement of worn components. Adopting these practices not only enhances performance but also extends the lifespan of the equipment.

Seasonal Preparation for Snow Plows

As the cold months approach, it becomes essential to ensure that equipment is ready to handle the challenges presented by winter conditions. A thorough examination and maintenance of machinery can enhance efficiency and prolong its lifespan. This segment focuses on key aspects to consider during this preparatory phase.

First, it’s vital to conduct a comprehensive inspection of the components involved in winter operations. Addressing any wear and tear will prevent breakdowns when the demand is high. Below is a table outlining critical tasks to consider during this preparatory process:

| Task | Description |

|---|---|

| Inspection of Hydraulic System | Check for leaks and ensure proper fluid levels. |

| Electrical Check | Test all connections and replace worn wiring. |

| Blade Maintenance | Sharpen and inspect blades for effective operation. |

| Tire Condition | Inspect tire pressure and tread for optimal traction. |

| Fluid Replacement | Change oil and coolant as needed for optimal performance. |

By following these guidelines, operators can ensure their equipment is well-prepared to tackle the winter season effectively, minimizing downtime and maximizing performance when it matters most.

Safety Features in Snow Plowing Systems

Ensuring operational safety in winter maintenance equipment is paramount. The integration of various protective elements not only enhances the performance of these systems but also safeguards the operator and surrounding environment. A comprehensive approach to safety is essential to minimize risks associated with adverse weather conditions.

One key aspect involves the implementation of automatic shut-off mechanisms. These features are designed to deactivate the machinery when specific parameters are exceeded, preventing potential accidents and equipment damage. Additionally, reflective markings and strategic lighting play a crucial role in enhancing visibility, ensuring that operators can navigate safely during low-light conditions.

Moreover, ergonomic design in control interfaces contributes significantly to user safety. Intuitive controls reduce the likelihood of operator error, enabling quick and effective responses to changing circumstances. Incorporating reinforced structures into the equipment further protects against impacts and increases overall durability, ensuring reliable operation throughout the season.