Understanding the essential elements of hydraulic mechanisms used in marine environments is crucial for maintaining optimal performance. These systems are designed to provide smooth operation and ensure proper control when navigating various conditions at sea.

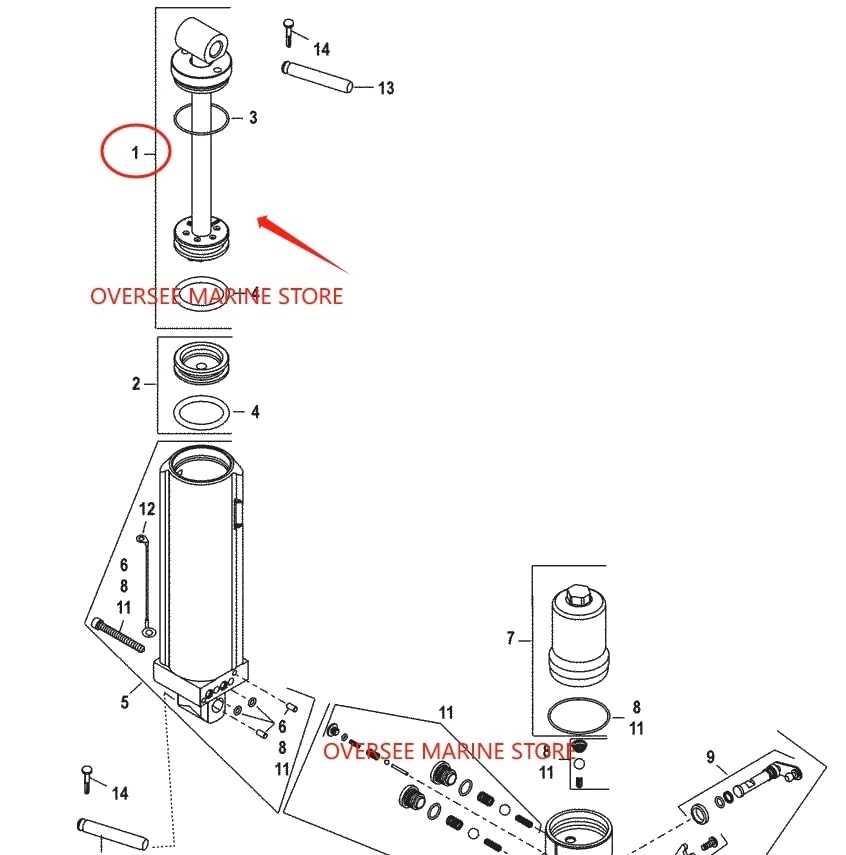

Focusing on the specific functional units involved in these systems helps to highlight the importance of each component. A clear view of their arrangement enables efficient troubleshooting and maintenance, which can extend the longevity of your equipment.

This section will guide you through the structural aspects and roles of individual components, offering valuable insights into their integration and overall functionality.

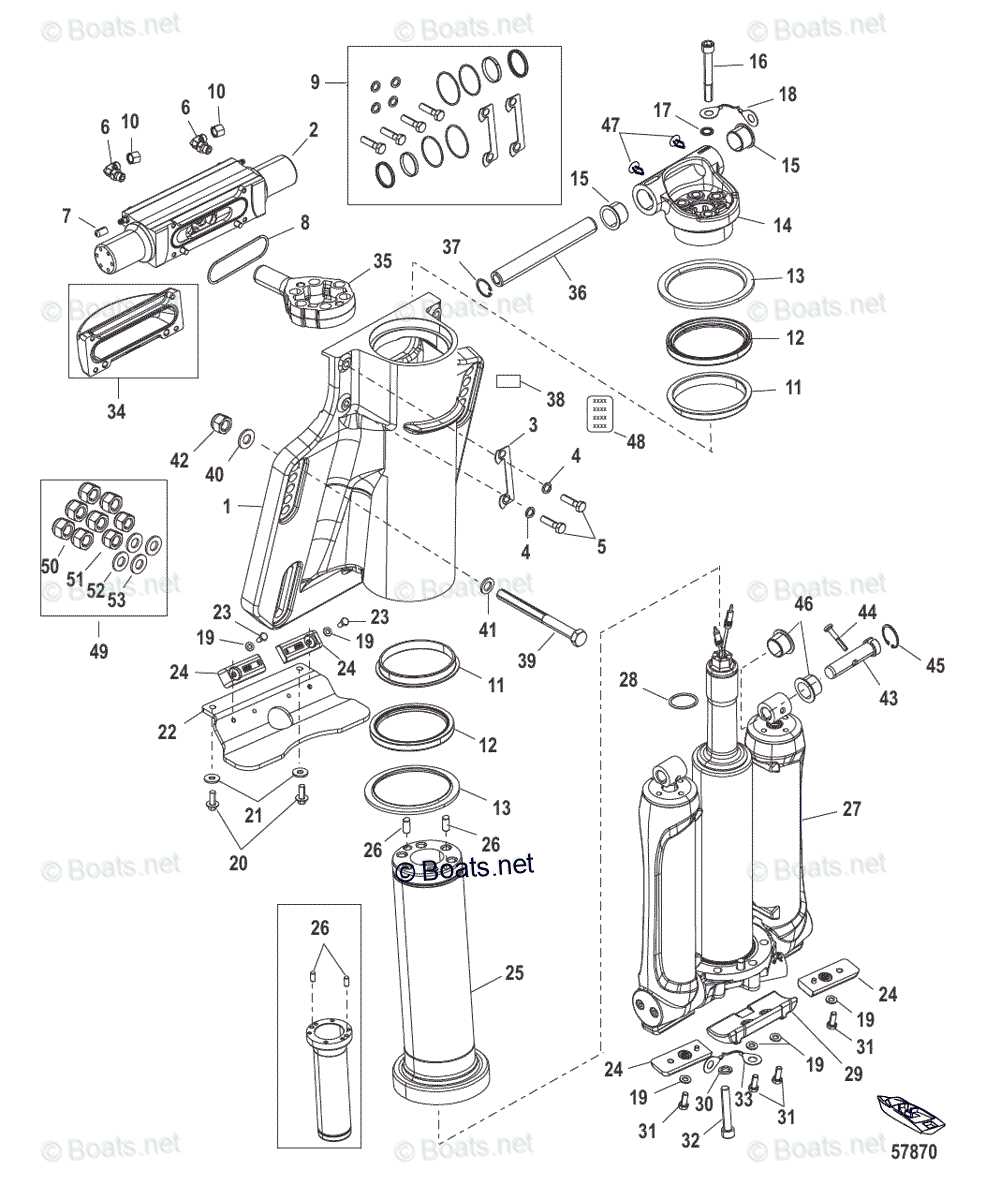

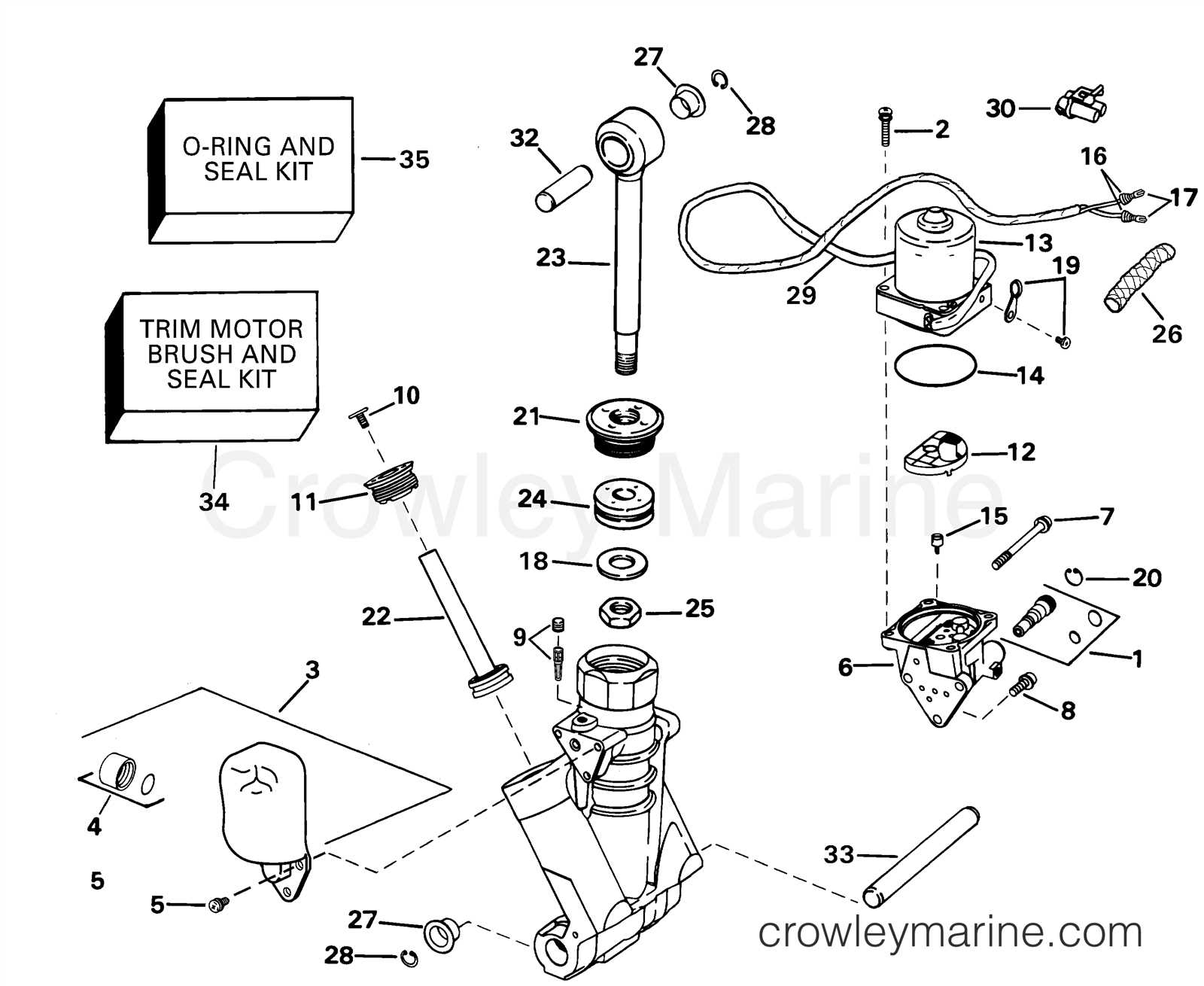

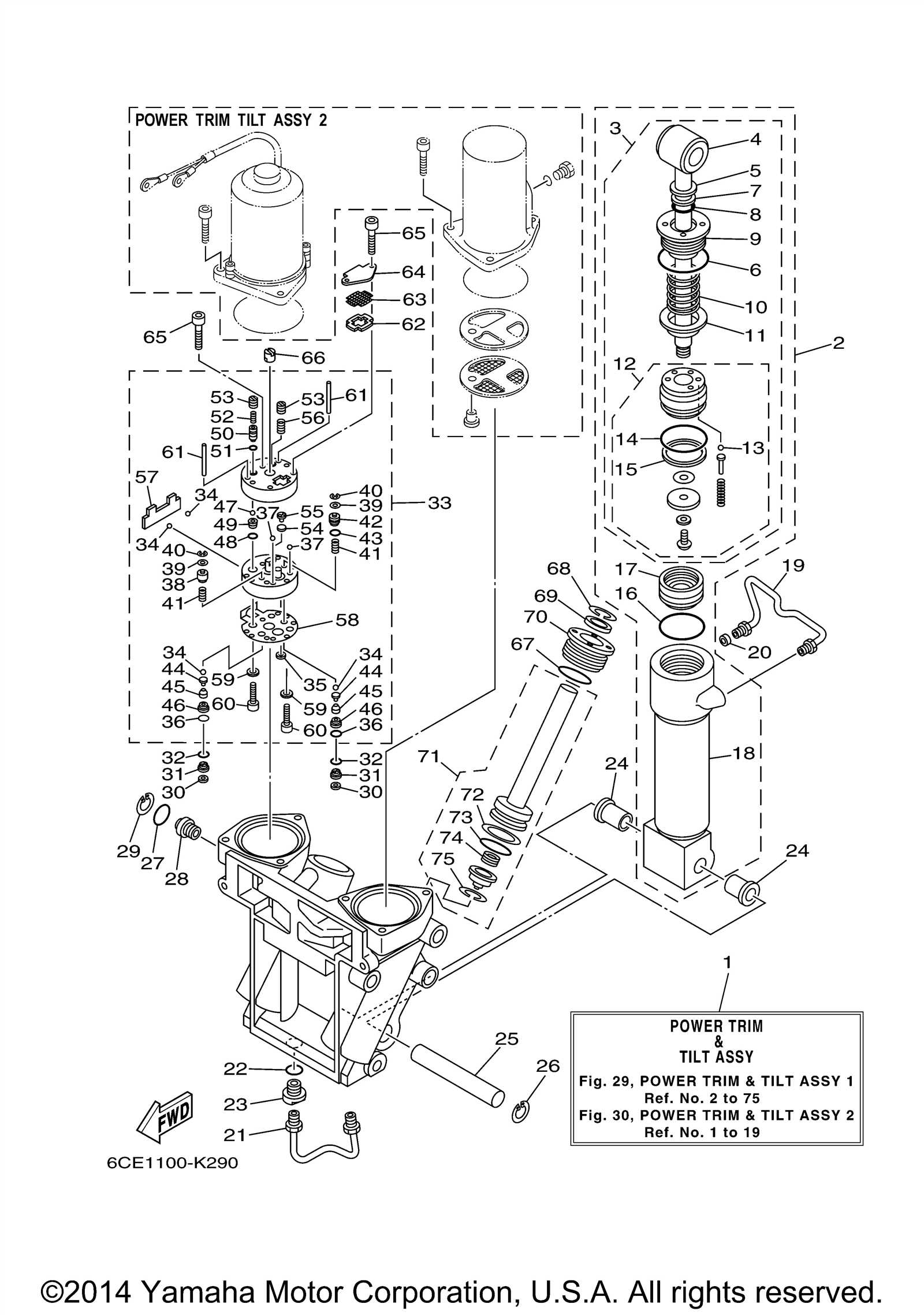

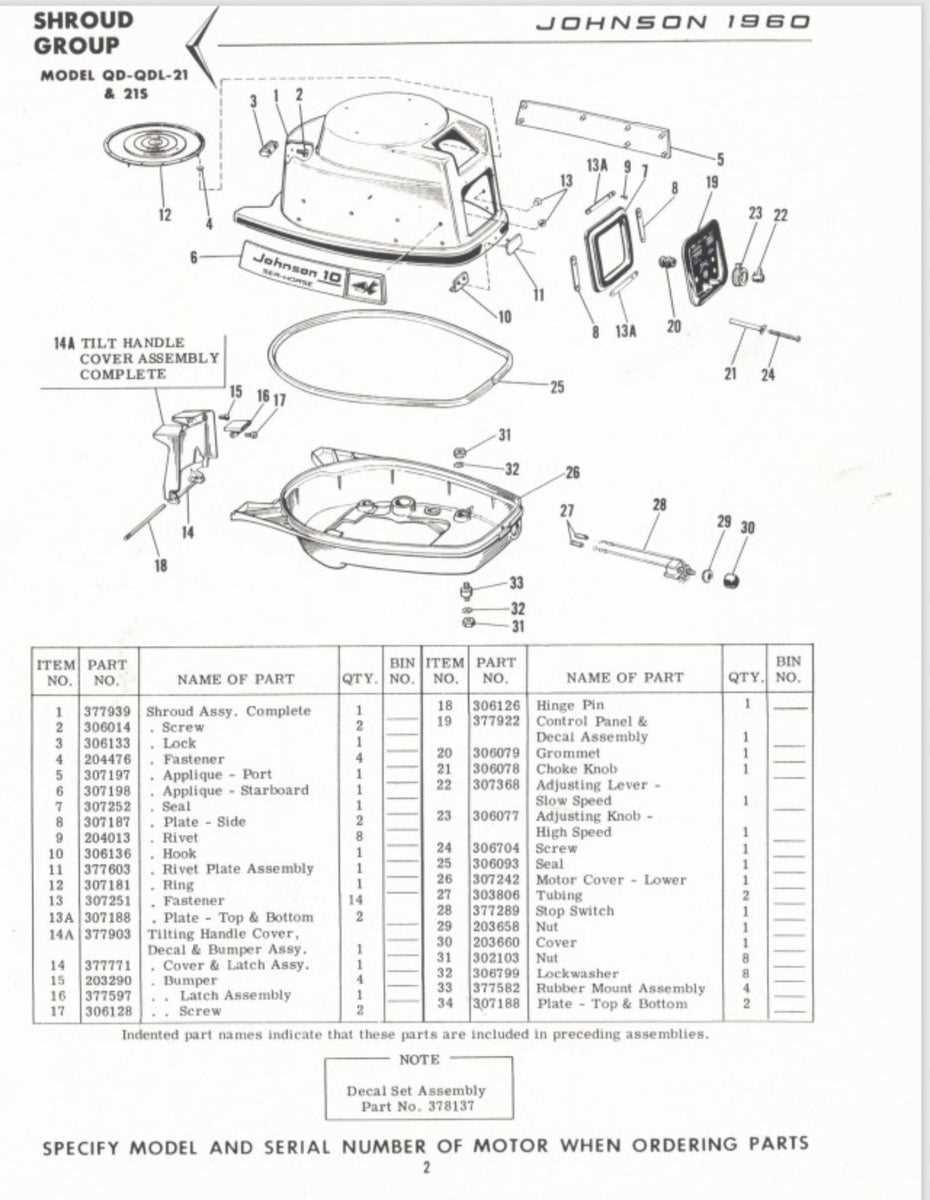

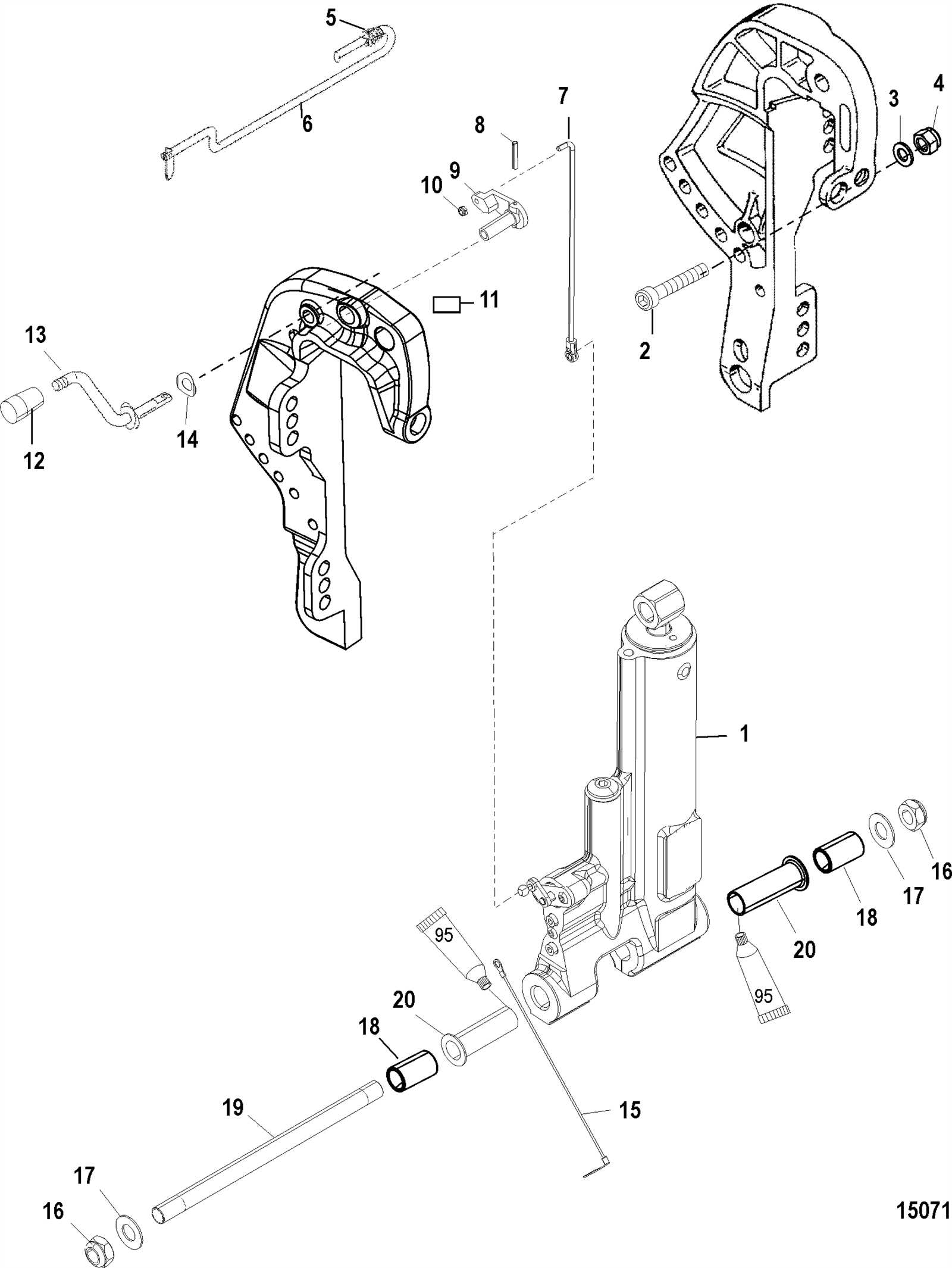

Mercury Tilt and Trim Components Overview

The system responsible for adjusting the angle and position of the outboard motor plays a crucial role in ensuring optimal performance and handling. Each component within this setup works together to deliver precise control and stability while navigating through various water conditions.

Key Elements of the Adjustment System

This assembly is made up of several critical elements that include actuators, pumps, and control units. These parts ensure that the engine can be repositioned with ease, allowing for enhanced maneuverability and comfort during operation.

Functionality of the System

The primary purpose of the mechanism is to facilitate smooth and accurate movement of the motor. Through a combination of hydraulics and electronic controls, this system adjusts the propulsion unit to suit different speeds and water conditions, optimizing performance and reducing wear.

Understanding the Function of Tilt and Trim

Optimizing the position of a boat’s propulsion system is crucial for enhancing its performance on the water. Adjusting the angle of the motor ensures smoother rides, better fuel efficiency, and improved control during navigation. This function allows boaters to adapt to changing water conditions, ensuring the vessel moves efficiently through various environments.

By fine-tuning the motor’s alignment, the boat can either rise to glide across the surface or settle into the water for more stability. These adjustments are key to achieving the best balance between speed, control, and comfort while operating a watercraft.

Key Parts in the Mercury System

Understanding the essential components of this advanced marine system is crucial for proper maintenance and functionality. Each element works in harmony to provide precise control and reliable performance in a marine environment.

The primary elements include a powerful motor, hydraulic mechanisms, and electronic controls, which ensure smooth adjustments and enhance the overall boating experience. These components interact seamlessly to deliver efficient handling, making navigation easier and safer.

By familiarizing yourself with these critical elements, you’ll be better equipped to manage the system and ensure it operates at peak efficiency.

How to Identify Key Hydraulic System Components

Understanding the essential elements of the hydraulic mechanism is crucial for effective maintenance and repairs. By recognizing the primary components, you can ensure optimal functionality and diagnose potential issues before they become major problems.

Key elements often include a motor, valves, and actuators, all working together to control the movement. It’s important to know how each part operates within the system to keep everything running smoothly. By focusing on the core elements, you’ll be able to perform targeted inspections and address specific needs efficiently.

Common Problems in Tilt Mechanisms

Various systems used for adjusting the angle of marine propulsion units can experience several operational issues over time. Understanding these challenges is key to maintaining the efficiency and longevity of the equipment.

Hydraulic Leaks

One of the frequent issues in these systems is hydraulic fluid leakage. It can cause slow or inconsistent movement, reducing overall performance. Regularly checking seals and connections helps prevent this problem.

Electrical Failures

Electrical malfunctions, such as faulty switches or wiring, can lead to difficulties in controlling the angle adjustments. Inspecting the electrical components for corrosion or damage is essential to ensure proper functionality.

Maintenance Tips for Trim Components

Proper upkeep of key adjustment mechanisms is essential for ensuring smooth performance and extending the lifespan of your system. Regular checks and preventive care help avoid costly repairs and maintain optimal functionality.

| Task | Frequency | Details | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lubrication | Every 3 months | Apply marine-grade grease to moving elements to prevent wear and ensure smooth motion. | ||||||||||||

| Inspection | Monthly | Visually examine all mechanical components for any signs of corrosion, cracks, or loose bolts. | ||||||||||||

| Cleaning | After each use | Rinse with fresh water and remove any debris to prevent build

Guide to Replacing Hydraulic Adjustment Systems

Replacing hydraulic lifting systems on marine engines requires careful attention to detail and precision. This process involves handling sensitive components that are crucial for the boat’s performance in various water conditions. In this guide, we will walk you through the steps to ensure that your marine engine’s lifting system is efficiently replaced and functions smoothly.

By following these steps, you can effectively replace your engine’s hydraulic system and maintain reliable performance on the water. Tools Needed for Mercury Trim RepairsTo successfully execute repairs on the hydraulic system, having the right tools is essential. A well-equipped toolkit can make the process smoother and more efficient, enabling you to tackle various tasks with ease. Here are the necessary instruments you will require:

Having these tools on hand will significantly facilitate the repair process, allowing you to complete tasks efficiently and effectively. Wiring Diagram for Mercury Trim SystemsThis section provides an overview of the electrical connections involved in the adjustment mechanisms for various marine propulsion units. Understanding the wiring layout is essential for troubleshooting and ensuring efficient operation. Proper connections enable seamless control and enhance the functionality of the lifting system. Key Components

Several crucial elements form the backbone of the electrical system. These include switches, relays, and connectors that facilitate communication between the control panel and the actuator. Each component plays a significant role in allowing the user to manage the elevation and positioning effectively. Connection Guide

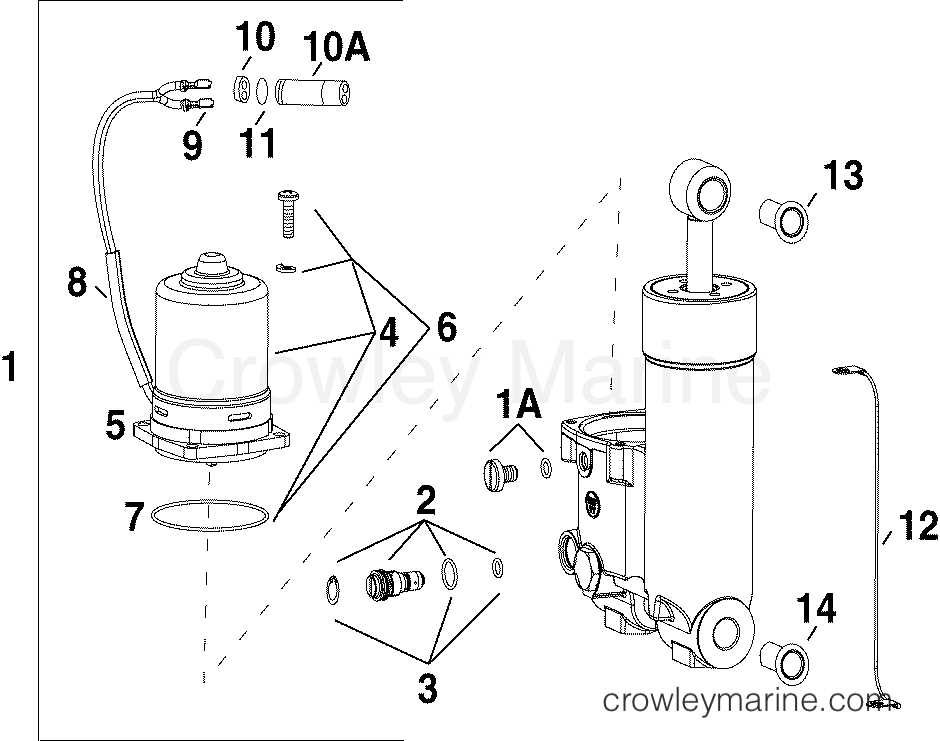

To achieve optimal performance, it is vital to follow the recommended wiring configurations. Each connection must be secure, and any corrosion should be addressed to maintain electrical integrity. Regular checks and maintenance of these connections can prevent operational issues and ensure longevity. Hydraulic Functionality in Mercury Tilt Systems

The hydraulic mechanisms employed in marine elevation systems play a crucial role in enhancing vessel performance and maneuverability. These systems utilize fluid dynamics to facilitate smooth movement and positioning of the outboard components. By harnessing the power of hydraulics, operators can achieve precise control over their equipment, allowing for improved efficiency during various water activities. Basic Principles of Hydraulic SystemsAt the core of these mechanisms lies the principle that liquids are incompressible, enabling them to transmit force effectively. When pressure is applied to the hydraulic fluid, it creates a force that can be directed to move different components. This efficiency allows for substantial lifting power without requiring excessive physical effort from the user. Components of Hydraulic Mechanisms

Key elements in hydraulic systems include pumps, cylinders, and valves, each serving a specific purpose. Pumps generate the necessary pressure to propel the fluid, while cylinders convert hydraulic energy into mechanical movement. Valves play a pivotal role in controlling the flow and direction of the fluid, ensuring that the entire system operates seamlessly. Together, these components create a reliable and effective system for managing elevation and positioning tasks. Compatibility of Mercury Trim Parts

When considering the integration of components within a marine propulsion system, it is crucial to ensure that all elements function harmoniously together. Understanding the interchangeability and functionality of various elements is essential for optimal performance and longevity. Different manufacturers may produce similar components designed to serve the same purpose. However, variations in specifications can affect compatibility. Below is a comparison of the compatibility among different component models:

How to Troubleshoot Trim Malfunctions

When experiencing issues with the lifting mechanism of your boat, it’s essential to identify the root cause to ensure smooth operation. Various factors can contribute to these problems, ranging from electrical faults to mechanical failures. This section provides guidance on how to systematically diagnose and resolve these issues, enhancing your vessel’s performance. Identify SymptomsBegin by observing any unusual behavior when attempting to adjust the lifting system. Common signs include slow response times, unusual noises, or complete inaction. Noting these symptoms can significantly aid in pinpointing the source of the malfunction. Check Electrical Connections

Electrical issues are often a primary cause of malfunctions. Inspect all wiring and connections for signs of wear, corrosion, or loose fittings. Ensure the power supply is stable and that the battery is charged. Addressing any electrical deficiencies is crucial for restoring proper function. |