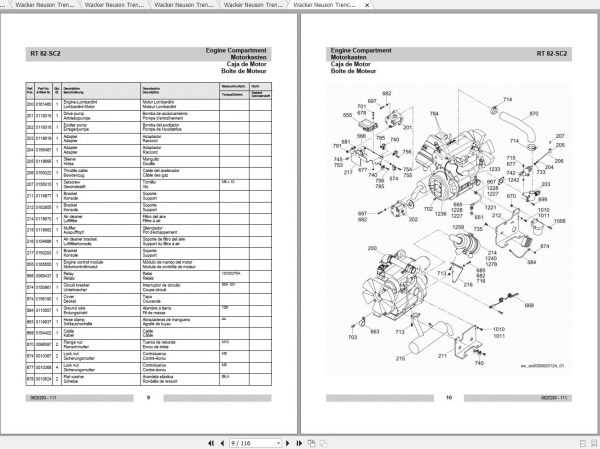

In the world of heavy machinery, a clear representation of individual elements is essential for effective maintenance and operation. Whether for repairs or upgrades, having access to a comprehensive layout of each component is crucial for technicians and operators alike. This overview serves as a valuable resource for anyone looking to enhance their understanding of the inner workings of specific machinery.

By familiarizing oneself with the intricate arrangement of mechanical parts, users can more efficiently identify issues and implement solutions. A well-structured guide enables a deeper appreciation for the equipment’s design and functionality. This knowledge not only aids in troubleshooting but also contributes to extending the lifespan of the machine through informed care and timely interventions.

Equipped with this insight, operators can confidently navigate through the complexities of maintenance tasks, ensuring that each component is properly assessed and attended to. This approach ultimately leads to improved performance and reliability in the field, making it an invaluable asset for anyone involved in the industry.

Regular upkeep is essential for ensuring the longevity and efficiency of any equipment. By following a few simple practices, you can prevent common issues and maintain smooth operation over time.

| Maintenance Task | Recommended Frequency | Details |

|---|---|---|

| Engine Oil Check | Before every use | Ensure the oil level is within the safe range and change it periodically based on usage. |

| Filter Cleaning | Every 50 hours | Clean air and fuel filters to maintain optimal performance and fuel efficiency. |

| Hose Inspection | Every 100 hours | Check for wear or leaks in the hoses, as these can affect operation and cause damage. |

| Fuel System Maintenance | Every 200 hours | Drain any accumulated water and clean the fuel tank to avoid contamination issues. |

Finding Genuine Parts Suppliers

Locating reliable suppliers for essential components is crucial for ensuring the longevity and performance of machinery. Whether dealing with routine maintenance or unexpected repairs, securing authentic items can make all the difference in keeping equipment running smoothly.

Trusted Sources for Quality Components

One of the most effective ways to find trustworthy providers is by checking reviews and recommendations from other users. Opt for suppliers that specialize in your type of equipment, as they are more likely to offer original replacements. Avoid unofficial distributors who may provide inferior alternatives.

Ensuring Authenticity

To guarantee that the items you purchase are genuine, always verify the credentials of the supplier. Look for those who have established a solid reputation and offer warranties or certificates of authenticity. This extra step can prevent issues with compatibility and long-term reliability.

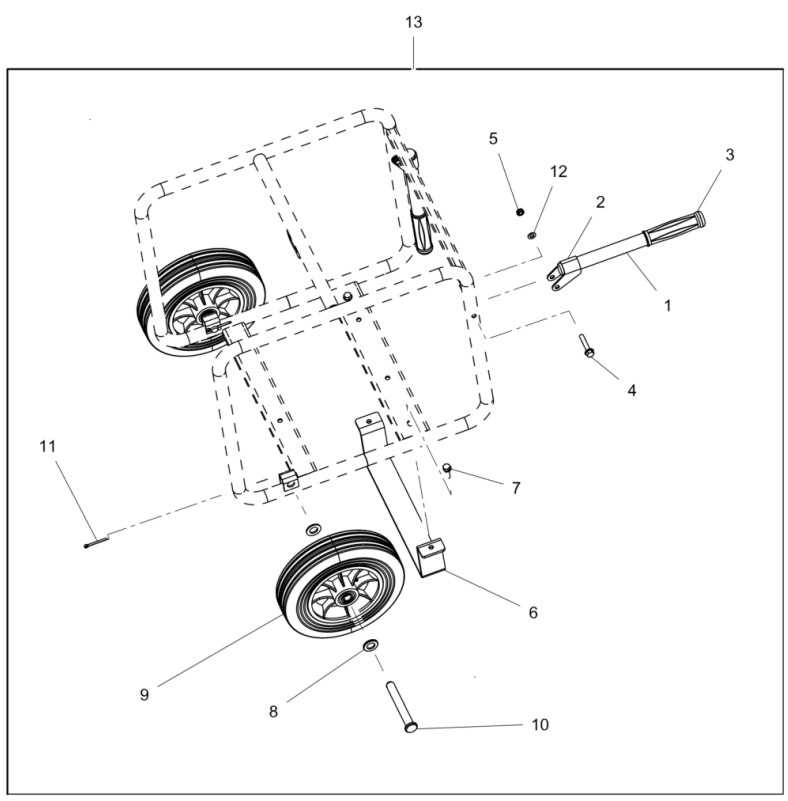

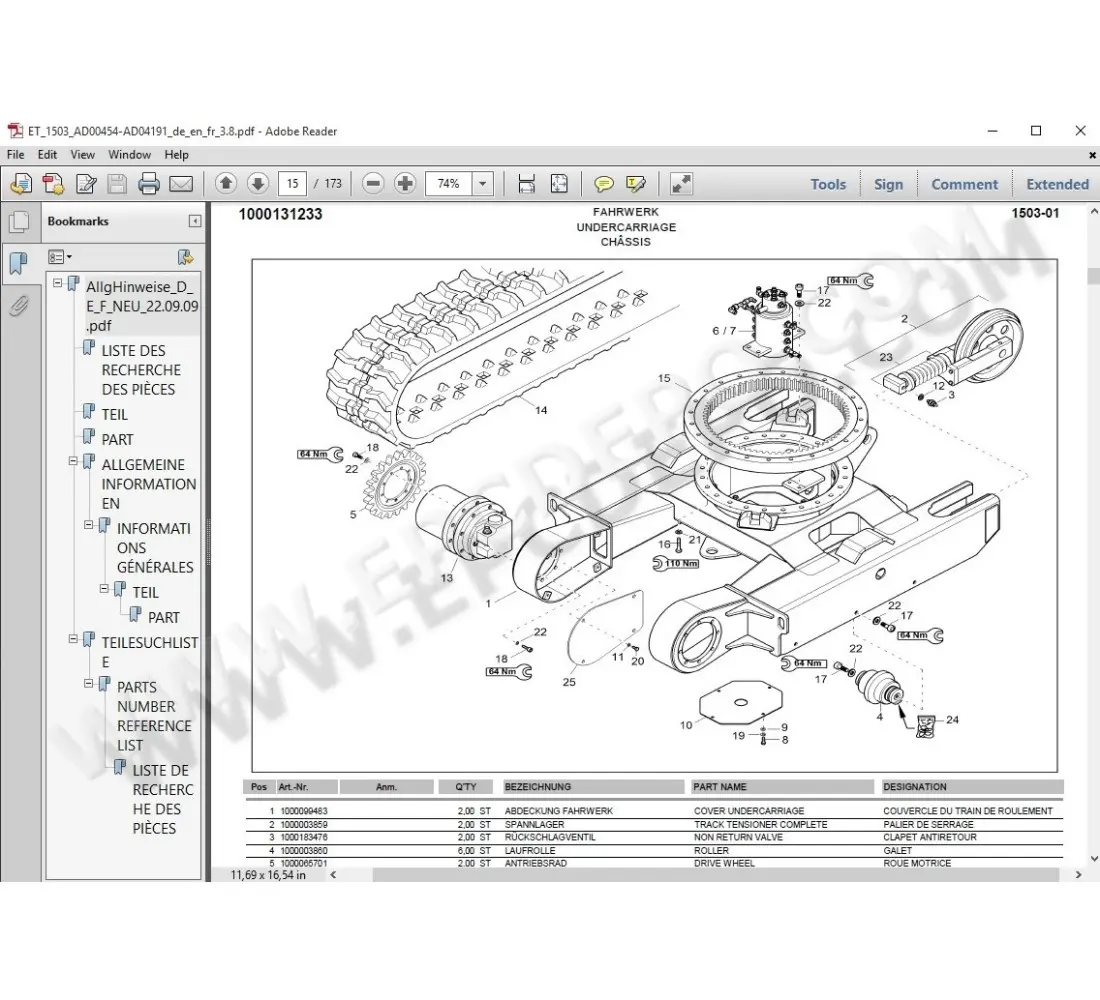

Understanding Part Numbers

Identifying equipment components can be simplified by familiarizing yourself with the numbering system used for individual items. Each item is typically assigned a unique identifier, which helps in distinguishing similar-looking pieces and ensures compatibility during maintenance or replacement.

This numbering system often follows a structured format, where different sections of the identifier provide specific information about the component, such as its type, size, or function. Knowing how to interpret these numbers can significantly reduce confusion and ensure you select the correct item for your needs.

By mastering this, you can streamline the ordering process, avoid delays, and maintain the efficiency of your machinery or tools. Understanding these identifiers is essential for anyone involved in the upkeep or repair of technical equipment.

Assembly Instructions for Components

Proper assembly of components is essential for ensuring the longevity and functionality of the equipment. This section provides a detailed guide on how to correctly assemble the key elements to ensure optimal performance. Attention to detail during assembly will help prevent future issues and ensure the equipment operates smoothly.

Preparation and Tools

Before starting the assembly, gather all necessary tools and hardware. It’s important to have the right equipment on hand to avoid damaging any components. Make sure each part is clean and free of debris to ensure proper connections. Having a clean workspace will also assist in avoiding any mishaps during the process.

Step-by-Step Assembly Process

Begin by organizing the parts in the order they will be assembled. Start with the foundation components and work your way up to more intricate parts. Ensure each component is securely attached before proceeding to the next step. Tighten all bolts and fasteners to the recommended torque specifications to avoid any loosening during operation. Double-check the alignment of all connected elements before completing the assembly.

Frequently Asked Questions

This section addresses common inquiries regarding equipment maintenance, troubleshooting, and operational procedures. The answers provided below aim to clarify various aspects and help users optimize the use of their machinery.

What should I do if my machine isn’t starting?

- Check the fuel level and ensure it is filled with the correct type of fuel.

- Inspect the spark plug for wear or dirt, and clean or replace it as necessary.

- Verify that all cables and connections are secure and undamaged.

How can I improve the efficiency of my equipment?

- Regularly service the engine by changing the oil and air filter according to the manufacturer’s schedule.

- Ensure that all moving parts are properly lubricated to reduce friction and wear.

- Clean the machine after each use to prevent buildup that could affect performance.

Resources for Further Information

For those looking to expand their understanding of equipment maintenance and technical specifications, a variety of reliable sources are available. Whether you are a professional or a newcomer to handling machinery, finding detailed manuals, instructional guides, and user forums can greatly enhance your knowledge.

Technical Manuals and Guides

Many manufacturers and industry experts provide downloadable manuals and guides online, offering step-by-step instructions for handling, repairing, and maintaining machinery. These resources are invaluable for gaining deeper insights into specific mechanical functions and troubleshooting techniques.

Online Communities and Forums

Engaging in discussions with experienced professionals through online forums can also provide practical advice. These communities often share tips, solutions to common problems, and recommendations for better performance. Additionally, video tutorials and instructional posts on specialized platforms can serve as a visual aid for those seeking hands-on guidance.

Customer Reviews and Experiences

Users often share their thoughts and feedback after using a product over time. These reviews can be extremely helpful for prospective buyers, offering real-world insights and highlighting key strengths and areas for improvement. Whether it’s the durability, ease of use, or overall performance, customer experiences give a better understanding of what to expect.

Positive Feedback

- Many customers appreciate the reliability and consistent performance, which has proven useful in various demanding tasks.

- Users often highlight how intuitive the operation is, even for those with limited technical knowledge.

- Another common point of praise is the machine’s efficiency, saving both time and effort during extended use.

Challenges and Areas for Improvement

- Some users mention that while the product performs well, occasional maintenance is required to ensure optimal functionality.

- There are also comments about the need for more detailed instructions, particularly for first-time users.

- A few reviews suggest minor adjustments could enhance its usability in specific environments.