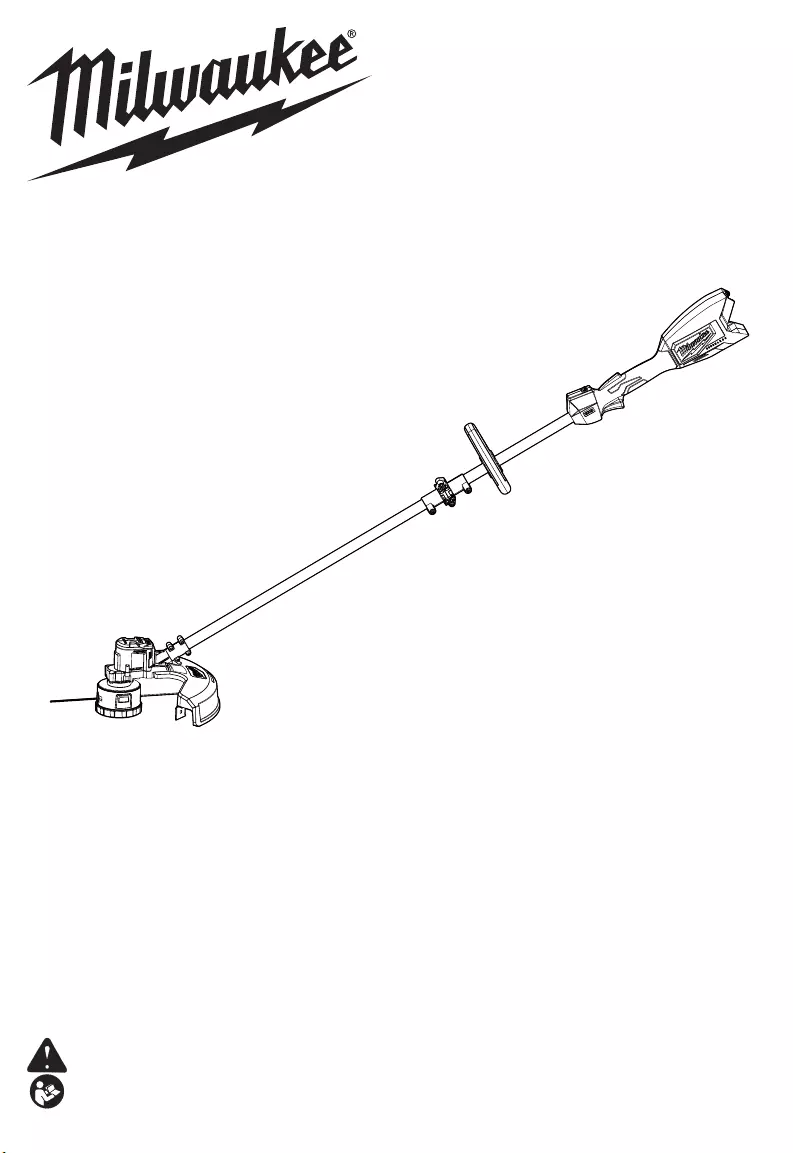

When it comes to maintaining a well-kept outdoor space, few tools are as effective as those designed for precision trimming. These devices ensure clean and smooth results, cutting through various types of vegetation with ease. Whether you’re dealing with a small backyard or a larger landscape, having the right equipment makes all the difference in achieving professional-grade results.

Understanding how each part of these machines functions is crucial for proper maintenance and repair. The mechanism of such tools involves multiple elements working together, from the cutting head to the drive system. Each component plays a specific role in delivering the power and efficiency required for effective performance.

In this section, we will delve into the various elements that make up these machines, highlighting their importance and how they contribute to the overall functionality of the tool. Whether you’re looking to replace a worn-out piece or simply gain a better understanding of how it all works, this guide will provide essential insights into the components you rely on for optimal performance.

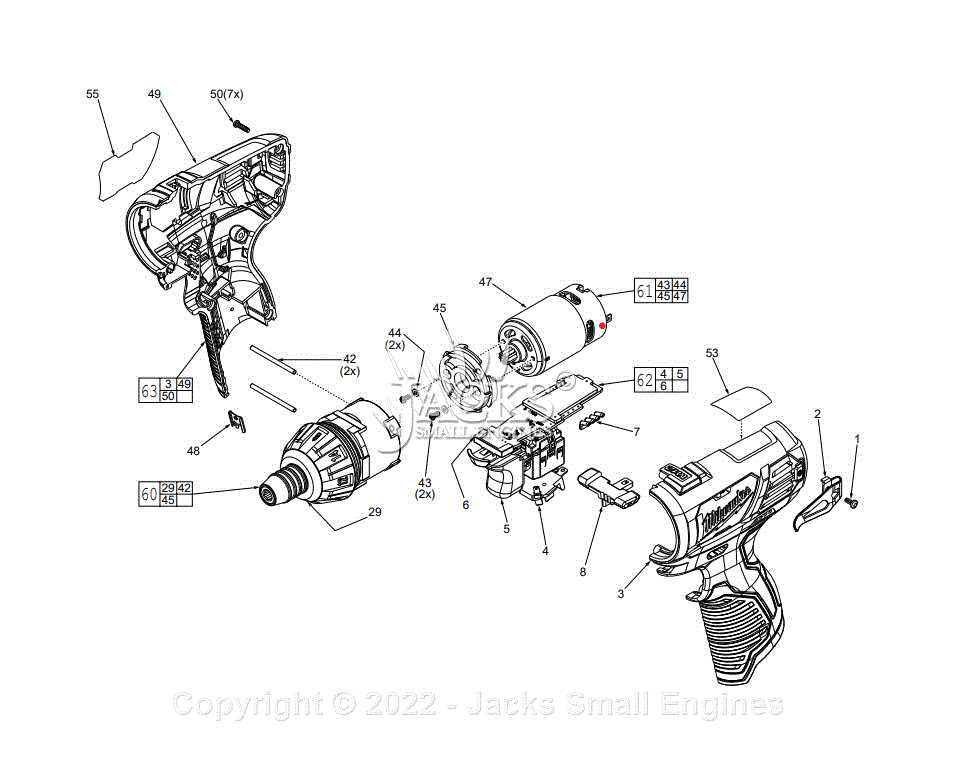

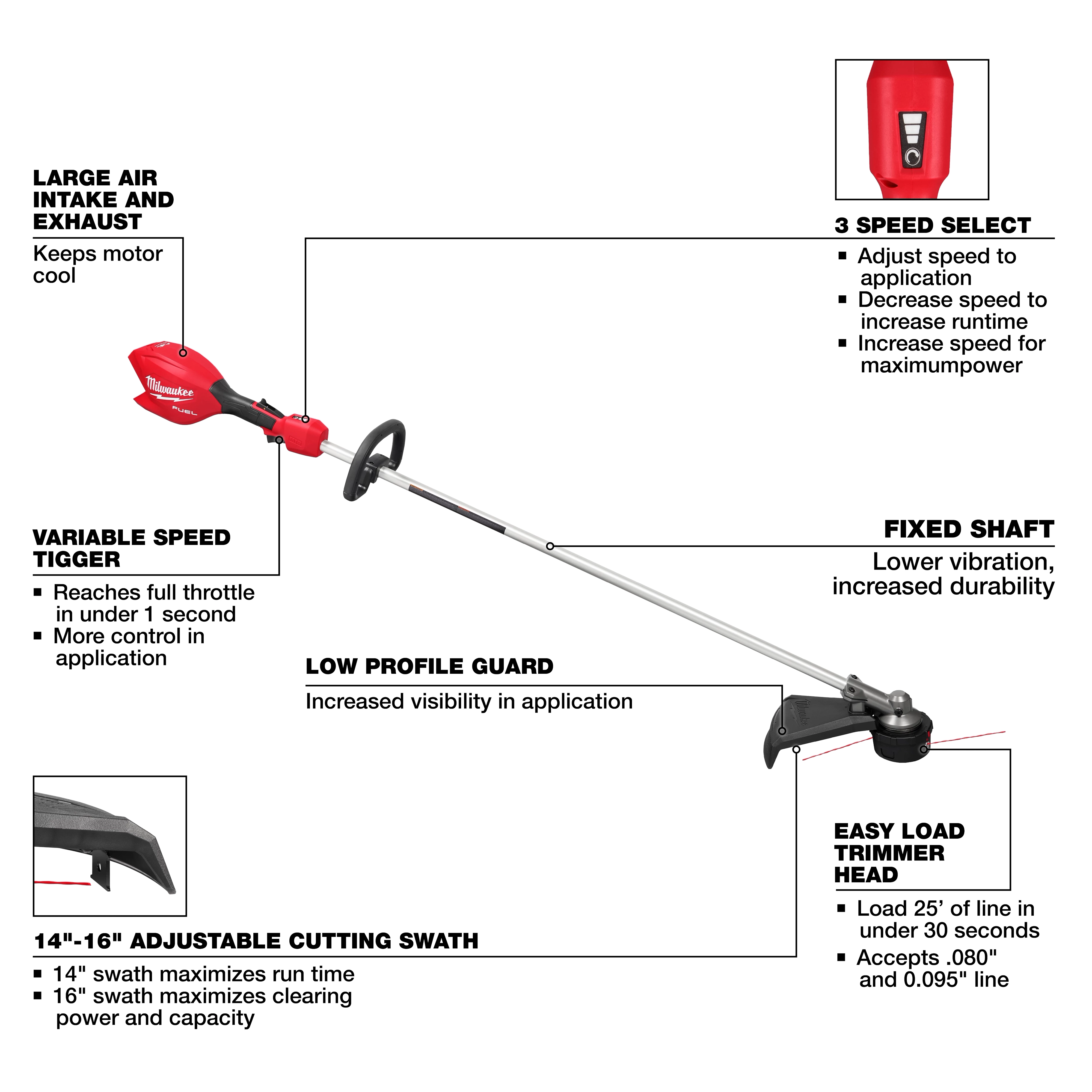

Components Breakdown of Cordless Trimmer

Understanding the different elements that make up a battery-powered grass trimmer is essential for efficient maintenance and repair. Each component works in harmony to ensure the device operates smoothly, delivering optimal performance. In this section, we’ll explore the key parts that allow this tool to trim grass and weeds effectively.

Power Source: The energy source typically involves a rechargeable battery that powers the motor, ensuring uninterrupted performance. Keeping the battery charged and well-maintained is critical for consistent operation.

Motor: The heart of the device, the motor, converts electrical energy from the battery into mechanical force. This component drives the cutting head, making it vital for smooth trimming.

Cutting Head: The cutting head houses the line or blade that actually cuts through vegetation. It’s crucial to regularly inspect and replace worn-out parts here to maintain sharp and efficient cutting.

Shaft: Connecting the handle and the cutting head, the shaft

Main Structure and Frame Assembly

The main structure and frame assembly serve as the foundation of the entire machine. This section is critical for providing stability and support, ensuring that all components are securely connected and function efficiently. It forms the backbone of the tool, allowing for proper alignment and optimal performance during use.

Frame components include several interconnected elements that contribute to the overall durability and balance of the device. Each part is engineered to withstand operational stress, providing both flexibility and strength for various tasks. The assembly ensures smooth operation, reducing vibrations and enhancing user comfort.

Proper alignment of the structural components is essential to maintain efficiency and prolong the life of the equipment. Regular inspections of the frame and its key elements help ensure that the device remains in top working condition.

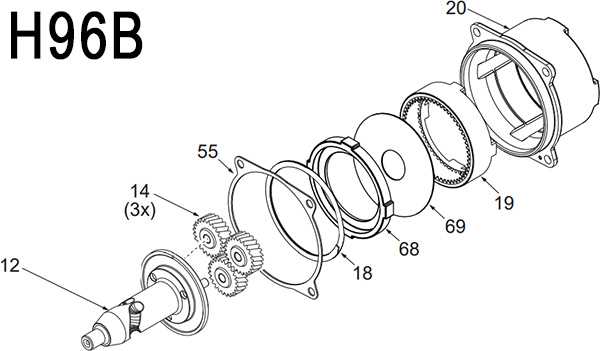

Drive Shaft and Transmission System

The drive shaft and transmission system play a crucial role in ensuring the efficient transfer of power from the motor to the cutting mechanism. This assembly is responsible for translating the rotational force into mechanical motion, allowing the machine to operate smoothly and perform cutting tasks with precision.

Structure and Components

The drive shaft is typically a long, rigid rod that connects the motor to the cutting head. It is designed to withstand significant torsional stress while transmitting force without losing efficiency. The transmission system, on the other hand, includes various gears and linkages that help in modifying the speed and torque to match the cutting needs.

Functionality and Maintenance

Both the drive shaft and transmission system must be well-maintained to ensure optimal performance. Regular inspection of these components for wear, alignment, and lubrication is essential. Proper

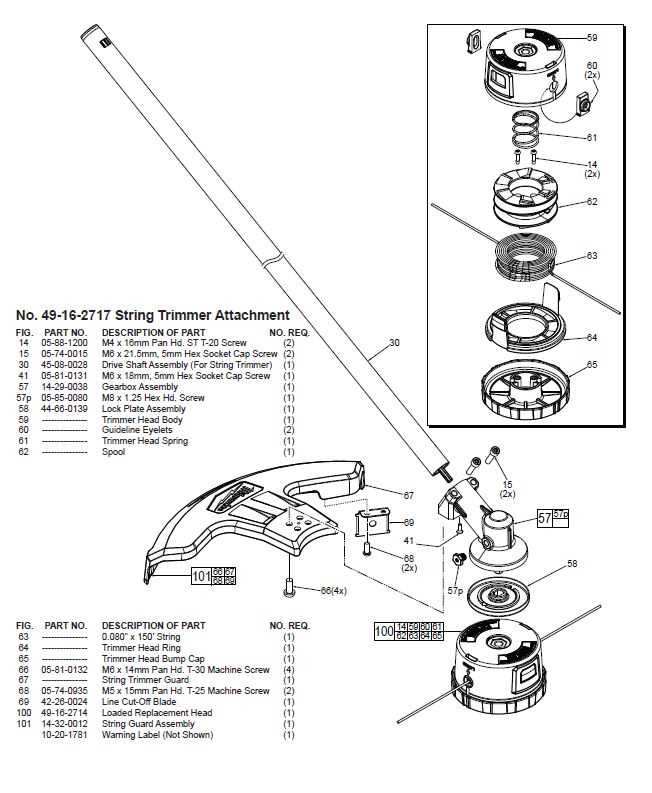

Cutting Head and Blade Parts

The cutting mechanism of any trimmer plays a crucial role in ensuring precise and efficient trimming. Understanding how the different components of the cutting head and blades function together can help maintain the tool’s effectiveness and extend its lifespan. This section covers the main elements involved in the cutting process, detailing their roles and the importance of keeping them in optimal condition.

The cutting head consists of several vital components, including the housing, blade attachment points, and safety mechanisms that protect both the user and the equipment. Proper alignment and secure attachment of these parts are essential to avoid malfunctions during operation. Regular inspection and maintenance of these elements ensure smooth functionality and prevent wear.

The blades are the most crucial part of the trimming process, responsible for cutting through vegetation with ease. Sharpness and material quality are key factors in their performance. Dull or damaged blades can reduce cutting efficiency and strain the motor, leading to potential breakdowns. Replacing or sharpening the blades as needed ensures consistent and clean cuts, preserving both the machine’s performance and the quality of the trim.

Handlebar and Grip Adjustments

Proper handlebar and grip positioning plays a crucial role in ensuring comfort and control during use. Adjusting these components not only improves ergonomics but also helps to reduce fatigue and strain during longer tasks. Regular checks and minor tweaks can significantly enhance the overall experience and ensure smooth operation.

Adjusting the Handlebar Height

To ensure maximum comfort, the handlebar height should be tailored to the operator’s preference. Adjusting it correctly can prevent back strain and provide better leverage during operation. Follow these steps to adjust the handlebar height:

- Loosen the locking mechanism located at the base of the handlebar.

- Raise or lower the handlebar to the desired height.

- Tighten the locking mechanism securely to prevent movement during use.

Grip Positioning and Comfort

Equally important to handlebar adjustments is ensuring that the grips are positioned correctly for optimal comfort. Poorly positioned grips can cause wrist discomfort and reduce control. Consider these tips for adjusting the grips:

- Ensure the grips are aligned in a way that supports a natural wrist position.

- If necessary, rotate the grips slightly to better fit your hand’s grip.

- Check that the grips are firmly secured and

Battery Connection and Power Supply

Understanding the relationship between the energy source and the device is crucial for ensuring optimal performance and longevity. A well-established connection between the power unit and the machinery plays a significant role in delivering the necessary energy for operation. Proper management of this connection contributes to efficient functionality, preventing interruptions during use.

Establishing a secure link between the battery and the device is essential for effective power transmission. Regular inspection of the terminals and connections can help prevent potential issues related to corrosion or looseness. Ensuring that the contacts are clean and free from debris will enhance the reliability of the power supply.

Moreover, selecting the right type of battery is vital. Compatibility between the power source and the equipment guarantees that the machine operates as intended. Users should consider the voltage and capacity specifications outlined by the manufacturer, as these factors significantly influence the overall efficiency of the device.

In addition to the connection quality, proper charging practices are equally important. Using the correct charger and adhering to recommended charging times can prevent battery damage and extend its lifespan. It is advisable to monitor the charging cycle to avoid overcharging, which can lead to overheating and reduced performance.

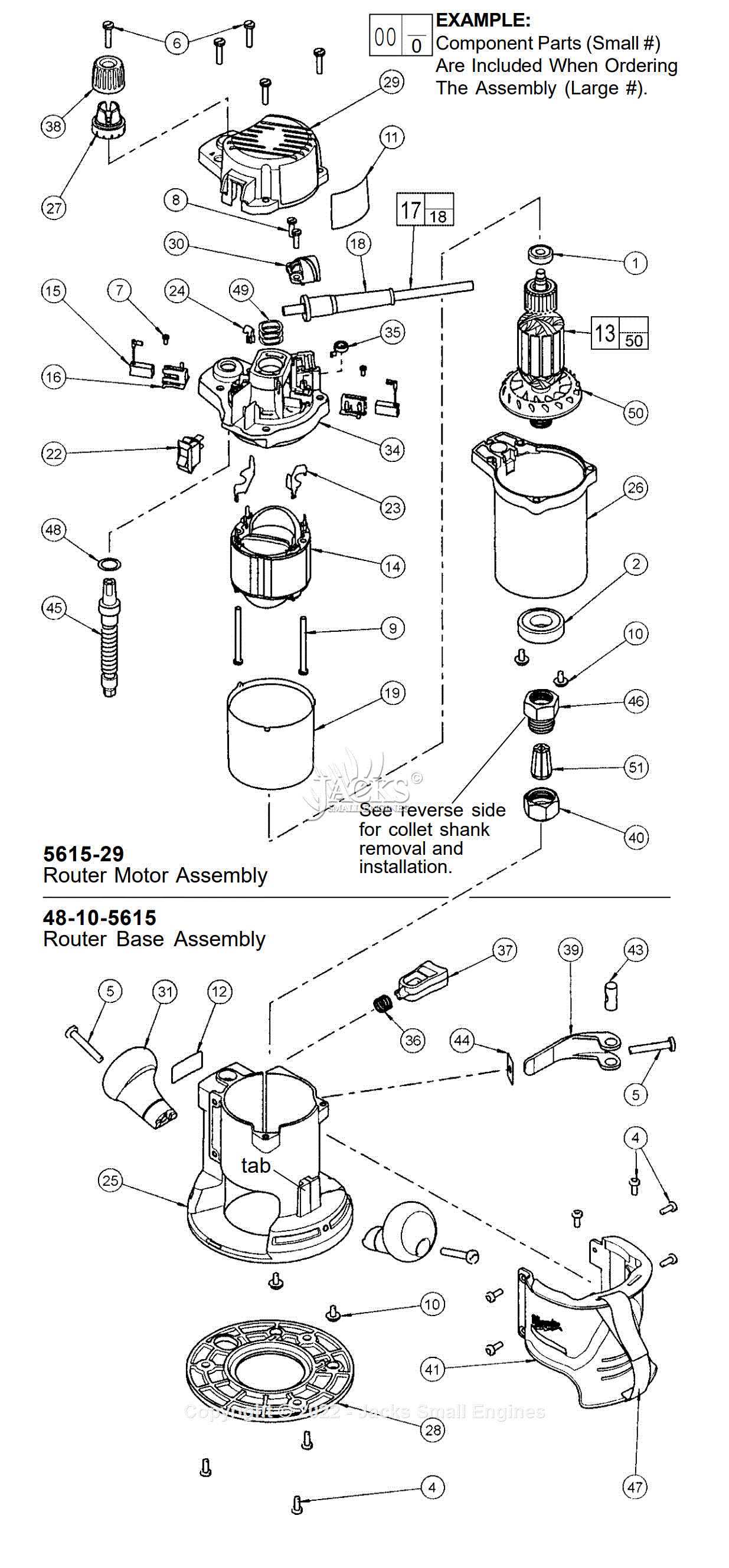

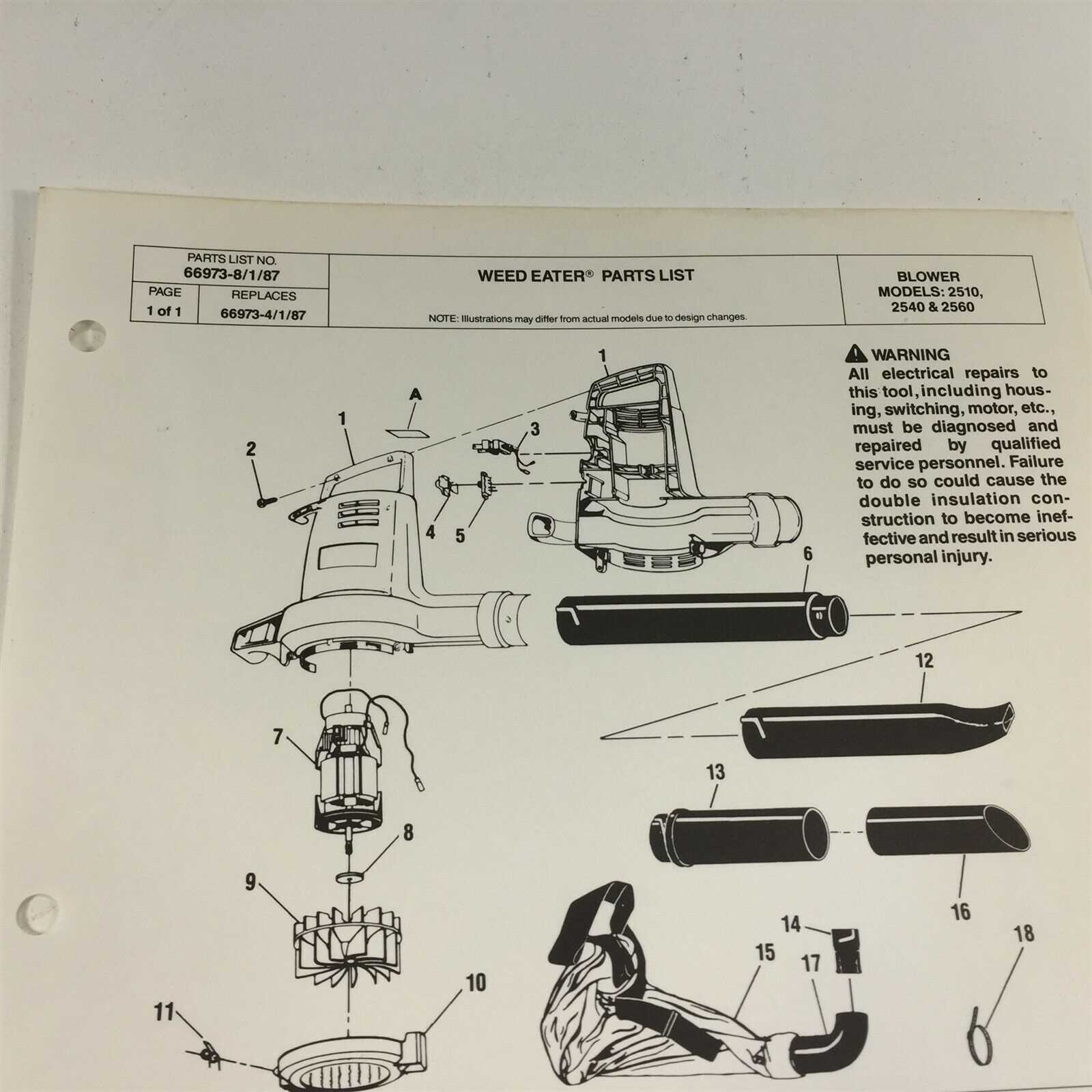

Motor Housing and Internal Mechanics

The motor housing serves as a critical component in the functionality of cutting tools, providing protection and structural integrity to the internal mechanisms. This assembly houses essential elements that contribute to the efficient operation of the device, ensuring that power is effectively transferred to the cutting mechanism. Understanding the design and components within the housing can enhance maintenance and repair practices, prolonging the life of the equipment.

Structure and Functionality

The housing is typically constructed from durable materials, designed to withstand the stresses of operation. It encases the motor and other internal components, safeguarding them from debris and external damage. Additionally, it plays a vital role in heat dissipation, allowing the motor to operate optimally without overheating. The internal layout often includes features that facilitate the alignment of the motor shaft with the cutting elements, ensuring efficient power transfer.

Maintenance Considerations

Trimmer Line Feeding Mechanism

The line feeding system in cutting tools is essential for maintaining efficiency during operation. This mechanism ensures that the cutting line is delivered smoothly and consistently, allowing for effective trimming and edging. Understanding how this system functions can help users optimize their tool’s performance and extend its lifespan.

Typically, there are several key components involved in the line feeding process:

- Spool: The spool holds the cutting line and allows it to unwind as needed.

- Feed Mechanism: This component automatically advances the line when it becomes worn, ensuring a fresh cutting edge.

- Line: The cutting line itself, which can vary in thickness and material, affects cutting performance.

- Guard: The protective shield helps keep debris contained and directs the line for optimal cutting angles.

In many models, the line feeding can be controlled manually or automatically, depending on the design and user preference. Manual systems often require the operator to tap the tool against the ground to release more line, while automatic systems advance the line as it wears down, providing a more seamless experience.

Proper maintenance of the feeding mechanism is crucial. Regularly checking the spool for wear, ensuring the line is correctly loaded, and cleaning the guard can prevent common issues such as line jamming or inefficient feeding. By understanding these aspects, users can enhance their trimming experience significantly.

Safety Guard and Protective Cover

The safety guard and protective cover are essential components designed to ensure the safe operation of trimming equipment. These elements provide a barrier that minimizes the risk of injury by deflecting debris and protecting the user from potential hazards. Properly functioning guards enhance the overall safety of the machine, allowing users to focus on their task without undue concern for their well-being.

Component Description Function Safety Guard A sturdy shield that surrounds the cutting area. Prevents debris from flying towards the operator. Protective Cover A protective layer that encases sensitive components. Safeguards internal parts from dust and moisture. Throttle Control and Trigger System

The throttle control and trigger mechanism play a crucial role in the operation of outdoor power equipment. These components allow the user to regulate the engine’s speed and power output effectively. A well-functioning system ensures optimal performance and enhances user experience during operation.

Functionality Overview

The throttle control is designed to modulate the airflow into the engine, directly influencing the speed of the motor. When the trigger is activated, it adjusts the throttle valve, allowing more air and fuel to enter the combustion chamber. This process is essential for achieving the desired power level while maintaining efficiency.

Components Involved

Several key components make up the throttle control and trigger system. Understanding these parts is essential for troubleshooting and maintenance.

Component Description Throttle Trigger The lever activated by the user to control engine speed. Throttle Cable A flexible cable that connects the trigger to the throttle valve. Throttle Valve Regulates the flow of air and fuel into the engine. Return Spring Provides resistance, ensuring the throttle returns to idle position when released. Replacement Accessories and Attachments

Having the right supplementary components can significantly enhance the performance and versatility of your gardening equipment. Various options are available that allow users to tailor their tools to better suit their specific landscaping needs. Understanding these accessories is essential for maintaining optimal functionality and efficiency.

Types of Accessories

Several types of attachments can improve the usability of your equipment. These may include specialized blades, line spools, and protective gear. Each accessory serves a distinct purpose, ensuring that the tool performs effectively across different tasks.

Compatibility Considerations

When selecting accessories, it is crucial to consider compatibility with your existing equipment. Not all attachments are universally suitable, so verifying the specifications is necessary to ensure proper fit and function.

Accessory Type Description Use Case Replacement Blades Durable blades designed for cutting through thick grass and weeds. Ideal for heavy-duty clearing tasks. Spool Replacements Pre-wound spools of line for easy reloading. Perfect for maintaining consistent cutting performance. Safety Gear Includes gloves, goggles, and protective clothing. Essential for ensuring user safety during operation. Troubleshooting Common Wear and Tear Issues

As with any mechanical tool, regular usage can lead to various challenges and deterioration. Identifying and addressing these issues promptly can enhance the lifespan of your equipment and ensure optimal performance. This section outlines common problems and effective solutions for maintenance and repair.

Identifying Common Issues

- Decreased Performance: If the tool is not functioning as efficiently as before, it may indicate wear in critical components.

- Unusual Noises: Strange sounds during operation can signal internal damage or loose parts.

- Difficulty Starting: Issues with ignition or fuel flow can result in challenges when attempting to power the tool.

Recommended Solutions

- Inspect Components: Regularly check key parts for signs of wear or damage, such as cracks or corrosion.

- Replace Worn Parts: If any components are found to be compromised, consider replacing them to restore functionality.

- Perform Routine Maintenance: Cleaning and lubricating moving parts can prevent buildup and reduce wear over time.