When it comes to navigating rugged landscapes, a reliable all-terrain vehicle is essential. Understanding the various elements that make up such a machine is crucial for both maintenance and performance. From the engine assembly to the suspension system, each component plays a significant role in ensuring a smooth ride and optimal functionality.

For enthusiasts and owners alike, having access to a detailed representation of these components can facilitate repairs and upgrades. This overview allows individuals to familiarize themselves with the intricacies of their vehicle’s build, enabling informed decisions when addressing issues or considering enhancements. Whether you’re looking to troubleshoot or simply gain a deeper understanding of your machine, exploring the layout of its internal structures is invaluable.

By delving into the specifics of these configurations, users can enhance their knowledge and skills, leading to improved vehicle performance and longevity. A well-informed operator can make the most out of their all-terrain experience, ensuring that every adventure is met with confidence and readiness.

Understanding the fundamental elements of an all-terrain vehicle is crucial for both maintenance and performance. These components work in harmony to ensure the vehicle operates efficiently in various terrains. Below are some of the key parts that contribute to the functionality and durability of these machines.

- Engine: The heart of the vehicle, providing the necessary power for movement.

- Transmission: This system transfers power from the engine to the wheels, allowing for speed adjustments and improved control.

- Suspension: Essential for handling rough terrain, the suspension absorbs shocks and enhances ride comfort.

- Brakes: Critical for safety, these components help slow down or stop the vehicle effectively.

- Wheels and Tires: Designed for traction and stability, they enable the vehicle to navigate various surfaces.

- Frame: The structural foundation that supports all other components, ensuring durability and stability.

- Electrical System: Powers lights, gauges, and other electronic accessories, contributing to overall functionality.

- Exhaust System: Responsible for directing exhaust gases away from the engine and reducing noise pollution.

Each of these components plays a vital role in the overall performance and safety of the vehicle, making it essential for owners to be familiar with their functions and maintenance requirements.

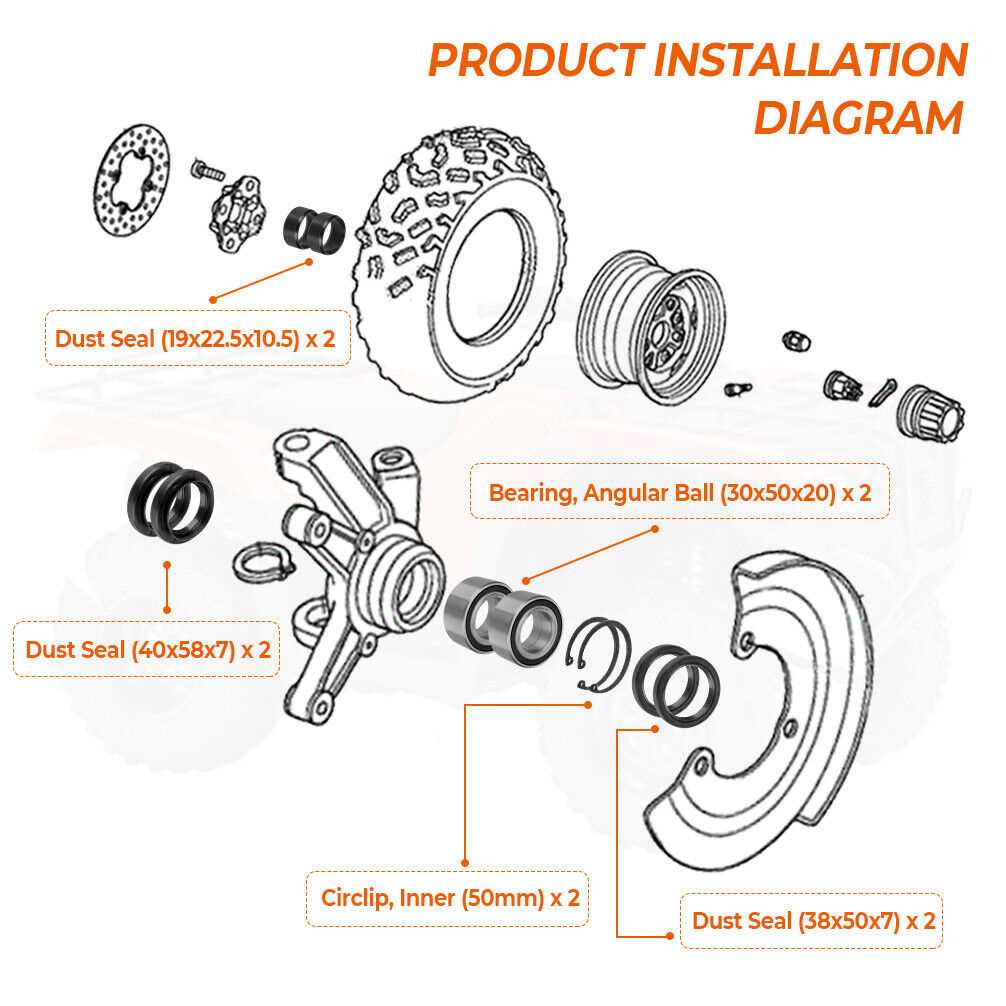

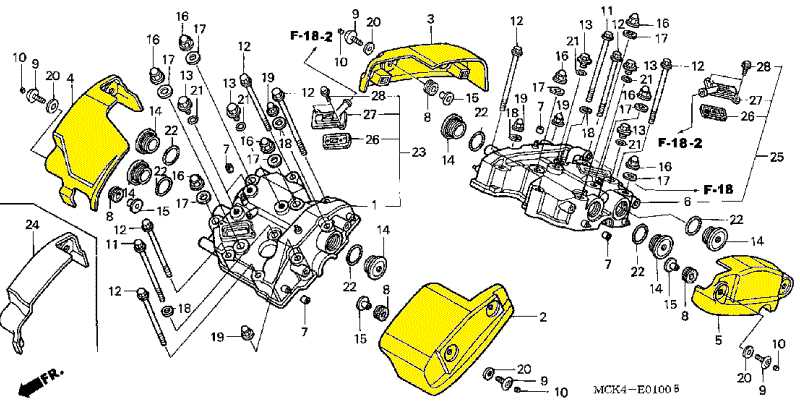

Understanding the Parts Diagram

This section delves into the visual representation of components, illustrating the intricate relationships between various elements within the machine. By grasping this schematic, one can gain insights into assembly, maintenance, and troubleshooting, enhancing the overall experience of working with the equipment.

Importance of a Schematic Representation

A visual guide serves as a crucial tool for identifying each element’s position and function. Understanding this layout can simplify the repair process and ensure that all components are correctly aligned. It also aids in recognizing potential wear and tear, facilitating proactive maintenance.

Common Components Illustrated

Several key components are typically highlighted in such visuals, each playing a vital role in the overall functionality. Below is a table summarizing some of these essential parts:

| Component Name | Function |

|---|---|

| Engine | Power source for the vehicle, converting fuel into motion. |

| Transmission | Transfers power from the engine to the wheels, enabling movement. |

| Braking System | Ensures safe stopping and control of the machine. |

| Suspension | Provides stability and comfort by absorbing shocks from the terrain. |

Key Features of 2000 Model

This model is designed to offer a perfect blend of performance and reliability, making it a popular choice among enthusiasts. Its robust construction and advanced engineering contribute to an exceptional riding experience, suitable for various terrains and conditions.

One of the standout characteristics is the efficient engine, delivering impressive torque and acceleration. The smooth transmission enhances control and responsiveness, ensuring that riders can navigate obstacles with ease. Additionally, the suspension system is crafted to provide excellent shock absorption, allowing for comfortable rides even on rugged paths.

Durability is another hallmark of this model, with high-quality materials used throughout its design. This ensures longevity and minimal maintenance needs, making it an economical choice for owners. The intuitive layout of controls also adds to user-friendliness, catering to both novice and experienced riders alike.

Commonly Replaced Parts

Over time, any utility vehicle can experience wear and tear, leading to the need for replacing various components to ensure optimal performance. Regular maintenance and proactive care can help extend the lifespan of these components, but some are more prone to damage or deterioration than others. This section will highlight the key components that often need attention and replacement due to frequent use or environmental factors.

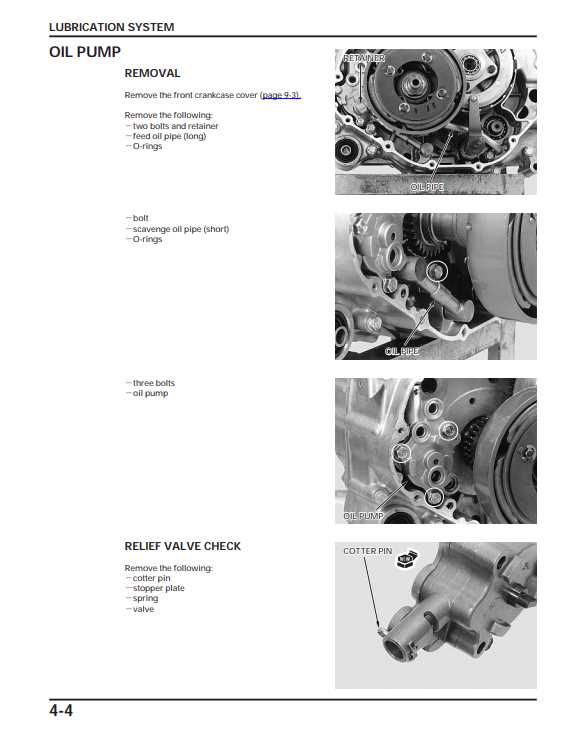

Engine and Transmission Components

The engine is one of the most vital areas where issues can arise due to regular operation. Items like spark plugs, filters, and gaskets frequently wear out and require periodic inspection and replacement. Additionally, transmission elements such as clutches and drive belts are commonly affected, especially when used in rugged conditions.

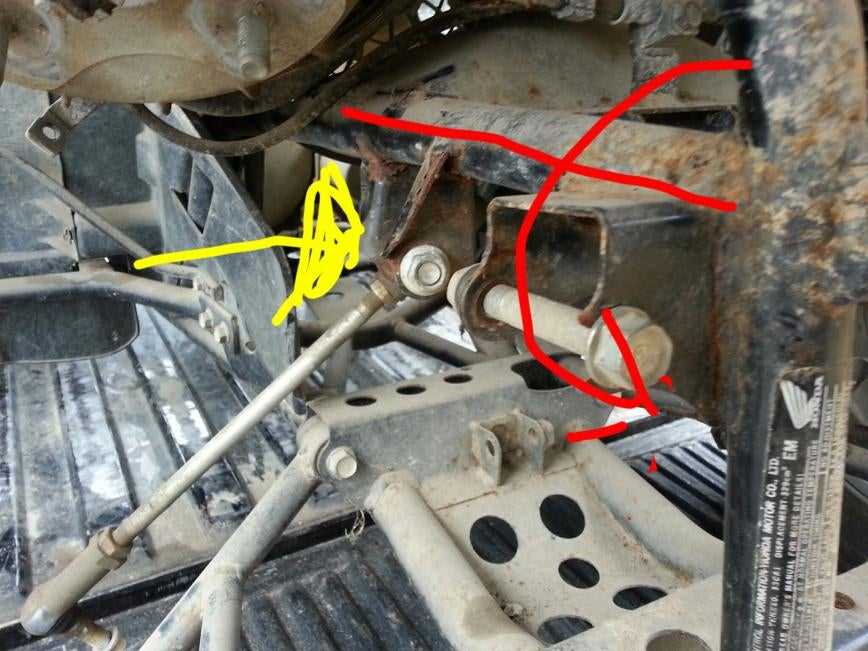

Suspension and Braking System

The suspension and braking systems are essential for a smooth and safe ride. Key elements like shock absorbers, bushings, and brake pads tend to wear down with continuous use, especially in

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your all-terrain vehicle requires consistent upkeep and attention to detail. By following a regular maintenance schedule and addressing potential issues early, you can significantly extend the life of your vehicle and avoid costly repairs down the road.

- Regular Fluid Checks: Keep an eye on essential fluids like engine oil, coolant, and brake fluid. Consistent monitoring and timely replacements prevent internal damage and overheating.

- Air Filter Cleaning: Ensure that the air filter is clean to maximize engine efficiency and reduce the intake of dust and debris, which can hinder performance.

- Tire Inspection: Check tire pressure and tread regularly to maintain grip and safety on various terrains. Proper tire care also helps to evenly distribute wear and tear.

- Battery Care: Keep the battery terminals clean and check for any signs of corrosion. Make sure the battery is properly charged to avoid sudden failures.

- Brake System Maintenance: Inspect brake pads and discs for wear.

How to Read Parts Diagrams

Understanding how to navigate technical illustrations is essential for effective repairs or maintenance. These visual guides help you identify and locate different elements of a system, ensuring that each component is properly assembled or replaced. By learning to interpret these visuals, you can confidently manage the assembly process without confusion.

The diagrams are typically organized with a clear structure, where each element is represented by a symbol or number. These references correspond to a list, making it easy to match components with their specifications or replacement information. Below is a basic table to demonstrate how different items are mapped out:

Item Number Description Quantity 1 Main Housing 1 2 Connector Bolt 4 3 Support Bracket 2 As you follow the table, you can cross-reference the illustrated components with the descriptions to understand their function and where they fit within the overall system. This helps ensure accuracy and efficiency when working on repairs or installations.

Differences Between Models

When comparing various models of utility all-terrain vehicles, it’s essential to highlight the subtle yet significant differences that set them apart. These differences can affect performance, reliability, and overall user experience, especially when considering the purpose and terrain where the vehicle will be used.

Engine Specifications

One of the key factors that distinguish these models is the engine design and capacity. While some feature a more robust engine for demanding tasks, others may prioritize fuel efficiency or ease of maintenance. It’s crucial to match the engine’s power output with the specific requirements of the rider’s environment.

Transmission and Handling

Another aspect to consider is the transmission type, which can vary from manual to automatic, impacting the vehicle’s ease of use. Additionally, handling features such as steering mechanisms, suspension systems, and braking technology can significantly alter the riding experience across different models.

Model Feature Model A Model B Engine Capacity 420cc 500cc Transmission Type Automatic Manual Suspension Independent Solid Axle Tools Needed for Repairs

When it comes to maintenance and fixing machinery, having the right tools at your disposal is crucial for achieving efficient and effective results. The following section outlines the essential instruments that will aid in performing various repairs, ensuring that you can handle any challenges that may arise during the process.

Essential Hand Tools

Utilizing a well-equipped toolkit is the foundation of successful repairs. Here are some key hand tools that every mechanic should have:

Tool Description Socket Set A collection of sockets in various sizes for loosening and tightening bolts. Wrenches Various wrenches, including adjustable, open-end, and box-end types, for gripping and turning fasteners. Screwdrivers A set of flathead and Phillips screwdrivers for driving screws into place. Pliers Used for gripping, twisting, and cutting wire or small components. Power Tools for Enhanced Efficiency

In addition to hand tools, power tools can significantly speed up the repair process and provide greater precision. Here are some commonly used power tools:

Tool Description Drill A tool for creating holes or driving screws quickly and efficiently. Impact Wrench Utilized for loosening stubborn nuts and bolts with high torque. Grinder A tool for sharpening blades and smoothing rough edges on metal. Saw Used for cutting through various materials, such as metal or wood. Finding Quality Replacement Parts

When maintaining a vehicle, sourcing reliable components is essential for ensuring optimal performance and longevity. Whether you’re repairing or upgrading, the right elements can make a significant difference in the overall functionality of your machine. This section will guide you through the process of identifying and obtaining high-quality replacements that meet your needs.

Researching Trusted Suppliers

Start by identifying reputable vendors who specialize in the type of components required. Online marketplaces, local dealerships, and specialized stores are all viable options. Look for reviews and ratings from previous customers to gauge the reliability of a supplier. A trustworthy source often provides warranties and clear return policies, which can be indicators of quality.

Understanding Compatibility

Ensuring that the replacements you choose are compatible with your specific model is crucial. Refer to user manuals or consult with knowledgeable professionals to confirm that the components will fit and function properly. Taking the time to verify compatibility can save you from future headaches and additional expenses.

Assembly and Disassembly Guide

This section provides a comprehensive overview of the procedures involved in the assembly and disassembly of an all-terrain vehicle, focusing on the essential steps and considerations necessary for a successful operation. Proper handling and understanding of the components will ensure efficient maintenance and longevity of the vehicle.

Before beginning the process, it is crucial to gather all necessary tools and components. This preparation will help streamline the workflow and minimize potential disruptions.

Tools Required

- Socket set

- Wrenches

- Screwdrivers

- Pliers

- Torque wrench

- Shop manual

Disassembly Steps

- Ensure the vehicle is on a flat, stable surface and that the ignition is off.

- Remove any accessories that may obstruct access to key components.

- Carefully detach the battery cables, starting with the negative terminal.

- Follow the manual to systematically remove parts, documenting each step for easier reassembly.

- Store removed components in a labeled container to prevent loss.

Assembly Steps

- Begin by ensuring that all parts are clean and free of debris.

- Refer to the documentation to ensure correct orientation and placement of each component.

- Install components in reverse order of disassembly, making sure to secure them with the appropriate fasteners.

- Reconnect the battery, starting with the positive terminal.

- Test the vehicle to ensure all systems are functioning properly.

Following these guidelines will aid in effectively managing the assembly and disassembly process, contributing to the overall performance and maintenance of the vehicle.

Resources for Honda Rancher Owners

Owning an ATV can be an exciting experience, but maintaining it requires access to the right resources. From manuals and guides to community support and specialized shops, having reliable information at your fingertips is essential for keeping your vehicle in optimal condition.

Online Resources

- Manufacturer Websites: Many manufacturers provide downloadable manuals and maintenance tips on their official sites.

- Forums and Community Groups: Engaging with online forums can offer insights from fellow enthusiasts who share their experiences and solutions.

- YouTube Channels: Numerous channels focus on repair and maintenance tutorials, making visual learning easier.

Local Support

- Dealerships: Authorized dealers can provide expert service, genuine components, and professional advice.

- Repair Shops: Independent mechanics with expertise in ATVs can offer personalized service and support.

- Parts Stores: Local retailers may carry essential supplies and accessories for your vehicle.