In the world of winter maintenance, a thorough grasp of the individual elements that comprise snow clearing machinery is essential. Each piece plays a crucial role in ensuring efficiency and effectiveness during harsh weather conditions.

By exploring the intricate relationships between these various components, operators can enhance their skills and optimize performance. This knowledge not only aids in troubleshooting but also empowers users to make informed decisions regarding repairs and upgrades.

Whether you are a seasoned professional or a newcomer to the field, delving into the specifics of these systems will provide a solid foundation for successful winter operations. Understanding how each element contributes to the ultimate goal of efficient snow removal is key to mastering this vital task.

Understanding Fisher Plow Components

Grasping the essential elements of a snow removal system is crucial for effective operation and maintenance. Each component plays a significant role in ensuring efficiency and reliability during winter weather challenges. A clear understanding of these elements can enhance both performance and longevity.

The main components include the framework, hydraulic systems, and control mechanisms. Each of these parts collaborates seamlessly to facilitate the movement and positioning of the blade, ensuring that it meets various terrain demands. Regular inspections and familiarity with these components are vital for optimal functionality.

For instance, the structural frame provides the necessary support, while hydraulic systems allow for smooth adjustments. Additionally, control mechanisms are essential for precise handling, enabling operators to navigate effectively. Awareness of how these elements interact can significantly improve user experience and operational success.

Overview of Plow Part Functions

This section provides an insight into the various components involved in the snow clearing process, focusing on their roles and significance in ensuring efficient operation. Each element contributes uniquely to the overall functionality and performance, enhancing maneuverability and effectiveness in challenging conditions.

Key Components and Their Roles

Understanding the essential elements can significantly improve operational efficiency. Here are some of the critical components and their primary functions:

| Component | Function |

|---|---|

| Blade | Shifts snow and debris away from the surface. |

| Frame | Provides structural support and stability. |

| Hydraulic System | Controls the positioning and angle of the blade. |

| Mounting Kit | Secures the assembly to the vehicle. |

Importance of Component Integrity

Maintaining the integrity of each element is crucial for optimal performance. Regular inspections and timely replacements can prevent malfunctions, ensuring that the entire system operates smoothly under various conditions.

Key Parts of Fisher Plows

Understanding the essential components of snow removal equipment is crucial for effective operation and maintenance. Each element plays a significant role in ensuring that the machinery performs efficiently, providing reliable service during winter conditions.

- Blade: The primary surface that interacts with snow, designed for optimal clearance and shaping.

- Mounting System: Facilitates secure attachment to the vehicle, allowing for stability during use.

- Hydraulic System: Powers the movement and angling of the blade, enabling precise control over snow displacement.

- Control Mechanism: The interface that allows the operator to manage blade functions easily.

- Skid Shoes: Adjustable components that protect the blade and determine the height at which it clears the ground.

- Deflector: A feature that helps direct snow away from the vehicle, improving visibility and efficiency.

Each of these components contributes to the overall functionality, making it essential to maintain them in good condition. Regular inspections and timely replacements can prevent operational issues and extend the lifespan of the equipment.

Common Issues with Plow Components

Understanding the typical challenges faced by equipment designed for snow removal is crucial for maintaining efficiency and longevity. Various components can experience wear and tear, leading to reduced performance or unexpected failures. Identifying these issues early can save time and money while ensuring optimal functionality during the winter season.

Worn Edges and Blades

One of the most frequent problems is the deterioration of edges and blades. Continuous contact with abrasive surfaces can cause them to become blunt or damaged. Regular inspection is essential to detect any signs of wear. Replacing these components promptly can improve effectiveness and prevent additional strain on other parts.

Hydraulic System Failures

Another common concern is related to the hydraulic mechanisms that control movement. Leaks or low fluid levels can hinder performance, leading to sluggish operation or total failure to engage. Routine maintenance of the hydraulic system, including checking for leaks and ensuring proper fluid levels, is vital for reliable operation.

Benefits of Using Genuine Parts

Opting for authentic components in machinery maintenance ensures optimal performance and longevity. These elements are designed specifically for the equipment, promoting seamless integration and reliable operation. Investing in genuine offerings can significantly enhance overall efficiency and reduce the likelihood of unexpected failures.

Quality Assurance

Authentic components undergo rigorous testing and meet high standards of quality. This commitment to excellence means that users can trust these products to deliver superior performance and durability. Using counterfeit or generic alternatives may lead to premature wear and tear, ultimately resulting in costly repairs and downtime.

Enhanced Reliability

When original items are used, the compatibility with the machinery is guaranteed. This reduces the risk of malfunctions and ensures that the system operates as intended. Reliability is crucial in any operational setting, as it minimizes disruptions and fosters a smoother workflow. By choosing genuine options, operators can maintain peace of mind knowing they are using the best available solutions for their needs.

How to Maintain Your Fisher Plow

Proper upkeep of your snow removal equipment is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also prevents costly repairs and downtime during critical winter months. Here are some essential tips to keep your apparatus in top condition.

- Regular Inspections: Conduct frequent checks for any signs of wear or damage. Focus on:

- Hydraulic connections

- Electrical components

- Structural integrity of the frame

- Fluid Levels: Ensure that all fluids are at the correct levels:

- Hydraulic fluid

- Transmission fluid

- Anti-freeze

- Cleaning: After each use, remove snow and ice buildup. Clean all surfaces to prevent corrosion.

- Lubrication: Regularly lubricate moving parts to minimize friction and wear. Pay special attention to:

- Pivot points

- Bearings

- Chains and cables

- Blade Maintenance: Keep the cutting edge sharp. Regularly inspect and replace if necessary to maintain performance.

- Storage: During off-season, store the equipment in a dry, sheltered area to protect it from the elements.

lessCopy code

By following these maintenance guidelines, you can ensure that your equipment remains reliable and efficient throughout the winter season.

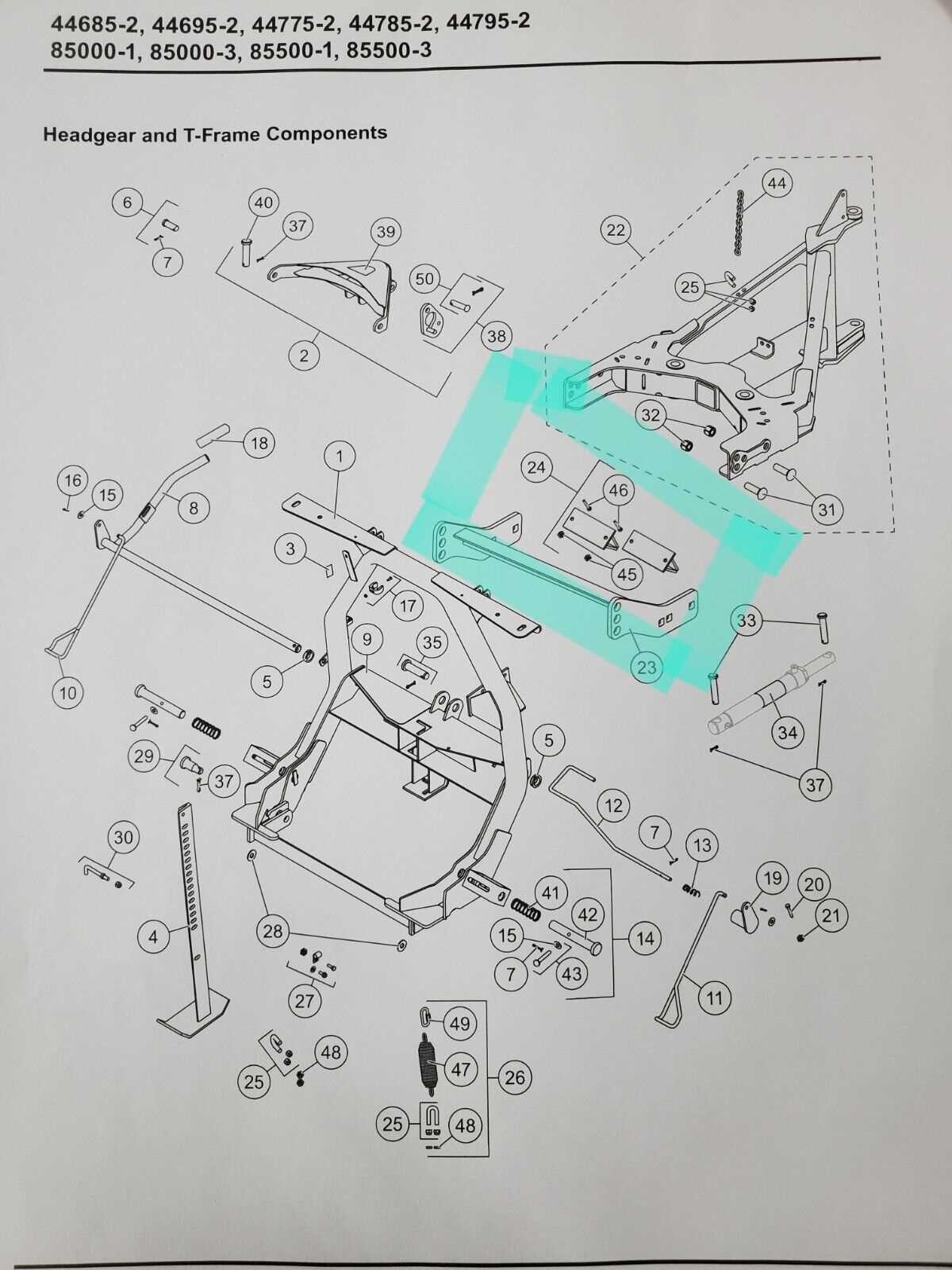

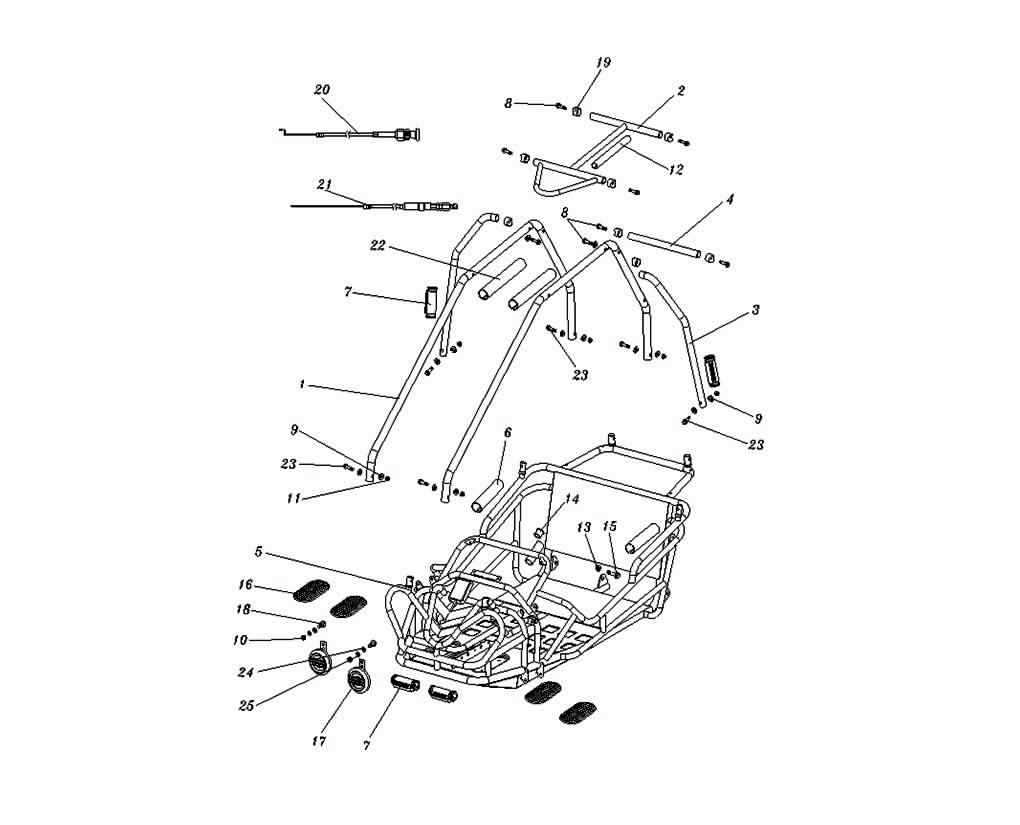

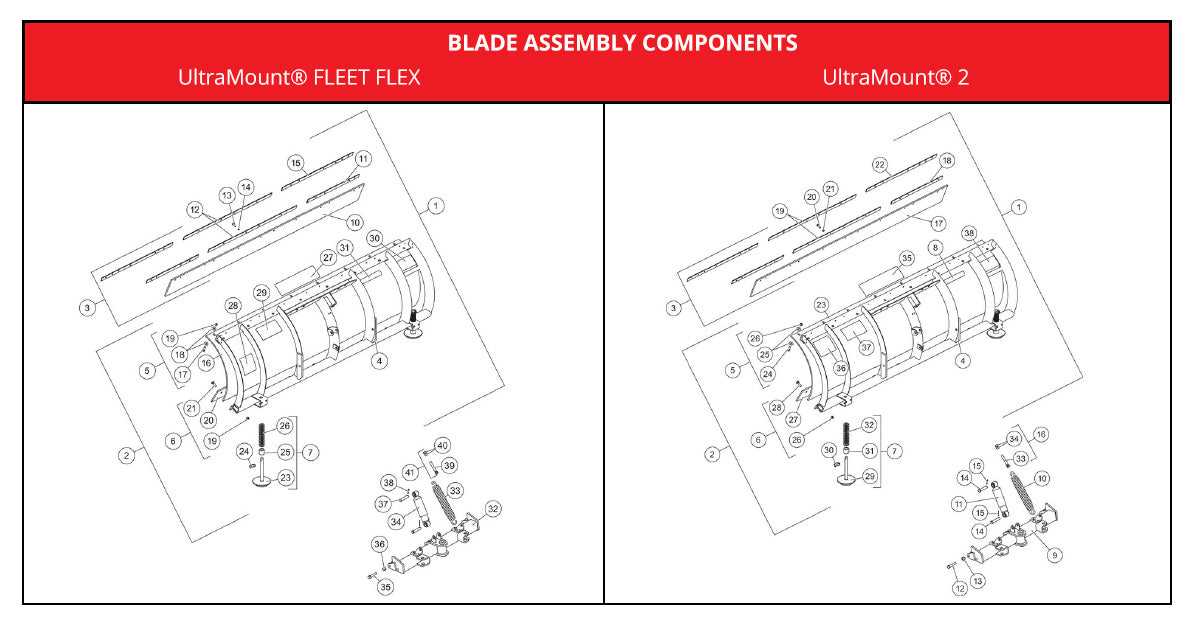

Identifying Parts by Diagram

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations can greatly aid in recognizing and categorizing each element, ensuring that users can easily pinpoint what they need. This approach not only simplifies the identification process but also enhances overall operational efficiency.

Key Components Overview

Each machinery configuration consists of various segments, each playing a vital role in its functionality. Familiarity with these segments allows users to troubleshoot issues and perform necessary replacements with confidence.

Visual Reference Table

| Component Name | Description | Function |

|---|---|---|

| Blade | The primary cutting edge. | To engage and clear materials from the surface. |

| Mounting Frame | Structure that secures the unit. | Provides stability and support during operation. |

| Hydraulic System | Fluid-powered mechanism. | Enables movement and adjustment of components. |

| Control Unit | Interface for user input. | Allows operation and adjustments to settings. |

Utilizing a visual guide effectively demystifies the machinery, making it easier for users to engage with and maintain their equipment. Being able to identify each element empowers individuals to take proactive steps in ensuring optimal performance.

Upgrading Fisher Plow Attachments

Enhancing your winter equipment can significantly improve efficiency and performance. By investing in high-quality accessories, users can achieve better results during harsh weather conditions. This section explores the various ways to optimize these tools for improved functionality.

One key aspect of upgrading is selecting compatible attachments that suit your specific needs. Consider attachments designed for versatility and durability, allowing for better adaptability across different tasks. Compatibility ensures that the upgrades integrate seamlessly with existing setups.

Another vital factor is the maintenance of the equipment. Regular inspections and timely replacements can prevent wear and prolong the lifespan of your gear. Investing in robust materials can also enhance the overall performance, ensuring reliable operation during the toughest conditions.

Lastly, technological advancements can play a crucial role in enhancing effectiveness. Exploring options that incorporate modern technology, such as automated controls or smart features, can provide the ultimate advantage in performance and ease of use.

Safety Tips for Plow Operation

Ensuring a safe working environment during snow removal is crucial for effective operation and to prevent accidents. Adhering to safety protocols can significantly reduce the risk of injury and equipment damage.

Always wear appropriate protective gear, including gloves, boots, and eye protection. Familiarize yourself with the vehicle’s controls and features before beginning work. Conduct a pre-operation inspection to identify any potential issues that could affect performance.

Be aware of your surroundings, including obstacles and pedestrians. Maintain a safe distance from edges and slopes to prevent tipping. Use caution when maneuvering in tight spaces, and communicate clearly with any ground personnel.

Regularly check for ice buildup and remove it to ensure optimal traction. Avoid sudden movements and sharp turns, as they can lead to loss of control. Finally, always follow the manufacturer’s recommendations for operation and maintenance to ensure longevity and safety.

Where to Buy Replacement Parts

Finding the right components for your equipment can greatly enhance its performance and longevity. There are several avenues to explore when seeking high-quality replacements, ensuring that your machinery operates efficiently.

- Authorized Dealers: Start by checking with official distributors. They often have a comprehensive inventory of genuine items, ensuring compatibility and reliability.

- Online Retailers: Many websites specialize in aftermarket solutions. These platforms provide a wide range of options, allowing you to compare prices and read reviews.

- Local Hardware Stores: Visiting nearby stores can yield surprising finds. Many carry essential components and can offer personalized advice based on your needs.

- Specialty Shops: Look for businesses that focus on specific types of machinery. They can provide expert guidance and specialized products tailored to your equipment.

- Auctions and Secondhand Markets: Occasionally, you can find quality items at reduced prices in auctions or online marketplaces. Always verify the condition before purchasing.

Regardless of the option you choose, ensure that you verify the compatibility of the components with your machinery for optimal performance.

Plow Parts Compatibility Considerations

When it comes to maintaining or upgrading your snow-clearing equipment, understanding the compatibility of various components is crucial. Ensuring that each element works seamlessly with others can significantly impact performance and longevity. This section outlines key factors to consider when selecting components for your equipment.

Key Factors for Compatibility

- Manufacturer Specifications: Always refer to the specifications provided by the manufacturer to determine which components are designed to fit together.

- Model Variations: Different models may have unique design features that affect compatibility. Verify that parts match the specific model in use.

- Material Quality: Ensure that materials used in components are compatible, as differences can affect durability and performance.

- Attachment Mechanisms: Check that attachment methods align, as this can impact installation and functionality.

Testing and Verification

- Consult the user manual for compatibility guidelines.

- Reach out to customer service for expert advice on matching components.

- Consider testing components in a controlled setting to ensure proper function before full installation.

Taking these considerations into account will help ensure that your equipment operates efficiently and effectively throughout the season.

Resources for Fisher Plow Owners

For those who rely on snow removal equipment during harsh winter months, having access to reliable information and tools is essential. Whether you are seeking maintenance tips, upgrade options, or troubleshooting advice, various resources can assist you in ensuring your equipment operates efficiently and effectively.

Online Communities

- Forums dedicated to snow management allow users to share experiences and solutions.

- Social media groups provide a platform for real-time discussions and advice.

- Dedicated websites often host blogs with valuable insights from experienced operators.

Official Resources

- Manufacturer websites offer user manuals and product specifications.

- Customer support lines can assist with specific inquiries regarding functionality.

- Authorized dealers provide information on the latest accessories and enhancements.