Within the intricate world of firearm engineering, a specific assembly plays a crucial role in the operation and reliability of the weapon. This collection of elements works in harmony to facilitate the cycling of ammunition, ensuring smooth firing and ejection processes. Gaining insight into this assembly is essential for both enthusiasts and professionals aiming to enhance their knowledge of weapon functionality.

Every individual element within this system serves a distinct purpose, contributing to the overall efficiency and performance of the firearm. From the initial ignition to the final extraction, each component must interact seamlessly. Understanding how these parts function together not only aids in troubleshooting but also enhances the user’s ability to maintain and modify their equipment effectively.

Exploring the intricacies of this assembly reveals a wealth of information about the engineering principles at play. By examining the configuration and interaction of these elements, one can appreciate the precision required in firearm design. This knowledge not only empowers users but also fosters a deeper respect for the craftsmanship involved in creating reliable and effective weaponry.

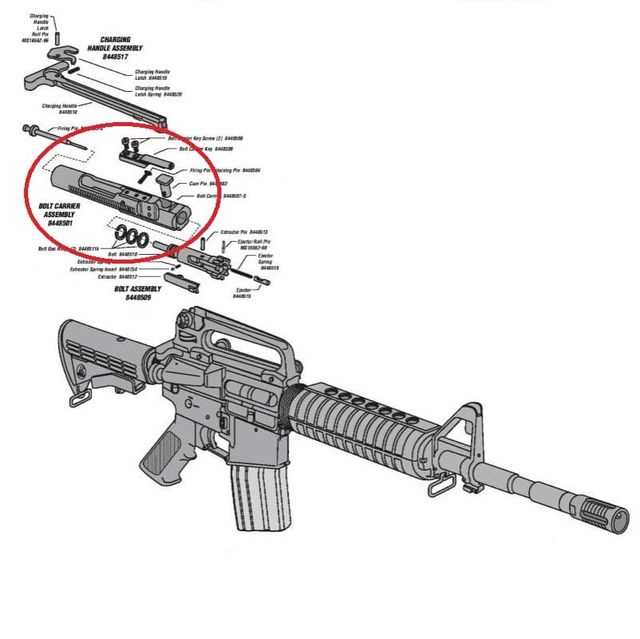

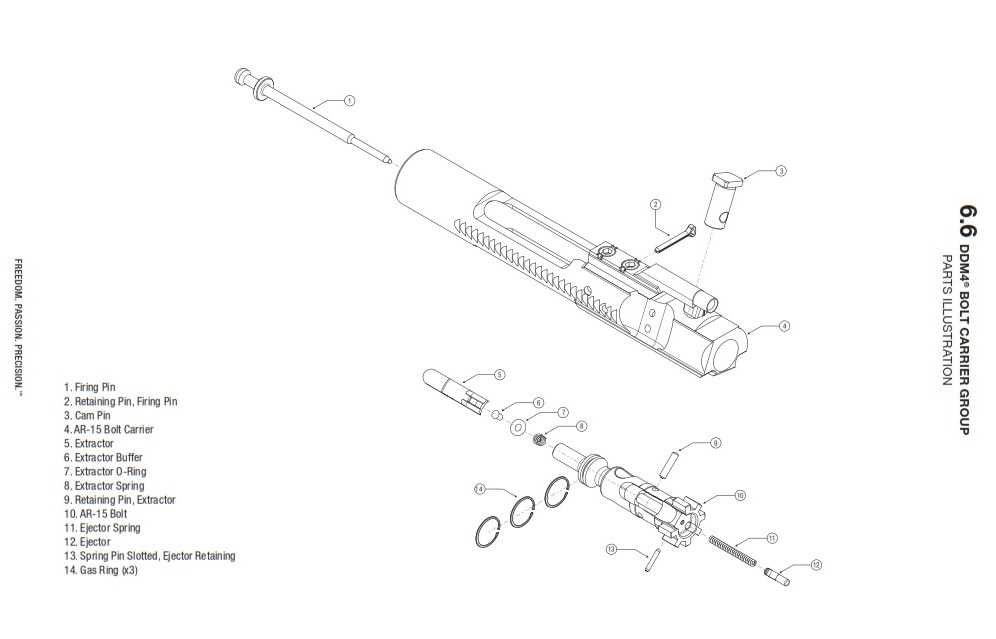

Understanding the Bolt Carrier Group

This section explores the essential assembly that plays a pivotal role in the functionality of semi-automatic and automatic firearms. Comprehending its components and their interactions is crucial for both enthusiasts and professionals aiming for optimal performance and reliability.

Key Components and Their Functions

At the heart of this assembly lies a mechanism designed to facilitate the cycle of firing, ejection, and reloading. The key elements include a moving housing that encapsulates the firing mechanism, a locking piece, and a projection that assists in cycling the action. Each component serves a specific purpose, ensuring seamless operation under various conditions.

Maintenance and Performance

Regular upkeep of this assembly is vital to maintain functionality and longevity. Cleaning and lubricating the mechanisms can significantly enhance reliability and performance. Understanding how each component interacts will ultimately lead to more informed decisions regarding maintenance and upgrades.

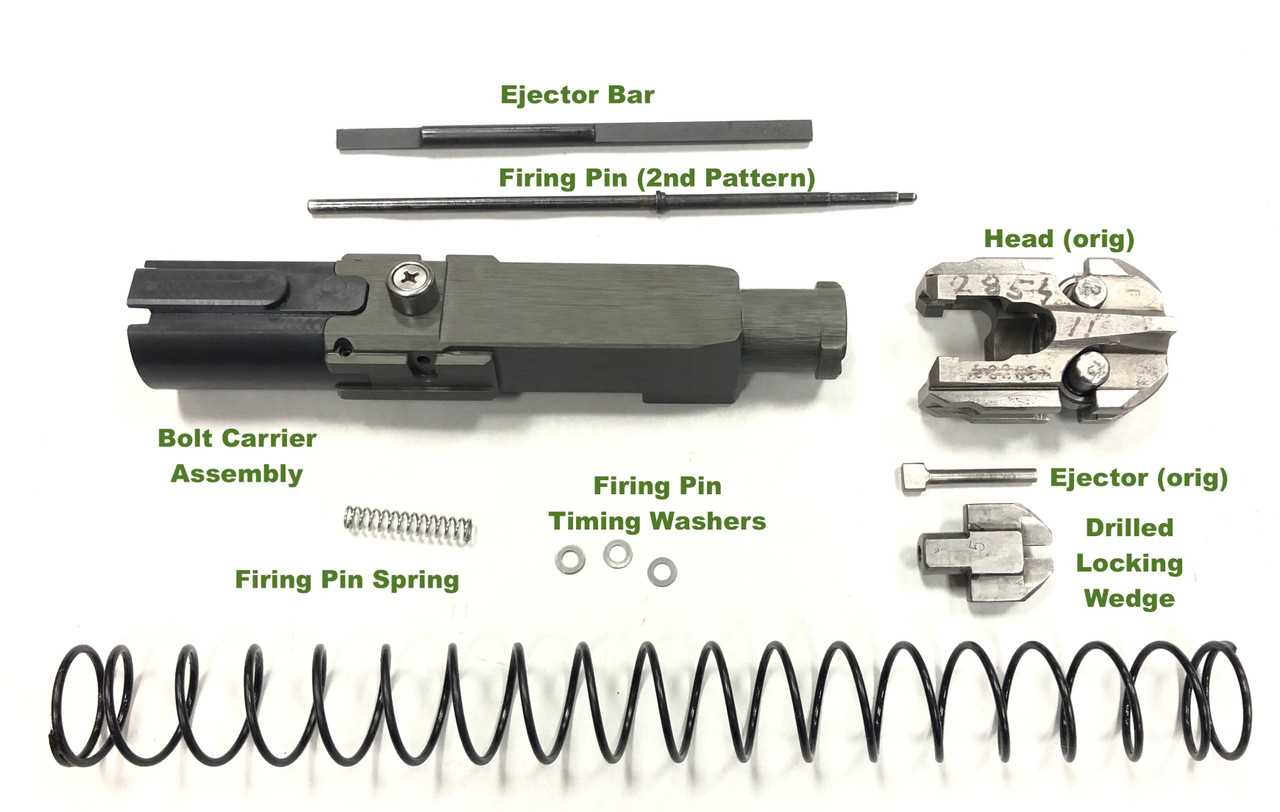

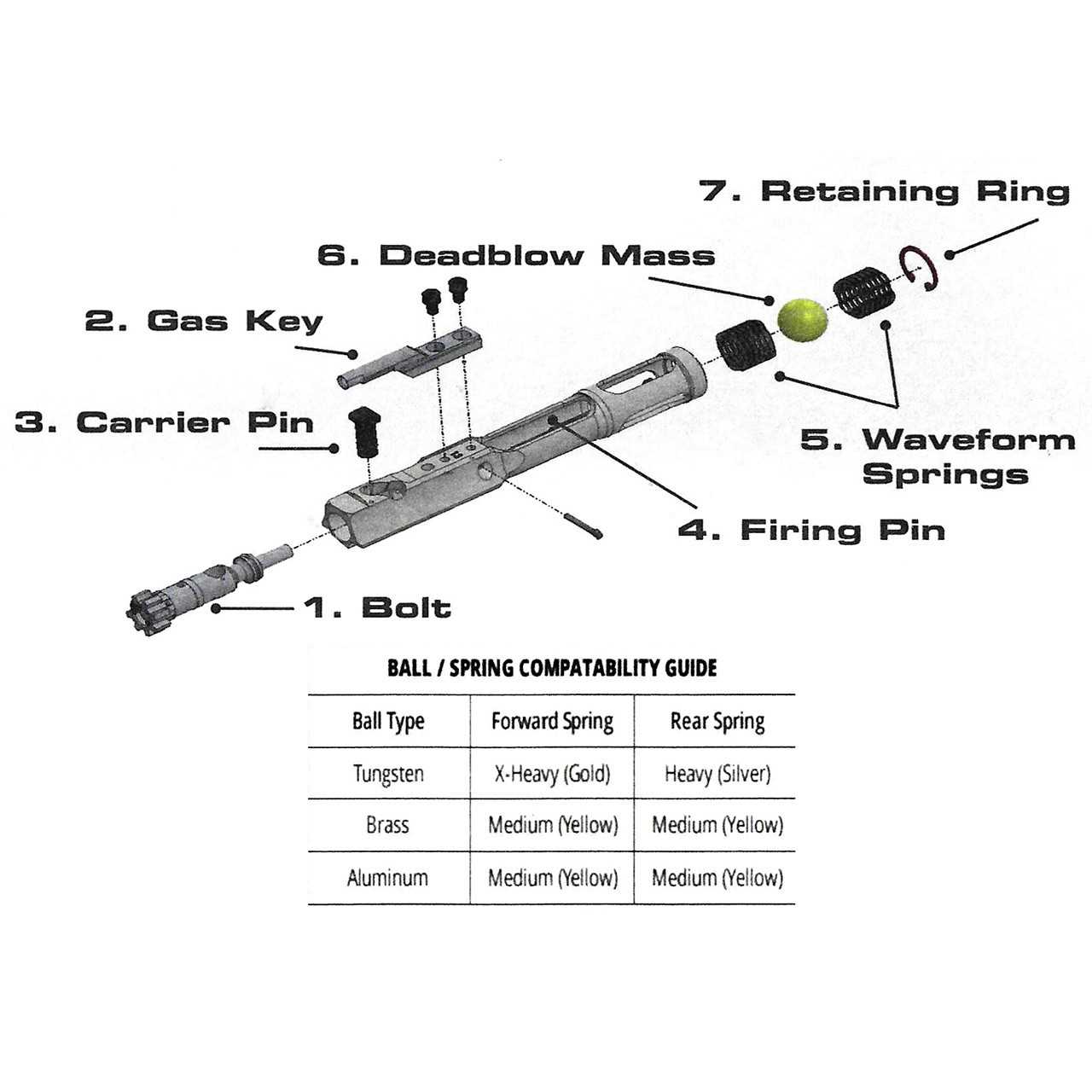

Components of the Bolt Carrier

The assembly responsible for the critical function of feeding, firing, and ejecting ammunition consists of several essential elements, each contributing to its overall performance. Understanding these components is vital for maintaining and enhancing the reliability of the system.

Main Elements

- Receiver: Houses the mechanism and provides structural support.

- Firing Pin: Initiates the ignition of the cartridge.

- Extractor: Ensures the spent casing is removed post-firing.

- Ejector: Forces the empty casing out of the chamber.

Supporting Features

- Gas Key: Directs gas to cycle the action.

- Cam Pin: Connects the assembly to the upper receiver and aids in rotation.

- Buffer: Absorbs recoil and stabilizes operation.

Functionality of Each Part

This section explores the roles played by various components within a critical assembly responsible for the operation of firearms. Each element contributes uniquely to the overall mechanism, ensuring reliability and efficiency during firing and cycling. Understanding these functions is essential for proper maintenance and performance optimization.

Key Components and Their Roles

- Headpiece: Engages with the chamber to facilitate the locking process, ensuring secure operation during firing.

- Sliding Mechanism: Transmits energy from the fired cartridge to initiate the ejection and reloading cycle.

- Spring Assembly: Provides the necessary tension to return the components to their original position after each cycle.

- Guide Rod: Ensures smooth movement and alignment of the assembly during operation, reducing friction and wear.

Importance of Each Element

- Locking Mechanism: Guarantees safety by preventing premature unlocking, which could lead to catastrophic failures.

- Extraction Device: Plays a vital role in removing spent cartridges from the chamber, allowing for uninterrupted firing sequences.

- Reassembly Features: Facilitate quick reinstallation and disassembly, crucial for cleaning and maintenance routines.

Each component works in harmony, and understanding their individual functions is crucial for firearm enthusiasts and professionals alike.

Common Materials Used in Construction

The selection of materials is crucial in the construction industry, influencing durability, performance, and cost-effectiveness. Various substances are employed, each with unique properties that cater to different needs and applications. Understanding these materials helps in making informed choices during the building process.

Metals

Metals are widely used due to their strength and versatility. They are essential in structural applications and offer a variety of benefits:

- Steel: Known for its high tensile strength and durability, commonly used in frameworks and reinforcements.

- Aluminum: Lightweight and resistant to corrosion, suitable for windows and roofing.

- Copper: Often utilized in plumbing and electrical systems due to its excellent conductivity.

Polymers

These synthetic materials have gained popularity for their lightweight nature and resistance to chemicals. Common uses include:

- PVC: Widely used for pipes, flooring, and window frames.

- Polycarbonate: Known for its impact resistance, often used in glazing and protective barriers.

- Composite materials: Combining various substances to achieve desirable properties, used in structural components and cladding.

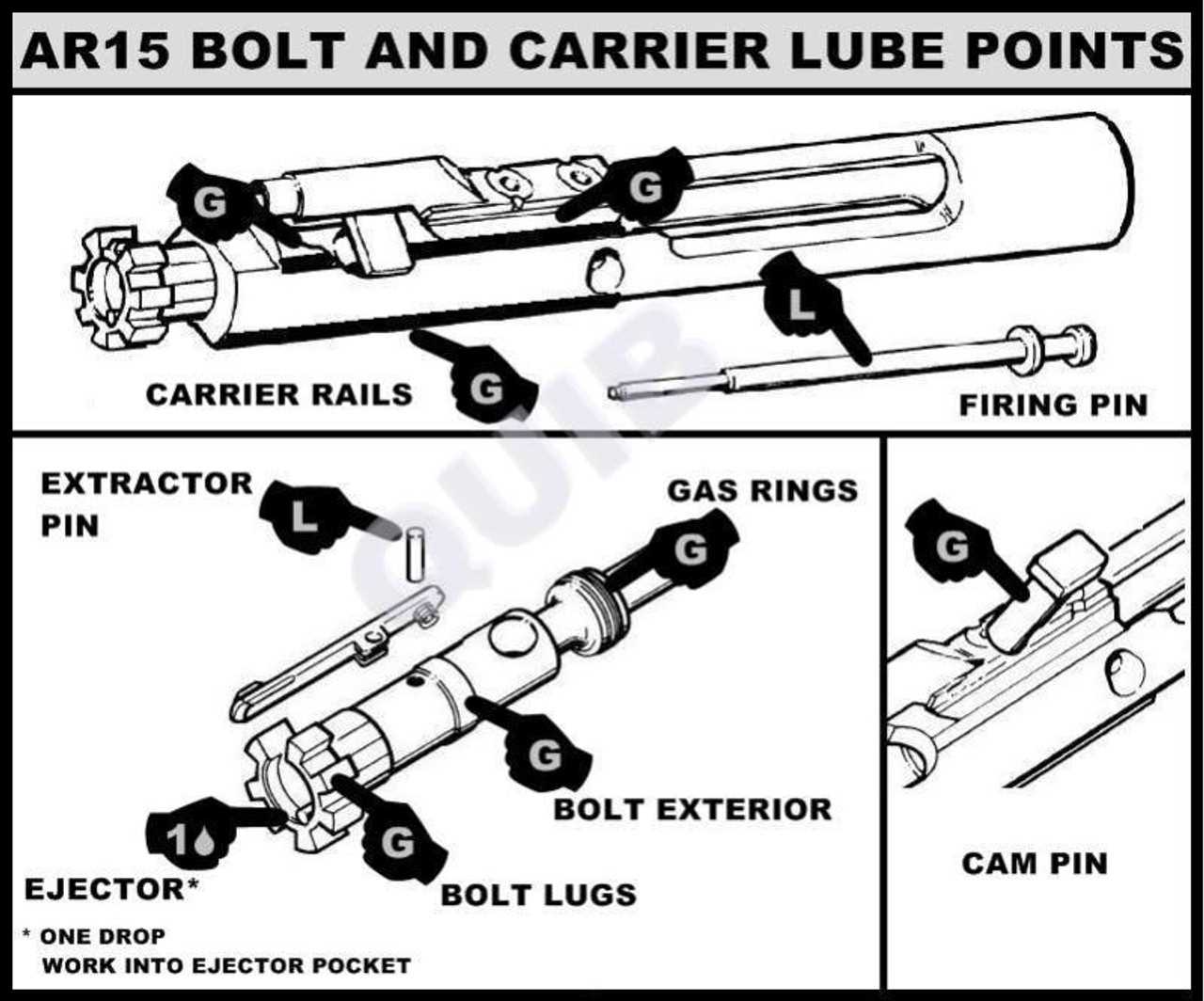

Importance of Proper Lubrication

Effective lubrication is crucial for maintaining the functionality and longevity of mechanical components. It reduces friction, minimizes wear, and ensures smooth operation, ultimately enhancing performance.

Key benefits of proper lubrication include:

- Reduction of friction and heat generation.

- Prevention of rust and corrosion.

- Extended lifespan of components.

- Improved efficiency and reliability.

Regular maintenance and appropriate application of lubricants can lead to optimal performance. Ensure the use of suitable products for specific environments and conditions.

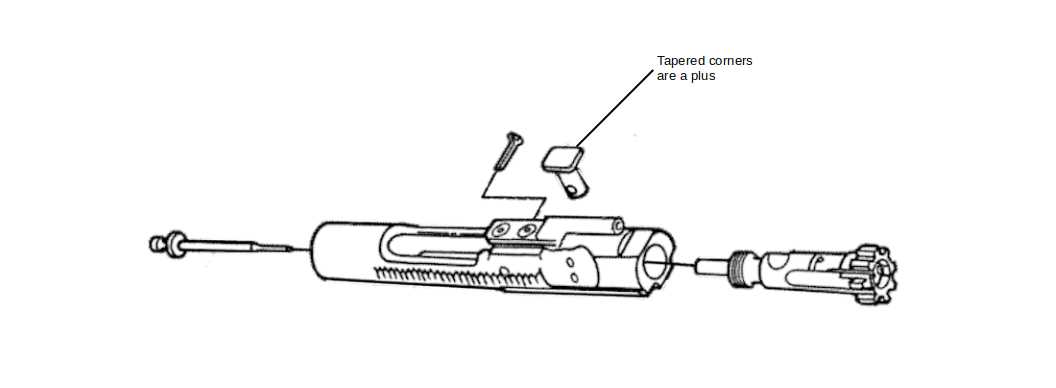

Visual Breakdown of the Diagram

This section provides an insightful examination of the various components illustrated in the schematic, offering clarity on their functions and interrelationships. Understanding these elements is crucial for grasping the overall mechanics involved.

- Primary Element: This is the central component that plays a vital role in the mechanism’s operation.

- Support Structure: This part ensures stability and proper alignment during function.

- Guide Rail: A crucial feature that facilitates smooth movement and control.

- Locking Mechanism: This ensures secure operation, preventing accidental disengagement.

By delving into these components, one can appreciate their ultimate importance in the overall system, enhancing both performance and reliability.

Maintenance Tips for Longevity

Regular upkeep is essential to ensure optimal performance and durability of essential components. Implementing a structured maintenance routine can greatly enhance lifespan and functionality.

- Clean components regularly to prevent buildup of residue and debris.

- Inspect for wear and tear, addressing any issues promptly to avoid further damage.

- Apply appropriate lubrication to reduce friction and enhance smooth operation.

- Store components in a dry, controlled environment to prevent corrosion.

- Follow manufacturer guidelines for replacement intervals and specific care instructions.

By adhering to these practices, you can significantly extend the life and effectiveness of your equipment.

Signs of Wear and Tear

Understanding the indicators of deterioration is essential for maintaining the functionality of your firearm. Regular inspection can help identify potential issues before they become significant problems, ensuring reliable performance and safety.

Common Indicators

- Surface Scratches: Look for any visible abrasions on the exterior surfaces. These can compromise the integrity of the components.

- Discoloration: Changes in color, especially darkening or rust, can indicate exposure to moisture or inadequate cleaning.

- Deformation: Any noticeable bending or warping may affect the alignment and function of the mechanism.

- Loose Fit: Parts that no longer fit snugly may suggest excessive wear, leading to operational issues.

Impact of Wear

- Decreased Reliability: Worn components can lead to malfunctions during critical moments.

- Increased Maintenance: More frequent servicing may be required to ensure proper function.

- Safety Risks: Compromised integrity can pose serious hazards during use.

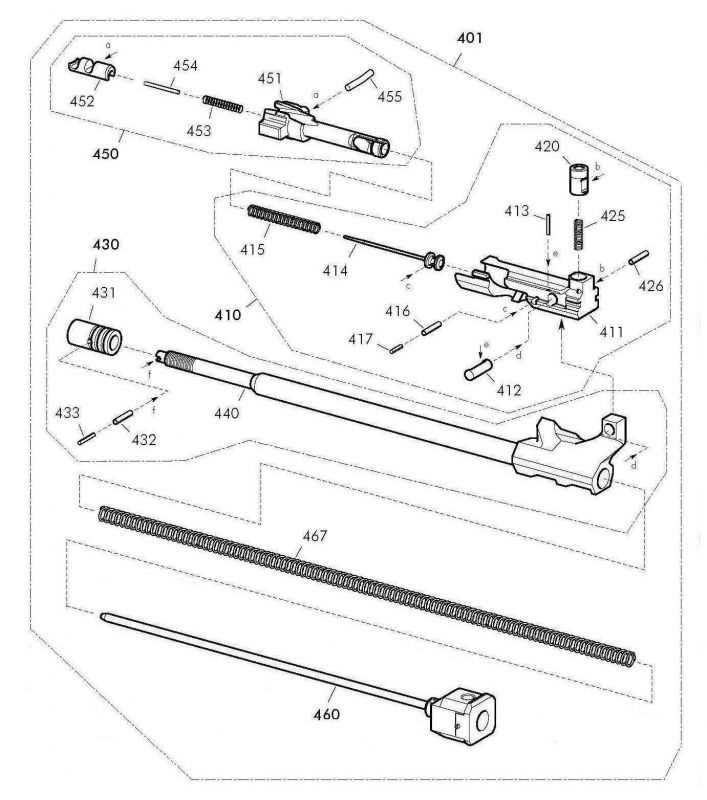

Comparison of Different Designs

In the realm of firearm mechanisms, the variation in designs significantly impacts performance, reliability, and user experience. Understanding these differences can aid in selecting the most suitable configuration for specific applications, whether for competitive shooting, tactical use, or personal defense.

Traditional vs. Modern Configurations

Traditional mechanisms often emphasize simplicity and reliability, utilizing fewer moving components, which can enhance durability. In contrast, modern configurations may incorporate advanced materials and engineering techniques to improve efficiency and reduce weight. While traditional designs have proven effective over time, contemporary options frequently offer enhanced performance metrics.

Operating Systems and Their Effects

The choice of operating system–whether direct impingement or piston-driven–plays a critical role in the overall functionality of the mechanism. Direct impingement systems are generally lighter and simpler, allowing for a more streamlined profile. However, piston-driven systems tend to provide better heat management and reduced fouling, which can enhance long-term reliability. Each system has its own set of advantages and trade-offs, making it essential for users to consider their specific needs.

Role in Firearm Cycling Process

The mechanism responsible for the operation of a firearm plays a crucial role in ensuring the weapon functions effectively and reliably. This process involves several key actions that allow for the loading, firing, and ejecting of ammunition. Understanding how each component contributes to this cycle is essential for comprehending the overall functionality of the firearm.

During the initial phase, the assembly interacts with the ammunition, facilitating its entry into the chamber. Once the trigger is pulled, the ignition of the round occurs, leading to the generation of gas that propels the projectile. The subsequent movement of the mechanism is vital for extracting the spent casing and preparing the system for the next round.

In essence, the coordination of these movements ensures a seamless transition between firing and reloading, ultimately impacting the reliability and efficiency of the weapon. Each element is designed to withstand the forces generated during operation, contributing to the durability and performance of the firearm.

Overall, the assembly’s design and functionality are integral to the cycling process, highlighting the importance of precision engineering in modern weaponry.

Impact on Accuracy and Reliability

The components responsible for the cycling of a firearm play a crucial role in its overall performance. Their design, materials, and interaction with other elements significantly influence how well the weapon functions under various conditions. A well-engineered assembly can enhance precision and ensure consistent operation, while deficiencies in these elements can lead to malfunctions and decreased shooting accuracy.

Key Factors Influencing Performance

Several factors contribute to the effectiveness of these critical elements, including fit, finish, and quality of manufacturing. Each aspect can affect how components interact during firing, impacting not only reliability but also the shooter’s ability to maintain accuracy over time.

| Factor | Impact on Performance |

|---|---|

| Fit | Ensures smooth operation and reduces wear. |

| Material Quality | Affects durability and resistance to deformation. |

| Finish | Influences friction and overall functioning. |

| Design | Optimizes cycling speed and reliability in various conditions. |

Conclusion

Understanding the significance of these components is essential for anyone seeking to enhance the performance of their firearm. By focusing on quality and precision in these crucial elements, shooters can achieve greater accuracy and dependability, leading to improved overall shooting experiences.

Aftermarket Upgrades and Options

Enhancing the functionality and performance of your firearm can be achieved through various modifications available in the aftermarket. These enhancements not only improve reliability but also tailor the weapon to better suit individual preferences and shooting styles.

One popular option is the introduction of precision-engineered components, which can significantly enhance accuracy and overall efficiency. Upgraded springs, improved lubrication systems, and high-quality materials are just a few examples of how enthusiasts can optimize their setups.

Another avenue involves aesthetic modifications, allowing users to express their personal style. Custom finishes, grips, and other cosmetic upgrades can transform the appearance while maintaining functionality.

Finally, integrating advanced technology, such as enhanced charging handles or adjustable systems, can elevate performance to the next level, ensuring that each user finds the ultimate configuration that meets their unique needs.

Regulatory Considerations for Modifications

When exploring alterations to firearm components, it is crucial to understand the legal landscape surrounding such changes. Various jurisdictions impose specific regulations that dictate what modifications are permissible, often influenced by safety concerns and legislative intent. Familiarity with these laws helps ensure compliance and prevents unintentional violations.

First and foremost, individuals must research federal, state, and local regulations that apply to their specific modifications. Consulting legal experts can provide clarity on complex laws and help navigate any potential restrictions. It’s important to consider that even seemingly minor adjustments can have significant legal implications.

Moreover, maintaining thorough documentation of any modifications can be beneficial, both for personal records and legal accountability. In the event of inspections or inquiries, having clear evidence of compliance can safeguard against potential issues.

In conclusion, staying informed about the regulatory framework is essential for anyone considering enhancements to firearm mechanisms. This proactive approach not only promotes safety but also fosters responsible ownership.