The intricate workings of small engines require a comprehensive grasp of their various components and how they interact. Understanding the configuration of these essential elements is crucial for effective maintenance and repair. Whether you’re a seasoned mechanic or a DIY enthusiast, familiarizing yourself with the layout can significantly enhance your troubleshooting capabilities.

In this section, we will explore the essential components of a specific engine model, focusing on their arrangement and functionality. By examining the structural aspects, you will gain insights into how each piece contributes to the overall performance and efficiency of the engine. This knowledge will empower you to identify potential issues and implement effective solutions.

Furthermore, recognizing the unique features of the engine’s structure can aid in the selection of appropriate replacement elements. As you delve into the details, you will uncover the importance of each part’s role within the system, allowing you to make informed decisions during repairs or upgrades.

Regular upkeep is essential for ensuring the longevity and efficiency of any mechanical equipment. By implementing consistent maintenance practices, users can prevent unexpected breakdowns and enhance the overall performance of their machines. This proactive approach not only safeguards against costly repairs but also contributes to a safer working environment.

One of the key advantages of routine maintenance is the early identification of potential issues. Addressing minor problems before they escalate can significantly reduce downtime and increase productivity. Regular inspections and servicing allow operators to spot wear and tear, ensuring that components function optimally.

- Enhanced Performance: Regular care helps maintain the equipment’s efficiency, allowing it to operate at peak performance.

- Increased Lifespan: Consistent maintenance prolongs the life of the machinery, maximizing the investment made in it.

- Cost-Effectiveness: Preventative measures are often more economical than major repairs or replacements that result from neglect.

- Safety Assurance: Well-maintained equipment reduces the risk of accidents and injuries, providing a safer work environment.

- Compliance with Regulations: Regular maintenance ensures adherence to industry standards and safety regulations.

In conclusion, establishing a routine maintenance schedule is vital for the optimal operation of any machinery. By prioritizing regular checks and services, users can enhance performance, save costs, and ensure safety in their operations.

Key Components in SV470 Assembly

This section explores the essential elements that contribute to the functionality and performance of the assembly. Understanding these crucial components allows for effective maintenance and troubleshooting, ensuring optimal operation over time.

- Engine Block: The core structure housing various internal components, providing durability and stability.

- Piston: A vital part that converts the pressure from combustion into mechanical work.

- Cylinder Head: This component contains the combustion chamber and houses the intake and exhaust valves.

- Crankshaft: Responsible for converting linear motion from the pistons into rotational motion, driving the assembly.

- Camshaft: Regulates the opening and closing of the valves, ensuring proper airflow and combustion.

- Fuel System: Comprising the fuel tank, pump, and injectors, this system is critical for delivering fuel to the engine.

- Cooling System: Maintains optimal operating temperatures by circulating coolant, preventing overheating.

By familiarizing oneself with these key components, operators can better comprehend the overall assembly and its efficiency.

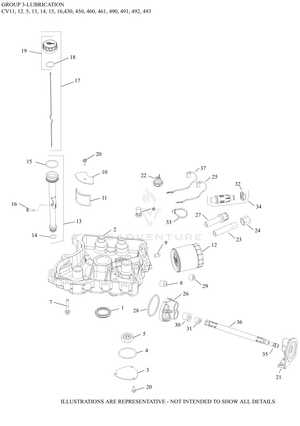

Identifying Parts with Diagrams

Understanding the layout and function of various components in machinery is essential for effective maintenance and repair. Visual aids serve as valuable tools in recognizing and locating these elements, ensuring that users can efficiently troubleshoot issues and perform necessary replacements. This section explores how illustrations can enhance comprehension and streamline the process of identifying individual elements within a complex system.

Benefits of Visual Representation

- Enhances clarity by providing a clear view of each component.

- Facilitates easier identification, reducing the chance of confusion.

- Serves as a reference for assembly and disassembly procedures.

- Promotes a better understanding of the relationships between different parts.

How to Use Illustrations Effectively

- Study the overall layout to familiarize yourself with the system.

- Identify individual components and their respective positions.

- Refer to labels or annotations that clarify specific functions.

- Use the visual guide as a checklist during maintenance tasks.

How to Source Genuine Kohler Parts

When maintaining your outdoor power equipment, acquiring authentic components is essential for optimal performance and longevity. Utilizing original manufacturer items ensures compatibility and reliability, reducing the risk of malfunctions. This guide will outline effective strategies for locating these genuine items, helping you make informed purchasing decisions.

Research Authorized Dealers

Start by identifying certified retailers in your area or online. Authorized dealers typically stock a comprehensive inventory of original components and can provide valuable advice on selection and installation. Visiting their websites or physical locations can offer insights into current availability and special promotions.

Utilize Manufacturer Resources

Many manufacturers provide online resources, including catalogs and search tools to assist customers in locating authentic items. These platforms often feature exploded views of equipment, simplifying the identification of necessary components. Additionally, customer service representatives can assist with inquiries regarding specific needs, ensuring you receive the correct items for your machinery.

Typical Issues and Troubleshooting Tips

When working with small engines, it’s common to encounter various challenges that can hinder performance and efficiency. Understanding these common problems and their solutions is essential for maintaining optimal functionality. This section outlines typical complications faced by users and offers effective troubleshooting strategies.

Here are some frequent issues and their potential causes:

- Starting Difficulties:

- Insufficient fuel supply

- Clogged air filter

- Faulty ignition system

- Uneven Engine Performance:

- Dirty or worn-out spark plug

- Improper fuel mixture

- Blocked exhaust system

- Overheating:

- Low oil levels

- Obstructed cooling fins

- Defective cooling fan

To troubleshoot these issues effectively, follow these tips:

- Check the fuel supply and ensure that it is clean and sufficient.

- Inspect the air filter and replace it if necessary to allow proper airflow.

- Test the ignition system components to confirm they are functioning correctly.

- Clean or replace the spark plug to improve starting and performance.

- Ensure the exhaust system is free from blockages to prevent power loss.

- Regularly check oil levels and refill as needed to avoid overheating.

- Remove any debris from cooling fins and ensure the cooling fan operates efficiently.

By identifying these common issues and implementing the suggested solutions, users can enhance the reliability and longevity of their small engines.

Comparing SV470 with Other Kohler Models

This section aims to highlight the distinctions and similarities between a specific engine model and its counterparts from the same manufacturer. By examining various aspects such as performance, design features, and applications, we can better understand how each model caters to different needs and preferences in the market.

Performance Comparison

The performance metrics of various engine models vary significantly, depending on design and intended use. The specific model in focus excels in delivering reliable power, making it suitable for various applications. However, some alternatives may offer enhanced torque or higher horsepower, catering to specialized tasks or larger machinery.

Design Features

Design features play a crucial role in determining usability and maintenance requirements. While some models prioritize compactness and lightweight construction, others focus on durability and extended service intervals. Notably, differences in cooling systems, air filtration, and fuel efficiency contribute to the overall user experience.

| Feature | Engine Model A | Engine Model B | Engine Model C |

|---|---|---|---|

| Power Output | 20 HP | 18 HP | 22 HP |

| Torque | 35 lb-ft | 30 lb-ft | 40 lb-ft |

| Weight | 120 lbs | 110 lbs | 130 lbs |

| Fuel Type | Gasoline | Gasoline | Gasoline |

DIY Repairs and Maintenance Guide

This section provides essential insights for individuals looking to perform repairs and maintenance on their outdoor power equipment. With a little knowledge and the right tools, you can enhance the lifespan and efficiency of your machinery, ensuring it operates smoothly when you need it the most.

Tools and Materials Needed

- Wrench set

- Screwdriver set

- Socket set

- Oil and fuel filters

- Replacement gaskets

- Lubricants

- Cleaning supplies

Common Maintenance Tasks

- Check and change the oil regularly to maintain optimal performance.

- Replace filters as per the manufacturer’s recommendations to ensure clean fuel flow.

- Inspect spark plugs and replace them if they show signs of wear or damage.

- Clean air filters to prevent debris from entering the engine.

- Examine belts and hoses for signs of fraying or cracking and replace as necessary.

Following these guidelines will not only help in avoiding major issues but will also save time and money in the long run. Regular attention to your equipment ensures that it remains in peak condition, ready for any task ahead.

Where to Find Repair Manuals

Accessing repair manuals is essential for anyone looking to maintain or fix their machinery efficiently. These resources provide detailed instructions, diagrams, and specifications necessary for successful repairs and maintenance tasks.

Here are some reliable sources to consider when searching for repair documentation:

- Manufacturer’s Website: Often, the original equipment manufacturers provide downloadable manuals directly on their websites, ensuring that you have the most accurate and updated information.

- Online Retailers: Websites that specialize in selling equipment often have a section for manuals. These can include both free and paid options.

- Automotive and Machinery Forums: Communities and forums dedicated to specific equipment types frequently share manuals and repair guides among users.

- Local Libraries: Many libraries have archives of repair manuals and reference books that can be accessed for free.

- Specialized Repair Shops: Local mechanics and repair shops might also have physical copies of manuals available for consultation.

Exploring these avenues can significantly simplify the repair process and enhance your understanding of the machinery.