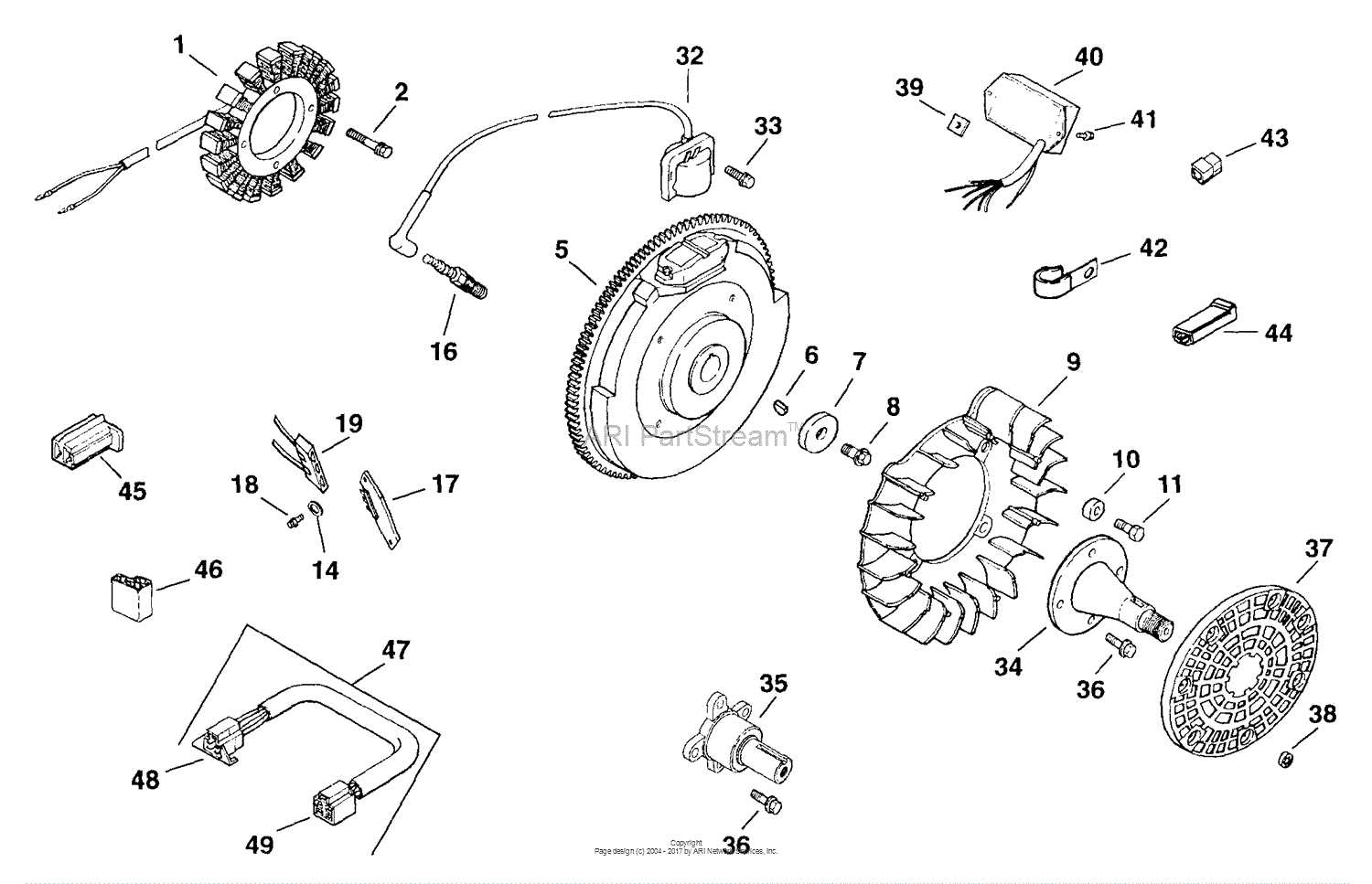

In the world of machinery and equipment, a clear representation of individual elements is crucial for effective maintenance and repair. This visual guide provides a structured overview of various components, illustrating their arrangement and interconnections. Such schematics serve as invaluable resources for technicians and enthusiasts alike, enabling them to navigate the complexities of machinery with ease.

Each section of this guide meticulously outlines specific assemblies, detailing their functions and relationships within the overall system. By breaking down intricate structures into manageable visuals, users can gain insights into how each element contributes to the operational efficiency of the entire unit. This clarity not only enhances understanding but also streamlines troubleshooting processes.

Moreover, the ability to reference a comprehensive layout aids in the identification of parts when sourcing replacements or upgrades. Whether you’re a seasoned professional or a newcomer to the field, familiarity with these representations can significantly enhance your capability to maintain and improve machinery performance. Dive into this informative exploration and unlock the potential of your equipment with confidence.

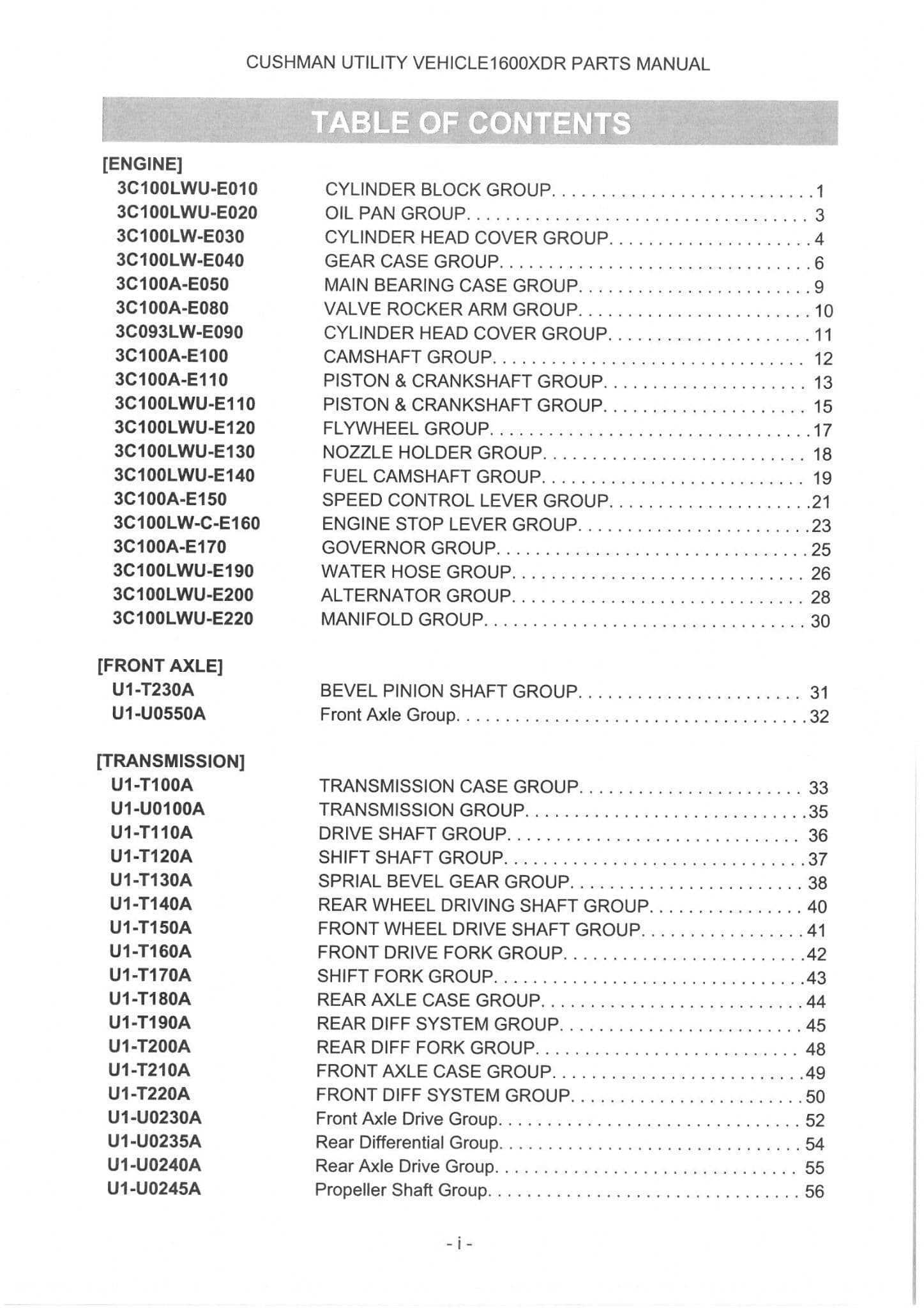

Cushman Parts Diagram Overview

This section provides an essential understanding of the components and their relationships within a specific vehicle system. Analyzing the various elements involved is crucial for maintenance, repair, and optimization.

Visual representations serve as valuable tools for both professionals and enthusiasts. They help to clarify the arrangement and function of each component, ensuring a comprehensive grasp of the overall structure.

- Key Benefits:

- Enhanced understanding of individual components

- Streamlined repair processes

- Improved maintenance practices

- Facilitation of troubleshooting procedures

- Common Elements:

- Mechanical parts

- Electrical components

- Fluid systems

- Frame and chassis structures

Utilizing such visual aids promotes efficiency and accuracy in handling the intricacies of the system, making it easier to navigate through repairs or enhancements. This approach not only saves time but also helps to prevent potential issues arising from misinterpretation of the components involved.

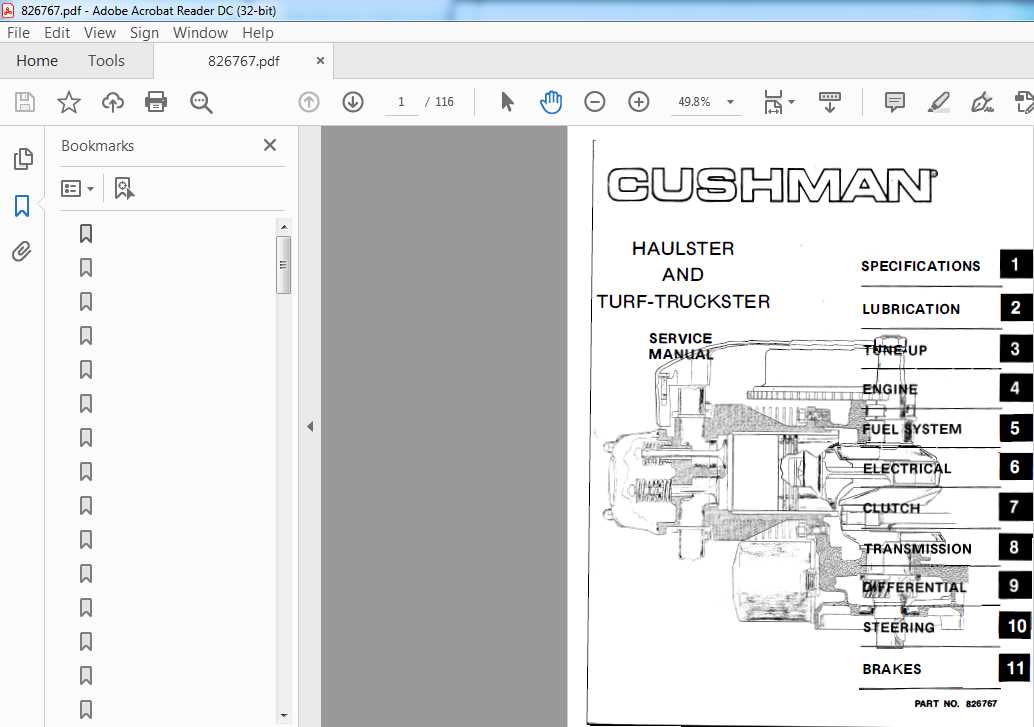

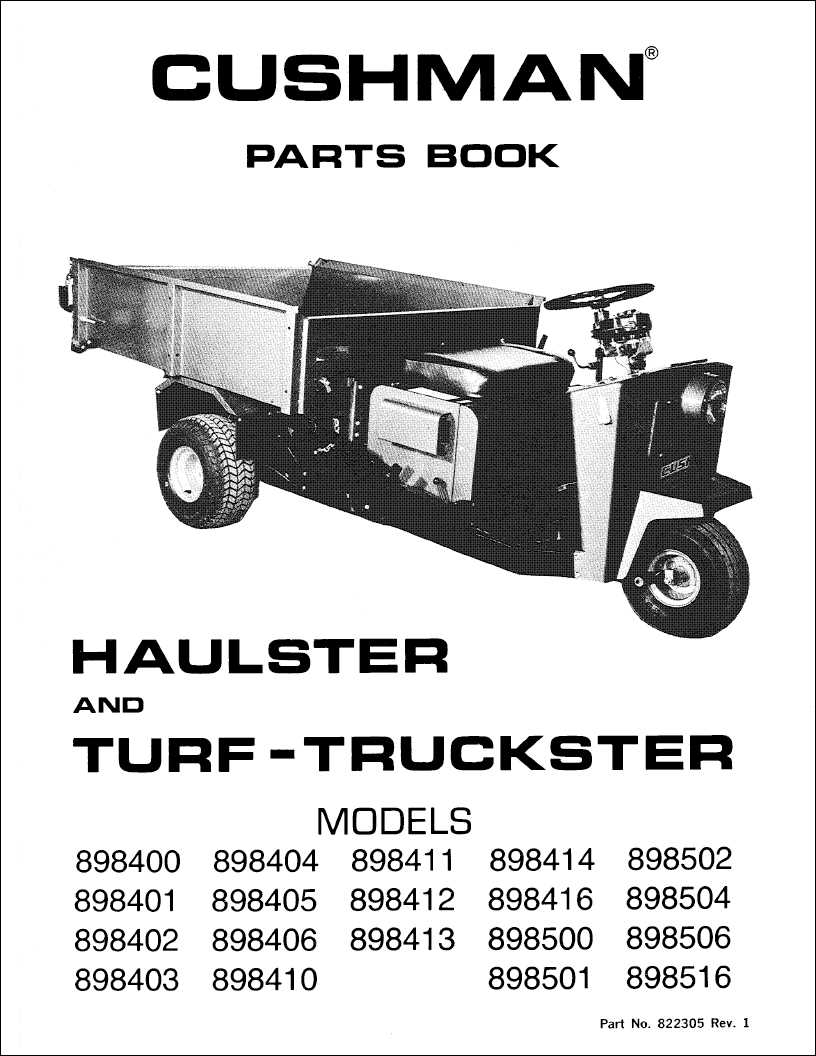

Understanding Cushman Models

Gaining insight into various vehicle configurations can significantly enhance the user experience and operational efficiency. This section explores the nuances of distinct models, shedding light on their unique features and functionalities. By examining these differences, users can make informed decisions based on their specific requirements.

Model Variations

Each model offers a unique blend of design and engineering, tailored to meet diverse applications. From compact units ideal for urban environments to more robust versions designed for heavy-duty tasks, understanding these variations is crucial. Users should consider factors such as performance capabilities, maintenance needs, and operational contexts when selecting the most suitable option.

Key Components

Familiarity with essential elements of these vehicles is vital for optimal usage. Key components, including the drive system, suspension, and electrical framework, play significant roles in overall performance. A thorough grasp of how these parts interact will not only aid in troubleshooting but also contribute to enhanced longevity and reliability of the vehicle.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding complex machinery and systems. They provide a clear overview, making it easier to identify individual elements and their relationships within the entire assembly. This clarity is essential for both maintenance and troubleshooting, ensuring that users can operate equipment effectively and efficiently.

Enhancing Communication

These visual aids significantly enhance communication among technicians, engineers, and users. By presenting information in an easily digestible format, they help convey intricate details that might otherwise be lost in verbal or written descriptions. When everyone involved has a common reference, collaboration improves, leading to quicker problem resolution.

Facilitating Maintenance and Repairs

Maintenance and repair processes benefit greatly from these illustrations. They allow for accurate identification of components that require attention, minimizing the risk of errors during disassembly or reassembly. Furthermore, they serve as valuable educational tools, enabling less experienced individuals to familiarize themselves with the intricacies of the equipment.

In summary, visual representations of components are indispensable resources that streamline communication and enhance the efficiency of maintenance practices.

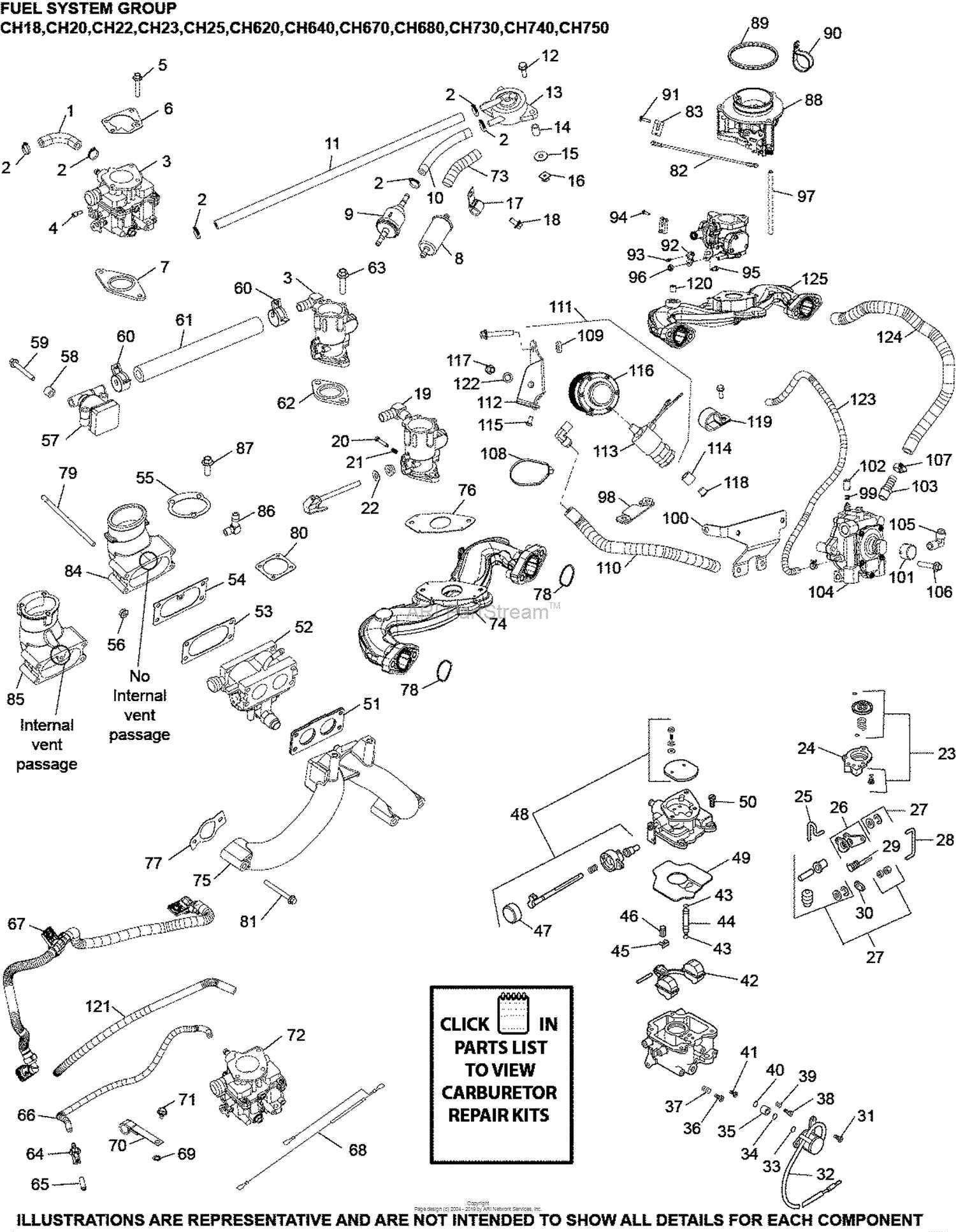

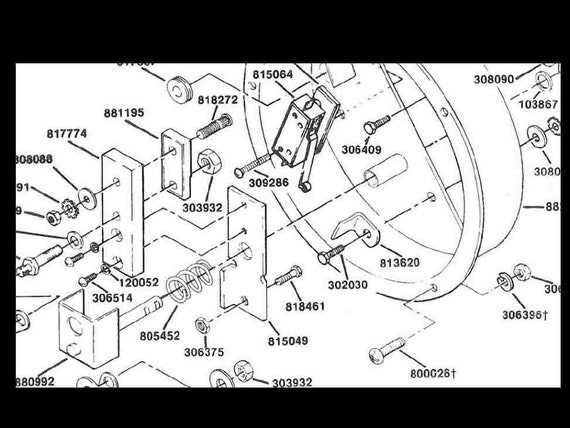

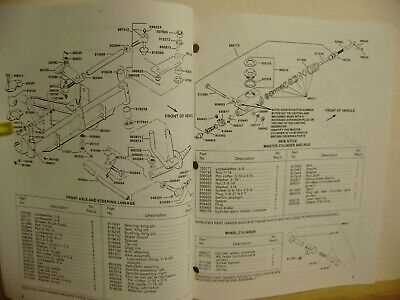

How to Read the Diagram

Understanding a visual representation of components is essential for effective maintenance and assembly. These illustrations provide a detailed overview of how each element interacts within a system, allowing for easier identification and troubleshooting.

Begin by familiarizing yourself with the overall layout, noting how parts are grouped and labeled. Key legends are typically included, offering explanations for symbols and annotations used throughout the illustration.

Next, trace connections between elements to grasp the flow and relationships. Pay attention to directional arrows that indicate movement or flow, as they are crucial for comprehending the system’s operation.

Finally, always refer back to the accompanying documentation for specific instructions or clarifications. This will enhance your understanding and ensure you can effectively apply the knowledge gained from the visual representation.

Common Parts in Cushman Equipment

Understanding the essential components of utility vehicles is crucial for effective maintenance and optimal performance. Various elements work together to ensure smooth operation, and being familiar with these components can aid in troubleshooting and repairs.

Engine and Transmission

The heart of any vehicle lies in its engine and transmission system. These components are responsible for generating power and transmitting it to the wheels. Regular checks on these systems can prevent breakdowns and enhance longevity.

Chassis and Suspension

The structure that supports the vehicle’s body and allows for stability is vital. The chassis, along with the suspension system, ensures a smooth ride by absorbing shocks from the terrain. Maintenance of these elements is essential for safety and comfort.

Regular inspections and timely replacements can lead to the ultimate enhancement of functionality, ensuring the equipment remains reliable and efficient.

Repair and Maintenance Insights

Effective upkeep of machinery is essential for ensuring optimal performance and longevity. Understanding the various components and their functions can greatly enhance the maintenance process. By following systematic procedures and utilizing the right tools, operators can minimize downtime and extend the lifespan of their equipment.

Regular inspections and timely servicing are vital practices. These measures not only prevent unexpected failures but also contribute to a more efficient operational workflow. Here are some key areas to focus on during maintenance routines:

| Area of Focus | Recommended Action |

|---|---|

| Fluid Levels | Check and refill oils, coolants, and other necessary liquids. |

| Wear and Tear | Inspect components for signs of damage or excessive wear. |

| Electrical Systems | Test batteries, wiring, and connections for integrity. |

| Tires and Wheels | Examine tire pressure and tread condition, and check for alignment. |

| Brakes | Assess brake pads and fluid levels; replace as necessary. |

By implementing these practices, operators can ensure their machinery operates smoothly and efficiently, ultimately leading to reduced operational costs and enhanced productivity.

Finding Replacement Parts Easily

Locating the right components for your vehicle can be a straightforward process with the right approach. Understanding where to search and how to identify the necessary items is essential for maintaining the functionality and performance of your equipment. With a bit of guidance, you can streamline the task of sourcing replacements effectively.

Utilizing Online Resources

The internet is a treasure trove of information and resources. Numerous websites specialize in providing detailed information about various models, including specifications and compatibility. Utilizing these online platforms allows you to quickly find the exact components you need by entering the model or serial number. This saves time and ensures you receive the correct replacements for your specific equipment.

Consulting Professional Services

Another efficient method is to reach out to professionals who specialize in your vehicle’s brand. Mechanics and dealers often have extensive knowledge and access to inventories that may not be available online. They can provide insights on the best options for replacements and may even assist in ordering or installing them, ensuring you have the right fit and quality for your needs.

Impact on Performance and Safety

The intricate relationship between components and their arrangement plays a crucial role in the overall effectiveness and security of machinery. Understanding how each element interacts can significantly enhance operational efficiency while minimizing risks associated with malfunction.

Optimized design leads to improved functionality, allowing equipment to perform at its best under various conditions. When all pieces work in harmony, the likelihood of wear and tear decreases, extending the lifespan of the machinery.

Safety considerations are paramount; a well-structured assembly reduces the chances of accidents. Ensuring that each component is accurately placed not only boosts performance but also safeguards operators and bystanders from potential hazards.

Tips for Efficient Troubleshooting

Effective problem resolution can save time and resources. Understanding common issues and their solutions enhances your ability to tackle challenges efficiently.

- Gather Information: Collect all relevant data before starting.

- Check Documentation: Utilize manuals and guides for reference.

- Visual Inspection: Look for obvious signs of wear or damage.

Once you have assessed the situation, consider the following steps:

- Isolate the Issue: Narrow down potential causes systematically.

- Test Components: Use appropriate tools to verify functionality.

- Consult Experts: Don’t hesitate to seek advice from knowledgeable sources.

By following these strategies, you can effectively identify and address issues, leading to quicker resolutions and optimal performance.

Resources for Further Information

This section aims to provide valuable materials and references for those seeking to deepen their understanding of components and mechanisms related to the topic at hand. By exploring a variety of sources, readers can gain insights into technical specifications, maintenance practices, and enhancements.

Online Databases

Numerous websites offer extensive databases filled with manuals, schematics, and user guides that are essential for troubleshooting and repairs. These platforms often include community forums where enthusiasts share experiences and solutions.

Technical Publications

Books and journals focused on machinery and engineering can serve as comprehensive guides. These publications cover topics from design principles to detailed analyses of specific models, enabling readers to delve into advanced concepts.

Case Studies of Successful Repairs

This section explores various instances where effective troubleshooting and restoration techniques have led to impressive outcomes in machinery maintenance. Each example demonstrates the importance of thorough assessment, precise identification of issues, and the implementation of suitable solutions. By examining these cases, we gain insights into best practices that can be applied to similar situations.

Example 1: Vintage Vehicle Restoration

A classic vehicle from the mid-20th century was showing signs of severe wear and mechanical failure. The restoration team approached the task methodically:

- Conducted a comprehensive inspection to pinpoint specific problems.

- Replaced worn-out components with high-quality replacements.

- Performed detailed cleaning and lubrication of the mechanical systems.

- Tested the vehicle rigorously to ensure optimal performance.

The result was a fully functional classic car that retained its original charm while benefiting from modern reliability.

Example 2: Industrial Equipment Overhaul

An aging piece of industrial machinery faced frequent breakdowns, leading to production delays. The maintenance team executed a strategic plan:

- Identified critical areas of deterioration through diagnostic analysis.

- Implemented upgrades to improve efficiency and longevity.

- Provided training for operators to enhance usage and care.

Following these steps, the machinery experienced a remarkable increase in uptime, boosting overall productivity and reducing operational costs.