The arrangement of various components within a system plays a crucial role in its functionality and maintenance. A well-structured layout provides users with the ability to easily identify and access essential elements, facilitating efficient operation and troubleshooting. By examining the organization of these elements, one can gain valuable insights into the overall design and purpose of the equipment.

When exploring the configuration of a particular model, it is essential to consider the interrelationships between different elements. Understanding how each component interacts with others can greatly enhance one’s ability to diagnose issues and implement effective solutions. In this section, we will delve into the intricacies of component arrangements, highlighting key features and their significance in the overall system.

Moreover, recognizing the layout aids in proper installation and replacement of essential elements, ensuring optimal performance. By familiarizing oneself with the organization of these components, users can enhance their operational knowledge and improve their proficiency in handling the equipment.

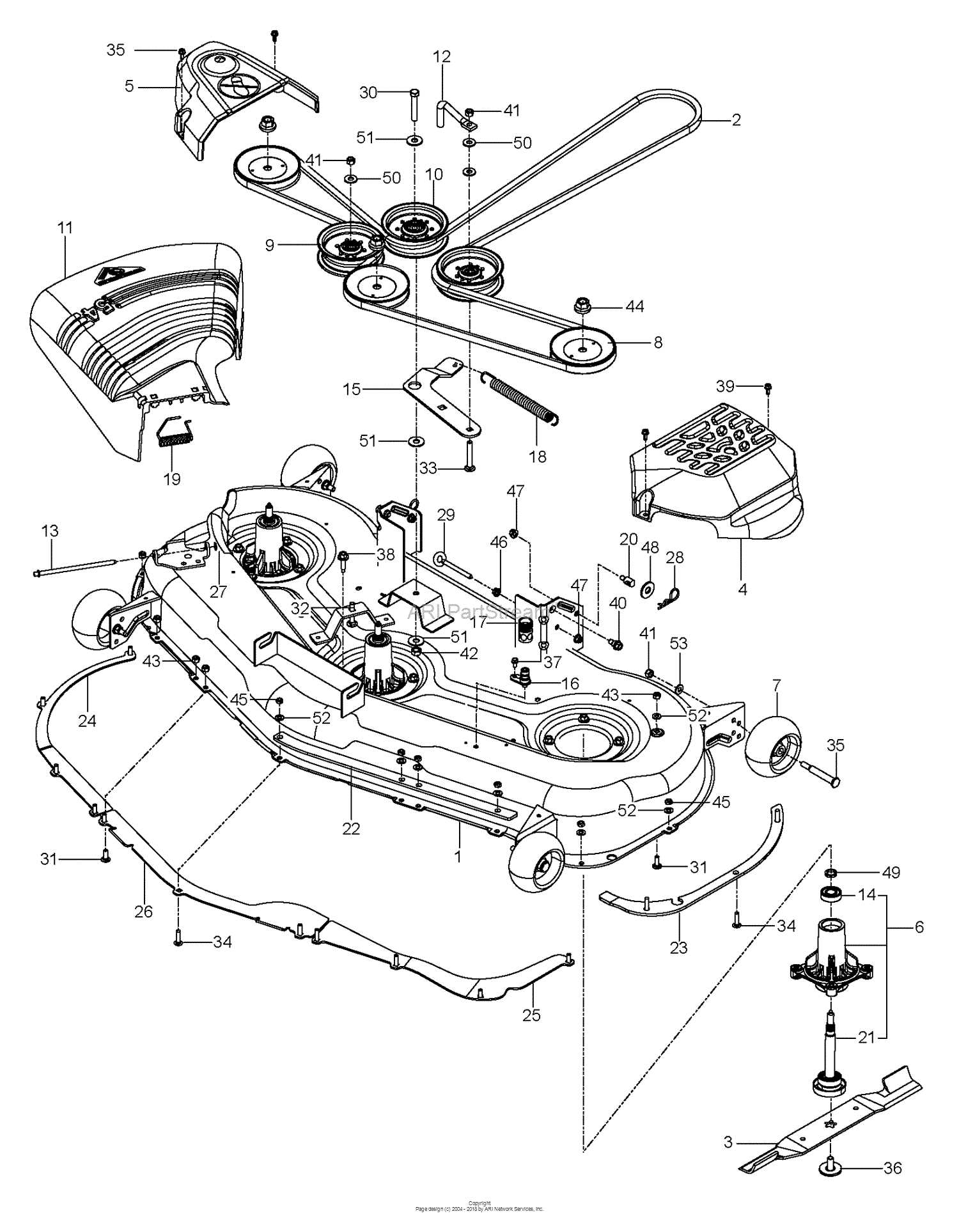

Key Components of the Z254 Diagram

The intricate layout of this device includes several essential elements that play crucial roles in its functionality. Understanding these components is vital for effective operation and maintenance. Each part serves a specific purpose, contributing to the overall performance and efficiency of the unit.

| Component Name | Description |

|---|---|

| Power Supply | Provides the necessary electrical energy for operation. |

| Main Controller | Manages the overall functionality and processes of the device. |

| Display Unit | Shows operational data and status to the user. |

| Input Interface | Allows user commands and data entry. |

| Output Ports | Facilitates communication with external devices. |

Importance of Accurate Parts Identification

Precise identification of components is crucial in any mechanical or electronic system. This process ensures that the right elements are selected and utilized, minimizing errors that could lead to malfunction or inefficiency. Without accurate recognition, operations may be disrupted, causing delays and additional costs for repairs or replacements.

Impact on Functionality

Identifying components correctly directly affects the performance of machinery or devices. When incorrect items are used, the overall functionality can suffer, leading to suboptimal results. Therefore, a thorough understanding of each element’s role is essential for maintaining operational excellence.

Enhancing Maintenance Efficiency

Effective maintenance relies heavily on knowing the correct specifications of each component. When technicians can accurately identify what is needed, they can streamline their processes, ensuring timely repairs and reducing downtime. This not only preserves the integrity of the system but also extends its lifespan.

| Aspect | Benefits |

|---|---|

| Operational Efficiency | Minimized downtime and improved productivity |

| Cost-Effectiveness | Reduced expenses on incorrect replacements |

| System Longevity | Increased lifespan through proper maintenance |

Common Issues in Z254 Maintenance

Proper upkeep of machinery often reveals a variety of challenges that can hinder optimal performance. Understanding these common difficulties is crucial for ensuring smooth operation and longevity. From mechanical wear and tear to electronic malfunctions, each issue can impact efficiency and productivity.

One frequent problem encountered during maintenance involves the deterioration of moving components, which can lead to jams or operational failures. Regular lubrication and timely replacement of worn parts are essential to prevent such occurrences. Additionally, power supply inconsistencies may result in unexpected shutdowns, emphasizing the importance of routine checks on electrical connections.

Another area of concern is the buildup of debris or contaminants within the system, which can affect overall functionality. Implementing a regular cleaning schedule and using protective covers can help mitigate this issue. Lastly, ensuring that software and firmware are updated is vital, as outdated systems can lead to compatibility issues and decreased performance.

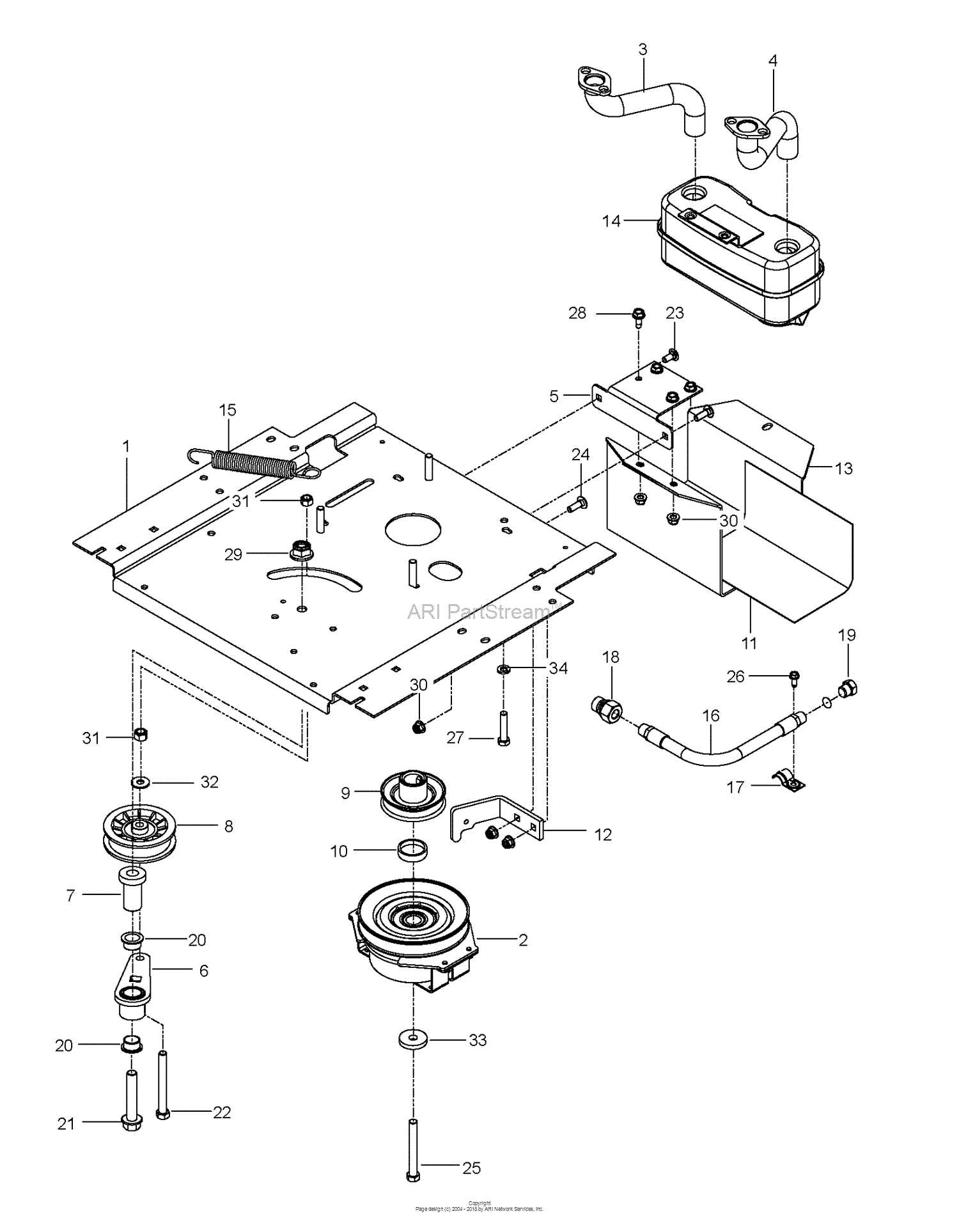

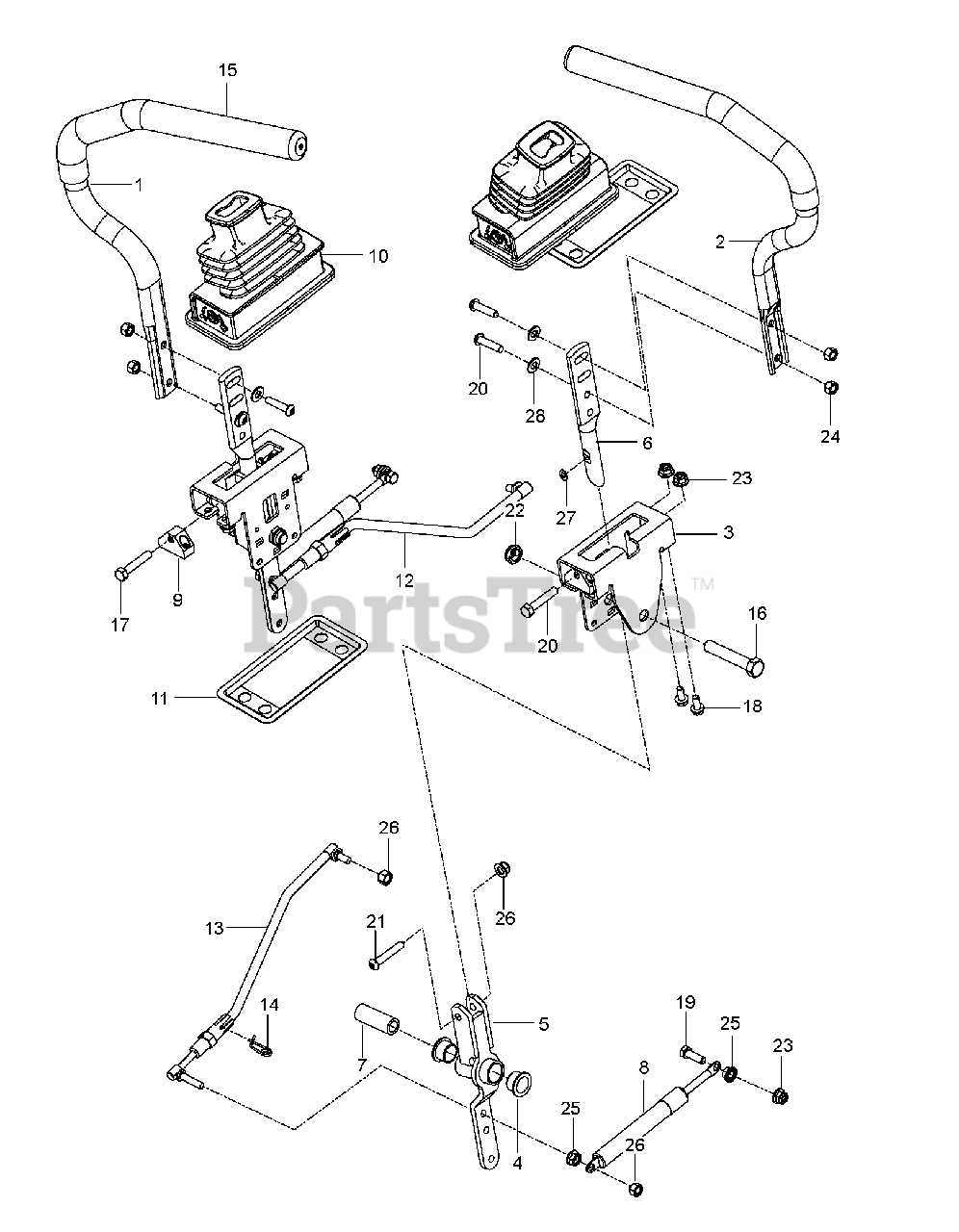

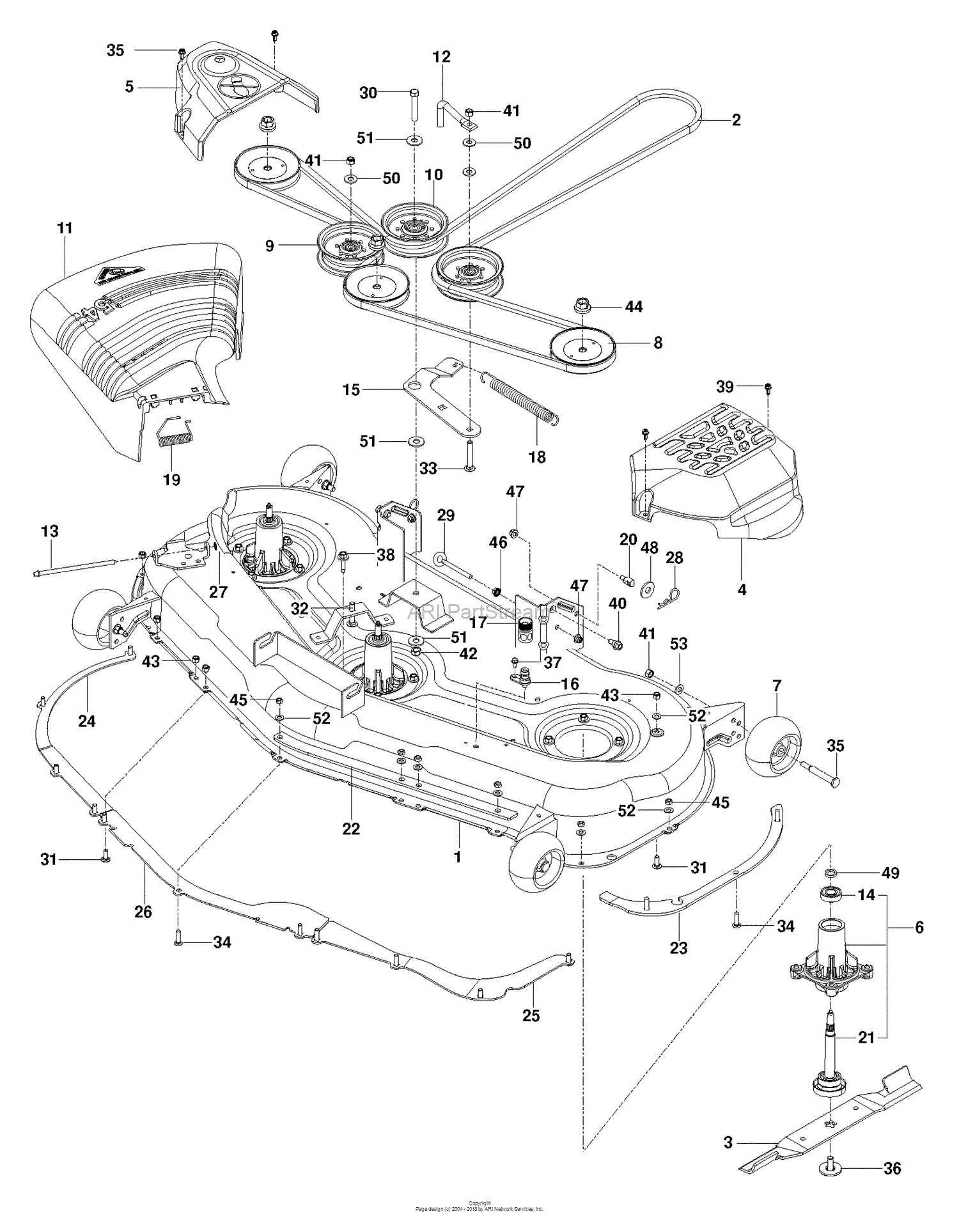

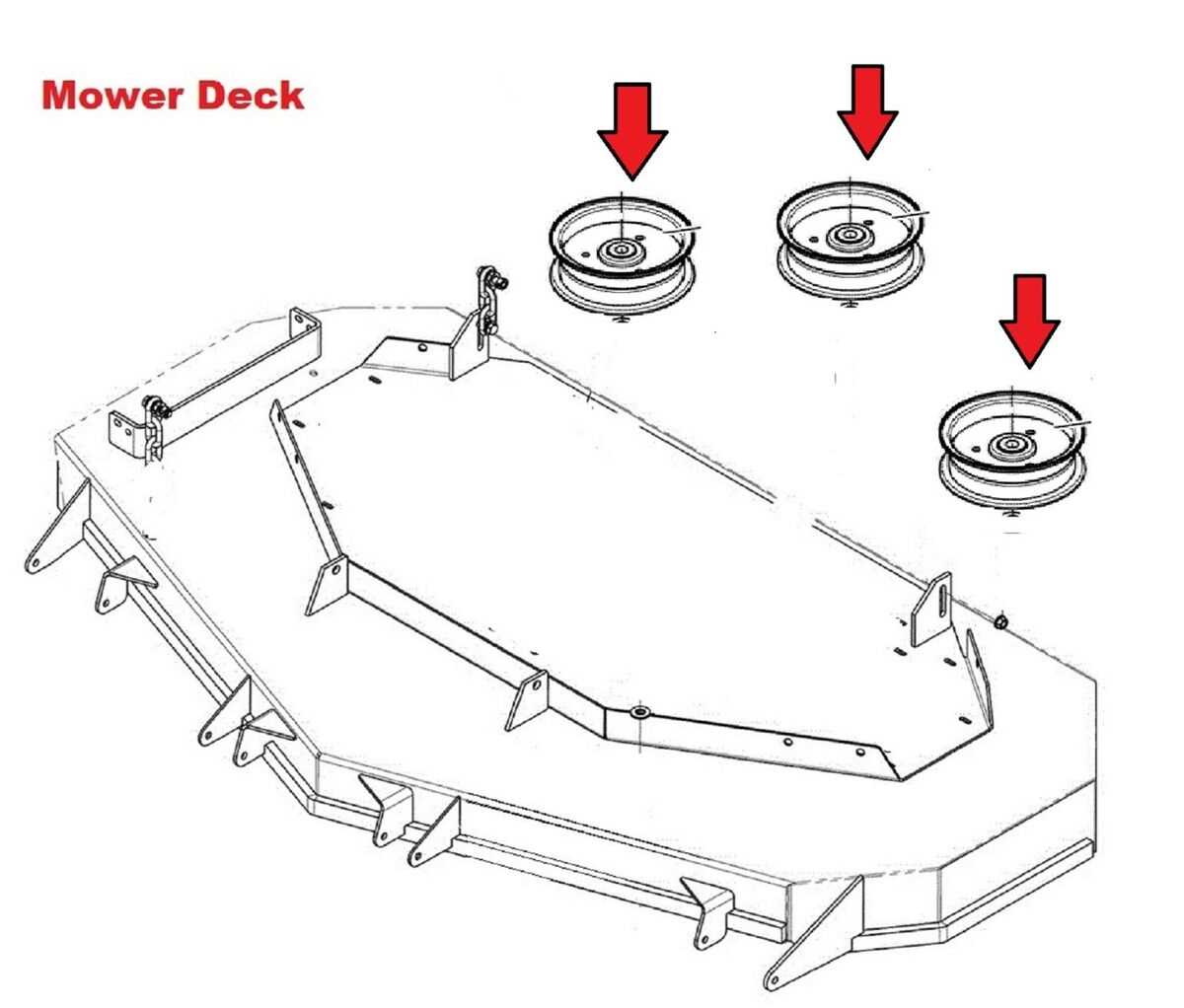

Interpreting the Parts Assembly Guide

This section focuses on understanding the assembly instructions for the various components involved in the system. By familiarizing oneself with the assembly guide, users can ensure proper integration and optimal functionality of each element within the unit.

When approaching the assembly guide, it is crucial to consider the following aspects:

- Component Identification: Recognizing each component’s role is essential for effective assembly.

- Step-by-Step Instructions: Carefully following the sequential steps helps avoid mistakes.

- Visual References: Utilizing accompanying illustrations can clarify complex assembly procedures.

Additionally, users should pay attention to the following guidelines:

- Review the entire guide before starting to familiarize yourself with the process.

- Gather all necessary tools and components in advance to streamline the assembly process.

- Take notes on any specific requirements or warnings highlighted in the guide.

By adhering to these principles, individuals can effectively interpret the assembly guide, leading to a successful integration of the components.

Tools Required for Z254 Repairs

When undertaking maintenance or fixing issues in specialized equipment, having the right tools is crucial for efficient and effective repairs. The proper instruments not only enhance the repair process but also ensure safety and precision in handling sensitive components. Understanding the essential tools can streamline troubleshooting and restoration efforts.

Essential Hand Tools

Basic hand tools form the foundation of any repair kit. These instruments are indispensable for disassembling and reassembling equipment components.

| Tool | Purpose |

|---|---|

| Screwdriver Set | To loosen or tighten screws on various components. |

| Wrench Set | For adjusting nuts and bolts securely. |

| Pliers | To grip, twist, and cut wires or small parts. |

Specialized Repair Equipment

In addition to hand tools, specialized equipment may be necessary to handle complex repairs effectively. These tools cater to specific tasks that require more precision or expertise.

| Tool | Purpose |

|---|---|

| Multimeter | To measure voltage, current, and resistance for troubleshooting. |

| Heat Gun | For applying heat to shrink tubing or remove components. |

| Desoldering Pump | To remove solder from connections for repairs or replacements. |

Comparative Analysis of Z254 Models

This section delves into the examination of various iterations of a specific device, focusing on their similarities and differences. By exploring these variations, we aim to provide a clearer understanding of how advancements and modifications have shaped functionality and user experience.

Key Features Across Models

When comparing different versions, several key characteristics stand out:

- Performance: Variants may differ in processing speed and efficiency.

- Connectivity: Some models offer enhanced communication capabilities.

- User Interface: The layout and accessibility of controls can vary significantly.

- Durability: Material quality and resistance to environmental factors may differ.

Target Applications

Each iteration is designed with specific use cases in mind, influencing their adoption in various sectors:

- Office environments, emphasizing efficiency and ease of use.

- Industrial applications, requiring robust performance under challenging conditions.

- Portable options aimed at flexibility for on-the-go tasks.

Step-by-Step Disassembly Process

Disassembling a complex device requires careful planning and execution to ensure that each component is handled appropriately. This section provides a detailed approach to dismantling, allowing for a systematic understanding of each step involved.

-

Preparation:

- Gather necessary tools such as screwdrivers, pliers, and anti-static wrist straps.

- Ensure a clean and organized workspace to prevent misplacing small components.

- Refer to the device’s manual for specific instructions and warnings.

-

Initial Steps:

- Power off the device and unplug it from any power sources.

- Remove any external attachments like cases, covers, or peripherals.

- Document the initial state with photos for reference during reassembly.

-

Component Removal:

- Begin by unscrewing or unclipping the outer casing, starting from the edges.

- Carefully detach any internal components, such as circuit boards or connectors, by loosening screws or unclipping them.

- Place each removed part in labeled containers to avoid confusion later.

-

Final Disassembly:

- Continue to disassemble internal sections until all components are removed.

- Inspect each part for damage and take notes for any necessary replacements.

- Maintain a systematic approach to ensure every piece is accounted for.

Following this methodical process will facilitate a smooth disassembly experience, making it easier to understand the assembly and function of each individual element.

Reassembly Tips for Optimal Performance

Ensuring efficient functionality after disassembly requires careful attention during the reassembly process. This section provides essential guidelines to enhance the performance of the equipment by properly reattaching components and verifying their positions.

Steps to Follow

Adhering to a structured approach can significantly impact the final outcome. Follow these key steps:

- Organize all components systematically to avoid confusion.

- Inspect each item for damage or wear before reinstallation.

- Ensure alignment and orientation match the original configuration.

Verification Checklist

After reassembly, utilize the following checklist to confirm that everything is in order:

| Component | Status | Notes |

|---|---|---|

| Connector | Secure | Check for proper engagement. |

| Fasteners | Tight | Ensure no parts are loose. |

| Alignment | Correct | Verify positioning with the original layout. |

By following these recommendations, you can achieve optimal functionality and prolong the lifespan of the equipment.

Resources for Further Z254 Learning

For those eager to deepen their understanding of the subject, a variety of materials and resources are available. These include manuals, online courses, and community forums that provide valuable insights and practical knowledge. Engaging with these resources can enhance one’s comprehension and skills related to the equipment in question.

Recommended Reading Materials

Books and guides that focus on technical aspects can be highly beneficial. Consider exploring comprehensive manuals that offer detailed explanations and troubleshooting techniques. Here are some suggestions:

| Title | Author | Publication Year |

|---|---|---|

| Technical Guide to Equipment | John Smith | 2020 |

| Understanding Operational Mechanisms | Jane Doe | 2019 |

| Maintenance and Repair Handbook | Alan Brown | 2021 |

Online Learning Platforms

Utilizing online platforms can facilitate flexible learning opportunities. Websites offering courses or tutorials on related technologies are excellent for gaining practical skills. Look for courses that focus on hands-on experience and provide certification upon completion.

Frequently Asked Questions About Z254

This section addresses common inquiries related to the model in question. It aims to provide clarity on various aspects, ensuring users have a comprehensive understanding of its functionalities, components, and maintenance requirements.

General Information

Many users seek information about the features and specifications of this device. Below are some frequently posed questions regarding its operation and capabilities:

| Question | Answer |

|---|---|

| What are the main features of this model? | The device offers advanced printing capabilities, user-friendly interface, and robust connectivity options. |

| How can I maintain it? | Regular cleaning and using compatible supplies are essential for optimal performance. |

| What troubleshooting steps should I follow? | Check connections, ensure proper supply usage, and consult the manual for specific error codes. |

Compatibility and Usage

Users often inquire about compatibility with different software and supplies. Understanding these factors is crucial for seamless operation.

| Compatibility | Details |

|---|---|

| Software | This model supports various design applications for efficient operation. |

| Supplies | Utilizing manufacturer-recommended supplies is advised for best results. |