This section delves into the intricate elements that comprise a particular model of machinery. By exploring the various components, users can gain valuable insights into the functionality and maintenance of the equipment. Understanding how each piece interacts enhances operational efficiency and prolongs the life of the machine.

In this discussion, we will highlight key features and functionalities of the components, offering a comprehensive overview. Recognizing the significance of each part allows for informed decisions regarding repairs and upgrades, ensuring optimal performance in diverse applications.

Through this examination, users will be equipped with essential knowledge that empowers them to navigate the complexities of their machinery. Whether for routine maintenance or troubleshooting, having a clear understanding of the internal workings is crucial for any operator.

Tuff Torq K51A Overview

This section provides an in-depth look at a specific type of transmission system designed for various outdoor equipment. Its construction and engineering principles play a crucial role in enhancing performance and durability in demanding conditions.

Features of this system include its robust build quality, which ensures longevity and reliability even under heavy usage. The design focuses on efficiency, providing smooth operation and seamless transitions between different speed settings.

Applications for this mechanism are diverse, ranging from residential lawn care tools to commercial-grade machinery. Understanding its components and functionality is essential for effective maintenance and optimal performance.

Overall, this system exemplifies innovative engineering aimed at meeting the needs of users who require high standards in performance and reliability for their equipment.

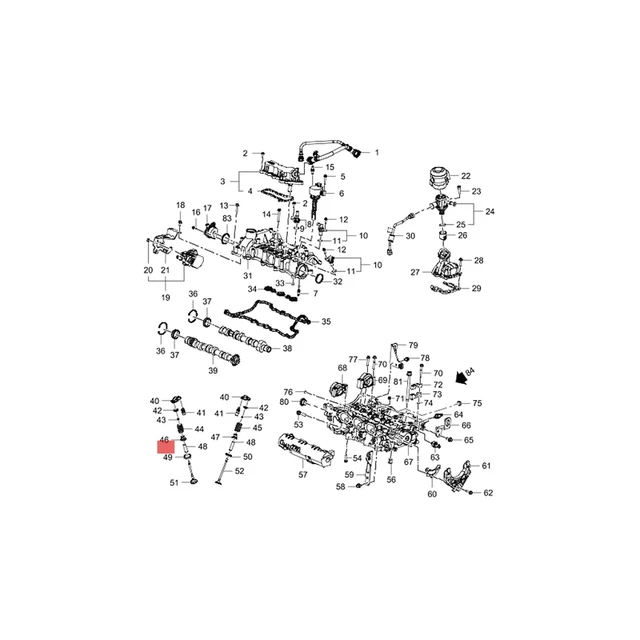

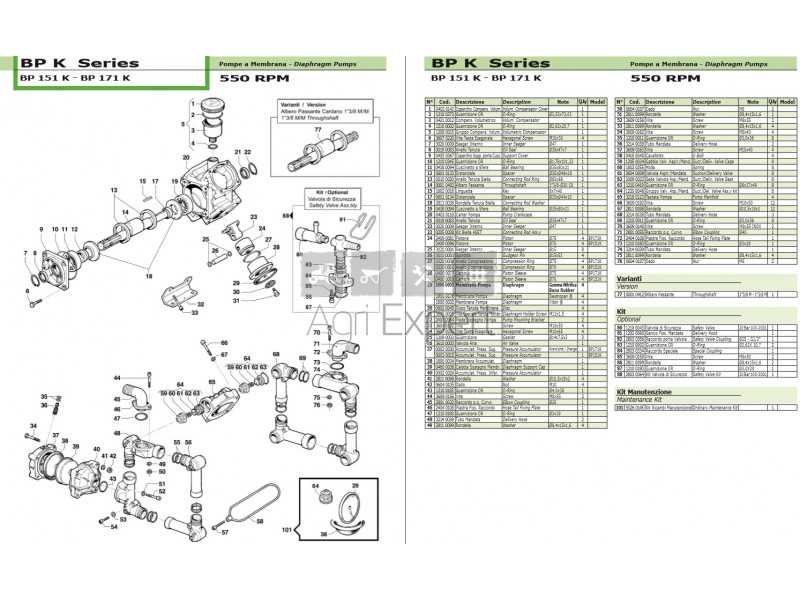

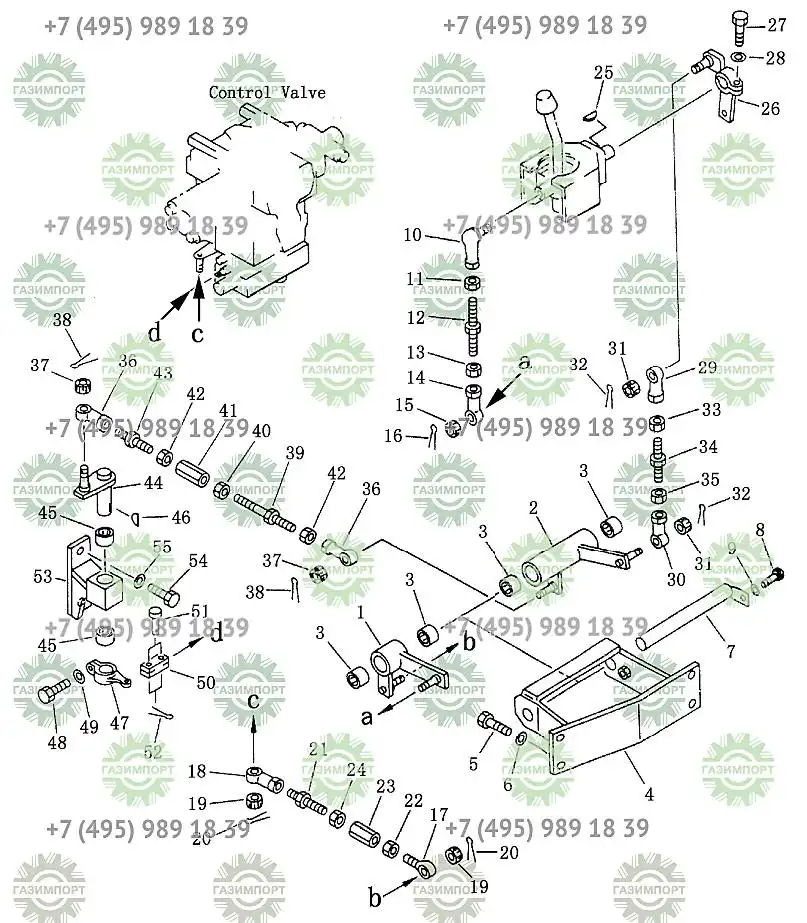

Understanding the Parts Diagram

Comprehending the schematic representation of components is essential for efficient maintenance and repair. This visual guide provides valuable insights into the configuration and relationships among various elements. Familiarity with these illustrations helps in identifying necessary components and understanding their functions within the system.

Key Components Overview

Each segment of the illustration typically highlights specific items that play crucial roles in the overall operation. Recognizing these elements enables technicians and users to quickly locate replacements or perform troubleshooting. Below is a summary of some fundamental elements often found in these representations:

| Component Name | Description |

|---|---|

| Drive Mechanism | Responsible for transferring power to the operational parts. |

| Control Unit | Manages the operational parameters and ensures efficiency. |

| Cooling System | Prevents overheating of components during prolonged use. |

| Housing | Encases and protects internal elements from external damage. |

Benefits of Familiarity

Understanding the layout of components fosters better problem-solving abilities and enhances repair efficiency. Knowledge of how different parts interact can lead to quicker diagnosis of issues and reduce downtime during maintenance activities.

Main Components of the K51A

The intricate assembly of this model consists of several crucial elements that work together to ensure optimal functionality and efficiency. Understanding these components can enhance both maintenance and performance, enabling users to appreciate the engineering behind the system.

Engine Assembly

This central unit provides the necessary power for operation. It converts fuel into mechanical energy, driving the entire mechanism. Regular checks on the engine’s condition can prevent significant malfunctions and ensure longevity.

Transmission System

This subsystem plays a vital role in transferring power from the engine to the wheels. It consists of gears and linkages that facilitate smooth movement. Proper maintenance of this system is essential for achieving optimal performance and responsiveness.

Functionality of Each Part

This section delves into the roles and contributions of various components within the mechanism, highlighting their significance in overall performance. Understanding how each element operates is crucial for efficient maintenance and effective troubleshooting.

Drive Shaft: This crucial element transmits power from the engine to the wheels, facilitating movement and ensuring the system operates smoothly.

Gear Assembly: The gear assembly plays a pivotal role in adjusting torque and speed, allowing the operator to control performance based on specific needs.

Hydraulic Pump: Responsible for generating hydraulic pressure, this component is vital for activating various functions, enhancing maneuverability and control.

Control Linkage: This system of rods and levers enables the user to direct operations effectively, translating manual inputs into precise actions.

Filter: Essential for maintaining cleanliness, the filter prevents contaminants from entering the hydraulic system, thereby prolonging the lifespan of the equipment.

Housing: The protective casing not only shields internal mechanisms from external elements but also ensures proper alignment and stability during operation.

Common Issues and Solutions

This section addresses frequent challenges faced by users and provides practical solutions to enhance performance and longevity.

- Engine Overheating:

Overheating can lead to significant damage. Ensure the cooling system is functioning properly and that there are no blockages. Regular maintenance checks are essential.

- Fluid Leaks:

Leaks can arise from various seals and gaskets. Inspect these areas regularly and replace any damaged components to prevent fluid loss.

- Poor Performance:

A decrease in efficiency may be due to clogged filters or worn-out belts. Clean or replace these parts as needed to restore optimal functioning.

- Noisy Operation:

Unusual sounds can indicate wear or misalignment. Check all moving components and adjust or replace as necessary to eliminate noise.

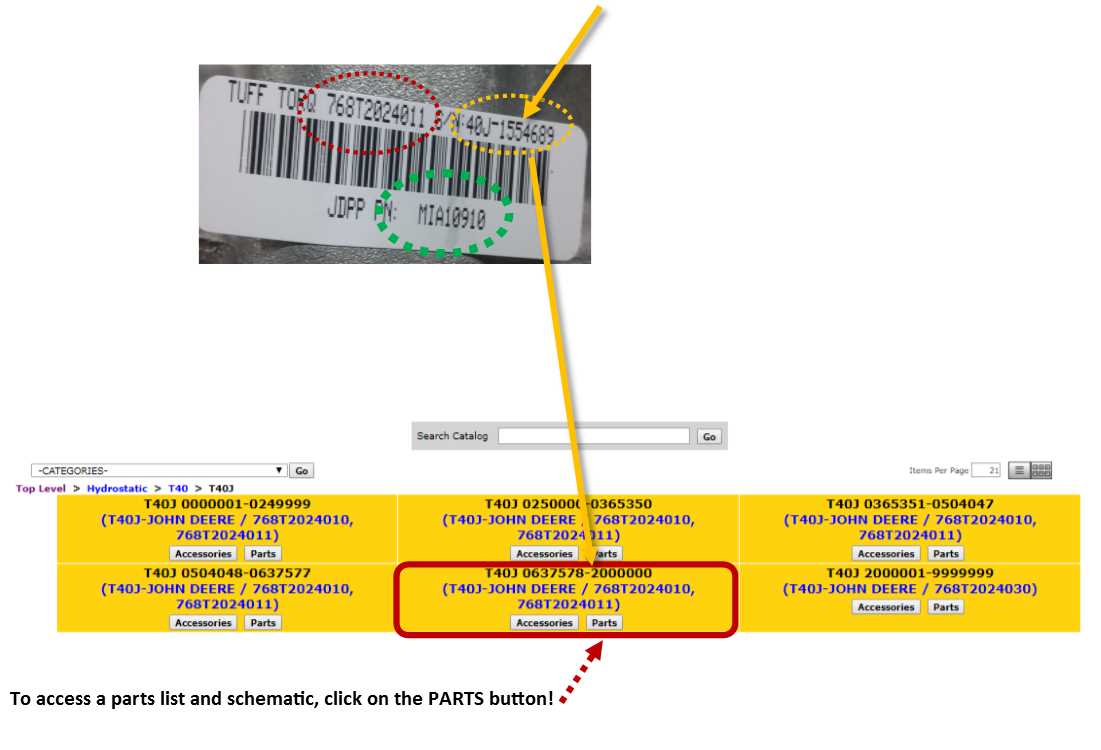

Replacement Parts Availability

When it comes to maintaining machinery, ensuring the availability of essential components is crucial for optimal performance. Access to quality replacements can significantly enhance the longevity and functionality of equipment. It is important for users to be informed about where to find these necessary items and the options available to them.

Sources for Components

Numerous retailers and online platforms specialize in offering high-quality replacements for various types of machinery. Authorized dealers often provide genuine items, ensuring compatibility and reliability. Additionally, aftermarket suppliers may offer alternatives that can be more cost-effective while still meeting performance standards.

Ordering and Delivery Options

Most suppliers provide convenient ordering systems, allowing users to select and purchase components easily. Shipping options can vary, with some retailers offering expedited delivery to minimize downtime. Checking stock levels and estimated delivery times is advisable to ensure timely access to needed replacements.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended lifespan and optimal performance of mechanical systems. By adhering to a few straightforward practices, you can prevent potential issues and enhance the overall functionality of your equipment.

- Routine Inspections: Periodically check for signs of wear and tear. Look for any unusual noises, leaks, or vibrations that could indicate underlying problems.

- Keep it Clean: Maintain cleanliness by regularly removing debris and dirt. This not only improves appearance but also prevents blockages and overheating.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction. Proper lubrication minimizes wear and enhances operational efficiency.

- Storage Conditions: When not in use, store equipment in a dry, cool place to prevent rust and damage from moisture.

- Follow Manufacturer Guidelines: Adhere to the maintenance schedule and recommendations provided by the manufacturer to ensure all components function as intended.

Implementing these maintenance strategies will significantly contribute to the durability and reliability of your machinery, allowing it to serve you effectively for years to come.

Assembly and Disassembly Guide

This section provides a comprehensive overview of the processes involved in putting together and taking apart the specified equipment. Proper handling during these procedures ensures optimal performance and longevity of the components.

Preparation for Assembly

Before commencing the assembly, gather all necessary tools and components. Ensure that the workspace is clean and organized to facilitate smooth operation. Inspect each piece for any signs of damage or wear that may affect functionality.

Steps for Disassembly

To safely disassemble the unit, begin by removing any external coverings. Carefully document the sequence of parts as they are taken apart to ease the reassembly process. Maintain an orderly arrangement of the components to avoid misplacement. Follow the reverse order of assembly for efficient disassembly.

Tools Required for Repairs

To effectively carry out maintenance or repairs on your machinery, having the right instruments is essential. Proper tools not only ensure that the job is completed efficiently but also help in avoiding potential damage to components. Below is a list of necessary equipment that will assist you in the repair process.

Basic Tools

- Wrenches (both adjustable and fixed)

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and standard)

- Socket set with various sizes

- Torque wrench

Specialized Equipment

- Parts cleaner for degreasing

- Compression gauge for testing

- Multimeter for electrical diagnostics

- Hydraulic jack for lifting

- Safety gear (gloves, goggles, etc.)

Having these tools on hand will greatly facilitate the repair process, making it smoother and more efficient. Always ensure that your tools are in good condition before starting any maintenance work.

Upgrading Your K51A Components

Enhancing the functionality and performance of your machine can significantly improve its overall efficiency. By replacing or upgrading specific elements, you can ensure that your equipment operates at its best, leading to a more satisfying user experience.

Evaluating Current Components: Start by assessing the existing components for wear and tear. Identifying parts that may be underperforming is crucial in determining what upgrades are necessary.

Choosing Quality Alternatives: Opt for high-quality replacements that offer better durability and performance. Investing in premium options can lead to longer-lasting improvements and enhanced capabilities.

Installation Process: Follow the manufacturer’s guidelines when installing new components. Proper installation ensures that everything functions smoothly and safely, minimizing the risk of future issues.

Regular Maintenance: After upgrading, maintain your machine regularly. Routine checks and servicing can prevent potential problems and extend the life of your newly upgraded elements.

By thoughtfully selecting and upgrading components, you can achieve optimal performance and reliability from your equipment.

Comparing K51A with Other Models

This section explores the distinctions and similarities between the K51A and various other machinery options in its category. By examining these comparisons, users can make informed decisions based on their specific requirements and preferences.

When evaluating different models, it is essential to consider factors such as performance, durability, and maintenance. The K51A exhibits notable strengths in these areas, making it a viable choice for many applications. However, alternative options may offer features that cater to unique operational needs.

For instance, while the K51A excels in efficiency, other models might prioritize enhanced power or advanced technological integrations. Understanding these nuances allows potential users to assess which machine aligns best with their objectives.

Additionally, compatibility with various attachments and accessories is another critical aspect to explore. Users should examine how the K51A compares in this regard to ensure optimal functionality within their specific contexts.

Resources for Further Information

This section aims to provide valuable sources for those seeking additional knowledge and guidance related to the specific machinery components discussed earlier. Accessing the right materials can enhance understanding and assist in maintenance or repairs.

Recommended Online Platforms

Books and Publications

- Comprehensive Guides on Mechanical Systems

- Maintenance Handbooks for Machinery

- Technical Manuals on Related Equipment