The efficient operation of a water circulation system is essential for maintaining the cleanliness and health of recreational water environments. Various elements work together to ensure proper flow and filtration, contributing to an enjoyable experience for users. Understanding these components can aid in effective maintenance and troubleshooting.

Key elements within this system include the main assembly that facilitates the movement of water, various filters that capture debris, and valves that control flow direction. Each component plays a vital role, and recognizing their functions can help users optimize their setup for maximum efficiency.

Familiarity with the layout of these components allows for easier identification of issues and streamlines the repair process. By knowing how each piece interacts within the larger system, users can ensure their recreational water environment remains safe and inviting.

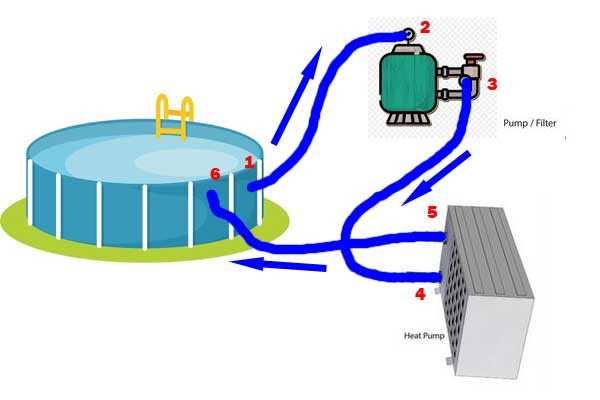

This section aims to provide an overview of the essential elements involved in the operation of a water circulation system for recreational basins. Each component plays a crucial role in ensuring efficient functionality and maintaining clarity within the aquatic environment. Understanding these elements helps in effective management and maintenance.

Key Components of the Circulation System

The following table outlines the vital components found within the system, highlighting their functions and significance:

| Component | Function |

|---|---|

| Motor | Powers the entire assembly, enabling movement of water. |

| Filter | Cleans debris and contaminants, ensuring water purity. |

| Skimmer | Removes surface debris, contributing to water clarity. |

| Return Jet | Distributes treated water back into the recreational area. |

Maintaining System Efficiency

Regular upkeep of these components is vital for optimal performance. Routine checks can prevent malfunctions and extend the lifespan of the system. Proper cleaning and timely replacements of essential parts can significantly enhance the overall effectiveness of the water circulation system.

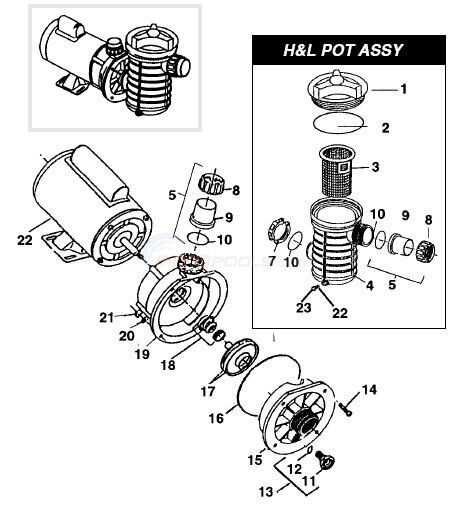

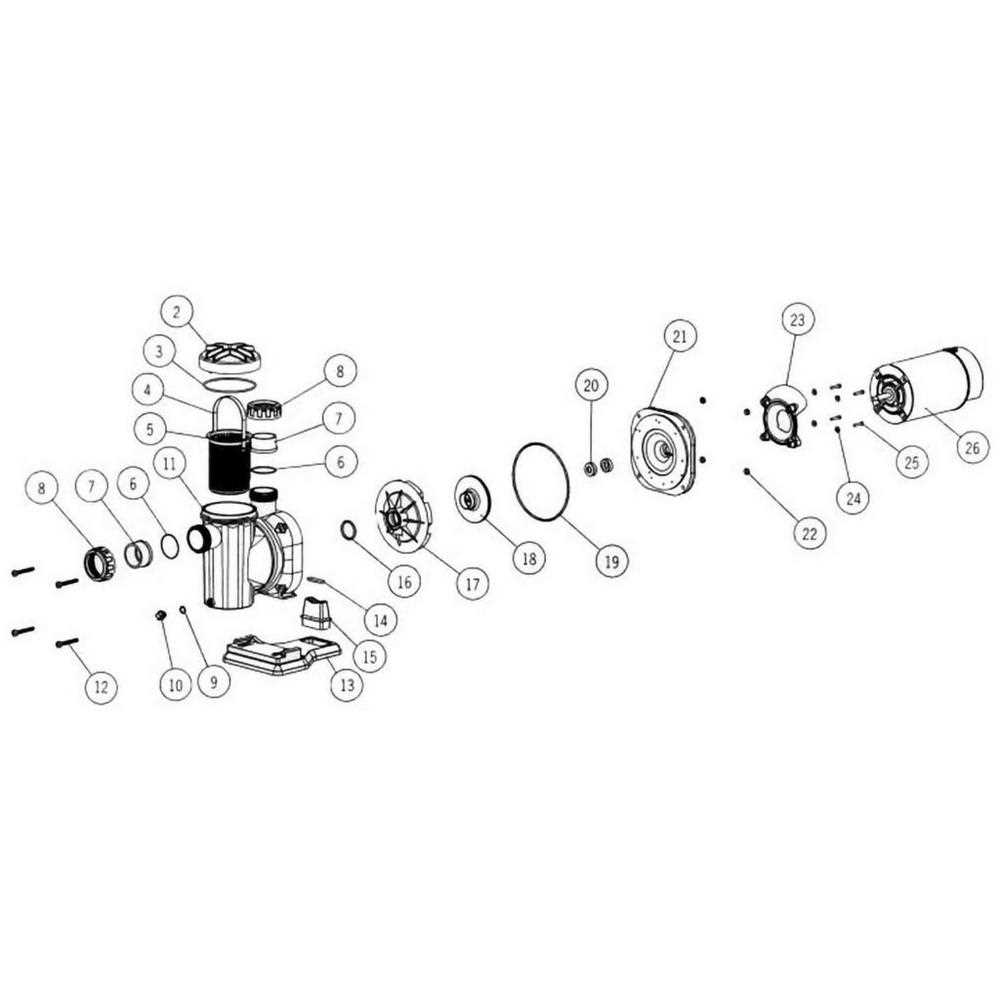

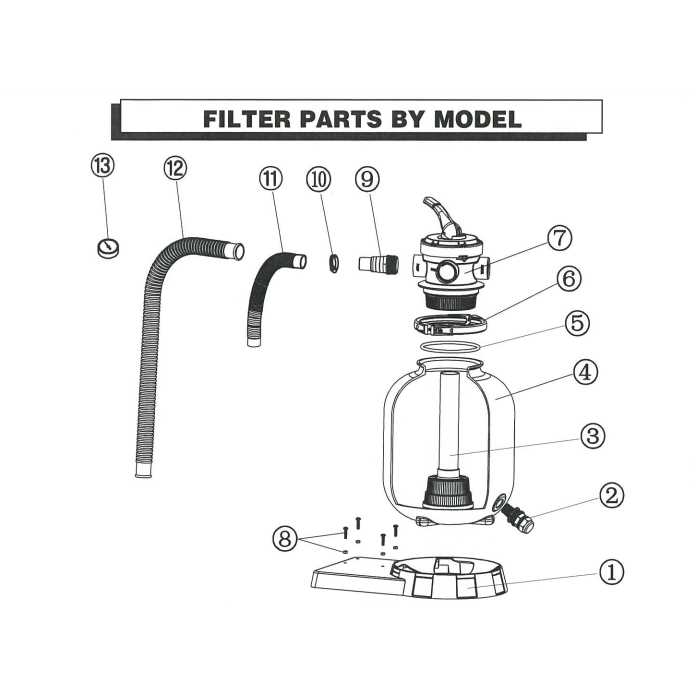

Essential Parts of a Pump System

Understanding the key components of a fluid circulation mechanism is crucial for effective operation and maintenance. Each element plays a vital role in ensuring the efficiency and reliability of the entire system.

1. Motor: The driving force behind the system, converting electrical energy into mechanical energy to facilitate fluid movement.

2. Impeller: A rotating component that increases the fluid’s velocity and directs it toward the discharge outlet, ensuring optimal flow rates.

3. Volute: The casing surrounding the impeller, designed to convert kinetic energy into pressure, directing the fluid smoothly to the discharge point.

4. Strainer: A filter mechanism that prevents debris and large particles from entering the system, protecting internal components from damage.

5. Seal: A critical element that prevents leaks by ensuring a tight fit between moving parts, maintaining system integrity and performance.

6. Discharge Outlet: The point where the fluid exits the system, designed to connect to various plumbing configurations for efficient distribution.

Recognizing these fundamental components enables users to troubleshoot issues effectively and maintain optimal functionality throughout the system’s lifespan.

Functions of Each Pump Element

Understanding the role of various components within a water circulation system is essential for efficient operation. Each element plays a specific function, contributing to the overall performance and effectiveness of the mechanism. Grasping these roles allows users to troubleshoot issues and maintain optimal functionality.

Motor

The motor serves as the heart of the mechanism, providing the necessary energy to initiate movement. It converts electrical energy into mechanical energy, enabling the flow of water throughout the system. A properly functioning motor is crucial for maintaining adequate pressure and ensuring that water circulates effectively.

Impeller

The impeller acts as a propelling device, moving water through the system. It spins rapidly, creating a centrifugal force that draws water in and pushes it out. This action is vital for maintaining circulation and preventing stagnation, which can lead to various complications.

Maintenance Tips for Pool Equipment

Proper care and attention to your aquatic facility’s equipment are essential for ensuring longevity and optimal performance. Regular upkeep not only enhances efficiency but also prevents costly repairs and replacements. Implementing a structured maintenance routine can significantly impact the overall health of your water system.

Regular Inspections

Conducting frequent evaluations of all essential components is crucial. Look for any signs of wear or damage, such as cracks or leaks, which could lead to more significant issues if left unaddressed. Ensure that all connections are secure and that filters are clean to maintain effective operation.

Cleaning Procedures

Keeping all equipment clean is vital for functionality. Remove debris and sediment from filters and other surfaces regularly. Consider using a gentle cleanser designed specifically for your equipment to avoid any potential harm. Maintaining a tidy environment around your setup will also help prolong the lifespan of these essential components.

Identifying Common Pump Issues

Understanding frequent complications that can arise in circulation systems is essential for maintaining efficiency and longevity. Regular monitoring and prompt action can prevent minor inconveniences from escalating into significant malfunctions.

One typical problem is insufficient flow, which may result from blockages or obstructions in the system. If water isn’t circulating as expected, check for any debris that could be obstructing the intake or discharge lines.

Another common issue is excessive noise. Unusual sounds during operation can indicate worn bearings or loose components. It is advisable to listen for any unusual vibrations or rattling that could signify underlying mechanical issues.

Leaking seals is also a prevalent concern. Regularly inspect connections and seals for any signs of moisture, which can lead to inefficient operation and increased wear over time. Early detection of leaks can save on costly repairs.

Lastly, overheating can occur due to prolonged use or inadequate ventilation. Ensuring that the unit has proper airflow and isn’t overworked will help prevent overheating and extend its lifespan.

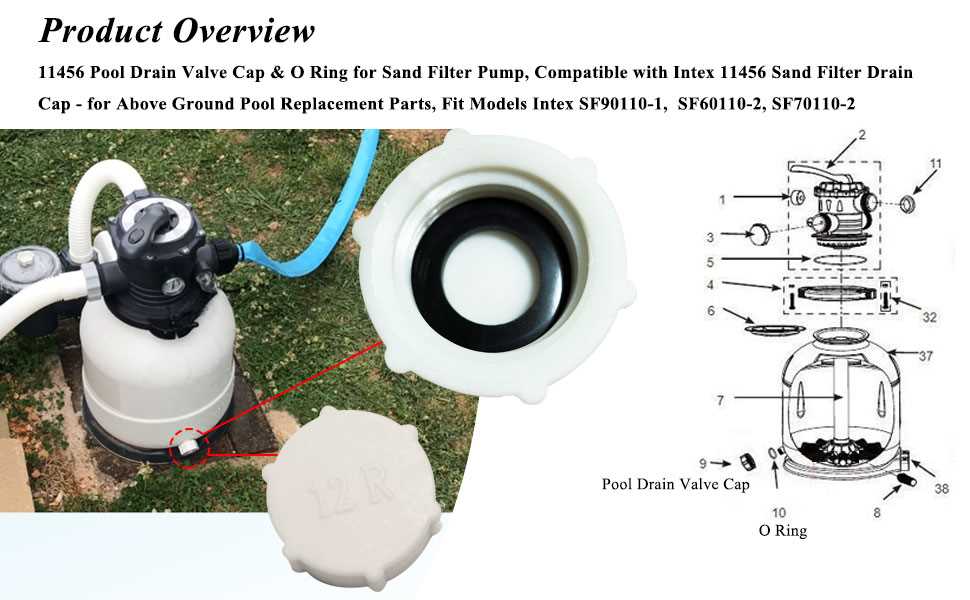

Replacing Worn-Out Pump Parts

Over time, essential components responsible for water circulation can deteriorate due to regular wear and tear. This can lead to reduced efficiency, making timely maintenance essential. When these elements become less effective, identifying the issue early and taking corrective action can prevent larger problems from arising.

To ensure smooth operation, it’s important to regularly inspect the system for signs of aging. If a part shows damage, replacing it promptly helps maintain optimal performance. Whether it’s a motor that no longer functions smoothly or smaller elements showing cracks, addressing these issues quickly can extend the system’s lifespan.

Replacing aged elements is a straightforward process that can be managed with basic tools and a proper guide. By following the recommended steps and using compatible replacements, you can restore the system to its original working condition without complications.

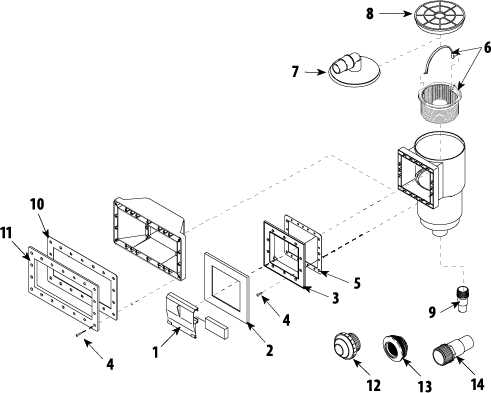

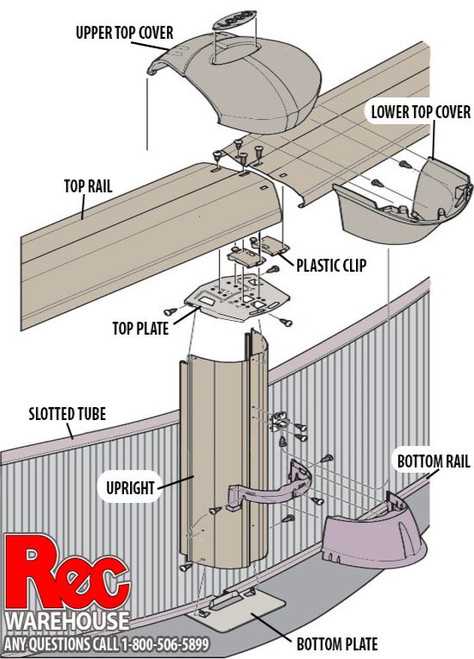

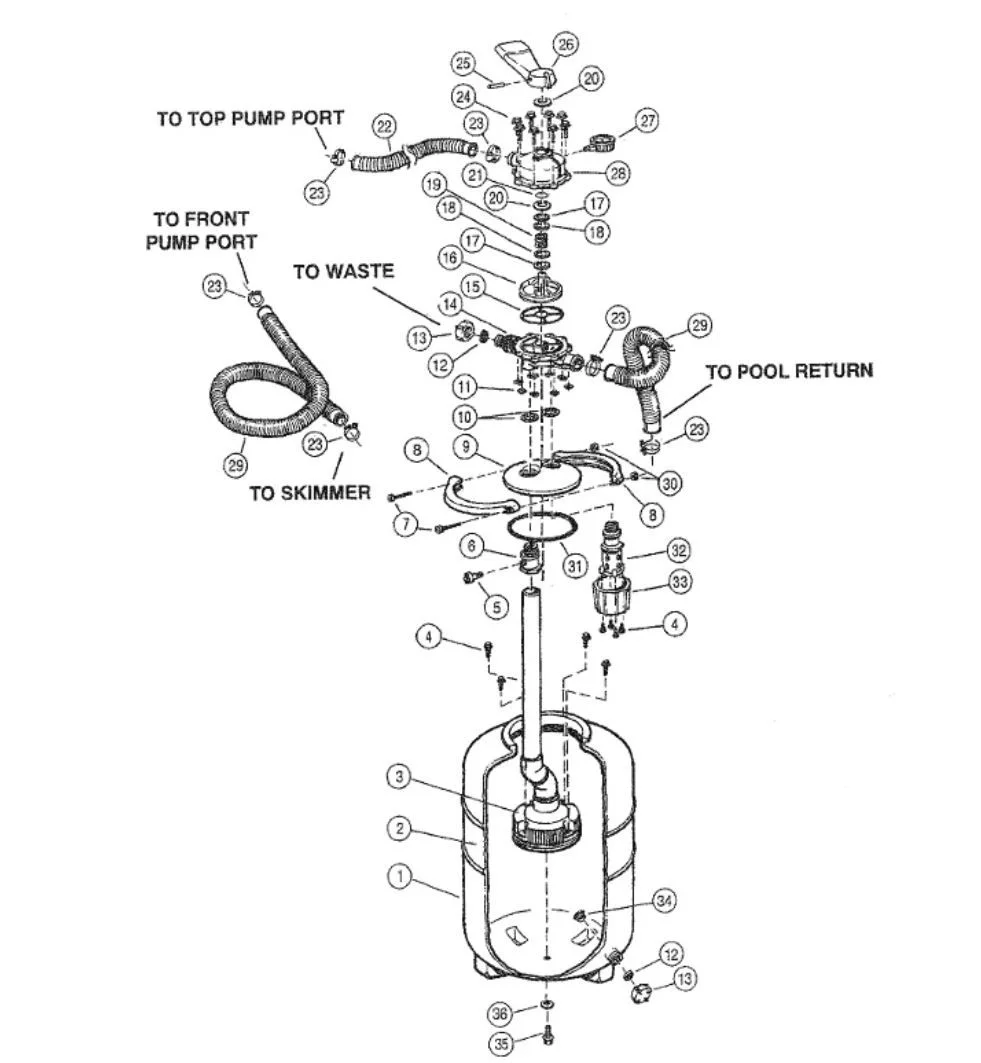

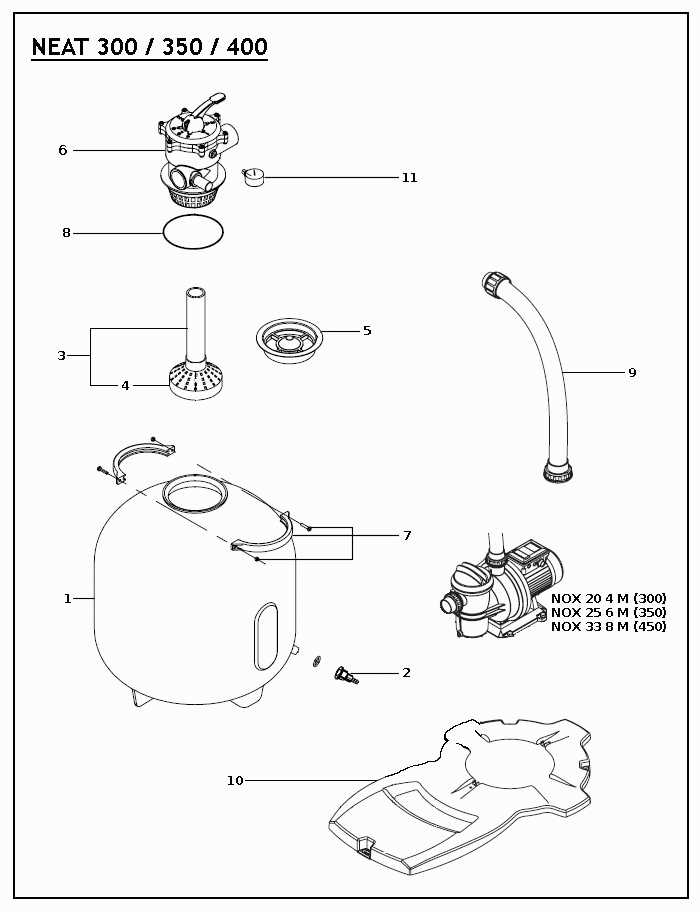

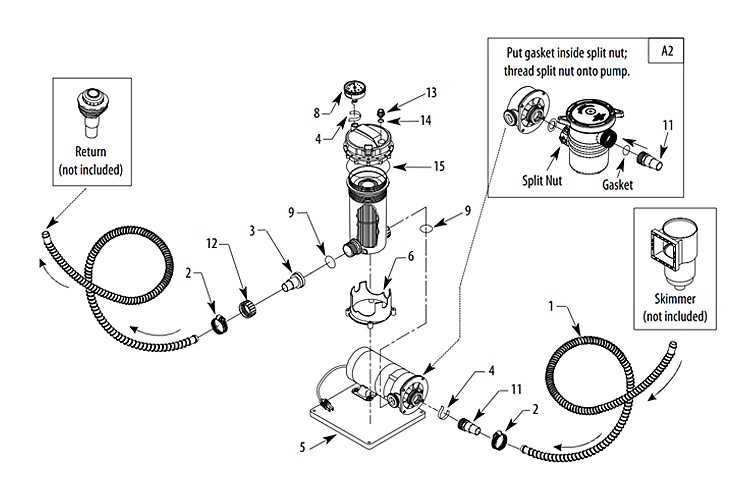

Visual Guide to Pump Parts Layout

Understanding the internal structure of a circulation system is essential for effective maintenance and operation. By familiarizing yourself with the various components and their arrangement, you can better assess the system’s functionality and detect potential issues before they escalate. Each section of the system is intricately designed to work together, ensuring smooth water flow and consistent performance. This guide provides a clear breakdown of the essential elements, giving you a comprehensive view of how everything fits and functions in harmony.

Component Arrangement

At the core of any water circulation device lies a network of interconnected pieces that serve distinct purposes. From the flow control mechanisms to the filtration section, each part has a role in maintaining efficiency. The flow system directs water through the setup, allowing for optimal movement and filtration. A well-constructed assembly enhances performance and extends the lifespan of the entire setup.

Key Elements in the Layout

In the overall structure, certain elements stand out due to their critical functions. The inlet section initiates the flow, leading water through various stages where it undergoes filtration and pressure regulation. The outlet ensures the proper return of water after it has been processed. Each element is precisely positioned to maximize the system’s effectiveness.

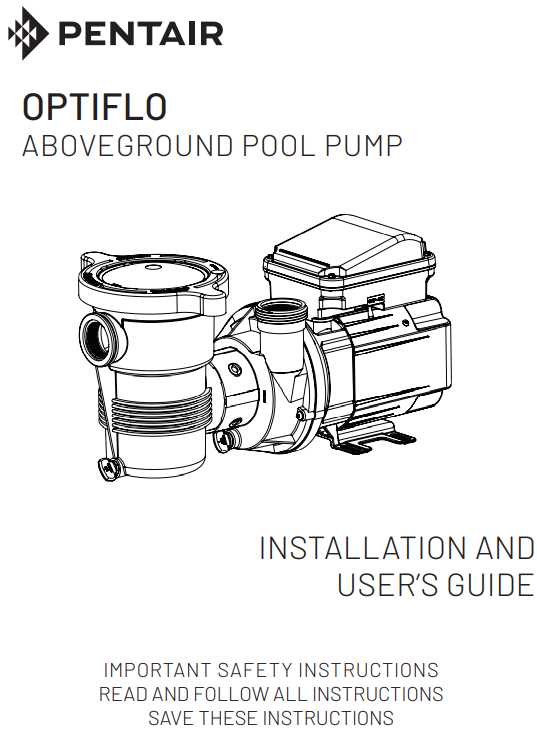

Importance of Proper Pump Installation

The efficiency and longevity of any water circulation system largely depend on how well its central unit is installed. A poor setup can lead to performance issues, resulting in increased energy consumption and potential damage to components. Ensuring a correct arrangement minimizes risks and optimizes overall functionality.

Key Factors for Successful Installation

Several elements must be considered during the installation process. First, the placement of the system should allow easy access for maintenance. Secondly, securing all connections tightly helps avoid leaks and reduces wear on the unit. Lastly, following guidelines on power compatibility is crucial to prevent malfunction or safety hazards.

Common Issues from Incorrect Setup

Improper installations can result in reduced water flow, overheating, or even system failure. In some cases, these problems can lead to costly repairs. Regular inspections and preventive measures help identify and correct installation errors before they escalate.

| Installation Step | Potential Risk if Ignored |

|---|---|

| Correct positioning | Restricted access for maintenance |

| Secure connections | Leaks and increased wear |

| Power compatibility check | Overload and malfunction |

Choosing the Right Pump for Pools

When selecting equipment for water circulation, it’s crucial to consider various factors that impact efficiency and performance. Making the right decision will ensure the system runs smoothly and effectively for a long time, keeping the water in optimal condition. The choice depends on various elements, from the size of the water space to the type of filtration system being used. Properly matching these components allows for enhanced longevity and reduced energy consumption.

Understanding Water Flow Requirements

One of the most important aspects to evaluate is the flow rate. Ensuring that the equipment can handle the volume of water and meet the circulation needs of the system is vital. Systems with insufficient flow might struggle to maintain cleanliness, while those with excessive capacity may lead to unnecessary energy usage. Consulting specifications and calculating the necessary flow can help in choosing a well-suited solution.

Compatibility with Filtration Systems

The relationship between the water circulation device and the filtration unit is also essential. Ensuring that both components work in harmony is key to maintaining clarity and cleanliness. Different filtration technologies may require specific characteristics from the circulating equipment, such as pressure levels and operational speeds, to function optimally.

Upgrading Components for Efficiency

Enhancing the performance of your system often requires evaluating the efficiency of its various elements. By selecting the right upgrades, you can significantly boost overall functionality while reducing energy consumption. This approach not only extends the lifespan of individual elements but also contributes to more sustainable operation.

Choosing Modern Alternatives

Newer technologies offer innovative solutions that surpass older designs in terms of efficiency. Whether it’s replacing outdated elements or adding advanced features, these improvements are essential for maintaining a high level of performance. Consider upgrading with models that have been optimized for energy use and longevity.

Maintaining Compatibility

When upgrading, it’s crucial to ensure that all components work seamlessly together. Compatibility between different elements is key to preventing issues like overloading or miscommunication. By confirming proper integration, you can achieve a more efficient and reliable system with minimal interruptions.