The intricate design of vehicles involves various crucial elements working in harmony to ensure optimal performance. A comprehensive understanding of these components can significantly enhance maintenance and troubleshooting efforts. By delving into the arrangements and functions of these parts, one can appreciate their roles within the larger system.

Familiarizing oneself with the configuration of these mechanical elements not only aids in identifying potential issues but also fosters a deeper knowledge of automotive technology. Such insights are invaluable for enthusiasts and professionals alike, as they pave the way for informed decisions regarding repairs and upgrades.

In this exploration, we will uncover the relationships and interdependencies among these essential elements, providing a clearer perspective on their contributions to overall vehicle functionality. By grasping the layout, users can effectively navigate the complexities of vehicle maintenance and performance enhancement.

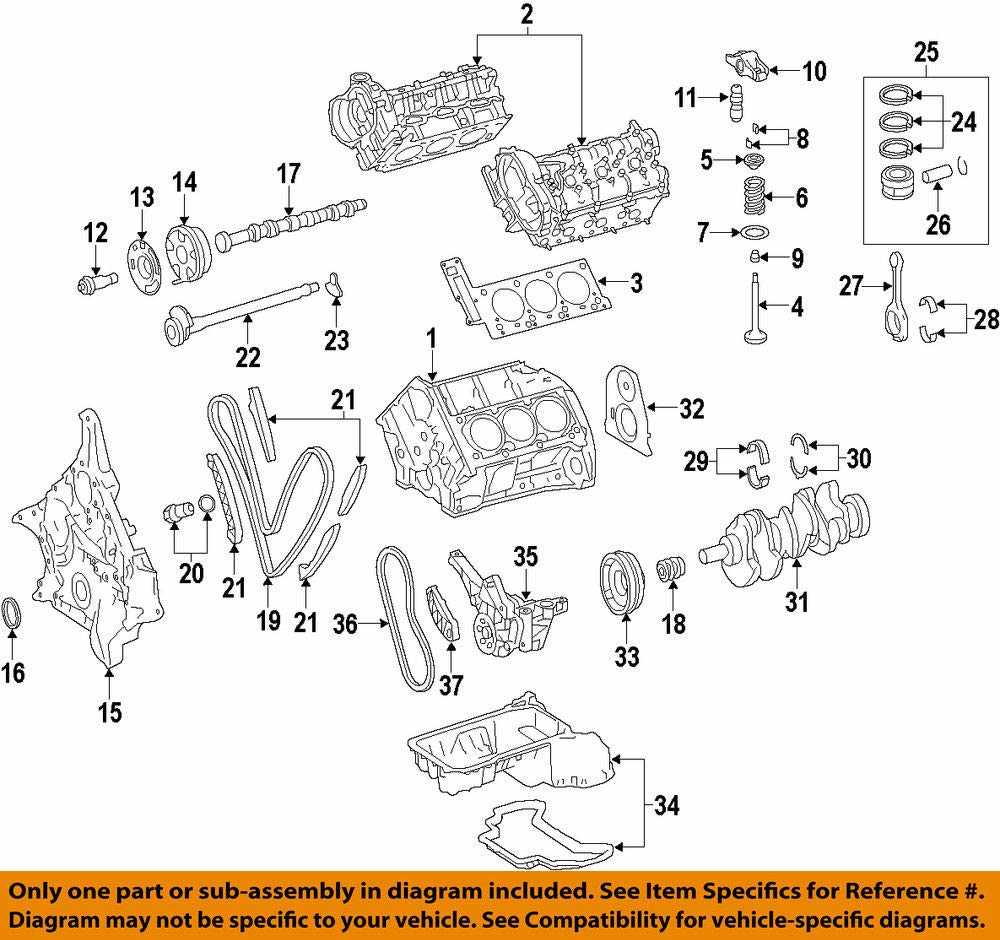

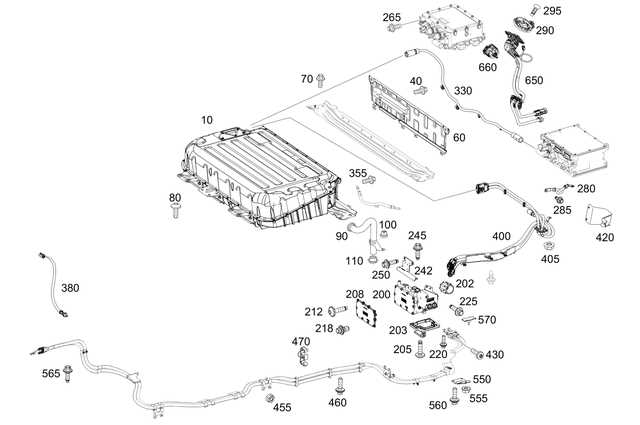

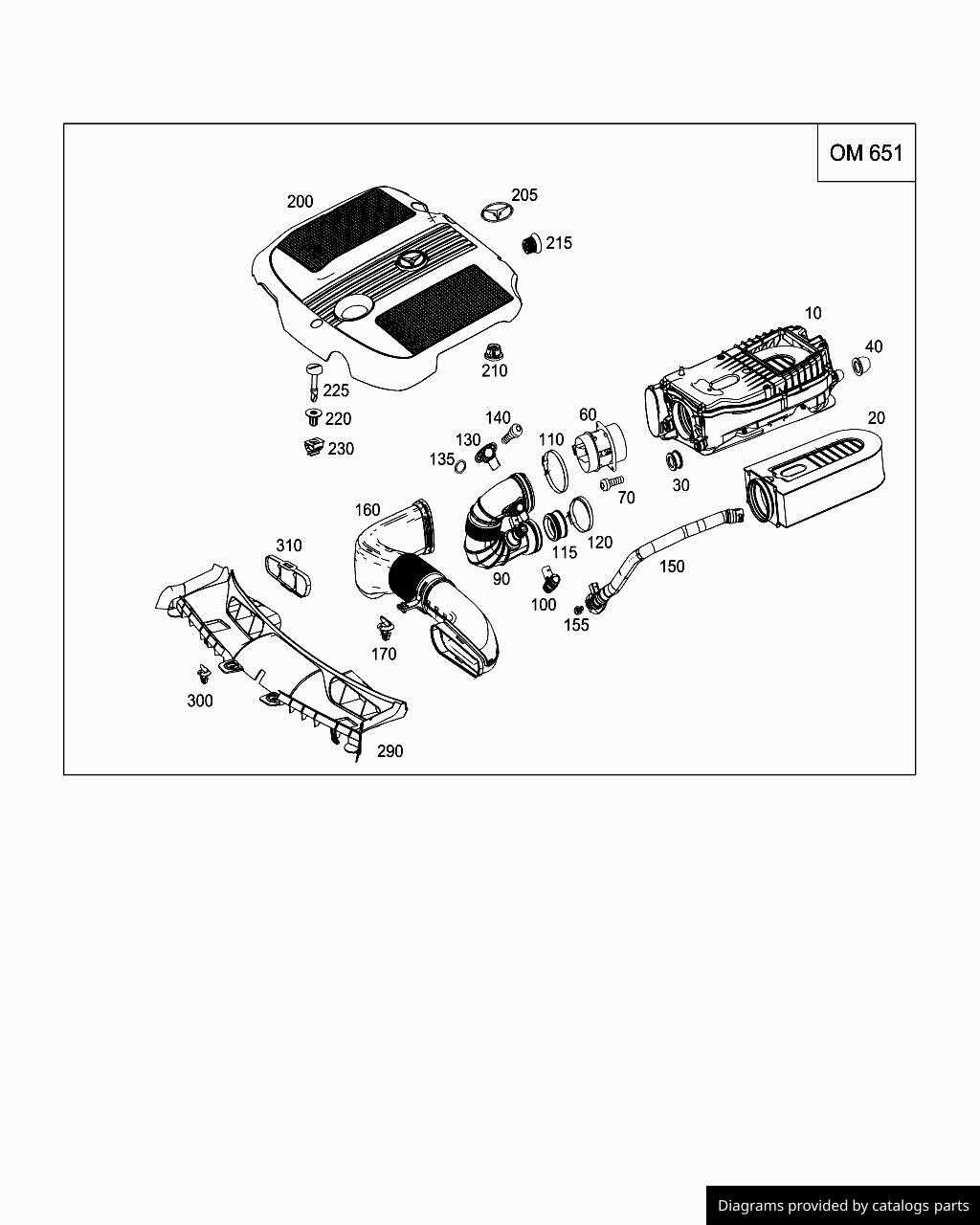

Mercedes Benz Engine Components Overview

This section provides a comprehensive look at the vital elements that comprise the internal combustion system of a vehicle. Understanding these components is crucial for anyone looking to maintain or enhance performance. Each part plays a significant role in the overall functionality, ensuring efficiency and reliability.

Key elements include the following:

| Component | Function |

|---|---|

| Cylinder Block | Houses the cylinders and supports other components. |

| Pistons | Convert pressure from combustion into mechanical energy. |

| Crankshaft | Transforms the linear motion of the pistons into rotational motion. |

| Camshaft | Regulates the opening and closing of the valves. |

| Timing Belt/Chain | Synchronizes the movement of the crankshaft and camshaft. |

| Valves | Control the intake of air and fuel and the expulsion of exhaust gases. |

| Oil Pump | Ensures lubrication of moving parts to reduce friction. |

Understanding Engine Part Functions

The various components within a vehicle’s power unit play crucial roles in its operation and efficiency. Each element contributes to the overall performance, ensuring smooth functioning and reliability. Understanding these roles helps in maintaining and optimizing the performance of the vehicle.

1. Combustion Chamber: This area is where the fuel-air mixture ignites, creating the energy needed for movement. Proper function is essential for optimal power output.

2. Crankshaft: The crankshaft converts the linear motion of the pistons into rotational motion, which ultimately drives the wheels. Its design and material affect the overall efficiency.

3. Camshaft: Responsible for controlling the timing of valve openings and closings, the camshaft plays a vital role in the intake and exhaust process, influencing performance and fuel economy.

4. Fuel Injection System: This system delivers fuel to the combustion chamber with precision, ensuring an appropriate mixture for efficient combustion. Advanced systems enhance performance and reduce emissions.

5. Cooling System: Maintaining an optimal temperature is crucial. The cooling system prevents overheating, thereby preserving the integrity of the components and prolonging the lifespan of the unit.

6. Lubrication System: This system minimizes friction between moving parts, reducing wear and tear. Adequate lubrication is essential for maintaining operational efficiency and preventing failures.

Each of these components works in harmony to ensure the functionality of the overall mechanism. A thorough understanding of their specific roles aids in effective troubleshooting and enhances vehicle longevity.

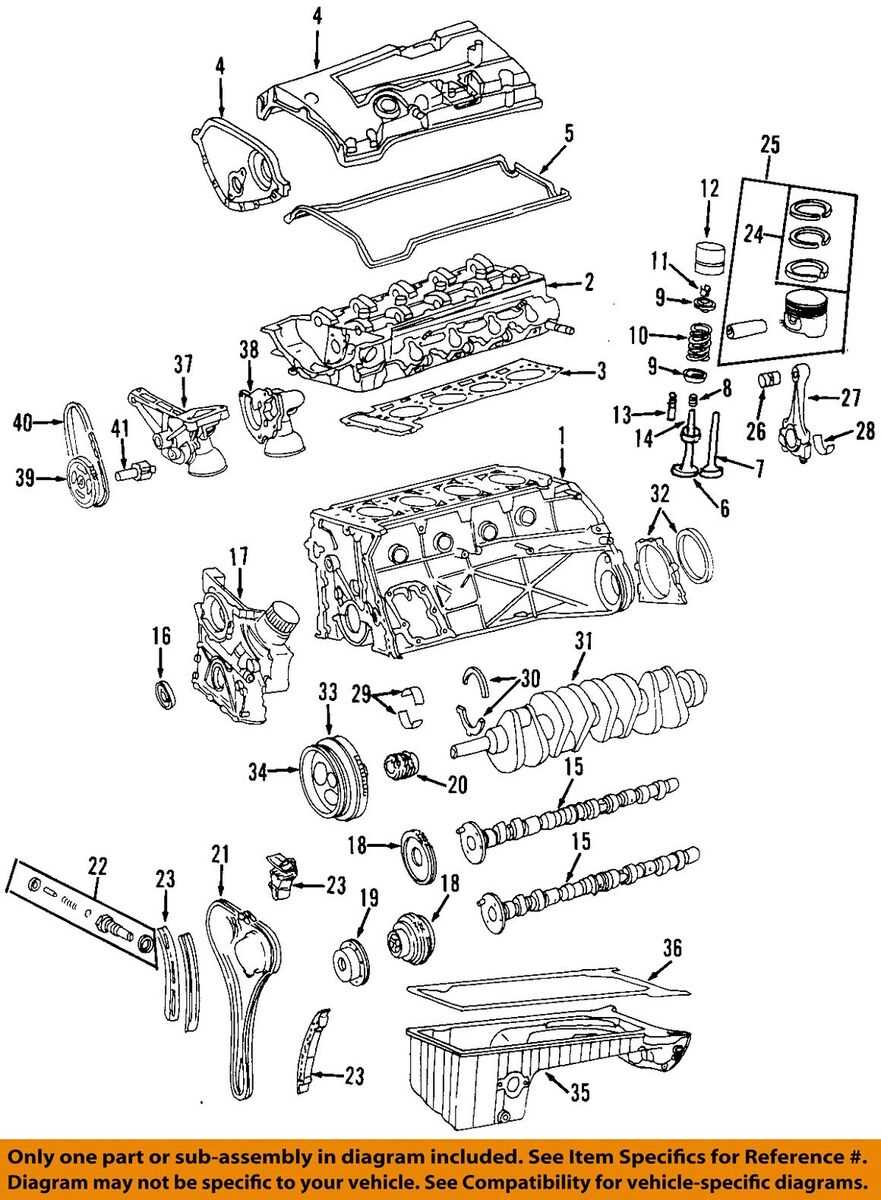

Key Parts in Engine Diagrams

Understanding the components of a power unit is essential for grasping how vehicles operate. Each element plays a significant role in ensuring the smooth functioning of the system. This section will explore vital components that are commonly highlighted in visual representations of automotive machinery.

Essential Components

Key components are typically categorized based on their functions and locations within the structure. These elements work in tandem to facilitate the necessary operations for optimal performance. Below is a brief overview of some of the critical components found in these visual guides.

| Component | Function |

|---|---|

| Cylinder Head | Encases the cylinders and houses the valves and spark plugs. |

| Crankshaft | Converts linear motion from pistons into rotational motion. |

| Piston | Moves up and down within the cylinder, creating compression. |

| Timing Belt | Synchronizes the rotation of the crankshaft and camshaft. |

Functionality and Interaction

The interaction between these components is critical for maintaining efficiency and power. Each part’s design allows it to work harmoniously with others, ensuring that energy is transformed and transmitted effectively throughout the system.

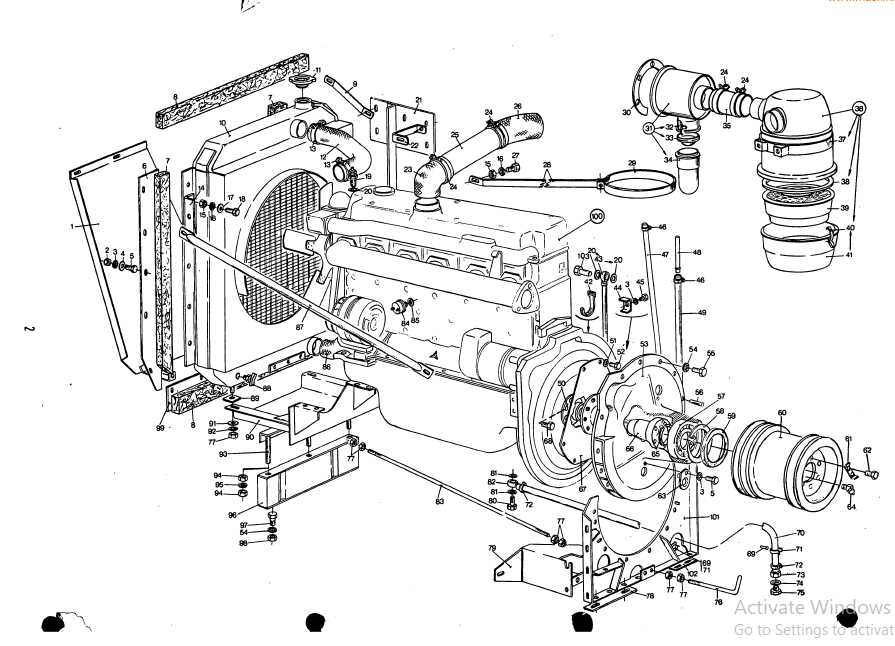

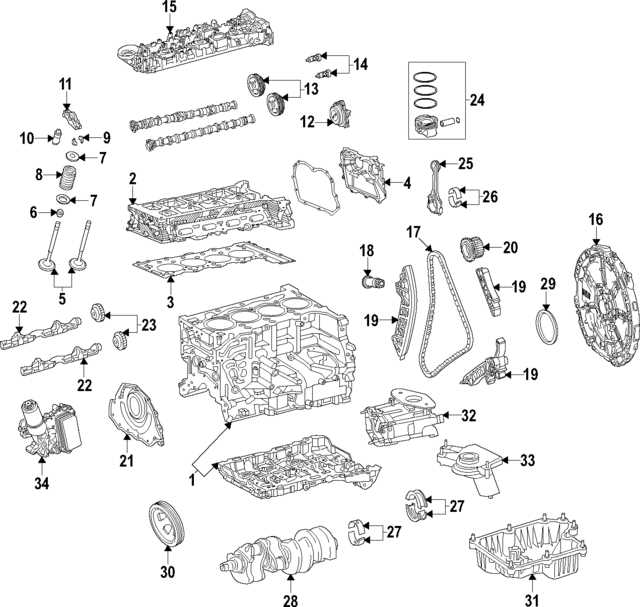

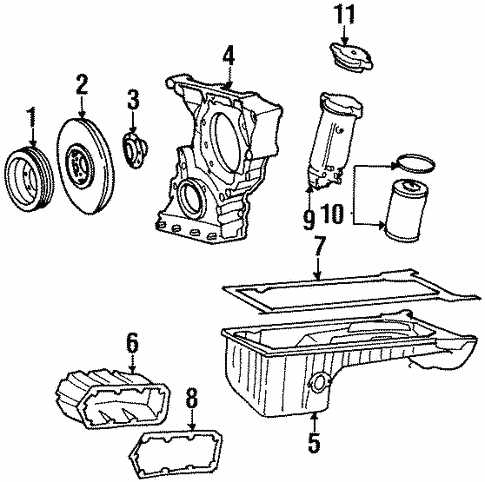

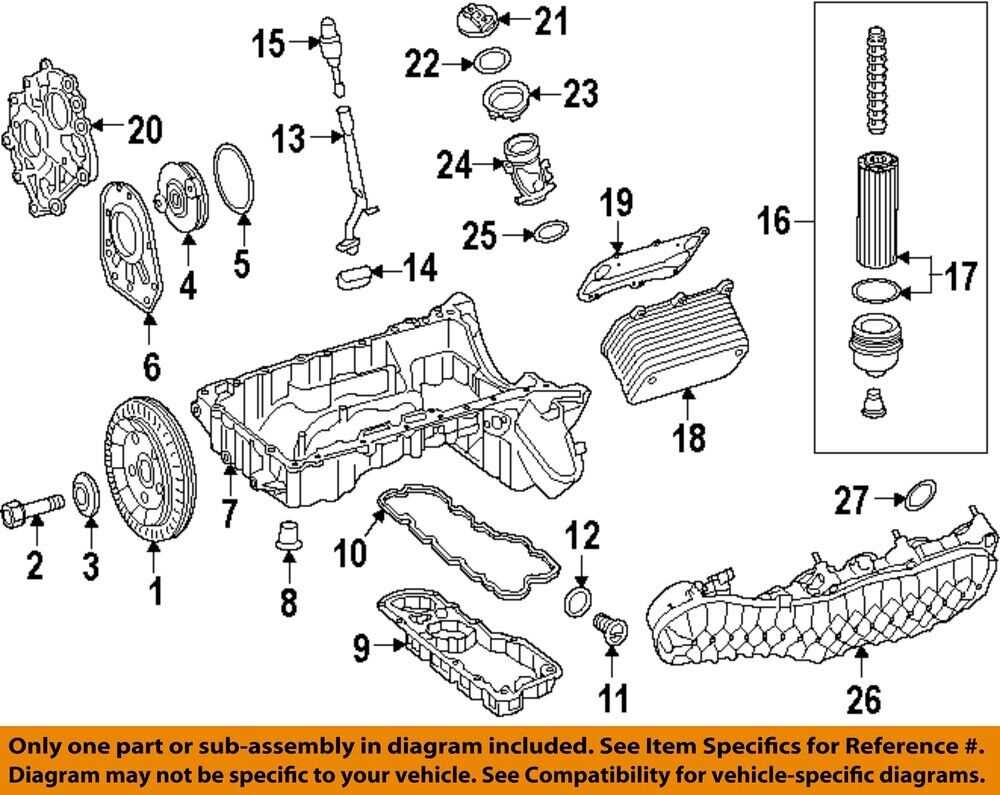

Visual Representation of Engine Layout

This section aims to provide a clear illustration of the arrangement and configuration of the various components within a power unit. Understanding how these elements are organized can significantly enhance the maintenance and repair processes.

The layout often consists of several key elements, each contributing to the overall function:

- Crankshaft: Central to the unit’s operation, converting linear motion into rotational energy.

- Pistons: Move within the cylinders, playing a vital role in the power generation cycle.

- Camshaft: Controls the timing of valve openings and closings, essential for efficient airflow.

- Valves: Regulate the entry of air and exit of exhaust, influencing performance and efficiency.

- Intake Manifold: Directs the air-fuel mixture into the combustion chamber.

- Exhaust Manifold: Channels the exhaust gases away from the chamber.

Each component’s positioning affects the functionality and efficiency of the entire assembly, making it crucial for technicians to understand the layout for effective troubleshooting and enhancement.

Importance of Engine Maintenance

Regular upkeep of a vehicle’s power unit is crucial for ensuring optimal performance and longevity. Proper care not only enhances functionality but also contributes to overall safety and reliability. Adopting a routine maintenance schedule can prevent unexpected breakdowns and costly repairs.

Here are several key reasons why routine maintenance is essential:

- Performance Optimization: Consistent checks help maintain peak performance levels, ensuring the vehicle runs smoothly.

- Fuel Efficiency: Well-maintained machinery tends to consume less fuel, saving money in the long run.

- Emission Control: Regular servicing minimizes harmful emissions, promoting environmental sustainability.

- Safety Assurance: A thorough inspection can identify potential issues, ensuring safer driving conditions.

- Cost Savings: Preventive maintenance is often more economical than addressing major repairs caused by neglect.

In conclusion, adhering to a maintenance schedule not only enhances the overall operation of the vehicle but also extends its lifespan, ultimately benefiting the owner.

Common Issues with Engine Parts

Various complications can arise within the components of a motor. Understanding these common challenges can assist in timely maintenance and repairs, ensuring the vehicle operates smoothly.

Frequent Problems

- Wear and Tear: Over time, components can degrade, leading to decreased performance.

- Fluid Leaks: Seals and gaskets may fail, resulting in leakage of essential fluids.

- Overheating: Insufficient cooling can cause components to overheat, potentially leading to serious damage.

- Noises: Unusual sounds can indicate misalignment or malfunction within moving parts.

Maintenance Tips

- Regularly inspect components for signs of damage or wear.

- Change fluids as recommended to maintain optimal performance.

- Address any unusual sounds or behaviors immediately to prevent further issues.

Identifying Engine Parts by Diagram

Understanding the components of a motor through visual representations is essential for effective maintenance and troubleshooting. A clear illustration can aid in recognizing various elements, their functions, and how they interact within the overall system. This section emphasizes the importance of utilizing visual aids to enhance knowledge and proficiency in handling automotive mechanics.

Key Components to Recognize

When examining visual representations, it is crucial to focus on the main components that are vital for the vehicle’s operation. Recognizing the configuration of the assembly can simplify the process of diagnosing issues. Common components include the crankshaft, pistons, and valve train, each playing a significant role in the overall functionality.

Utilizing Visual Aids for Troubleshooting

Using illustrations not only helps in identifying components but also serves as a guide during repair procedures. By following the visual cues, users can systematically address malfunctions and ensure proper assembly. This method fosters a deeper understanding and enhances confidence when working with automotive mechanisms.

Role of Each Engine Component

Understanding the function of various elements within a motor is essential for grasping how it operates efficiently. Each component plays a vital role in the overall performance, contributing to power generation, fuel efficiency, and reliability. This section delves into the significance of these crucial elements and their interactions.

Key Elements and Their Functions

The following list outlines the primary components and their respective roles:

- Piston: Converts the force from combustion into mechanical energy.

- Cylinder: Houses the piston and provides the space for fuel combustion.

- Crankshaft: Transforms the up-and-down motion of the pistons into rotational energy.

- Camshaft: Controls the opening and closing of valves, regulating air and fuel intake.

- Valves: Manage the flow of air and fuel into the combustion chamber and exhaust gases out.

Importance of Component Interaction

Each element must work in harmony to achieve optimal functionality. The synchronization of movement and timing among these components is critical. If one part fails or operates inefficiently, it can lead to a decline in overall performance and potential mechanical issues. Maintaining these elements ensures longevity and reliability in operation.

Differences in Engine Models

This section explores the variations among different power unit configurations found in various automotive brands. Understanding these distinctions is crucial for enthusiasts and professionals alike, as they influence performance, efficiency, and overall vehicle characteristics.

Key Variations in Specifications

Different configurations may feature unique specifications that affect their capabilities. These specifications include displacement, compression ratios, and the number of cylinders, which contribute significantly to the engine’s power output and fuel consumption.

| Model Type | Cylinder Count | Displacement (L) | Power Output (hp) | Torque (lb-ft) |

|---|---|---|---|---|

| Standard | 4 | 2.0 | 150 | 180 |

| Performance | 6 | 3.0 | 300 | 300 |

| Turbocharged | 4 | 2.5 | 250 | 270 |

Impact on Driving Experience

The variations in these configurations can lead to significant differences in how a vehicle handles on the road. While some setups prioritize speed and power, others may focus on efficiency and smoothness, catering to different driving preferences.

How Diagrams Aid Repairs

Visual representations play a crucial role in the maintenance and restoration of complex machinery. They offer a clear and concise overview of components and their interconnections, making it easier for technicians to understand intricate systems. This enhanced comprehension is essential for efficient troubleshooting and repair processes.

By utilizing these illustrative guides, mechanics can quickly identify the location and function of various elements. This streamlined approach reduces the time spent on diagnostic procedures, allowing for a more effective resolution of issues. Additionally, visual aids facilitate communication among team members, ensuring everyone is on the same page regarding tasks and objectives.

Furthermore, having access to these informative visuals can significantly improve the overall safety of repair work. By highlighting critical areas and potential hazards, they help technicians avoid mistakes that could lead to accidents or further damage. In conclusion, these helpful tools are indispensable for anyone involved in the upkeep of sophisticated machinery.

Tools for Engine Parts Identification

Understanding the various components within a vehicle’s power unit is essential for maintenance and repair. Various instruments are available to assist in recognizing and analyzing these elements, making the process more efficient and accurate.

Visual Reference Materials

Diagrams and charts serve as excellent visual aids for recognizing different elements within a power unit. These resources can provide clarity on the arrangement and function of each component, helping users to locate and identify them easily.

Digital Applications

With advancements in technology, numerous mobile applications and software programs have emerged. These tools often include interactive features that allow users to explore and understand the configuration of various elements, enhancing knowledge and facilitating efficient diagnostics.

Learning from Engine Component Diagrams

Understanding mechanical systems can be greatly enhanced through the study of visual representations that illustrate their individual elements and interactions. These representations serve as valuable tools for both novices and experienced individuals looking to deepen their comprehension of how various components function together.

By examining such visuals, one can gain insights into:

- The arrangement and positioning of various components.

- The relationships between different parts and their functions.

- The flow of energy and fluids within the system.

These representations also facilitate troubleshooting by providing a clear overview of how parts connect and operate. This knowledge can help identify potential issues more efficiently.

Furthermore, utilizing these visuals fosters a better understanding of maintenance practices. By recognizing where specific elements are located, individuals can perform inspections and repairs with greater accuracy.

In summary, studying visual representations of mechanical components enriches one’s knowledge, aids in problem-solving, and enhances maintenance skills, ultimately leading to a more efficient understanding of complex systems.