When it comes to outdoor adventures and heavy-duty tasks, having a reliable mechanism for hauling or lifting can make all the difference. This essential tool consists of various elements that work in harmony to ensure efficiency and safety. Familiarizing yourself with these components can enhance your understanding of its operation and maintenance.

Whether you’re an enthusiast or a casual user, knowing how each element contributes to the overall functionality is vital. From the motor to the mounting hardware, every piece plays a significant role in ensuring that the system performs optimally. A clear representation of these elements can aid in troubleshooting and improve your ability to make informed decisions regarding upgrades or replacements.

Furthermore, a comprehensive overview of these components can empower users to carry out maintenance tasks with confidence. Understanding the intricate relationship between the various parts not only extends the life of your device but also enhances its performance during crucial moments. Embracing this knowledge is a step towards ensuring that you are always prepared for your next challenge.

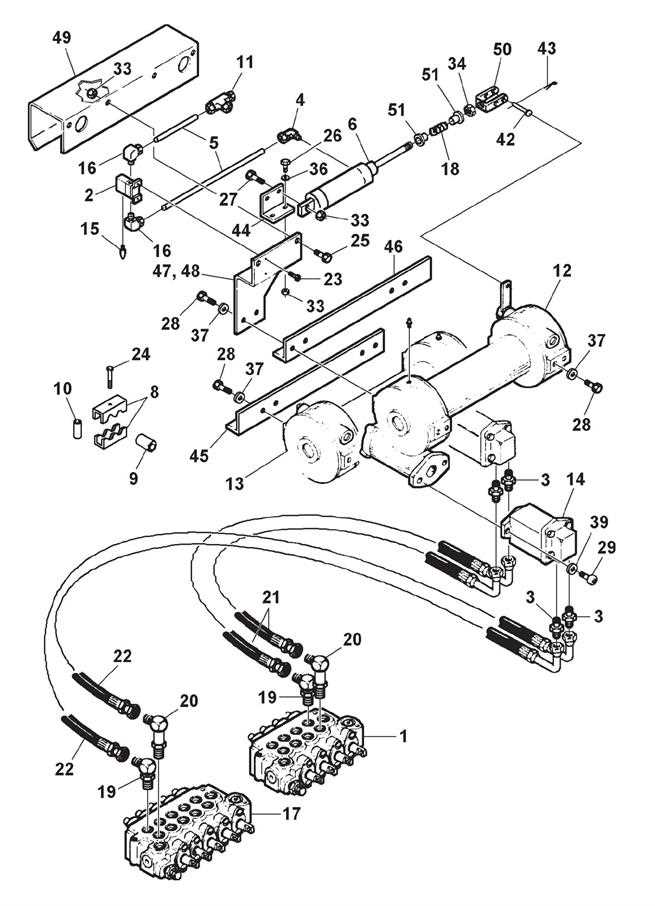

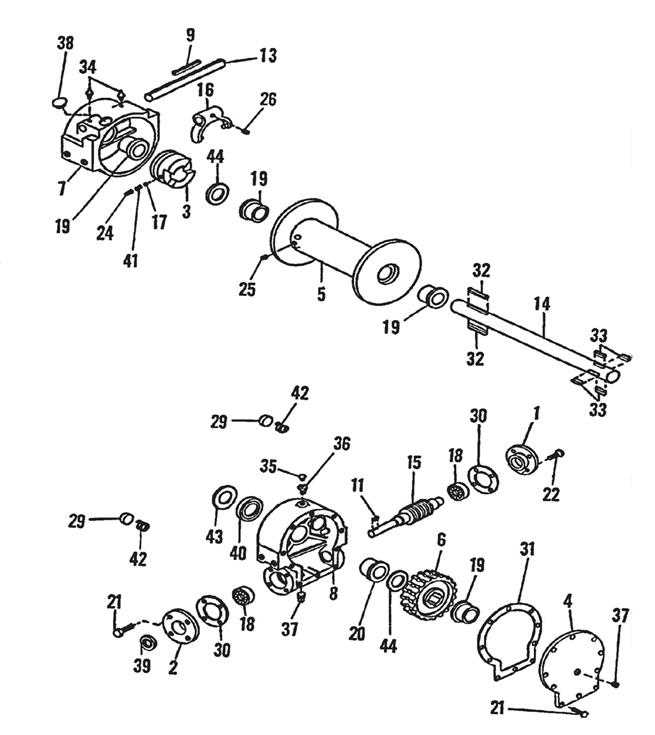

This section delves into the fundamental components and structure of a pulling mechanism, providing insight into its functionality and assembly. Understanding how each element interacts within the system is crucial for efficient operation and maintenance.

The assembly consists of several key components that work in unison to achieve optimal performance. Below is a table outlining these essential elements, their functions, and the significance of each within the mechanism.

| Component | Function | Importance |

|---|---|---|

| Motor | Drives the pulling mechanism | Provides the necessary power for operation |

| Drum | Holds the cable or rope | Facilitates the winding and unwinding process |

| Gear System | Transmits power from the motor | Enhances torque for effective pulling |

| Remote Control | Allows operation from a distance | Increases safety and convenience during use |

| Mounting Plate | Secures the assembly to a vehicle or structure | Ensures stability and reliability during operation |

Identifying Key Replacement Parts

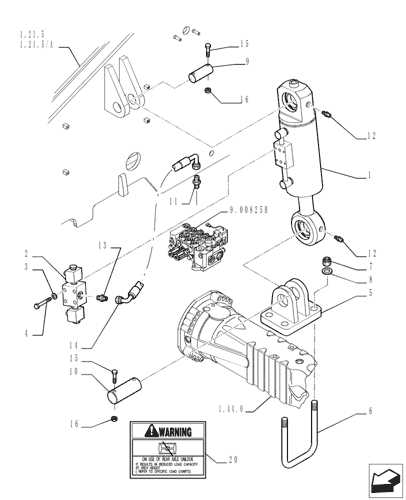

Understanding the essential components of your equipment is crucial for effective maintenance and repair. Recognizing these vital elements not only ensures smooth operation but also helps you make informed decisions when replacements are necessary.

To efficiently identify key components, consider the following categories:

- Electrical Elements: These include motors, switches, and connectors that control the device’s functionality.

- Mechanical Components: Gears, cables, and pulleys that facilitate movement and support load handling.

- Mounting Hardware: Brackets, bolts, and nuts that secure components in place, ensuring stability during use.

By familiarizing yourself with these categories, you can streamline the replacement process, ultimately extending the lifespan of your equipment. Make sure to consult the manufacturer’s specifications for accurate identification and compatibility.

Maintenance Tips for Winch Longevity

Proper upkeep is essential to ensure the reliability and durability of your hauling device. Regular maintenance not only extends its lifespan but also enhances its performance when needed the most. Here are some key practices to keep in mind.

Regular Inspection

Conduct routine checks to identify any signs of wear and tear. Focus on the following areas:

- Inspect cables or ropes for fraying or damage.

- Check connectors and hardware for rust or corrosion.

- Examine the motor and gearbox for unusual sounds or leaks.

Lubrication and Cleaning

Maintaining cleanliness and lubrication is vital for smooth operation. Follow these guidelines:

- Clean the device regularly to remove dirt, debris, and mud.

- Apply appropriate lubricants to moving parts to prevent friction.

- Ensure that electrical components are free of moisture and dirt.

By following these maintenance tips, you can significantly enhance the performance and lifespan of your equipment, ensuring it remains ready for any challenges ahead.

Common Issues and Troubleshooting Guide

When operating recovery tools, it’s essential to be aware of potential challenges that can arise. Understanding these common complications can significantly enhance performance and ensure safety during use. This guide provides insights into frequent problems and offers solutions to address them effectively.

Here are some typical issues users may encounter:

- Mechanical Malfunctions: Components may wear out or become damaged over time, leading to decreased efficiency.

- Electrical Failures: Wiring issues or battery problems can disrupt the functionality, preventing proper operation.

- Overheating: Excessive use without adequate cooling can cause overheating, which might result in system shutdowns.

To troubleshoot these issues, consider the following steps:

- Inspect Components: Regularly check for wear and tear. Replace any damaged parts as necessary.

- Check Electrical Connections: Ensure all wiring is secure and free from corrosion. Verify that the power source is functioning correctly.

- Monitor Operating Time: Limit continuous operation to prevent overheating. Allow sufficient cooling periods between uses.

- Consult User Manual: Refer to the provided manual for specific instructions and guidance tailored to the equipment.

By addressing these common complications proactively, users can maintain the reliability and longevity of their recovery equipment.

Benefits of Using Genuine Parts

Opting for authentic components is essential for maintaining the longevity and reliability of your equipment. High-quality replacements ensure optimal performance, safety, and durability, setting them apart from generic alternatives. When you choose genuine elements, you are making a wise investment in the functionality and lifespan of your machinery.

Here are several advantages of selecting original components:

- Enhanced Compatibility: Genuine components are designed specifically for your device, ensuring a perfect fit and seamless integration.

- Superior Quality: Authentic replacements are manufactured to meet strict quality standards, providing increased durability and reliability.

- Improved Performance: Using original elements can lead to enhanced efficiency and effectiveness, resulting in better overall functionality.

- Long-Term Cost Savings: Investing in genuine components can reduce the need for frequent replacements and repairs, ultimately saving money over time.

- Warranty Protection: Many manufacturers offer warranties on their genuine components, providing peace of mind and protection against defects.

In conclusion, choosing authentic elements is vital for anyone looking to maintain the integrity and functionality of their equipment. By prioritizing quality and compatibility, you can ensure that your machinery performs at its best for years to come.

Safety Precautions When Operating Winches

When using heavy lifting equipment, ensuring safety is paramount. Proper precautions can prevent accidents and injuries during operation. Understanding the necessary measures is essential for anyone handling such equipment, whether in professional settings or recreational activities.

Pre-Operation Checks

Before engaging the device, inspect it thoroughly for any signs of wear or damage. Ensure that all components are functioning correctly and securely attached. Check the load capacity and confirm that it matches the task at hand. Familiarize yourself with the control mechanisms and emergency procedures to ensure a smooth operation.

Personal Protective Equipment

Wearing appropriate personal protective gear is crucial when operating lifting machinery. Ensure that you have sturdy gloves, safety goggles, and a hard hat if necessary. Protective footwear can also help prevent injuries from falling objects or accidents. Always prioritize personal safety and encourage others in the vicinity to do the same.

Comparing Different Winch Models

When it comes to selecting a recovery tool, various models present unique features and capabilities tailored to different needs. Understanding the distinctions among these options can help users make informed decisions based on their specific requirements and preferences. Whether you are considering capacity, speed, or the type of control system, evaluating these elements is crucial for effective utilization.

Factors to Consider

- Capacity: The pulling strength of a recovery device is fundamental. Depending on the application, users should assess whether they need a lighter unit for smaller tasks or a more robust option for heavier loads.

- Speed: The recovery rate can significantly impact efficiency. Some models offer rapid operation, while others may prioritize strength over speed.

- Control Systems: Remote and manual controls vary among models, providing different levels of convenience and ease of use.

Popular Options

- Electric Units: Known for their user-friendly features and quick setup, electric systems are ideal for general purposes.

- Pneumatic Devices: These offer powerful performance but may require additional equipment to operate effectively.

- Hydraulic Models: Typically found in industrial settings, hydraulic options are excellent for heavy-duty tasks due to their exceptional strength.

By considering these factors and options, individuals can select the most suitable recovery solution tailored to their specific needs and intended applications.

Winch Accessories to Enhance Performance

Optimizing the functionality of recovery equipment is essential for ensuring efficiency and safety during operations. The right enhancements can significantly improve usability, speed up recovery processes, and provide additional security. By integrating various accessories, users can customize their setup to meet specific needs and conditions.

Essential Components for Improved Efficiency

Incorporating additional elements, such as snatch blocks, can greatly increase the pulling power while reducing stress on the primary equipment. This allows for more effective load management, especially in challenging situations. Furthermore, using tree savers and other protective gear helps prevent damage to surrounding environments while enhancing the durability of the setup.

Safety Gear for Secure Operations

Safety should always be a priority when engaging in recovery tasks. Adding features like winch straps and safety hooks can prevent accidents and ensure a secure connection during operation. These accessories not only contribute to personal safety but also enhance the overall performance of the recovery system, allowing for greater peace of mind during challenging maneuvers.

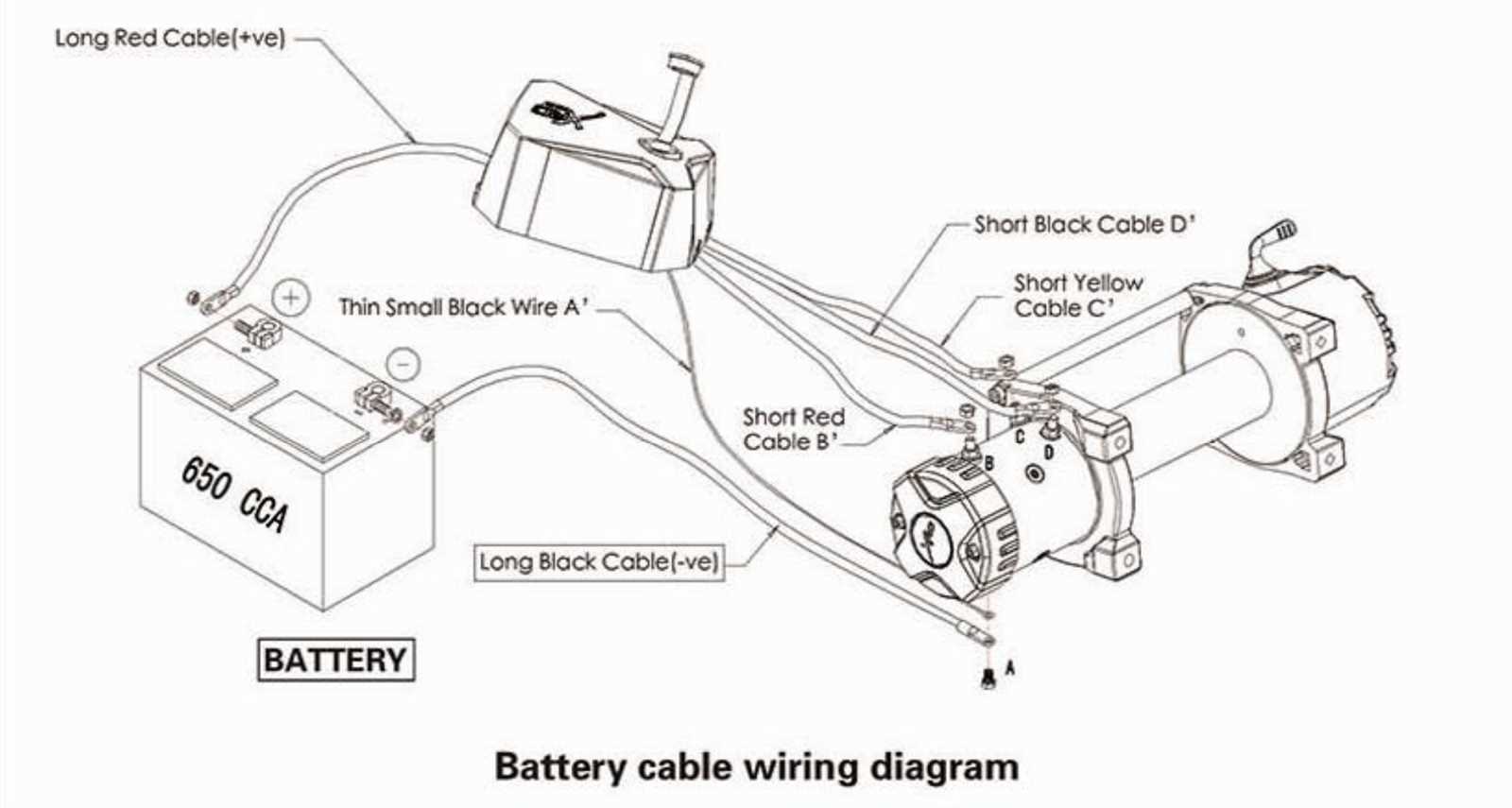

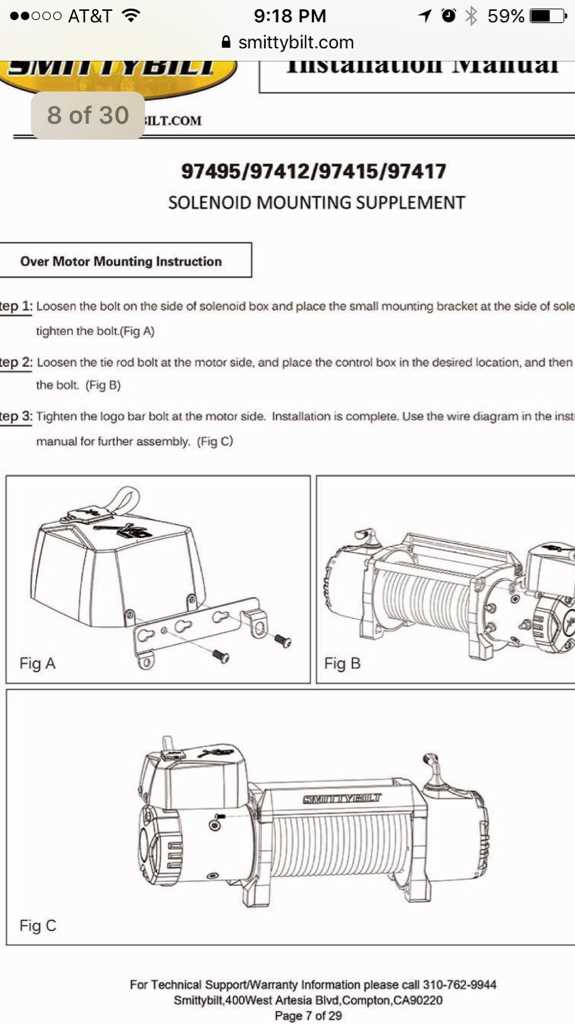

Step-by-Step Assembly Instructions

This section provides a comprehensive guide to the assembly process of the equipment. Follow these steps carefully to ensure a successful setup, enhancing performance and longevity. Proper organization of components will facilitate an efficient assembly, reducing potential errors.

Preparation for Assembly

Before starting, gather all necessary components and tools. Familiarize yourself with each element and its function. Lay out the parts in a designated workspace to streamline the process.

Assembly Process

Follow these sequential steps to assemble the device:

| Step | Action | Description |

|---|---|---|

| 1 | Attach Base | Secure the base plate to the main frame using bolts. |

| 2 | Install Drum | Align the drum with the central shaft and tighten the screws. |

| 3 | Connect Gearbox | Fasten the gearbox to the motor, ensuring a tight fit. |

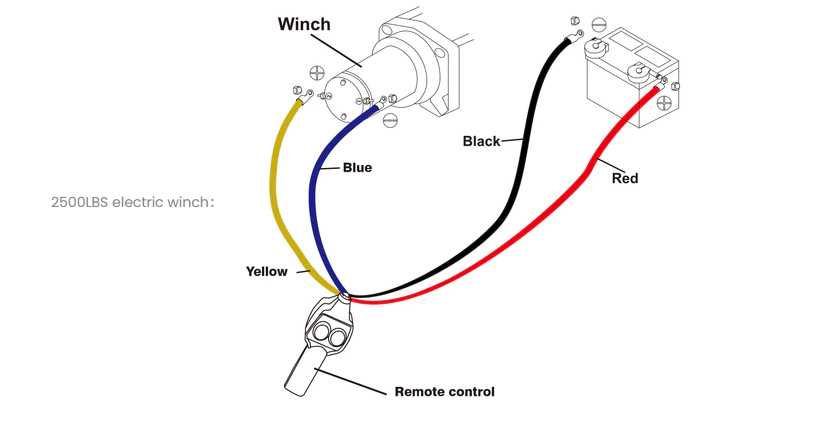

| 4 | Wire the Motor | Connect the electrical wires according to the provided schematic. |

| 5 | Final Checks | Inspect all connections and tighten any loose components. |

Once the assembly is complete, perform a thorough inspection to confirm that all parts are secure and correctly positioned. This careful approach ensures optimal functionality and safety.