Understanding the configuration of complex equipment is essential for both enthusiasts and professionals alike. This section aims to provide a detailed exploration of the arrangement of various elements, helping users gain insights into functionality and maintenance. By dissecting the structure, individuals can enhance their operational knowledge and ensure optimal performance.

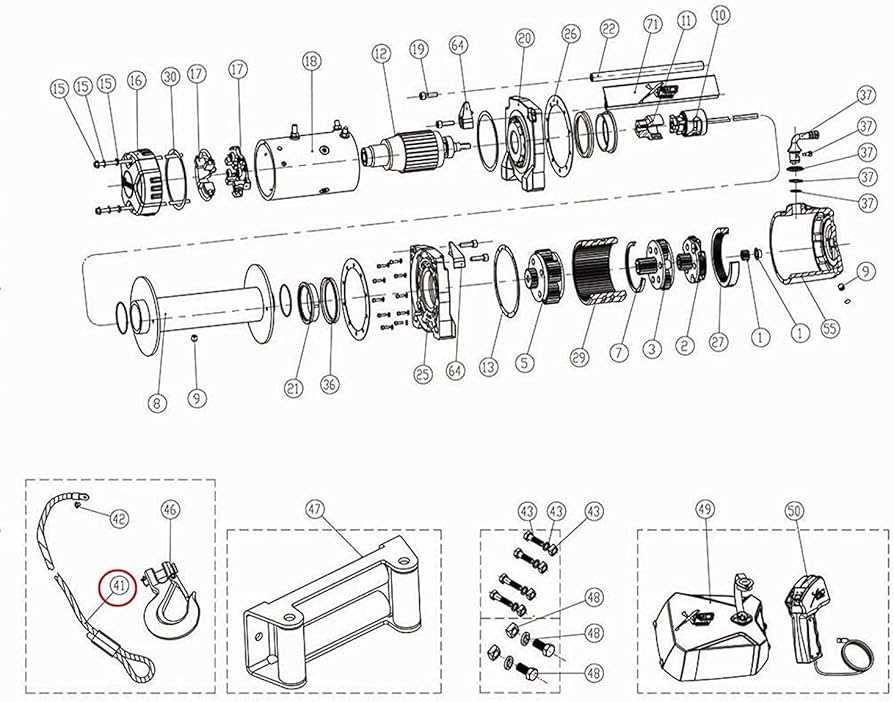

When examining the intricacies of such systems, it becomes clear that each segment plays a vital role in the overall efficiency. Recognizing how individual components interconnect allows for better troubleshooting and repair strategies. Whether you’re looking to upgrade, replace, or simply familiarize yourself with the mechanics, having a visual representation can significantly aid in comprehension.

Moreover, this analysis not only serves as a guide for repairs but also empowers users to make informed decisions regarding modifications and enhancements. A thorough understanding of how parts fit together can lead to improved functionality and longevity of the equipment in question. With the right knowledge, users can approach their projects with confidence and precision.

Understanding Smittybilt X20 Components

In the realm of off-road and outdoor adventures, comprehending the various elements of a winching system is crucial for optimal performance. Each component plays a significant role in ensuring reliability and efficiency during challenging situations. This section delves into the key features and functionalities of these essential mechanisms, providing insights into their interconnections and purposes.

Key Elements of the Winching System

- Motor: The powerhouse that drives the entire mechanism, providing the necessary force to pull or lift heavy loads.

- Drum: This cylindrical component serves as the spool for the cable or rope, allowing for smooth winding and unwinding.

- Remote Control: A crucial element that enables the operator to control the winch from a safe distance, enhancing safety and convenience.

- Gearbox: This assembly translates the motor’s rotational force into the necessary torque, determining the winch’s pulling capacity.

- Mounting Plate: The base that secures the winch to the vehicle, ensuring stability during operation.

Understanding the Functionality

Each of these components must work in harmony to achieve effective operation. Regular maintenance and understanding the specific roles of each part are essential for maximizing the performance and longevity of the winching system. Knowledge of these elements not only aids in troubleshooting but also enhances the overall experience during outdoor endeavors.

Overview of the X20 Winch System

The winch system under discussion is engineered for high performance, designed to facilitate the lifting and pulling of heavy loads with ease. Its robust construction and advanced features make it suitable for various applications, whether off-road adventures or industrial use. This system ensures reliability and efficiency, making it an essential tool for enthusiasts and professionals alike.

Featuring a powerful motor and a durable cable, this winch is built to withstand challenging conditions. Its intuitive controls allow for seamless operation, enabling users to manage operations from a safe distance. The system’s design emphasizes both strength and precision, ensuring that it can handle demanding tasks while maintaining user safety.

Moreover, the incorporation of cutting-edge technology enhances its functionality, providing features such as automatic braking and wireless control options. These innovations not only improve ease of use but also add a layer of safety during operation. Overall, this winch system stands out as a reliable companion for anyone needing dependable lifting and pulling capabilities.

Key Features of the Smittybilt X20

This section outlines the standout attributes of a popular off-road winch designed for rugged terrain and demanding conditions. Its advanced engineering and robust construction make it a reliable tool for adventurers and outdoor enthusiasts. With a focus on durability and performance, this winch is equipped to handle various challenges encountered in off-roading scenarios.

One of the most significant aspects of this winch is its impressive pulling capacity, which allows it to tackle heavy loads with ease. This feature is complemented by a powerful motor that ensures consistent performance under strenuous conditions. Additionally, the synthetic rope enhances safety and efficiency, reducing the risk of recoil during operation.

Moreover, the inclusion of a wireless remote control adds convenience, enabling users to operate the winch from a safe distance. This functionality is vital during recovery situations, providing peace of mind while managing challenging tasks. The winch’s weather-resistant design further extends its longevity, making it suitable for various environmental conditions.

Finally, the integrated braking system contributes to a controlled and secure winching experience, preventing potential accidents during use. All these characteristics combine to create a highly efficient and dependable winching solution for enthusiasts looking to explore the great outdoors.

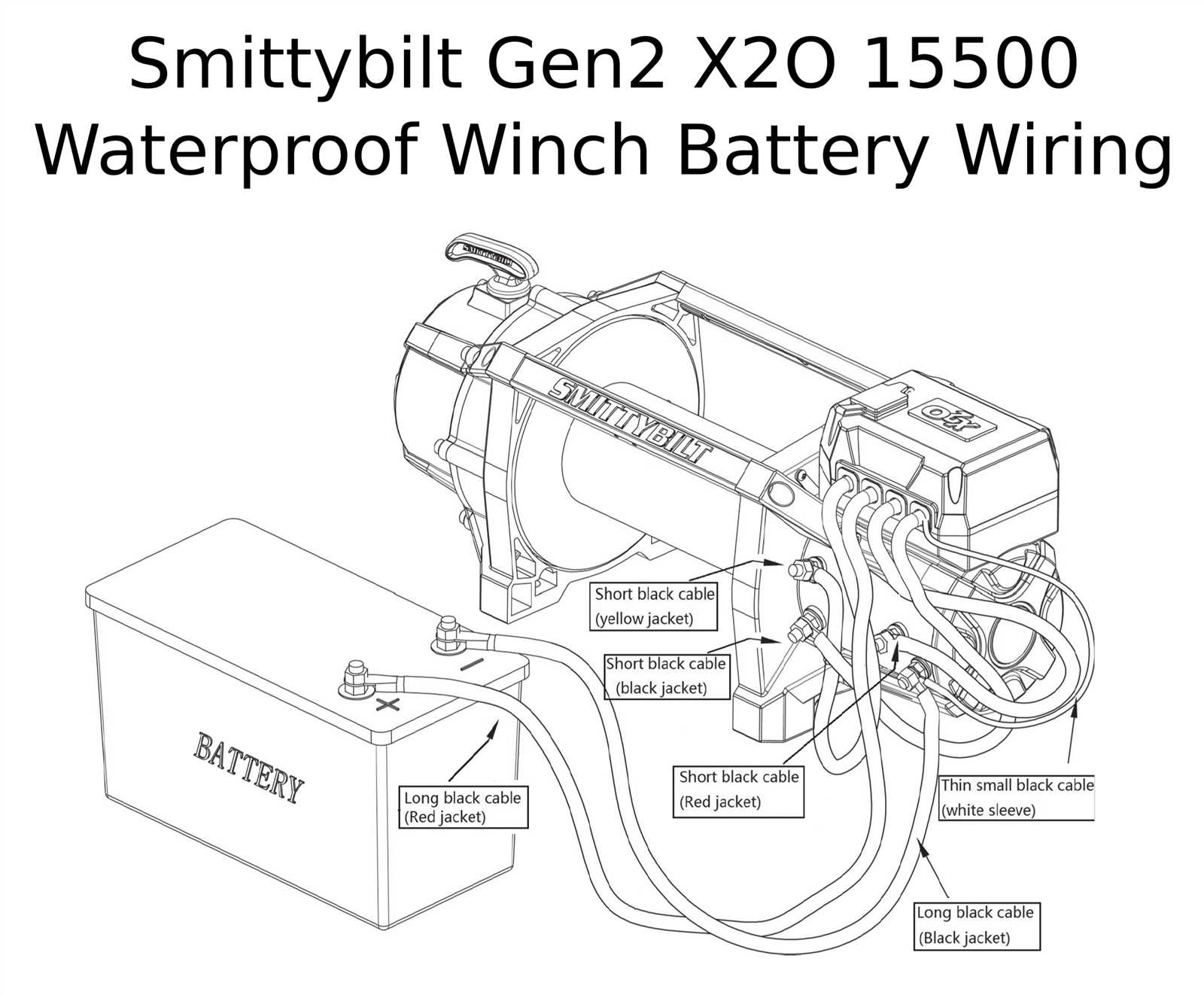

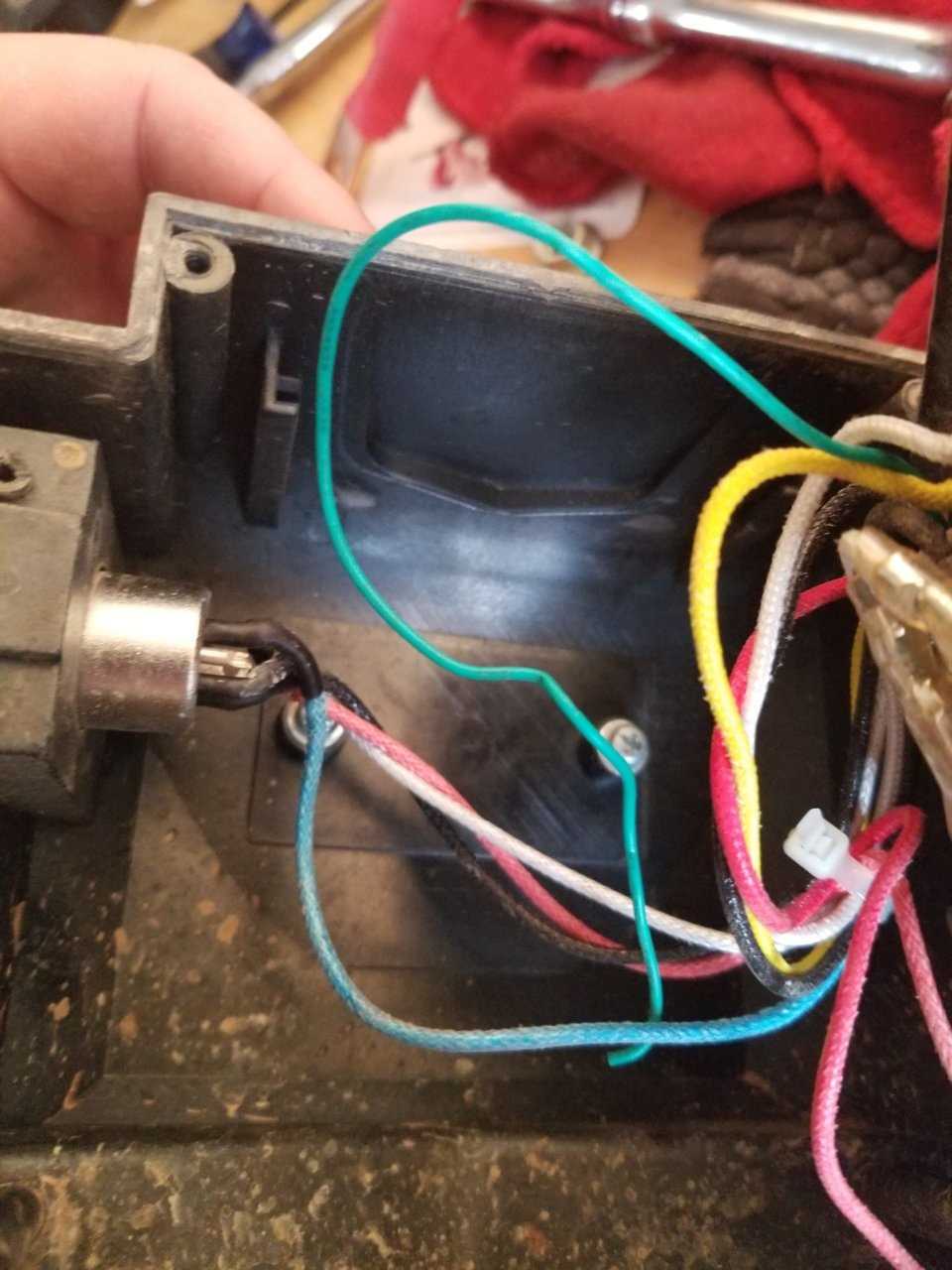

Exploring X20 Electrical Connections

Understanding the electrical linkages of a winching system is crucial for optimal performance and reliability. These connections play a vital role in ensuring that the various components work harmoniously, allowing for efficient operation. A solid grasp of these linkages can enhance both safety and functionality during usage.

Types of Electrical Linkages

Different types of connections are integral to the effective operation of the winching system. Familiarity with each type will help in troubleshooting and maintenance:

- Power Supply Connection: This connection delivers electricity from the battery to the motor, ensuring sufficient power for operation.

- Control Switch Connection: This linkage allows the user to operate the winch remotely, facilitating convenience and control.

- Ground Connection: Essential for safety, this connection prevents electrical faults and enhances the overall efficiency of the system.

Maintenance Tips for Electrical Linkages

Regular upkeep of the electrical connections is necessary for prolonged functionality. Here are some recommended practices:

- Check for loose connections regularly to prevent operational failures.

- Inspect wiring for wear and tear, and replace damaged wires promptly.

- Ensure all connections are free of corrosion, as this can impede performance.

- Test the system periodically to ensure all components are functioning properly.

Maintenance Tips for the X20 Parts

Ensuring optimal performance and longevity of your equipment requires regular upkeep and attention to detail. Proper care and routine checks can significantly enhance functionality, reduce wear and tear, and ultimately extend the life of various components. Adopting a systematic approach to maintenance not only safeguards your investment but also enhances safety during operation.

Regular Inspections

Conducting periodic assessments is essential to identify potential issues before they escalate. Focus on key areas that may exhibit signs of wear, corrosion, or damage. It’s advisable to check connections, seals, and any moving parts for proper functionality.

Lubrication and Cleaning

Keeping components well-lubricated reduces friction and minimizes wear. Use appropriate lubricants for specific materials and environments. Additionally, regular cleaning of parts helps prevent the accumulation of dirt and grime, which can hinder performance.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Every Month | Look for signs of wear or damage. |

| Lubrication | Every Three Months | Use manufacturer-recommended lubricants. |

| Cleaning | Every Six Months | Remove dirt and debris to maintain efficiency. |

Common Issues and Solutions

In any mechanical system, users often encounter a variety of challenges that can affect performance and reliability. Understanding these issues and their solutions is crucial for maintaining optimal functionality. This section aims to address frequent concerns that may arise and offer practical solutions for effective resolution.

Below are some common issues that users might face, along with potential remedies:

- Electrical Failures:

- Issue: Unexpected shutdown or power loss.

- Solution: Check the battery connections and ensure they are tight. Inspect the wiring for any signs of damage.

- Mechanical Problems:

- Issue: Unusual noises during operation.

- Solution: Examine moving parts for wear and tear. Lubricate components as necessary to reduce friction.

- Overheating:

- Issue: System runs hotter than normal.

- Solution: Ensure proper airflow around the unit. Clean any debris obstructing vents and check the cooling system.

- Connection Issues:

- Issue: Inconsistent or weak connections.

- Solution: Verify all connectors are secure. Replace any corroded or damaged connectors.

- Performance Decline:

- Issue: Reduced efficiency over time.

- Solution: Regularly inspect and replace worn-out components. Schedule routine maintenance to keep the system in peak condition.

Addressing these common challenges promptly can help ensure a smoother operation and prolong the lifespan of the equipment. By being proactive and aware of potential issues, users can mitigate risks and enhance overall performance.

How to Replace X20 Components

Replacing essential components of your winch can significantly enhance its performance and extend its lifespan. This process involves identifying worn or damaged parts and methodically substituting them with new ones. Following a systematic approach will ensure that the installation is successful and that the device operates efficiently.

Preparation Steps

- Gather necessary tools, including wrenches, screwdrivers, and replacement components.

- Ensure you have a clean, well-lit workspace to facilitate the process.

- Disconnect the power source to prevent accidental engagement during the replacement.

Replacement Procedure

- Start by removing the outer casing of the winch to access the internal components.

- Carefully detach the damaged parts, taking note of their configuration for reference.

- Install the new components, ensuring they fit securely in place.

- Reassemble the outer casing and verify that all screws and bolts are tightened appropriately.

- Reconnect the power source and perform a test to confirm that everything functions as intended.

Regular maintenance and timely replacement of worn components can prevent potential failures and ensure that your winch remains in optimal condition for years to come.

Accessories for Smittybilt X20 Winch

When enhancing the performance of your recovery device, selecting the right complementary tools is crucial. These additions can significantly improve the efficiency and safety of your operations, ensuring that you are well-prepared for any situation that may arise during off-road adventures or heavy-duty tasks.

There are numerous options available that can elevate your winching experience. Below are some essential accessories to consider for optimizing the functionality of your recovery system:

| Accessory | Description | Benefits |

|---|---|---|

| Recovery Strap | A durable strap used for towing or pulling. | Lightweight, minimizes vehicle damage, and provides high tensile strength. |

| Snatch Block | A pulley system that redirects the winch line. | Increases pulling power and allows for multi-directional pulls. |

| Wireless Remote Control | A remote for operating the winch from a distance. | Enhances safety by allowing operation from a safe distance. |

| Fairlead | A guide for the winch line to reduce wear. | Ensures smooth line retrieval and extends the life of the winch line. |

| Winch Cover | A protective cover to shield the winch from elements. | Prevents rust and debris accumulation, prolonging the winch’s lifespan. |

Investing in these accessories can not only enhance your recovery device’s capabilities but also ensure safer and more effective operations during challenging situations.

Benefits of Upgrading X20 Parts

Enhancing the components of your winch can significantly improve its overall performance and reliability. Upgrades not only provide better functionality but also ensure that your equipment operates efficiently under various conditions. Investing in higher-quality replacements can lead to a more durable setup that withstands the rigors of off-road adventures.

Improved Performance

One of the most notable advantages of upgrading is the enhancement of the winch’s performance. Newer and advanced components can deliver greater pulling power and faster recovery times, enabling you to tackle more challenging terrains without hesitation.

Increased Durability

Upgrading components often means investing in materials and designs that are engineered to last. This durability translates into fewer breakdowns and repairs, saving time and money in the long run. Additionally, a robust setup can provide peace of mind during demanding tasks.

| Component Type | Benefits |

|---|---|

| Winch Motor | Higher efficiency and better torque delivery |

| Drum | Increased line capacity and enhanced strength |

| Remote Control | Improved usability and safety during operation |

| Gear System | Faster retrieval speeds and reduced wear |

Comparing X20 with Other Models

When evaluating various winching systems, it is essential to analyze the distinctions between different models available in the market. This comparison enables potential users to understand the unique features and advantages each system offers, facilitating informed decision-making tailored to specific needs and preferences.

The winch under consideration stands out due to its remarkable pulling capacity and robust design, making it suitable for heavy-duty applications. In contrast, some competitors may offer lighter alternatives that excel in portability but may not match the same level of strength. Evaluating the construction quality, ease of installation, and user-friendly features will also reveal significant differences among the various options.

Moreover, assessing the technological enhancements found in certain models, such as advanced remote controls and integrated safety features, can be a game-changer for many users. While some systems prioritize sheer power, others may focus on additional functionalities that improve overall usability. By understanding these variations, individuals can select a winching system that aligns with their specific requirements, ensuring optimal performance and reliability in various scenarios.

Resources for Smittybilt X20 Owners

For individuals who own specific winching equipment, having access to reliable information and resources is crucial for effective usage and maintenance. Various platforms provide valuable insights, user manuals, and community support, enhancing the experience of operating this type of machinery. Below are several categories of resources that can help enhance understanding and efficiency for owners.

Official Manufacturer Resources

- User Manuals: Detailed guides that offer instructions on setup, usage, and maintenance.

- Technical Support: Dedicated support lines or chat services for troubleshooting and assistance.

- Product Registrations: Options to register equipment for warranty and updates on new products or services.

Community and Online Forums

- Discussion Boards: Online platforms where users can share experiences, tips, and advice.

- Social Media Groups: Dedicated groups for owners to connect and discuss related topics.

- Video Tutorials: Visual guides available on platforms like YouTube for practical demonstrations and tips.