In the realm of power equipment, a comprehensive knowledge of the various elements that constitute a tool is essential for optimal functionality and maintenance. Each component plays a pivotal role, contributing to the overall performance and longevity of the device.

Grasping the intricacies of these individual pieces allows users to troubleshoot effectively and carry out repairs with confidence. Familiarity with the layout and connections between parts can ultimately enhance the user experience and ensure seamless operation.

As we delve deeper into this topic, we will explore how understanding these essential elements not only empowers users but also facilitates informed decisions when it comes to repairs and upgrades. This knowledge serves as the ultimate foundation for anyone seeking to maximize the potential of their equipment.

Understanding Bosch Drill Components

Grasping the intricate elements of power tools enhances efficiency and maintenance. Each component plays a crucial role in ensuring optimal functionality, contributing to the overall performance of the equipment.

Core Elements

At the heart of these tools lies a motor, which drives the mechanism. Coupled with gears and bearings, it ensures smooth operation. Additionally, the casing protects internal components while providing a grip for the user.

Additional Features

Many advanced models include variable speed settings and torque adjustments, allowing for greater control during use. Understanding these features can significantly impact the effectiveness of your tasks. Ultimately, familiarizing yourself with each component fosters better care and longevity.

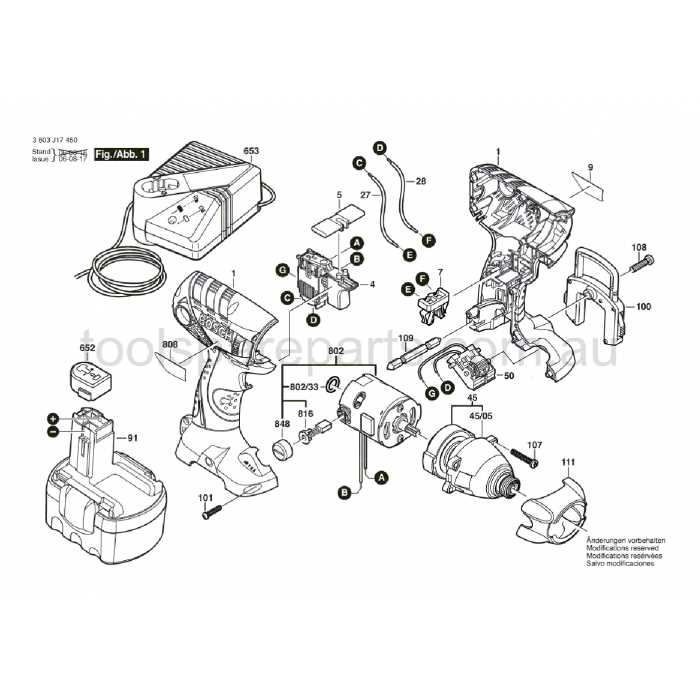

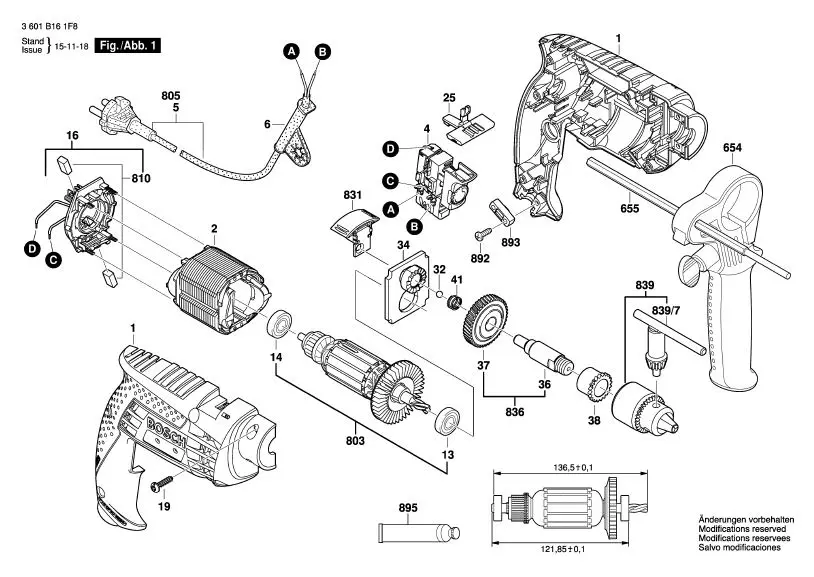

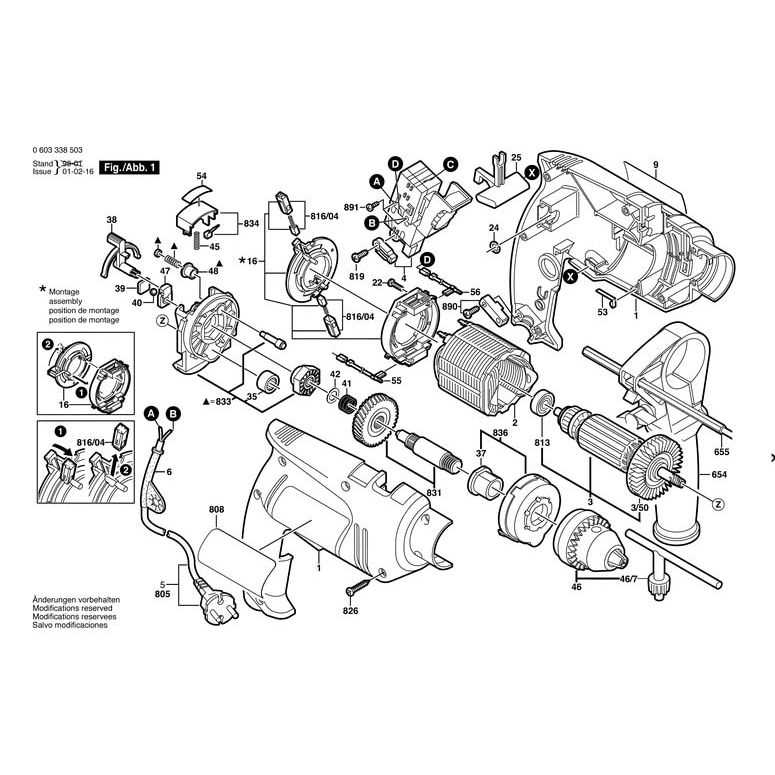

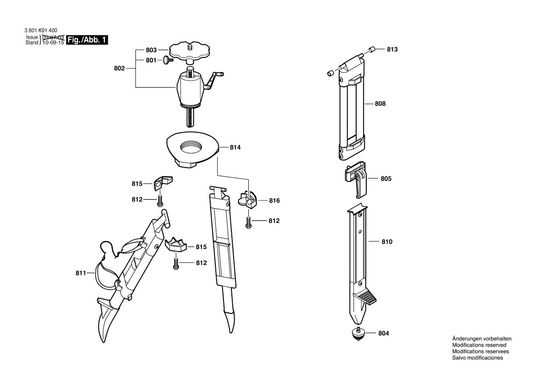

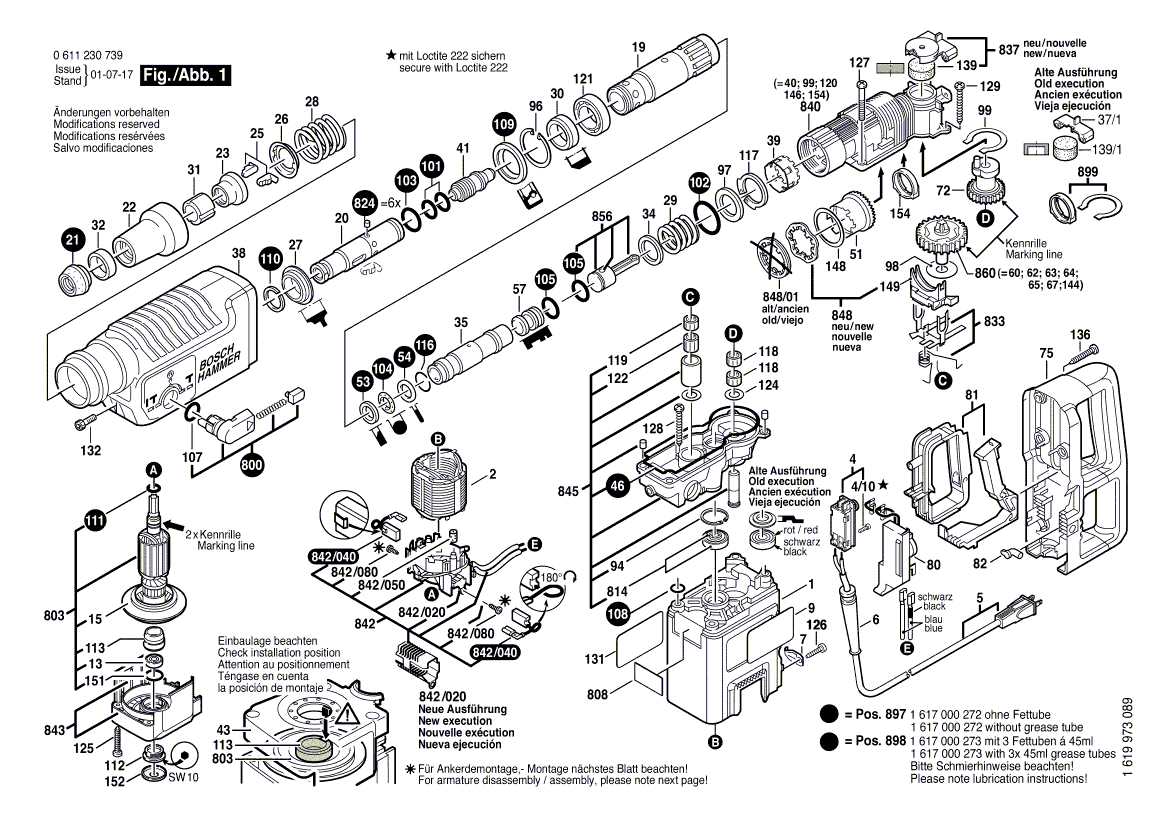

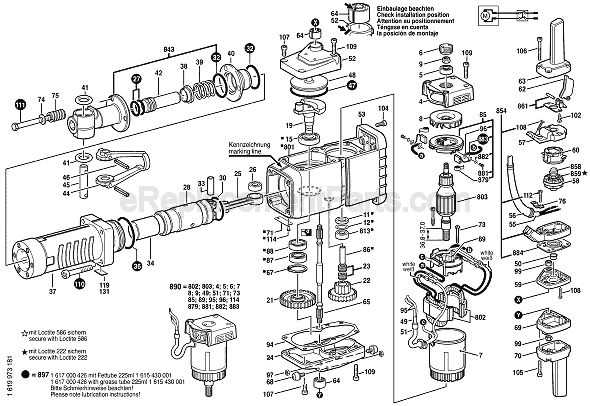

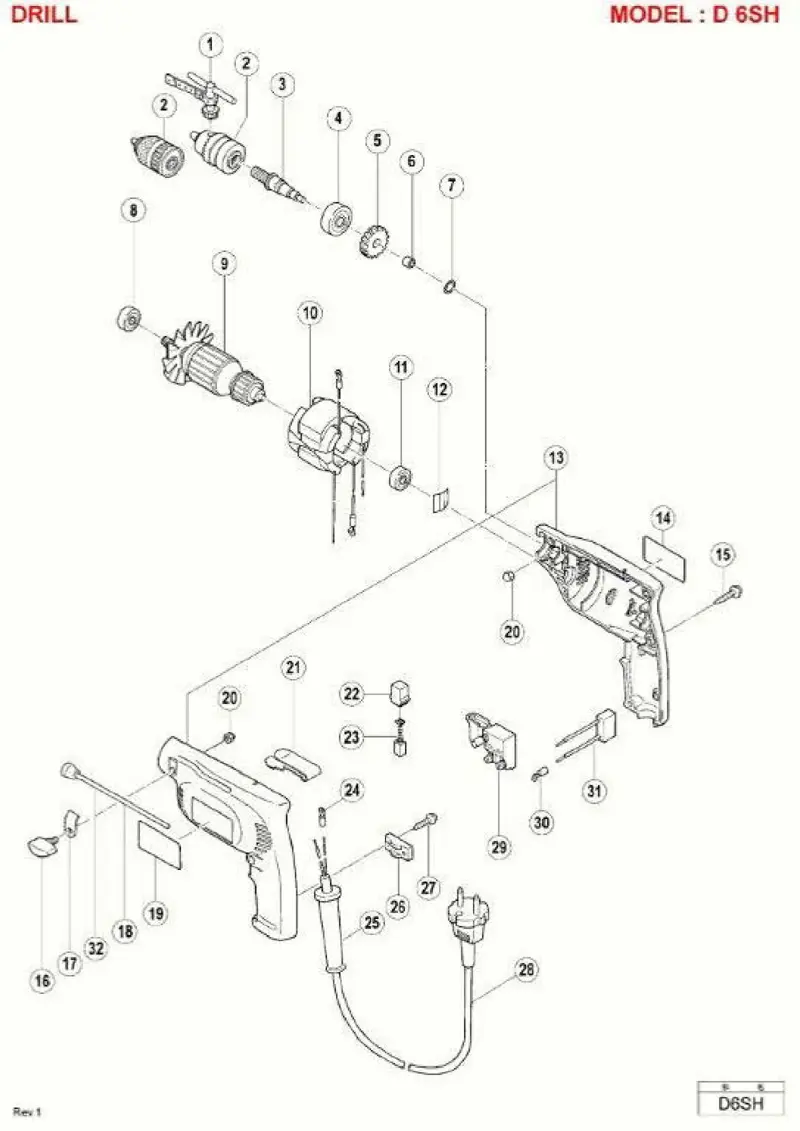

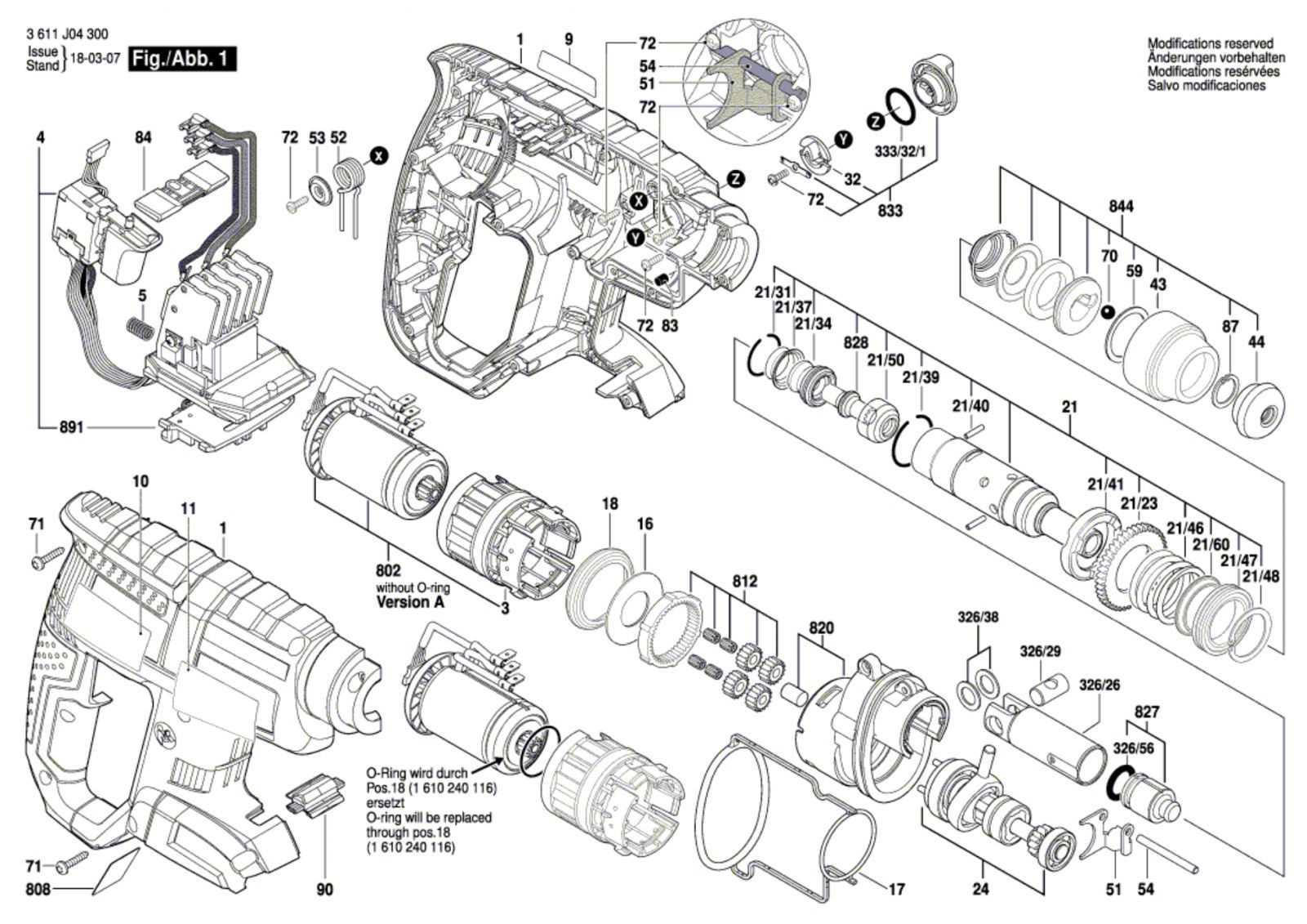

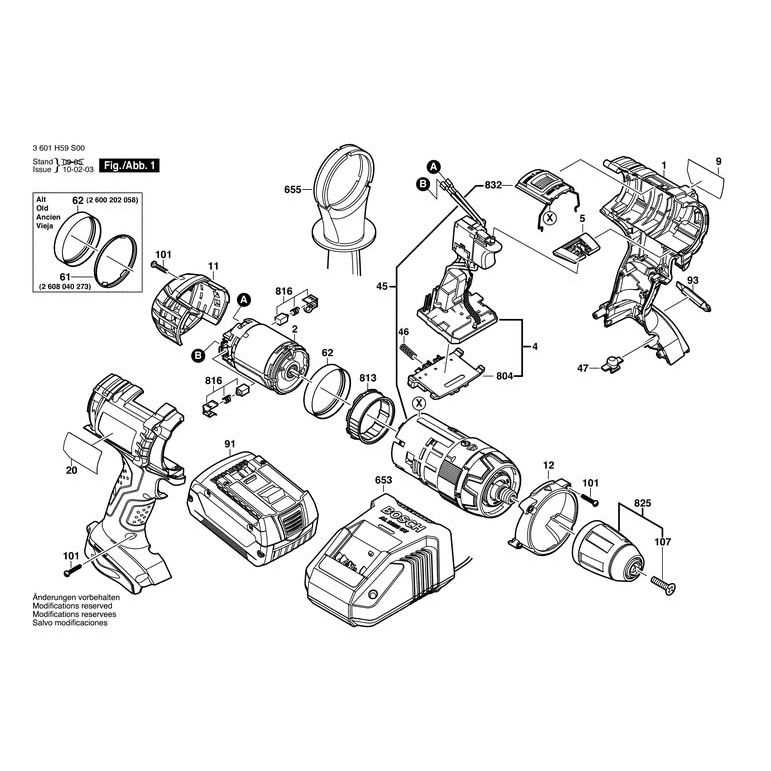

Importance of Drill Parts Diagrams

Understanding the components of a tool is crucial for effective maintenance and troubleshooting. Detailed illustrations serve as valuable resources, providing clarity on how each element fits into the overall mechanism. This knowledge enhances repair processes and ensures optimal functionality.

Moreover, these visual representations facilitate better communication among users, technicians, and manufacturers. When individuals can easily reference specific components, it streamlines the discussion around repairs and upgrades, leading to more efficient solutions.

Additionally, having access to comprehensive visuals aids in the education of new users, promoting safe and effective handling. As individuals delve into the intricacies of their equipment, they gain confidence and proficiency, which ultimately enhances their overall experience.

Common Bosch Drill Models Explained

This section delves into various popular models produced by a well-known manufacturer, highlighting their distinct features and functionalities. Understanding these models can aid users in selecting the right tool for their specific tasks, ensuring efficiency and effectiveness in their projects.

Overview of Popular Models

Each model is designed with specific applications in mind, catering to both casual users and professionals. Below is a summary of several commonly utilized models, focusing on their main attributes and advantages.

| Model Name | Power (Watts) | Chuck Size (mm) | Speed Settings |

|---|---|---|---|

| Model A | 600 | 13 | 2 |

| Model B | 750 | 13 | 3 |

| Model C | 500 | 10 | 1 |

Choosing the Right Tool

When selecting a tool, consider the nature of the tasks you intend to perform. Models vary in terms of power, versatility, and ease of use. Assessing your specific needs will guide you toward the most suitable option, enhancing your overall productivity.

Identifying Key Parts in Diagrams

Understanding the components of any mechanical device is essential for effective usage and maintenance. Familiarizing oneself with the visual representations of these elements can greatly enhance one’s ability to troubleshoot issues and perform repairs efficiently. This section delves into the essential components often highlighted in schematic illustrations.

Common Elements in Visual Representations

When examining visual guides, certain components frequently appear. Recognizing these parts can aid in grasping the overall functionality of the device.

- Power Source: The component that provides energy, crucial for operation.

- Housing: The outer shell that protects internal mechanisms.

- Trigger Mechanism: The feature that initiates action.

- Chuck: The clamp that secures accessories in place.

- Gear Assembly: The system responsible for translating movement and force.

Tips for Efficient Identification

To effectively identify and understand these components, consider the following strategies:

- Familiarize yourself with terminology related to mechanical devices.

- Cross-reference visual guides with user manuals for context.

- Take notes on each part’s function to reinforce understanding.

- Practice by dismantling and reassembling devices to gain hands-on experience.

By focusing on these elements and employing practical strategies, one can enhance their comprehension of mechanical systems and improve their skills in handling them. Understanding these key components is the first step towards becoming proficient in maintenance and repair tasks.

How to Read Drill Parts Diagrams

Understanding technical illustrations is crucial for effective assembly and maintenance of tools. These visuals provide a detailed view of individual components and their interconnections, enabling users to identify and source replacements when necessary. By grasping the symbols and layout, you can enhance your repair and upkeep skills significantly.

| Symbol | Meaning |

|---|---|

| Circle | Component |

| Arrow | Connection or flow direction |

| Shaded area | Part to be removed |

| Numbered list | Assembly order |

Familiarizing yourself with these conventions will ultimately make troubleshooting and repairs more efficient and straightforward.

Maintaining Your Bosch Drill Efficiently

Proper upkeep of your power tool is essential for optimal performance and longevity. Regular attention to key components can prevent breakdowns and ensure reliable operation. Understanding how to care for your equipment not only enhances its efficiency but also improves safety during use.

Regular Cleaning

Dust and debris can accumulate, affecting functionality. Ensure to clean the exterior regularly and check internal mechanisms as per the manufacturer’s guidelines. Using compressed air can effectively remove particles from tight spaces.

Lubrication and Inspection

Routine lubrication of moving parts is crucial. Apply suitable grease to reduce wear and tear. Additionally, inspect cables, switches, and housing for any signs of damage to maintain operational safety and effectiveness.

Replacing Parts: A Step-by-Step Guide

When it comes to maintaining tools, knowing how to substitute components is essential for ensuring optimal performance. This guide provides clear, sequential instructions to help you navigate the replacement process effectively. By following these steps, you can prolong the lifespan of your equipment and enhance its efficiency.

Step 1: Gather Necessary Tools and Components

Before starting the replacement process, make sure you have all the required tools and new components at hand. This may include screwdrivers, wrenches, and any specialized tools specific to your equipment. Having everything ready will streamline the procedure and reduce downtime.

Step 2: Disassemble the Equipment

Carefully take apart the tool to access the components that need replacement. Refer to your user manual for guidance on how to disassemble it properly. Ensure that you keep track of screws and small parts to facilitate reassembly later. Taking photos during disassembly can also be helpful for reference.

Common Issues with Bosch Drills

Power tools can sometimes encounter problems that affect their performance and usability. Understanding these common challenges can help users maintain their equipment and extend its lifespan. Below are some frequent issues experienced with these versatile tools, along with potential solutions.

Frequent Malfunctions

Users may notice various malfunctions that can disrupt work. These can stem from wear and tear, improper usage, or manufacturing defects. Addressing these issues promptly is crucial to ensure optimal performance.

| Issue | Possible Cause | Solution |

|---|---|---|

| Overheating | Extended use or blocked ventilation | Allow to cool and check for obstructions |

| Reduced power | Battery issues or motor wear | Replace battery or inspect motor components |

| Inconsistent speed | Faulty trigger switch | Repair or replace the switch |

Maintenance Tips

Regular maintenance can prevent many common issues. Users should clean their tools frequently, check for loose connections, and ensure that batteries are charged and functioning properly. Additionally, following the manufacturer’s guidelines can significantly enhance durability.

Where to Find Replacement Parts

Locating suitable components for your tools can often seem daunting, but there are several effective avenues to explore. Whether you require specific elements for repairs or upgrades, understanding where to search can save you time and effort.

One of the most reliable options is the official manufacturer’s website, which typically features a comprehensive catalog of components tailored to their products. Additionally, authorized retailers often stock these essential items and can provide guidance on compatibility and installation.

For those seeking alternatives, online marketplaces offer a wide range of options, including both original and third-party components. User reviews can help assess the quality and reliability of these alternatives. Local hardware stores may also carry common elements or be able to order them for you.

Finally, forums and community groups dedicated to tool enthusiasts can be valuable resources. Members often share their experiences and recommendations, which can lead you to hard-to-find components or trusted suppliers.

Enhancing Performance Through Upgrades

Improving functionality and efficiency is crucial for maximizing the potential of your tools. By investing in enhancements, users can experience significant boosts in performance, making tasks easier and more effective.

Key Areas for Improvement

- Power Supply: Upgrading to a more robust battery can lead to longer usage times and quicker recharges.

- Gear Mechanisms: Opting for higher-quality gears can enhance torque and speed.

- Ergonomics: Improved grips and designs can reduce fatigue during extended use.

Benefits of Upgrading

- Increased Productivity: Enhanced tools lead to faster completion of tasks.

- Durability: Quality components often result in a longer lifespan.

- Versatility: Upgrades can allow for a wider range of applications and materials.