Unlocking the intricate design and functionality of a renowned construction implement unveils a fascinating realm of engineering marvels. This section delves into the intricate inner workings of a robust device, showcasing its internal components and their strategic placements. Understanding these crucial elements provides insights into how this tool operates with precision and reliability.

In this exploration, we navigate through the core mechanisms that drive this tool’s performance, highlighting the interconnections and relationships between its various functional units. By unraveling these complexities, we gain a deeper appreciation for the thoughtful design and engineering prowess embedded within each component.

Join us on a journey into the heart of this construction companion, where each piece plays a crucial role in ensuring efficiency and durability on the job site. This insightful investigation aims to demystify the internal architecture, shedding light on the synergy between form and function in this essential tool.

Understanding the Inner Workings of Bosch Jackhammers

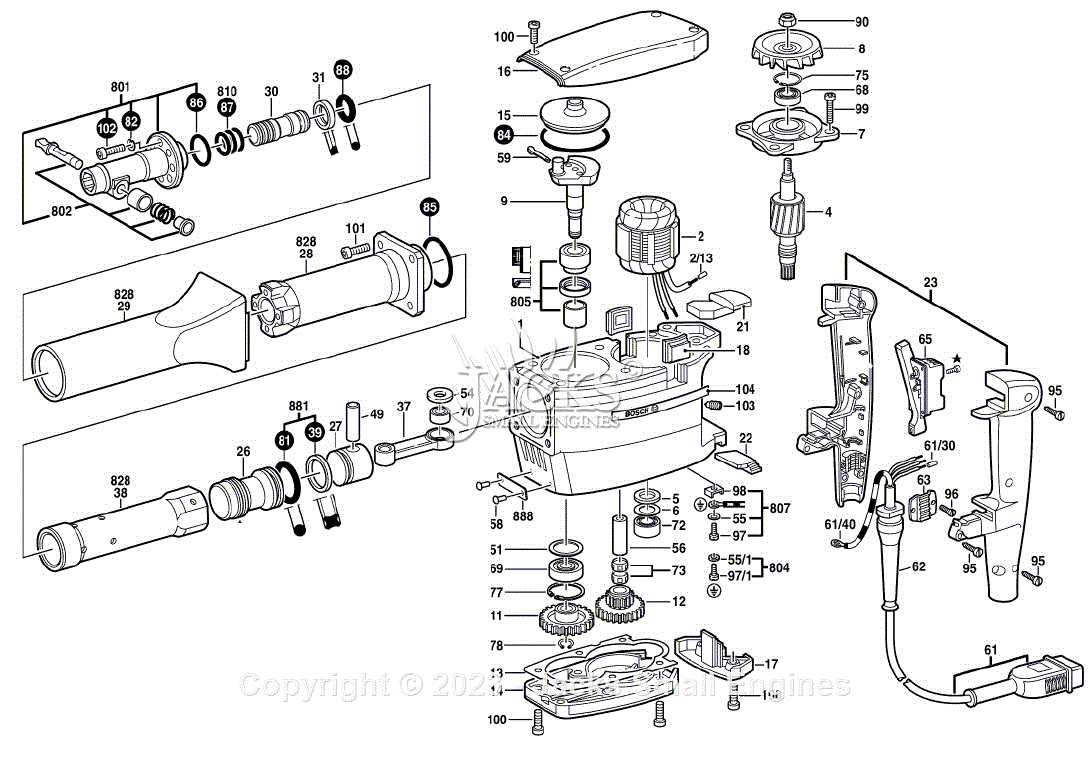

In delving into the intricate mechanisms that drive Bosch jackhammers, we uncover the sophisticated interplay of components that power these robust tools. Exploring the internal architecture reveals a network of interconnected systems, each fulfilling crucial functions in tandem with others. These systems orchestrate the kinetic energy transformation, facilitating the impactful force necessary for effective demolition tasks.

Examining the operational dynamics further unveils the integration of structural elements and mechanical assemblies, which harmonize to amplify and direct forces with precision. This synergy ensures optimal performance under varying operational conditions, emphasizing reliability and endurance in demanding construction environments.

Understanding the interdependencies among these components provides insight into the engineering finesse behind Bosch jackhammers, illuminating the nuanced balance between power, control, and durability. Such comprehension underscores the meticulous design philosophy aimed at delivering consistent, efficient performance throughout prolonged usage.

Identifying Key Components in a Bosch Jackhammer

Understanding the fundamental elements of a powerful demolition tool is essential for both effective operation and maintenance. Recognizing these vital pieces can enhance the user’s experience and ensure optimal performance. This section will delve into the crucial components that contribute to the functionality of this equipment.

Key elements include the following:

- Power Source: The energy provider that drives the entire mechanism, whether it’s electric or pneumatic.

- Impact Mechanism: This element is responsible for generating the force needed to break through tough surfaces.

- Chisel or Bit: The detachable piece that directly contacts the material, available in various shapes for different tasks.

- Housing: The outer shell that encases the internal components, designed for durability and comfort during use.

- Handle: The gripping part that allows for better control and maneuverability while operating the device.

Each of these components plays a critical role in ensuring the tool operates efficiently and effectively. Familiarity with them can aid in troubleshooting, maintenance, and selecting the right equipment for specific tasks.

Overview of Mechanisms Found in Jackhammer Components

In this section, we delve into the intricate inner workings that power the functionality of various components within the jackhammer apparatus. Our focus is on elucidating the operational principles governing these pivotal mechanisms.

Dynamic Components: We explore the dynamic elements that drive the jackhammer’s powerful performance, examining the mechanisms responsible for generating impactful forces.

Structural Integrity: The robust construction of each part ensures durability under strenuous conditions, supporting reliable operation throughout prolonged usage.

Operating Mechanisms: An analysis of the operational mechanisms uncovers the precise methods employed to initiate and sustain effective percussive action.

Energy Transfer: We examine the efficient transfer of energy through components, optimizing the jackhammer’s ability to deliver consistent and efficient results.

Regulation and Control: Detailed insights into the regulatory mechanisms highlight their role in maintaining operational control and safety standards.

Integration and Synchronization: The seamless integration and synchronization of various components ensure harmonious functioning, enhancing overall performance.

Explaining the Functionality of Each Bosch Jackhammer Part

This section delves into the various components of a demolition tool, exploring their individual roles and how they contribute to the overall operation of the equipment. Understanding these elements is crucial for effective usage and maintenance, ensuring optimal performance during heavy-duty tasks.

Power Source: The energy generator provides the necessary force to initiate the tool’s action. It can be electric or pneumatic, impacting the efficiency and application of the device.

Impact Mechanism: This component is responsible for converting the energy supplied by the power source into rapid, striking movements. It is vital for breaking through tough surfaces with precision and effectiveness.

Chisel: The specialized attachment is designed to penetrate and break apart materials. Different shapes and sizes of chisels are available, each suited for specific types of work, from demolition to excavation.

Housing: The outer shell protects the internal mechanisms and provides a grip for the user. It is engineered for durability and comfort, ensuring safety during prolonged use.

Vibration Dampening System: This system minimizes the vibrations experienced by the user, enhancing comfort and reducing fatigue during operation. It also helps to prolong the tool’s lifespan by lessening wear on components.

Control Mechanism: The user interface allows for adjustments in power and speed, enabling tailored operation based on the material being worked on and the user’s preferences. This ensures efficiency and accuracy in handling various tasks.

By understanding the role of each element, users can enhance their experience and effectiveness when employing this powerful equipment for their projects.

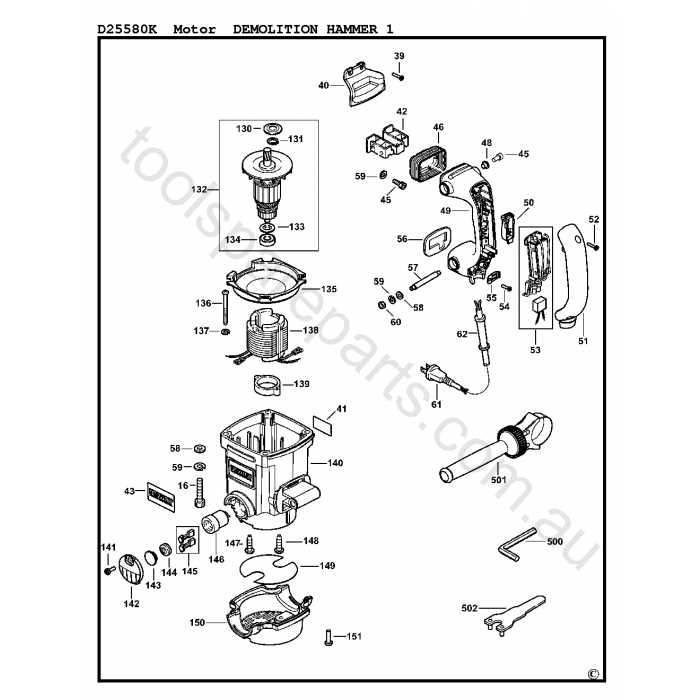

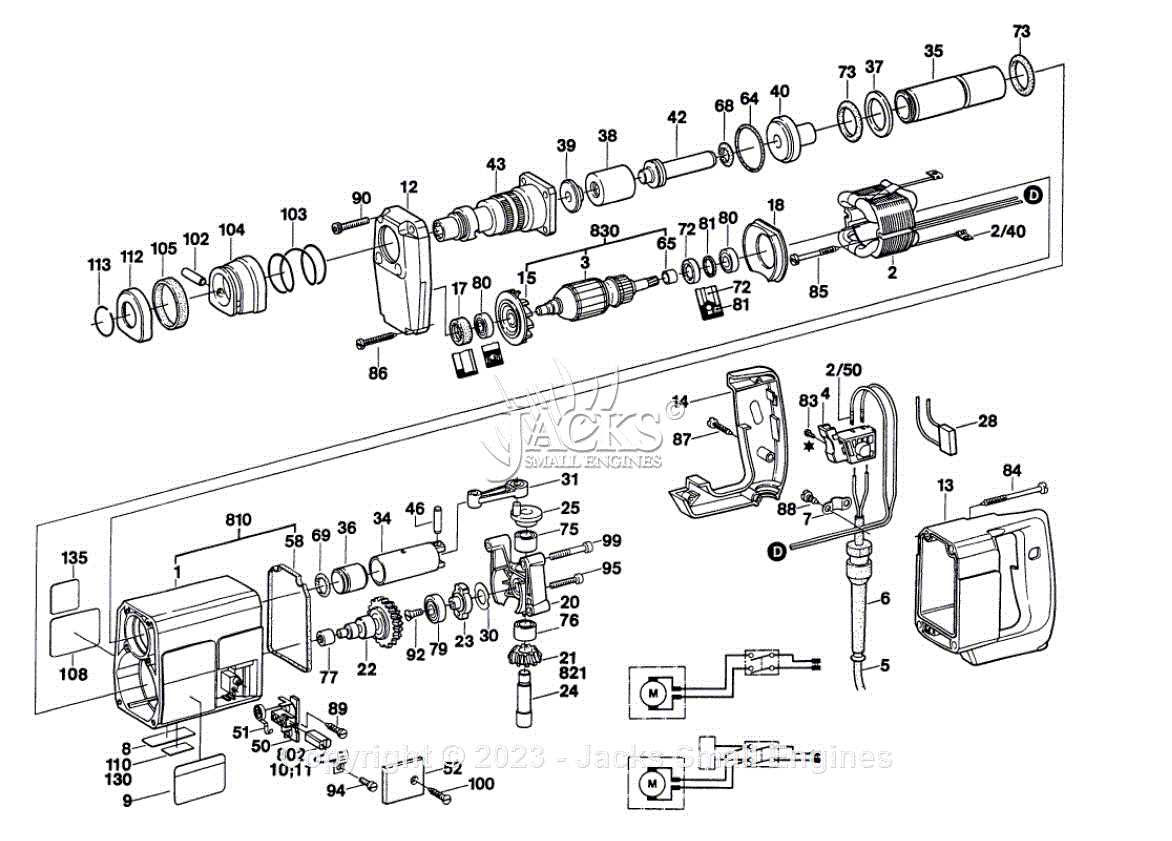

Visual Guide to the Parts of a Bosch Jackhammer

This section provides an insightful overview of the various components found in a powerful demolition tool, emphasizing their functions and importance. Understanding the elements of this equipment can greatly enhance the user experience and maintenance efficiency.

Key Components Overview

- Handle: Designed for optimal grip and control during operation.

- Trigger: Initiates the tool’s action and allows for speed adjustment.

- Chisel: The main attachment used for breaking concrete and other hard surfaces.

- Piston: Drives the chisel forward with significant force.

- Housing: Encases the internal mechanisms, providing protection and structural integrity.

Maintenance Considerations

Regular upkeep of each component is crucial for longevity and performance. Here are some essential maintenance tips:

- Inspect the grip for wear and replace if necessary to maintain safety.

- Clean the chisel regularly to prevent buildup and ensure optimal performance.

- Check the piston and internal mechanisms for any signs of damage or misalignment.

- Ensure the housing is free of cracks and debris to protect internal parts.

Common Issues and Troubleshooting Bosch Jackhammer Parts

Understanding the common problems that can arise with heavy-duty tools is essential for effective maintenance and prolonged lifespan. Many issues can stem from wear and tear, improper use, or inadequate upkeep. Recognizing these problems early can help prevent more serious damage and ensure optimal functionality.

Below are some frequent challenges encountered with these powerful tools, along with practical solutions to address them:

| Issue | Symptoms | Troubleshooting Steps |

|---|---|---|

| Poor Performance | Reduced impact force or sluggish operation | Check for air leaks, inspect the piston, and ensure all connections are secure. |

| Excessive Vibration | Unusual shaking during operation | Examine the mounting hardware, and verify the condition of the handle and isolation mounts. |

| Overheating | Tool becomes excessively hot | Ensure adequate lubrication, check the cooling system, and avoid prolonged usage without breaks. |

| Noise Issues | Increased noise levels during use | Inspect for loose components, worn bearings, and confirm that all parts are properly secured. |

| Air Leaks | Loss of pressure and efficiency | Identify and replace damaged seals or hoses, and tighten any loose fittings. |

Regular inspection and maintenance can significantly reduce the likelihood of encountering these issues. Addressing problems promptly ensures that tools remain in peak condition, enhancing performance and safety.

Maintenance Tips for Bosch Jackhammer Components

Ensuring the longevity and performance of heavy-duty equipment requires regular care and attention. Proper upkeep not only enhances efficiency but also minimizes downtime caused by unexpected failures. Understanding the essential aspects of maintenance can significantly contribute to the reliable operation of the tools in question.

Regular Inspections

Conducting frequent assessments of all elements is crucial. Check for signs of wear, damage, or loosening. Pay attention to seals and gaskets, as their integrity is vital for preventing leaks. Keeping an eye on these components can help identify issues before they escalate, ensuring smooth functionality.

Lubrication and Cleaning

Applying appropriate lubricants to moving parts is essential for reducing friction and wear. Additionally, keep the device clean from dust and debris, which can interfere with performance. Regularly wipe down surfaces and remove any accumulated material to maintain optimal operation.

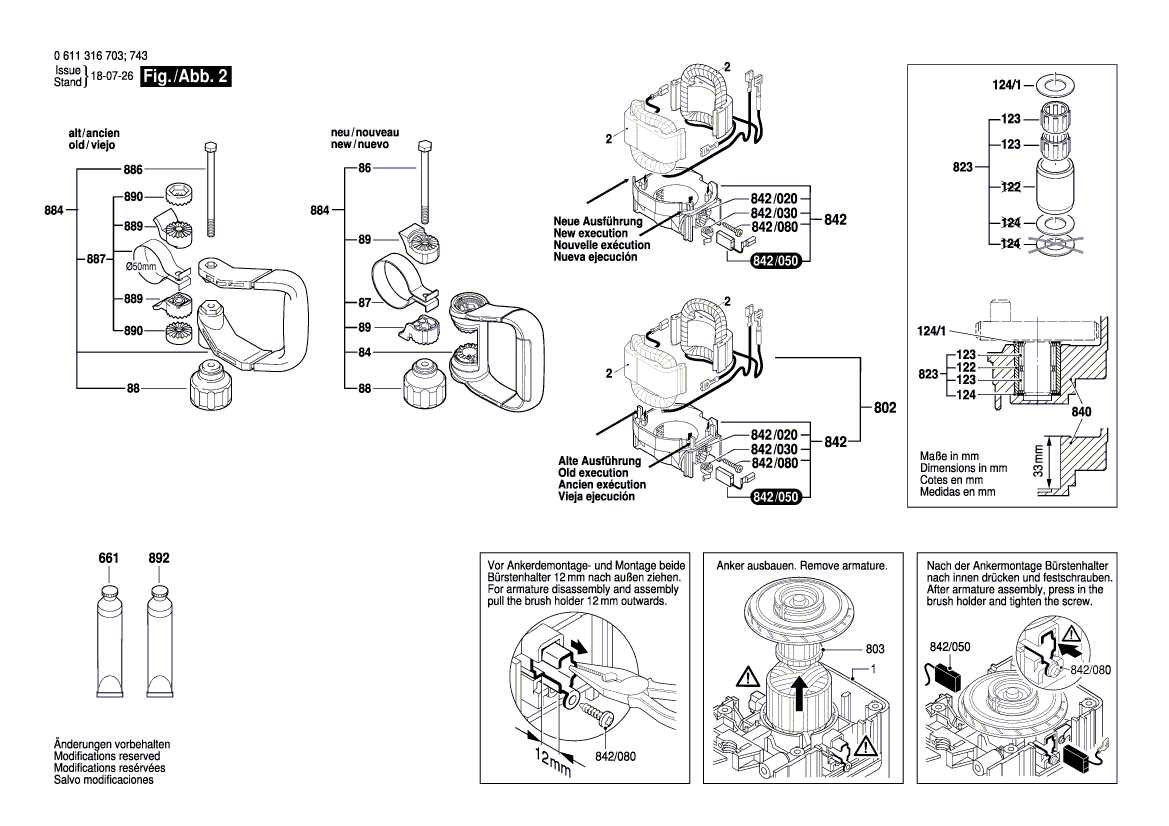

Replacing and Upgrading Bosch Jackhammer Parts

Maintaining and enhancing the functionality of heavy-duty equipment is crucial for optimal performance. This section focuses on the methods and considerations involved in swapping out or enhancing components of a powerful tool designed for rigorous tasks. Regular updates not only improve efficiency but also extend the lifespan of the machine.

When it comes to modifications, assessing the current state of the equipment is vital. Identify which elements require replacement or upgrading based on wear and tear or performance issues. Keeping an eye on the quality of components is essential; opting for reliable and durable alternatives can significantly impact overall efficiency.

Moreover, proper installation techniques are key to ensuring that new components fit seamlessly and function effectively. Consulting a user manual or seeking guidance from experienced professionals can provide invaluable insights during this process. Additionally, maintaining a routine schedule for inspections and replacements can help prevent unexpected breakdowns and maintain productivity.

Ultimately, investing time and resources into upgrading and replacing elements of this powerful tool can yield impressive results, enhancing both performance and reliability.

Compatibility Guide for Bosch Jackhammer Parts

This section aims to provide an overview of how various components interact within a specific power tool model. Understanding these relationships is crucial for ensuring optimal performance and longevity. Identifying the correct components can greatly enhance efficiency during operation and maintenance.

When selecting replacement items or upgrades, compatibility becomes a key factor. Below is a table that outlines common elements and their corresponding models, facilitating easier decision-making for users.

| Component Type | Compatible Models |

|---|---|

| Impact Mechanism | Model A, Model B, Model C |

| Power Supply Unit | Model A, Model D |

| Handle Assembly | Model B, Model E |

| Vibration Dampening System | Model C, Model D |

| Tool Holder | Model A, Model E |

Consulting this guide can help ensure the proper selection of components, minimizing the risk of compatibility issues and enhancing overall functionality.

Practical Applications of Bosch Jackhammer Parts

The various components of a powerful demolition tool play crucial roles in its performance and versatility. Understanding the utility of these elements can significantly enhance the efficiency of construction and renovation projects. Each section of the device contributes to its overall functionality, allowing users to tackle diverse tasks with ease.

Optimizing Demolition Tasks

In heavy-duty construction, knowing how to utilize the different elements effectively can streamline the demolition process. By selecting the appropriate attachments, operators can efficiently break through concrete, asphalt, and other tough materials. This adaptability not only speeds up job completion but also ensures precise results, minimizing collateral damage to surrounding structures.

Maintenance and Longevity

Proper care and understanding of individual components are essential for extending the lifespan of the tool. Regular inspections and timely replacements of worn parts help maintain peak performance. By investing time in upkeep, users can avoid costly repairs and ensure consistent reliability during demanding tasks.