In the realm of mechanical maintenance and repair, having a thorough grasp of the various elements that comprise a specific machining apparatus is essential. Each component plays a crucial role in ensuring optimal performance and longevity. This section delves into the intricate relationships between these elements, emphasizing their functions and interactions.

Visual representations can greatly enhance comprehension, allowing technicians to quickly identify individual components and their placements. By familiarizing oneself with these visual aids, one can develop a more profound understanding of the entire system, ultimately leading to improved efficiency during repairs and maintenance tasks.

Whether you are a seasoned professional or an enthusiastic novice, grasping the layout and functionality of each part is invaluable. This knowledge not only aids in effective troubleshooting but also empowers users to make informed decisions when seeking replacements or upgrades, ensuring the reliability and effectiveness of the machining tool.

The focus of this section is to provide a comprehensive introduction to a specific model of machinery widely utilized in the automotive sector. This tool plays a crucial role in the maintenance and refurbishment of wheel components, ensuring optimal performance and safety for vehicles. Understanding the various elements that constitute this equipment is essential for both users and technicians alike.

In this overview, we will explore the essential features and functionalities of the equipment, highlighting its significance in enhancing efficiency and precision in automotive repairs. Key components will be identified, each serving a unique purpose that contributes to the overall operation of the tool.

Additionally, we will discuss the advantages of familiarizing oneself with the equipment’s design and layout, emphasizing how such knowledge can lead to improved troubleshooting and maintenance practices. By gaining insight into the intricacies of this machine, users can maximize its potential and ensure long-lasting reliability.

Key Points to Cover:

- Introduction to the equipment’s role in automotive service

- Importance of understanding its structure

- Benefits of proper maintenance and operation

Key Components of the Machine

Understanding the essential elements of this specialized equipment is crucial for effective operation and maintenance. Each component plays a significant role in the overall functionality, contributing to precision and efficiency in its applications.

Main Functional Elements

- Motor System: Provides the necessary power to operate the machine.

- Cutting Tool: Designed for shaping and refining the surfaces of the components.

- Control Panel: Facilitates user interaction, allowing for adjustments and monitoring of the operation.

- Workholding Mechanism: Secures the item being processed, ensuring stability during operation.

Supportive Features

- Frame Structure: Offers robust support for the entire assembly, enhancing durability.

- Cooling System: Maintains optimal temperatures, preventing overheating during extended use.

- Safety Mechanisms: Includes features designed to protect the operator and the machine from potential hazards.

Understanding the Brake Lathe Functionality

This section delves into the essential mechanisms that allow for precision machining of disc surfaces. The device plays a crucial role in ensuring optimal performance and safety in automotive systems.

At its core, the equipment operates by rotating the component while a cutting tool engages with the surface. This process effectively removes imperfections and achieves a smooth finish, enhancing the overall efficiency of the braking system.

Components such as the drive mechanism, cutting tools, and adjustment systems work in tandem to facilitate accurate machining. Understanding these elements is vital for effective maintenance and operation, ensuring longevity and reliability in performance.

Maintenance Tips for Longevity

Ensuring the durability of your machinery requires a proactive approach to upkeep. Regular care not only enhances performance but also extends the lifespan of the equipment. By implementing effective maintenance strategies, you can minimize wear and tear, ensuring optimal functionality over time.

Regular Inspections

Conduct frequent evaluations of your equipment to identify any signs of deterioration or potential issues. Pay attention to critical components and make adjustments as needed to prevent larger problems.

Lubrication and Cleaning

Consistent lubrication of moving elements is vital for reducing friction and preventing premature damage. Additionally, keeping the machinery clean helps eliminate debris that can hinder performance and lead to unnecessary repairs.

Common Issues and Troubleshooting

In any mechanical system, users may encounter various challenges that can affect performance and efficiency. Understanding typical problems and their solutions is essential for maintaining optimal functionality and ensuring longevity.

One frequent issue involves inconsistent operation, which can stem from worn components or improper calibration. Regularly checking and adjusting these elements can prevent further complications.

Another concern is vibration during use, often caused by misalignment or imbalance in the system. Ensuring all parts are securely fastened and aligned correctly can significantly reduce this problem.

Furthermore, noise during operation may indicate the need for lubrication or the replacement of worn parts. Regular maintenance and timely inspections are vital to address such concerns promptly.

In summary, recognizing and addressing these common issues can enhance the performance and reliability of the equipment, allowing for smoother and more efficient operation.

Replacement Parts Availability

Access to essential components is crucial for maintaining and restoring the functionality of machinery. Ensuring that these vital elements are readily available can significantly enhance the performance and longevity of equipment. Understanding where to source these components is key for both efficiency and effectiveness in repairs.

Various suppliers offer a range of options for acquiring the necessary replacements. Many manufacturers provide direct sales, while third-party vendors may also carry compatible items. Online marketplaces have become invaluable resources, allowing users to compare prices and availability easily.

It is important to verify the compatibility of components with specific models. Detailed descriptions and specifications can aid in making informed purchasing decisions. Furthermore, exploring both new and refurbished options can provide cost-effective solutions without compromising quality.

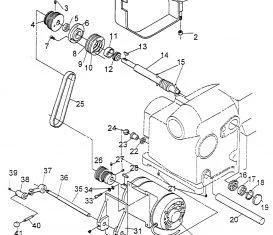

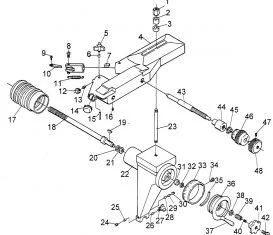

Step-by-Step Assembly Guide

This section provides a detailed roadmap for the careful construction of a precision machining tool. Following these instructions will ensure that each component fits seamlessly, optimizing performance and longevity.

Begin by organizing your components. Lay out all pieces systematically to facilitate an efficient assembly process. This will help you identify each item easily and avoid confusion.

Next, consult the reference chart. Understanding the layout of each section is crucial. Familiarize yourself with the configurations to ensure correct placements and connections.

Proceed with the main structure. Start assembling the core framework, ensuring that all joints are secure and stable. This foundational step is vital for the tool’s overall integrity.

Install additional mechanisms. Carefully integrate the secondary components, paying attention to alignment and functionality. Ensure that each piece operates smoothly within the assembly.

Conduct a final inspection. After assembly, review each part meticulously. Look for any misalignments or loose fittings, making adjustments as necessary to guarantee optimal operation.

Safety Precautions When Operating

Ensuring a secure working environment is paramount when handling machinery. Adhering to safety measures not only protects the operator but also enhances the overall effectiveness of the equipment. Awareness and preparation can significantly reduce the risk of accidents.

Wear Protective Gear: Always equip yourself with appropriate safety attire, including gloves, goggles, and hearing protection. This gear minimizes exposure to potential hazards while operating the equipment.

Maintain a Clean Workspace: Keeping the area tidy reduces the chance of tripping or mishaps. Ensure that tools and materials are organized and out of the way before beginning any task.

Follow Manufacturer Guidelines: Familiarize yourself with the operational instructions provided by the manufacturer. Understanding the equipment’s features and functions is essential for safe usage.

Inspect Equipment Regularly: Conduct routine checks on the machinery to identify any wear or damage. Promptly addressing issues ensures safe and efficient operation.

Stay Focused: Concentration is crucial. Avoid distractions while operating, as a lapse in attention can lead to accidents.

Upgrading Parts for Enhanced Performance

Improving the components of your machinery can significantly elevate its functionality and longevity. By selecting higher-quality alternatives and modern enhancements, users can experience increased efficiency and precision during operation. This proactive approach not only boosts productivity but also reduces the frequency of maintenance required.

When considering upgrades, it is crucial to assess the compatibility of new components with existing equipment. Below is a comparison table that outlines various upgrades available, their benefits, and recommended usage:

| Component | Upgrade Option | Benefits | Recommended Usage |

|---|---|---|---|

| Cutting Tool | High-Speed Steel | Enhanced durability and cutting efficiency | Heavy-duty applications |

| Drive Belt | Polyurethane Belt | Increased strength and flexibility | High-performance settings |

| Control System | Digital Interface | Improved accuracy and user experience | All applications |

Investing in superior components not only enhances operational effectiveness but also contributes to a smoother workflow and superior output quality. Evaluating and upgrading your equipment is a wise strategy for any user aiming for optimal performance.

Comparison with Other Models

When evaluating different machining tools, it’s essential to understand how each model measures up against its competitors. Variations in design, functionality, and performance can significantly impact user experience and efficiency. This comparison aims to highlight the strengths and weaknesses of a particular model in relation to others within the same category.

One notable distinction lies in the precision and adaptability of the machines. Some alternatives may offer enhanced capabilities for specific tasks, catering to various user needs. Additionally, the ease of use and maintenance requirements can vary greatly, influencing the overall choice for both professional and hobbyist applications. Performance metrics, such as speed and accuracy, are crucial when determining the best fit for a workshop.

Moreover, while certain models are celebrated for their robust build quality and longevity, others might prioritize innovative features that enhance versatility. Cost considerations also play a pivotal role in decision-making, as the initial investment can differ widely across brands and specifications. By examining these aspects, users can make informed choices tailored to their specific requirements.

User Experiences and Feedback

This section delves into the insights and evaluations shared by users regarding the functioning and reliability of a specific type of machining tool used in vehicle maintenance. It highlights various perspectives, showcasing both positive interactions and areas for improvement, thereby providing a comprehensive overview of user satisfaction.

Positive Reviews

Many users express appreciation for the efficiency and precision offered by this machining equipment. The ability to achieve accurate results with minimal effort has been a significant point of praise. Here are some common sentiments:

| User | Feedback |

|---|---|

| John D. | Impressive performance, cuts down on processing time significantly. |

| Lisa K. | Exceptional reliability; I’ve used it for years without issues. |

| Mark R. | The setup was straightforward, and the results were spot on! |

Areas for Improvement

While many users have shared positive experiences, some have pointed out aspects that could enhance functionality. Common suggestions include:

| User | Suggestion |

|---|---|

| Anna M. | A more detailed manual would be helpful for beginners. |

| Paul T. | Occasional calibration issues could be addressed with better design. |

| Eva J. | Increased accessibility to replacement components would be beneficial. |