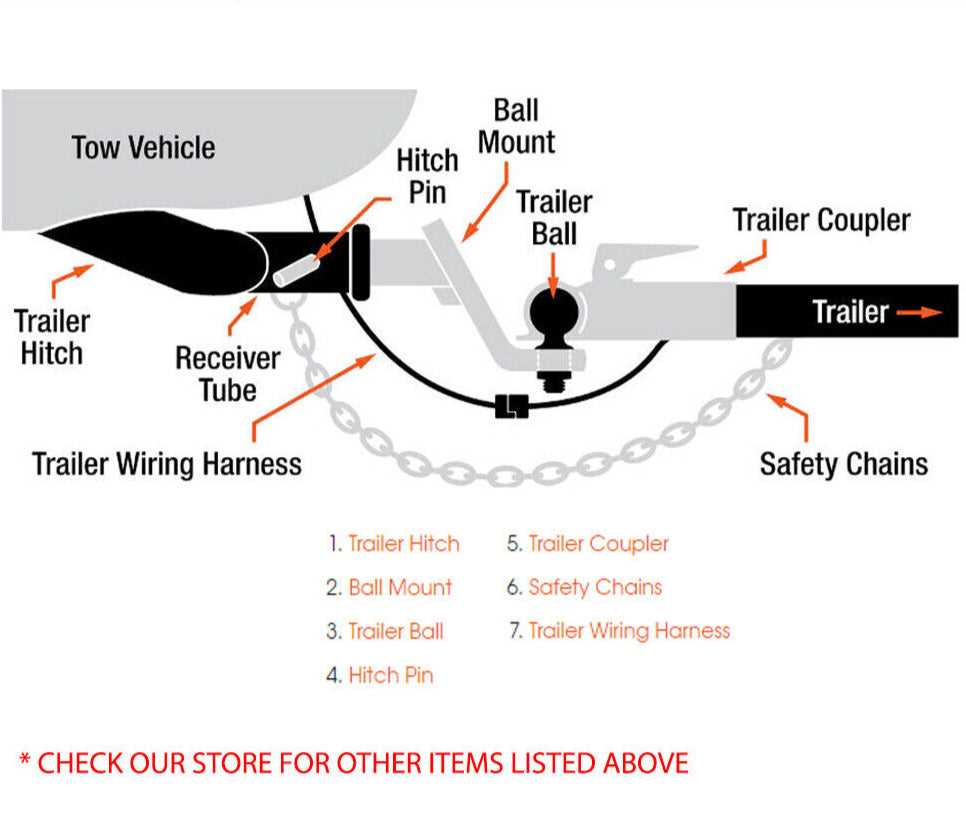

In the realm of towing, an intricate assembly of elements works in harmony to ensure safety and functionality. Each component plays a vital role in achieving the ultimate performance during transport. Familiarizing oneself with these crucial elements enhances both knowledge and efficiency.

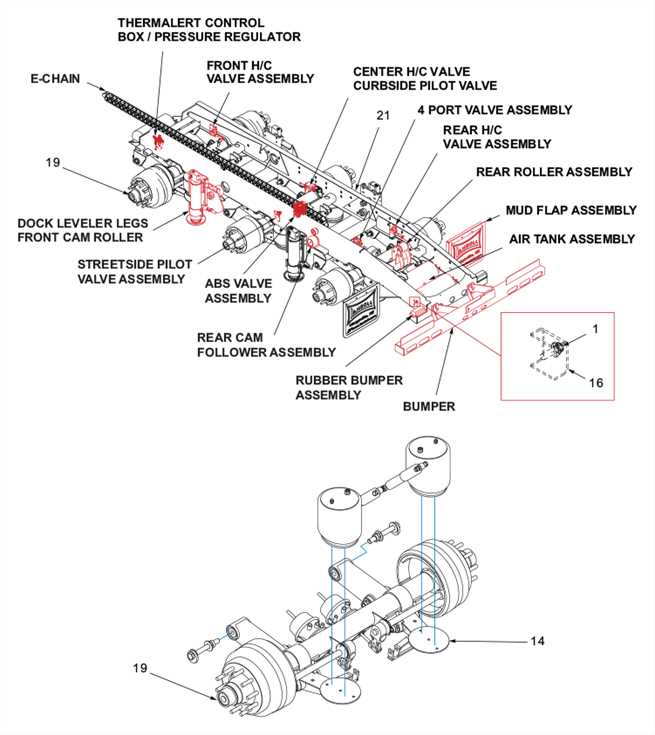

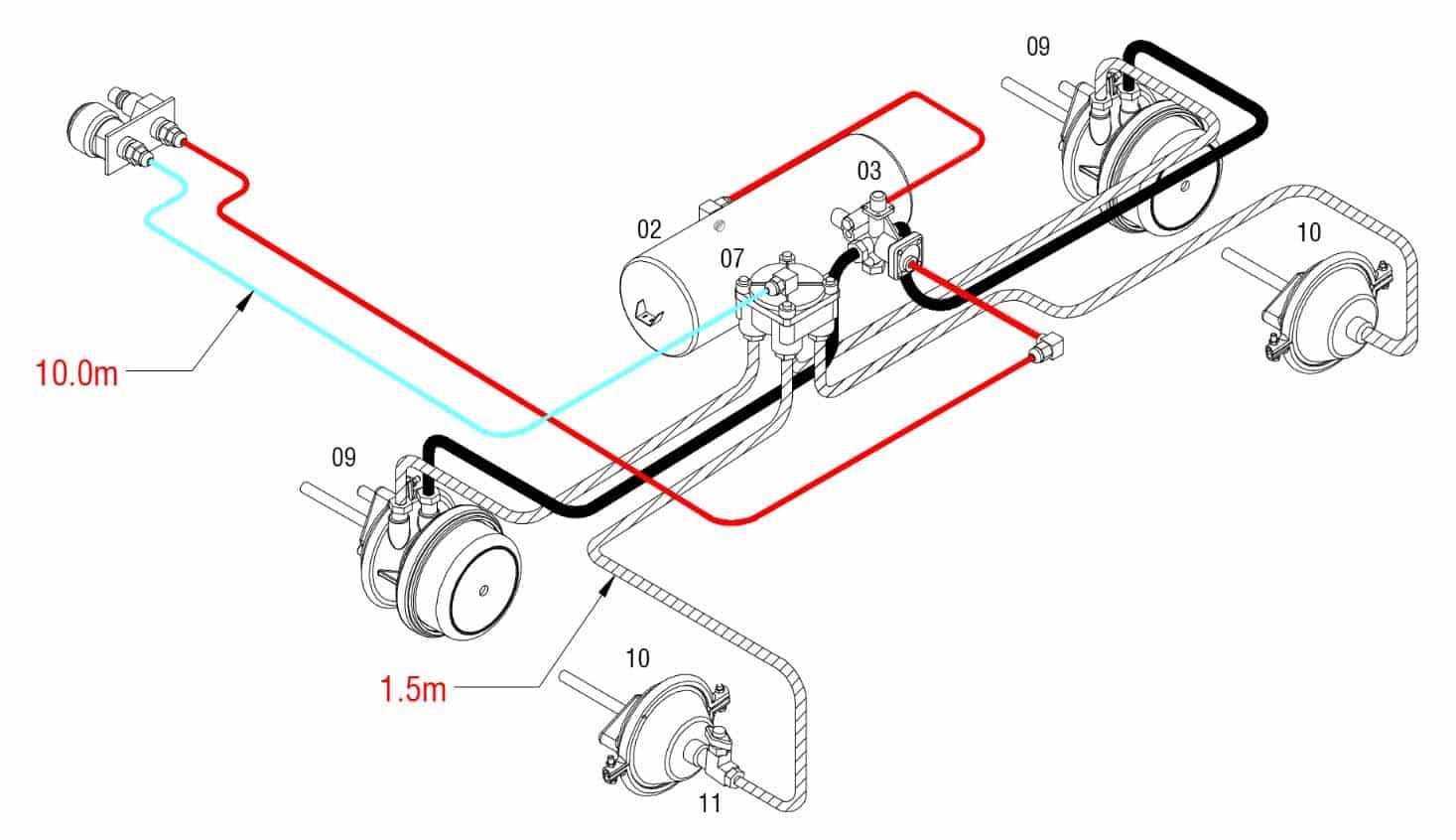

Exploring the layout of these mechanisms unveils the complexity and precision involved in their design. By dissecting the interconnections and functionalities, one can appreciate how these pieces contribute to the overall operation. A detailed visual representation can significantly aid in grasping these relationships.

For enthusiasts and professionals alike, comprehending the anatomy of these systems empowers better maintenance and troubleshooting. Engaging with this topic allows for deeper insights into enhancing towing safety and reliability, ensuring that every journey is undertaken with confidence.

Understanding Trailer Brake Systems

Effective stopping mechanisms are crucial for safe towing operations. These systems ensure that the load is managed properly, enhancing control and stability during transport. A comprehensive understanding of how these mechanisms function is essential for maintenance and troubleshooting.

There are several key components that contribute to the overall effectiveness of these systems:

- Actuators: Devices that engage the stopping mechanism, often triggered by the towing vehicle.

- Control Modules: Electronic units that regulate the operation, ensuring a balanced response.

- Wiring Harness: The network of electrical connections that facilitate communication between components.

- Hydraulic Components: Elements that utilize fluid pressure to activate the stopping mechanism.

Understanding these components allows users to better grasp the entire system’s functionality and troubleshoot potential issues effectively. Here are some critical aspects to consider:

- Maintenance: Regular checks can prevent failures and enhance performance.

- Compatibility: Ensuring all components work harmoniously with each other is vital.

- Load Capacity: Knowing the weight limits is essential for safe operation.

By familiarizing oneself with these systems, operators can enhance safety and efficiency, ensuring that every journey is secure and reliable.

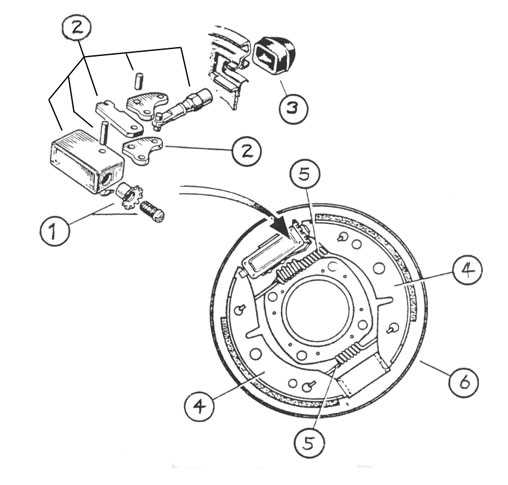

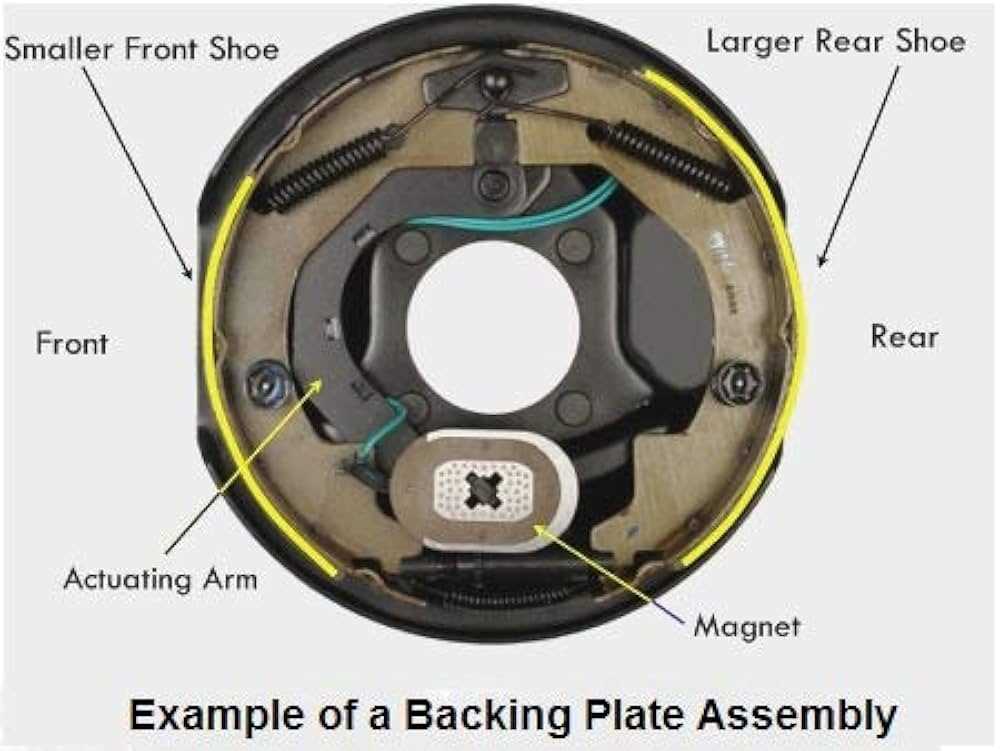

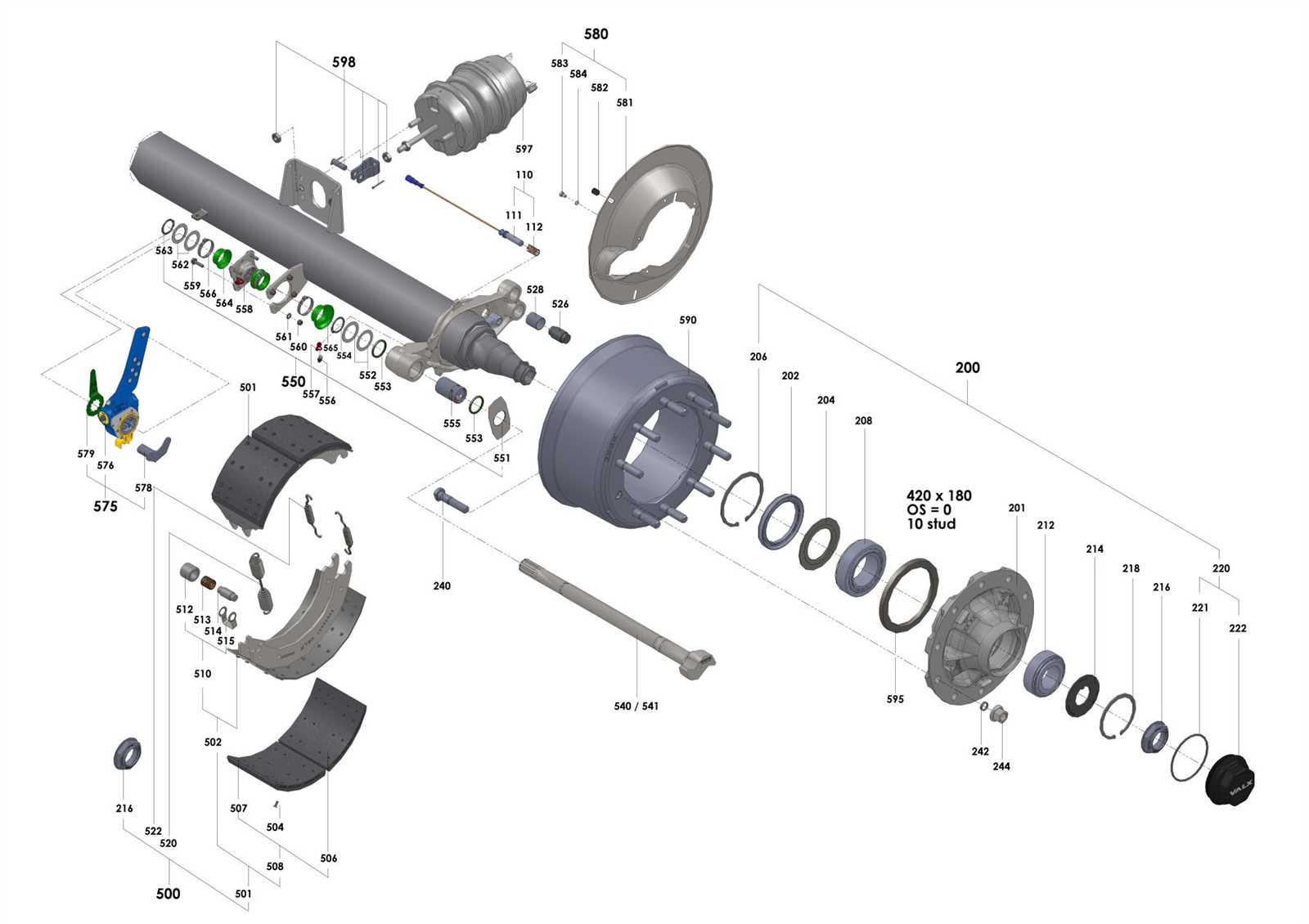

Essential Components of Trailer Brakes

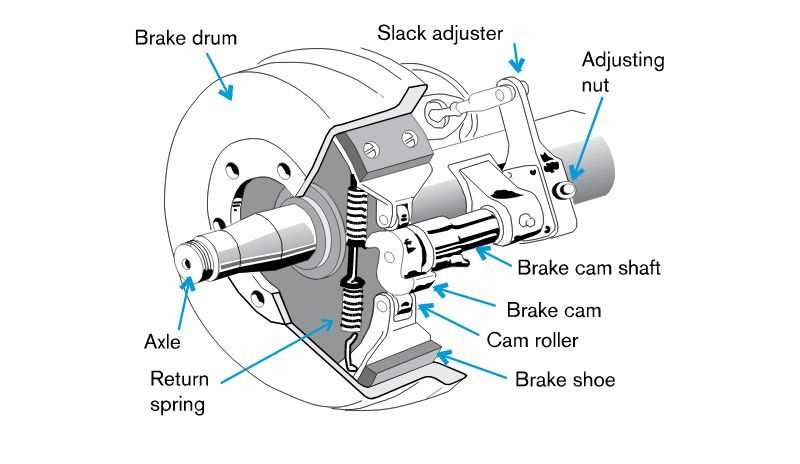

Understanding the critical elements involved in the stopping system of a vehicle is fundamental for ensuring safety and functionality. Each component plays a specific role in the overall mechanism, contributing to the effective operation and reliability of the system.

| Component | Description |

|---|---|

| Actuator | This device converts hydraulic or pneumatic pressure into mechanical force to engage the stopping system. |

| Drums | These cylindrical elements provide a surface for friction materials to grip and slow down the wheels. |

| Shoes | Friction materials attached to the actuating mechanism that press against the drums to create stopping power. |

| Backing Plate | A sturdy base that holds the shoes and other components in place, ensuring proper alignment and operation. |

| Linkage | Connective hardware that transmits movement from the actuator to the shoes, facilitating the engagement process. |

| Hydraulic Lines | Flexible tubes that carry fluid from the actuator to the cylinders, enabling responsive activation of the stopping mechanism. |

| Adjuster | A mechanism that maintains the optimal distance between the shoes and drums for consistent performance. |

Each of these elements is crucial for the effective performance of the stopping system, contributing to the overall safety of the vehicle and its load.

Types of Brake Systems Explained

Understanding the various mechanisms used to slow down or stop vehicles is crucial for anyone involved in automotive maintenance or repair. Each system employs different technologies and designs, tailored to meet specific performance and safety requirements. This section will explore the primary types of systems commonly utilized in vehicles, highlighting their unique features and functionalities.

Hydraulic Systems

Hydraulic mechanisms rely on fluid pressure to transfer force from the pedal to the stopping components. This design allows for efficient force multiplication, providing strong and responsive action with minimal effort from the operator. Typically, these systems feature components such as master cylinders and wheel cylinders, which work together to ensure effective stopping power.

Pneumatic Systems

Pneumatic systems utilize compressed air to activate the stopping elements. Commonly found in larger vehicles, such as buses and trucks, this technology offers significant advantages in terms of force application and responsiveness. The use of air pressure allows for rapid actuation, which is essential for heavy-duty applications where quick stopping is necessary for safety.

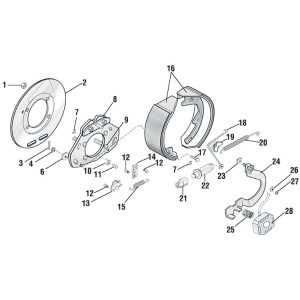

How Brake Components Work Together

Understanding the interaction between various components is crucial for ensuring effective stopping power and safety. Each element plays a specific role, contributing to the overall functionality of the system. When these elements work in harmony, they enhance the vehicle’s ability to slow down or come to a complete halt.

Key Elements and Their Functions

- Actuators: These devices initiate the stopping process by applying pressure, translating the driver’s commands into mechanical action.

- Friction Materials: These components create the necessary grip to slow down or stop the movement, converting kinetic energy into heat.

- Hydraulic System: This system transfers force from the actuator to the friction materials, allowing for smooth and responsive action.

- Support Structures: These elements provide the necessary stability and alignment, ensuring that all components function correctly together.

Cooperation for Optimal Performance

For maximum efficiency, the coordination of these elements is essential. When any component is malfunctioning or misaligned, it can lead to decreased performance or even failure. Regular maintenance and inspection can help identify issues early, ensuring that all components are working as intended. Properly functioning systems not only improve safety but also enhance overall driving experience.

Common Trailer Brake Issues

Understanding the typical problems that can arise with stopping mechanisms is essential for ensuring safety on the road. Various factors can lead to malfunctions, affecting performance and reliability.

Wear and Tear: Over time, components can degrade due to constant friction and exposure to the elements. Regular inspection can help identify these issues early.

Contamination: The presence of dirt, moisture, or oil can interfere with the effectiveness of stopping systems. Keeping components clean is crucial for optimal function.

Electrical Failures: Malfunctions in wiring or connections can lead to inadequate response when the stopping system is engaged. Checking for loose or corroded connections can prevent these problems.

Alignment Issues: Improper alignment of mechanisms can cause uneven wear and reduced efficiency. Regular adjustments are necessary to maintain proper positioning.

Addressing these common challenges proactively can enhance safety and prolong the lifespan of stopping systems.

Maintenance Tips for Brake Parts

- Inspect regularly for wear and tear.

- Clean components to remove debris and dust.

- Replace worn items promptly to maintain optimal performance.

- Ensure proper alignment during installation.

- Use quality lubricants to reduce friction.

Following these simple guidelines can significantly enhance the reliability and effectiveness of your system, contributing to a safer driving experience.

Identifying Worn Out Components

Recognizing when critical elements have deteriorated is essential for maintaining safety and performance. Regular inspection can prevent issues that may arise from neglecting these components.

Key signs of wear include:

- Unusual noises during operation

- Vibrations or pulling to one side

- Visual signs of cracking or fraying

To ensure functionality, consider the following checks:

- Inspect for surface damage

- Check for excessive play or movement

- Look for corrosion or rust buildup

Addressing these indicators promptly can enhance the longevity and reliability of the system.

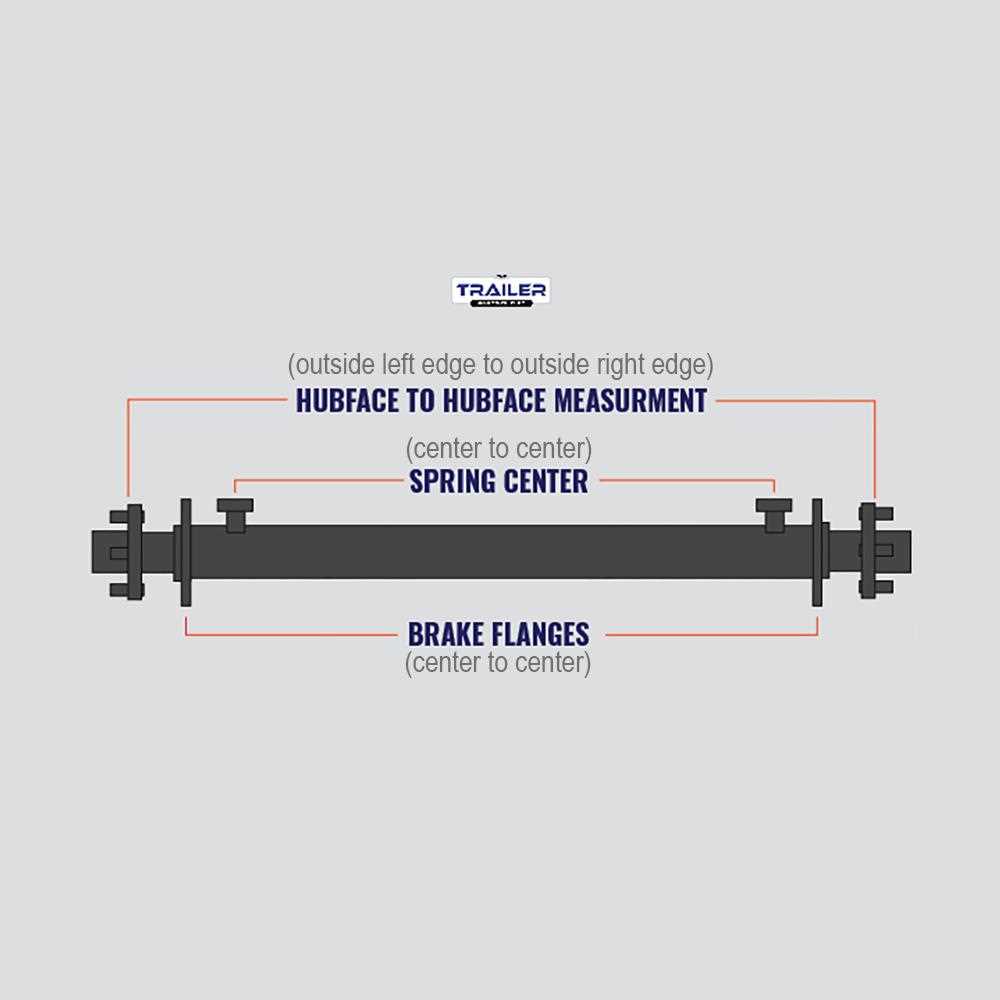

Choosing the Right Brake Parts

Selecting the appropriate components for your stopping system is crucial for optimal performance and safety. Various factors influence this choice, including compatibility, durability, and design. Ensuring that you make informed decisions will ultimately enhance the efficiency of your vehicle.

Compatibility is paramount; it’s essential to choose components that align with your specific model and year. Mismatched elements can lead to inadequate functionality and safety risks.

Consider the durability of materials as well. High-quality components typically offer better resistance to wear and tear, providing longer service life and reliable performance under various conditions.

Finally, examine the design features that may enhance efficiency, such as weight reduction or improved aerodynamics. These innovations can significantly impact the overall handling and responsiveness of your vehicle.

Installation Guidelines for Trailer Brakes

Proper setup of stopping mechanisms is crucial for safe towing. This section provides essential instructions to ensure reliable functionality and compliance with safety standards. Follow these guidelines closely to achieve optimal performance.

- Preparation

- Gather necessary tools: wrenches, screwdrivers, and safety gear.

- Ensure all components are compatible with your vehicle’s specifications.

- Read the manufacturer’s manual for specific recommendations.

- Assembly

- Begin by securely mounting the stopping system to the axle.

- Connect the actuator or control mechanism according to instructions.

- Ensure all connections are tight and free of debris.

- Adjustment

- Adjust the engagement settings to achieve proper responsiveness.

- Test the system by applying pressure to ensure smooth operation.

- Make any necessary modifications to achieve desired performance.

- Final Checks

- Inspect all connections for security and alignment.

- Verify that the system operates correctly under various conditions.

- Conduct a road test to assess functionality and safety.

By adhering to these guidelines, you can ensure a safe and efficient installation that enhances overall performance during towing operations.

Importance of Regular Inspections

Regular examinations of critical systems are essential for maintaining safety and performance. Ensuring that all components are functioning properly not only prevents unexpected failures but also enhances the overall efficiency of the vehicle. By committing to routine assessments, one can identify potential issues before they escalate into costly repairs or hazardous situations.

Safety Assurance

One of the primary benefits of consistent evaluations is the assurance of safety for both the operator and others on the road. Components that are worn or malfunctioning can lead to serious accidents. By prioritizing inspections, individuals can mitigate risks and contribute to a safer driving environment.

Cost-Effectiveness

Proactive maintenance saves money in the long run. Detecting minor problems early can prevent extensive damage, which would require expensive repairs. Regular checks facilitate timely interventions, ensuring that all systems operate smoothly and effectively.

In conclusion, committing to frequent inspections is crucial for enhancing safety and reducing costs. This practice not only protects individuals but also promotes the longevity of the vehicle.

Upgrading Your Trailer Brake System

Enhancing your towing setup can significantly improve safety and performance. As time goes on, the components responsible for slowing down and stopping your load may need an upgrade to ensure reliability. Modern technology offers various options that can elevate your experience and provide peace of mind on the road.

Benefits of Modernization

Investing in new components can lead to improved responsiveness and reduced wear on your vehicle. Advanced systems often feature better materials and engineering, which translates to increased durability and efficiency. Additionally, newer mechanisms may provide enhanced control, allowing for smoother handling and better stability, especially when navigating challenging terrains.

Choosing the Right Upgrades

When considering enhancements, it’s essential to evaluate your specific needs and the weight of your load. Consulting a professional can help you select components that suit your towing capacity and driving conditions. Look for features such as adjustable settings, improved materials, and compatibility with your existing setup to ensure a seamless transition.

Embracing modern technologies not only boosts performance but also contributes to safer journeys, making it a worthwhile investment for any towing enthusiast.

Legal Requirements for Trailer Brakes

Understanding the regulations surrounding stopping mechanisms is crucial for ensuring safety on the road. Different regions have specific mandates that dictate when and how these systems must be implemented on vehicles that tow loads. Compliance with these standards not only enhances safety but also protects the interests of all road users.

In many jurisdictions, the law requires that certain weight thresholds necessitate the inclusion of stopping systems. These rules aim to provide adequate stopping power, particularly in emergency situations. Additionally, regular inspections and maintenance of these systems are often mandated to ensure they function effectively at all times.

Failure to adhere to these legal stipulations can result in penalties, including fines and potential liability in case of accidents. Therefore, it is essential for vehicle owners to familiarize themselves with the applicable laws in their area to guarantee safe and lawful operation.

Future Trends in Trailer Brake Technology

As the industry evolves, advancements in stopping mechanisms are becoming increasingly sophisticated, aiming to enhance safety and efficiency. Innovations in materials, electronic controls, and automation are paving the way for a new era of vehicle control, ultimately leading to improved performance in various driving conditions.

One significant trend is the integration of smart technology, which allows for real-time monitoring and adjustments based on environmental factors. This development not only optimizes functionality but also provides critical data for maintenance and performance assessments.

Furthermore, the move towards electric systems is gaining momentum, offering a more sustainable and reliable alternative to traditional setups. These systems promise reduced wear and tear, enhancing longevity and performance over time.

In addition, the adoption of advanced materials is set to revolutionize durability and efficiency, ensuring that components withstand harsh conditions while minimizing weight. This shift will contribute to better fuel economy and overall vehicle performance.