When maintaining outdoor power equipment, a clear understanding of the engine’s structure is essential. Knowing how various elements interact can significantly enhance performance and longevity. This section delves into the arrangement of components within a specific engine model, offering insights into its design and functionality.

Visual representations of engine assemblies provide a valuable reference for anyone looking to perform repairs or upgrades. By familiarizing oneself with the configuration of key components, users can identify parts more easily, ensuring efficient maintenance practices. Such knowledge not only facilitates troubleshooting but also empowers individuals to make informed decisions regarding replacements and repairs.

Furthermore, having a comprehensive grasp of the overall layout allows for better planning of maintenance schedules. This approach can help prevent issues before they arise, ensuring that the equipment remains in optimal condition. Understanding the intricacies of engine assemblies ultimately contributes to a smoother and more reliable operation.

Briggs 625EX Overview

This section provides a comprehensive overview of a well-known small engine model, focusing on its design and functionality. This engine is widely recognized for its reliability and efficiency, making it a popular choice among users.

The construction features a robust framework that ensures durability in various conditions. Its efficient performance is supported by advanced technology, which optimizes fuel consumption while delivering impressive power output.

Moreover, maintenance is simplified through easily accessible components, promoting longevity and ease of service. The design incorporates user-friendly features, catering to both novice and experienced operators.

Overall, this engine exemplifies a balance of performance and dependability, making it an ideal solution for a variety of outdoor tasks.

Key Components of 625EX

The effective operation of small engines relies on several essential elements that work together seamlessly. Understanding these critical parts can enhance maintenance practices and improve overall performance. Each component plays a unique role, contributing to the engine’s efficiency and reliability.

Essential Elements

- Power Unit: The heart of the engine, responsible for converting fuel into energy.

- Fuel System: Manages the delivery and mixture of fuel to ensure optimal combustion.

- Ignition Mechanism: Initiates combustion through a spark, igniting the fuel-air mixture.

- Cooling System: Regulates the engine’s temperature to prevent overheating.

- Lubrication System: Provides essential oil flow to reduce friction between moving parts.

Supporting Components

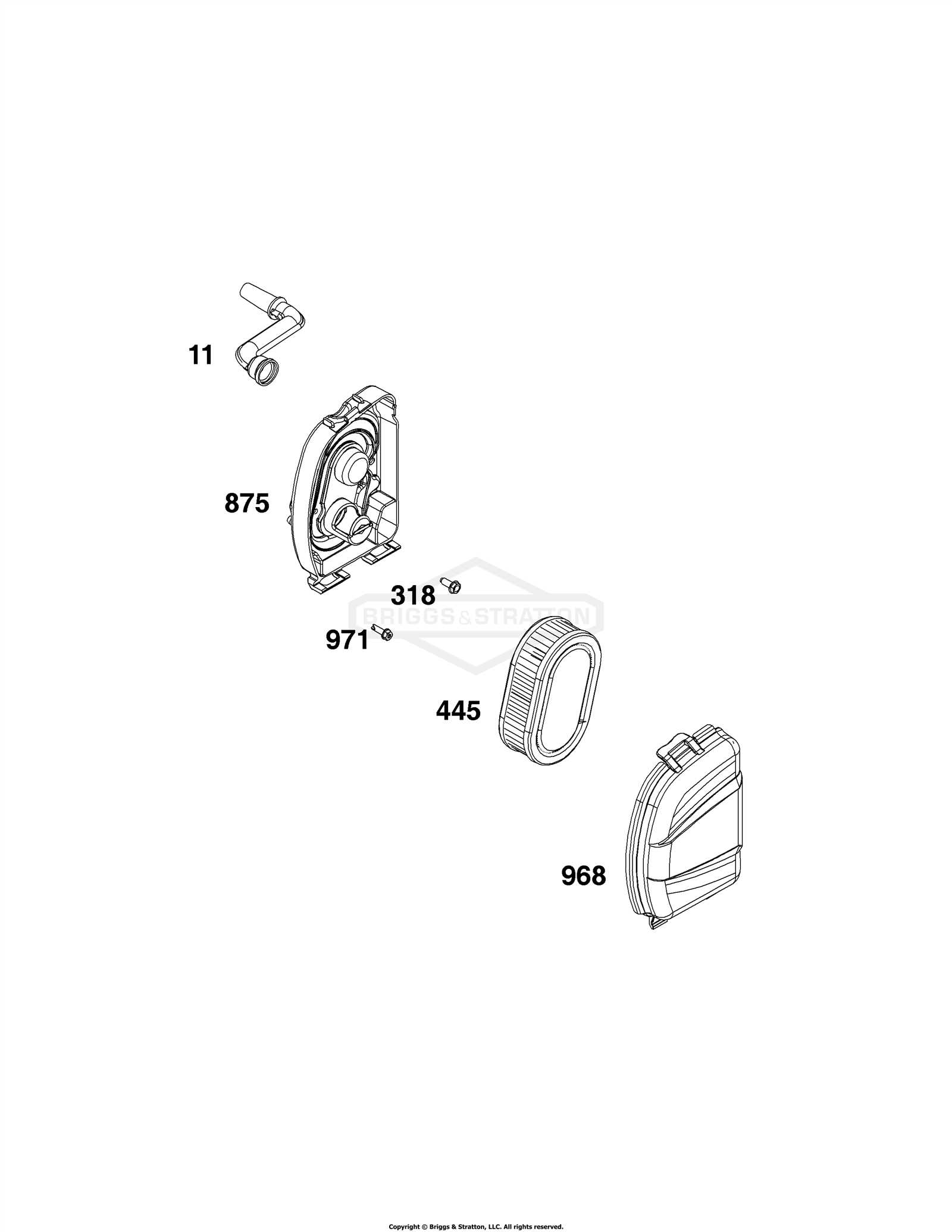

- Air Filter: Ensures clean air enters the combustion chamber, improving efficiency.

- Exhaust System: Channels exhaust gases away, maintaining optimal pressure.

- Starter Mechanism: Facilitates the initial engine start-up.

- Throttle Control: Regulates engine speed and power output based on demand.

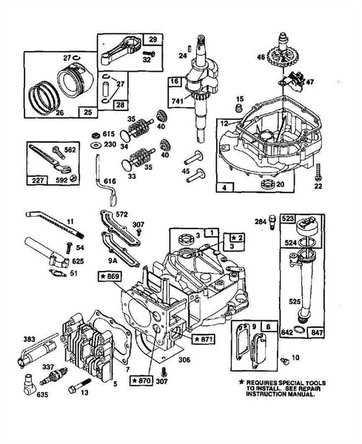

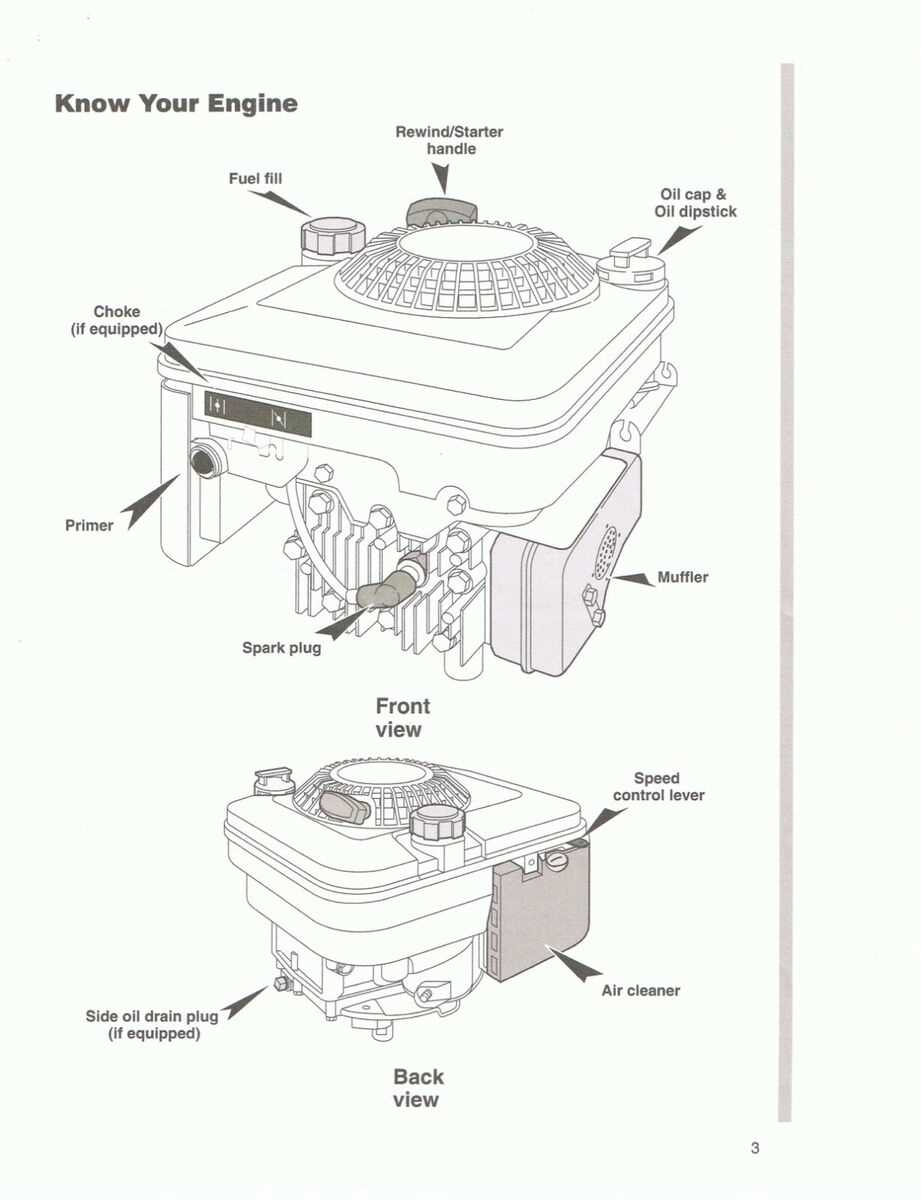

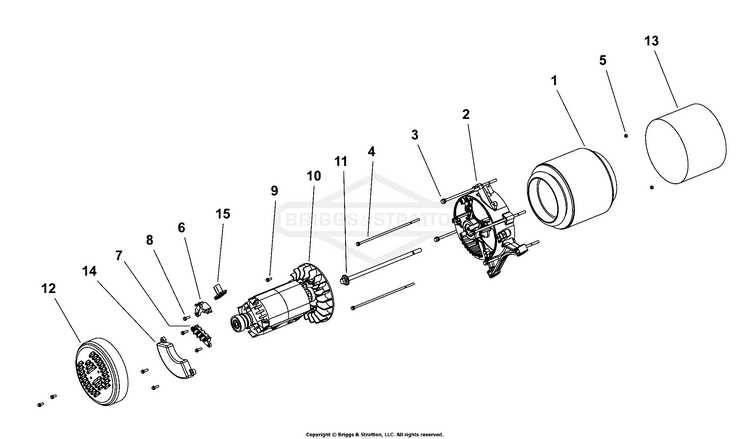

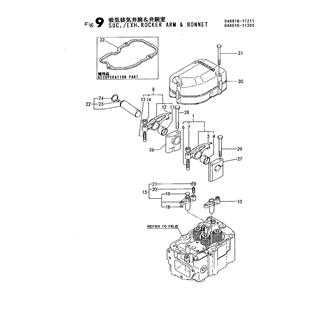

Understanding the Parts Diagram

Interpreting the visual representation of components is essential for effective maintenance and troubleshooting. This illustration serves as a guide, enabling users to identify various elements and their functions within the assembly. Familiarity with this representation can significantly enhance one’s ability to perform repairs and upgrades.

Key Elements of the Illustration

Every visual guide typically includes several critical aspects that are important for understanding:

- Labels: Each component is often marked with a specific identifier, making it easier to reference when seeking replacements or repairs.

- Connections: Lines or arrows may indicate how different parts interact or connect with one another, highlighting the flow of operation.

- Grouping: Similar components might be grouped together, facilitating a quicker overview of related parts.

Benefits of Using Visual References

Utilizing these representations provides numerous advantages:

- Enhanced clarity in identifying components, reducing the risk of errors during assembly or disassembly.

- Improved efficiency in locating necessary replacements, ultimately saving time and effort.

- Better understanding of overall functionality, aiding in the diagnosis of issues.

Identifying Common Issues

Understanding typical problems that may arise with outdoor power equipment is crucial for effective maintenance and repair. Recognizing these challenges early can prevent further complications and ensure optimal performance.

Engine Starting Difficulties

One of the most prevalent issues involves the engine failing to start. This can stem from various factors, such as fuel supply problems, battery issues, or ignition system failures. Regular checks of these components can aid in quick diagnosis and resolution.

Performance Fluctuations

Another common concern is inconsistent performance, which may manifest as stalling or reduced power output. This can often be attributed to clogged filters, improper fuel mixtures, or wear in critical engine components. Routine inspections and timely replacements can mitigate these effects.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular care and attention. By following a few key practices, you can significantly enhance performance and extend the lifespan of your machinery.

Routine Inspection

Conducting periodic checks can help identify potential issues before they escalate. Consider the following:

- Examine for signs of wear and tear.

- Check fluid levels regularly.

- Inspect air filters and replace as needed.

Cleaning and Lubrication

Keeping your equipment clean is essential for optimal functioning. Follow these steps:

- Remove debris and dirt after each use.

- Apply appropriate lubricants to moving parts.

- Ensure ventilation areas are unobstructed.

Tools Needed for Repairs

Proper maintenance and repair of small engines require specific instruments to ensure effective and safe execution of tasks. Utilizing the right tools not only simplifies the repair process but also enhances the longevity of the equipment.

- Wrenches: Essential for loosening and tightening various components.

- Screwdrivers: Useful for removing and securing screws in place.

- Pliers: Handy for gripping and manipulating small parts.

- Socket Set: Provides a range of sizes for different fasteners.

- Torque Wrench: Ensures that bolts are tightened to the correct specifications.

Having these tools readily available will facilitate a smoother repair process, allowing for more efficient troubleshooting and problem resolution.

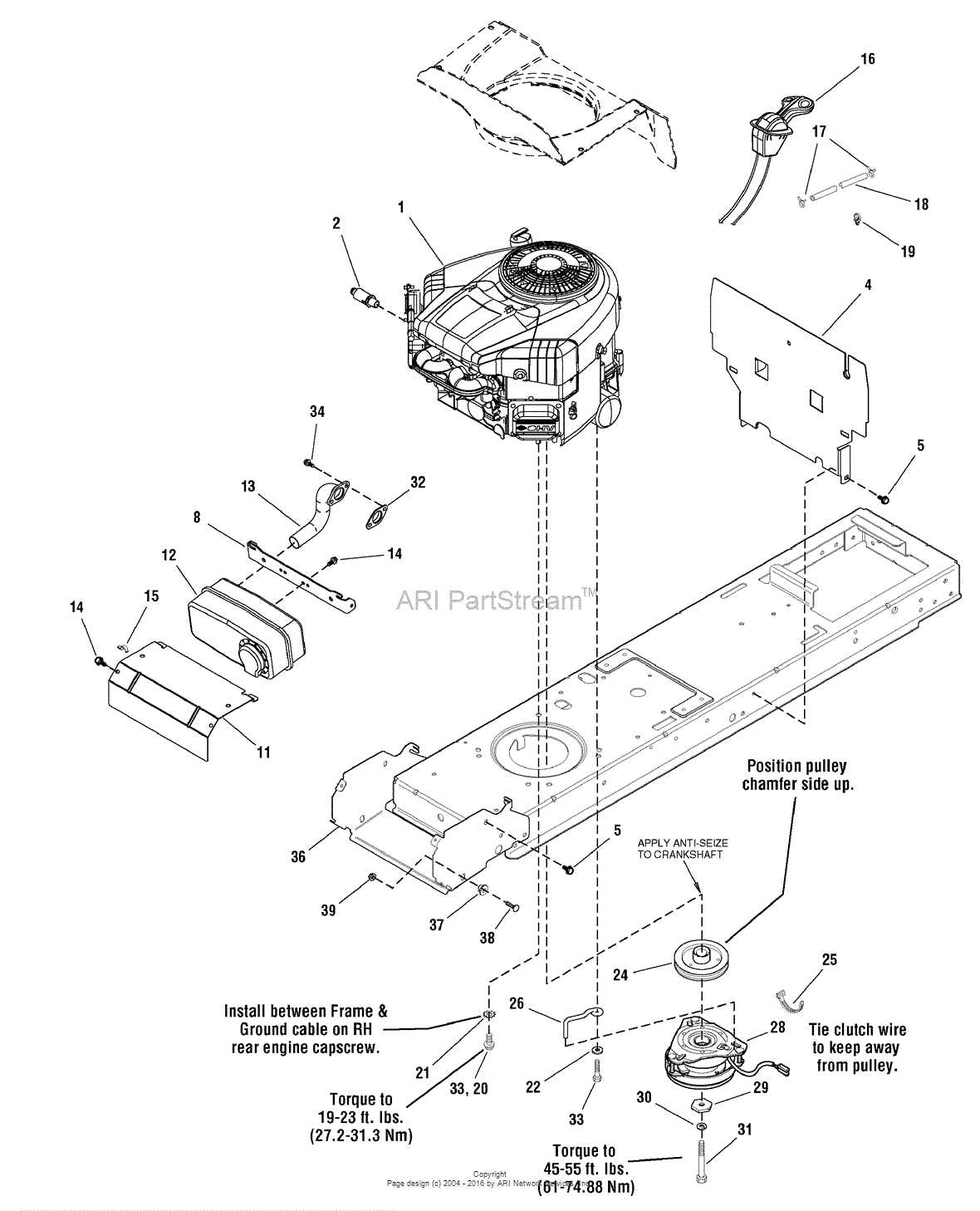

Replacing Major Components

When it comes to maintaining small engines, understanding how to replace essential parts is crucial for ensuring optimal performance. This process can enhance longevity and efficiency, helping the machinery run smoothly.

Before starting the replacement, it’s important to gather the necessary tools and components. Here are some common elements that may need attention:

- Fuel system components

- Ignition system parts

- Air filtration elements

- Exhaust components

Follow these steps for a successful replacement:

- Disconnect the power source to ensure safety.

- Carefully remove the existing component, taking note of how it is attached.

- Install the new part, ensuring it is securely fastened and properly aligned.

- Reconnect any necessary connections, including fuel and electrical links.

- Test the engine to confirm that the new part is functioning correctly.

By regularly inspecting and replacing critical elements, you can maintain the efficiency and reliability of your machinery for years to come.

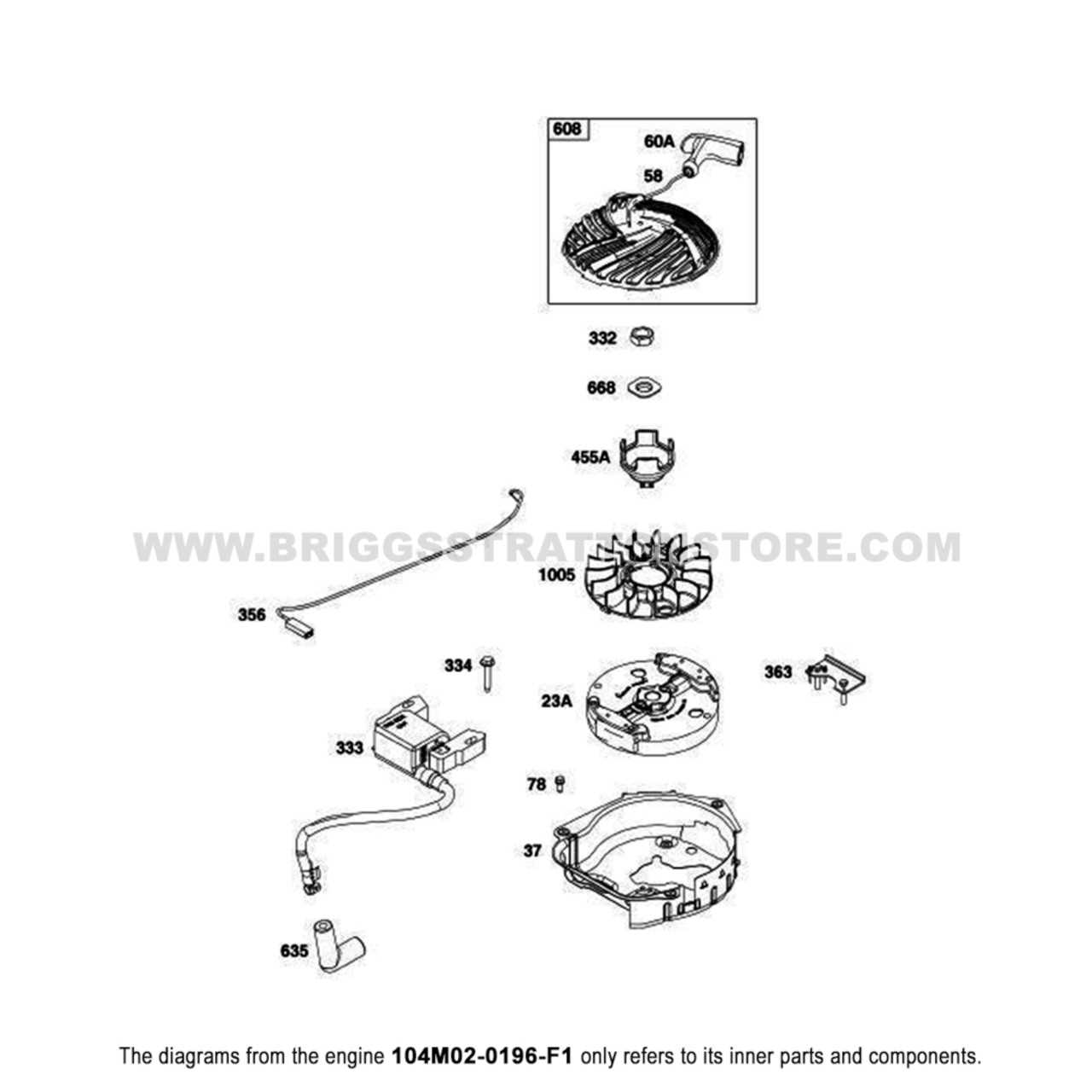

Wiring and Electrical System

The wiring and electrical components of small engines play a crucial role in their overall functionality. These systems are responsible for providing the necessary power to various parts of the engine, ensuring efficient operation. Understanding the layout and connections of these components is essential for troubleshooting and maintenance.

The electrical setup typically includes a battery, ignition system, and various sensors. Proper connections are vital to prevent issues such as short circuits or electrical failures. Regular checks can help identify wear and tear in wiring, which may lead to performance problems.

Additionally, knowing how to interpret wiring schematics is beneficial for diagnosing electrical issues. Diagrams often outline the connections between components, making it easier to follow the flow of electricity throughout the system. Familiarity with these elements enhances the ability to maintain and repair small engines effectively.

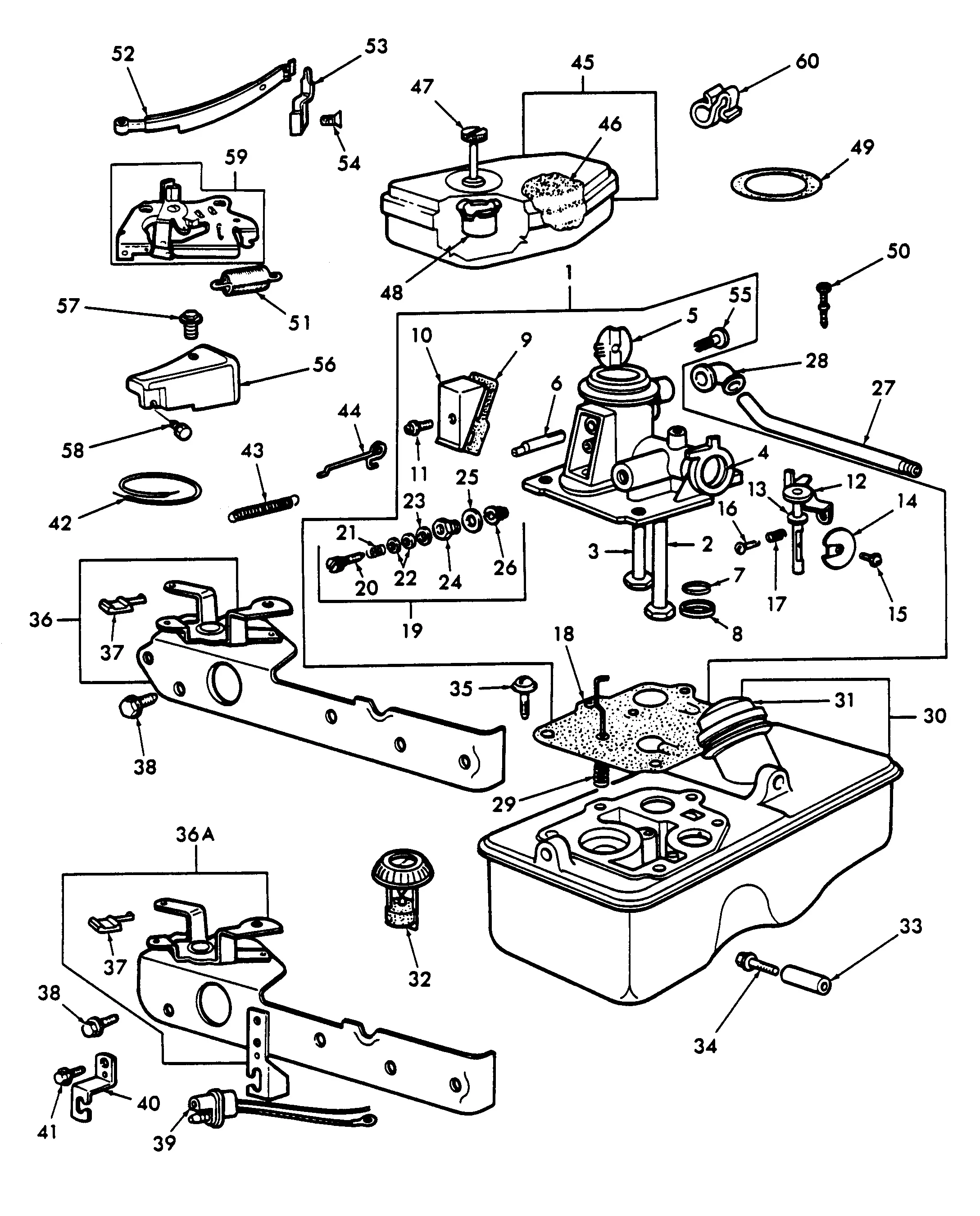

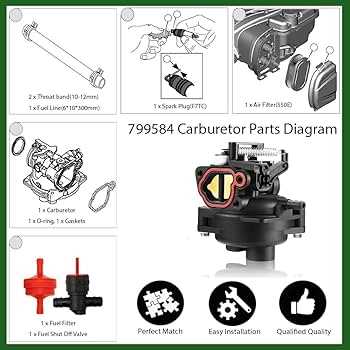

Fuel System Insights

The fuel system plays a crucial role in ensuring efficient engine performance. It is designed to deliver the appropriate amount of fuel to the combustion chamber, facilitating optimal power output and smooth operation. Understanding the components and functions of this system can enhance maintenance and troubleshooting efforts.

At its core, the fuel delivery mechanism comprises several key elements, including the fuel tank, lines, filter, and injector. Each component contributes to the overall functionality, working together to transport fuel while minimizing impurities. Regular inspection of these parts can prevent clogs and ensure a steady flow.

Moreover, fuel quality significantly impacts performance. Utilizing clean, appropriate fuel can help prevent issues such as misfires or reduced efficiency. Awareness of the system’s design can empower users to make informed decisions regarding maintenance and upgrades, ultimately leading to improved operational reliability.

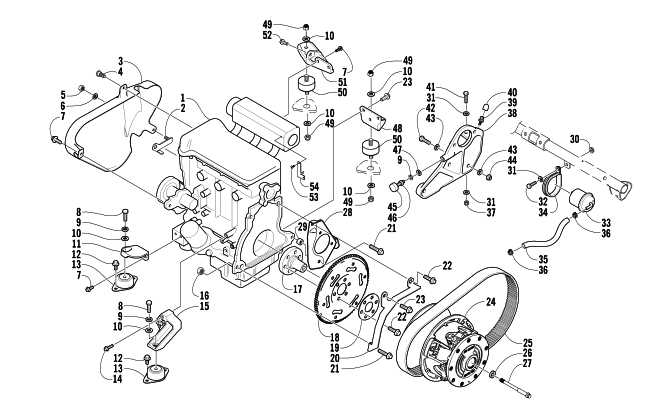

Engine Performance Enhancements

Improving engine efficiency and output involves a variety of strategies that can significantly elevate performance. By focusing on key components and tuning methods, enthusiasts can achieve enhanced responsiveness and power. These enhancements not only optimize fuel consumption but also ensure a smoother operational experience.

Upgrading the air intake system can lead to increased airflow, which is crucial for combustion. This can be achieved by installing high-performance filters or intake manifolds that allow for better air delivery to the engine.

Tuning the fuel delivery system is another essential aspect. Adjusting fuel injectors or upgrading to a more efficient fuel pump can ensure that the engine receives the optimal fuel-air mixture for maximum performance.

Exhaust modifications also play a vital role. Implementing performance headers or cat-back exhaust systems can reduce back pressure and improve exhaust flow, resulting in higher output and efficiency.

Lastly, engine tuning software can be utilized to recalibrate the engine’s management system. This allows for adjustments to timing and fuel maps, maximizing the engine’s potential while accommodating modifications.

Safety Precautions During Repairs

When undertaking maintenance on mechanical devices, it is crucial to prioritize safety to prevent accidents and injuries. Following proper precautions ensures not only the longevity of the equipment but also the well-being of the individual performing the repairs.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is essential. This includes gloves to protect hands from sharp edges and chemicals, safety goggles to shield eyes from debris, and sturdy footwear to safeguard against falling objects. Wearing a mask may also be advisable to avoid inhaling harmful particles.

Work Environment Safety

Maintaining a clean and organized workspace is vital. Ensure that the area is free from clutter and well-lit. Additionally, make sure to use tools that are in good condition and suitable for the task at hand. Disconnecting power sources before starting any repair work can prevent unexpected electrical hazards. Always consult the relevant manuals for specific safety instructions related to the equipment.

Where to Find Replacement Parts

Locating suitable components for maintenance or repair can be essential for ensuring the longevity of your machinery. Fortunately, there are several avenues to explore when searching for these essential items.

Authorized Dealers

One of the most reliable sources for obtaining necessary components is through authorized dealers. These locations typically offer:

- Genuine components that meet manufacturer standards

- Knowledgeable staff who can assist with compatibility questions

- Warranty options for additional peace of mind

Online Retailers

Another convenient option is to utilize online retailers. The benefits include:

- Access to a wider range of components

- Customer reviews to guide purchase decisions

- Often competitive pricing and discounts

By exploring these resources, you can ensure that you find the appropriate items to keep your equipment running smoothly.

Resources for Further Learning

Exploring reliable sources for additional knowledge can significantly enhance your understanding of engine maintenance and repair. By utilizing various materials, you can gain insights into troubleshooting, assembly, and best practices that ensure optimal performance.

Books and Manuals

- Comprehensive guides on small engine mechanics

- Manufacturer-specific maintenance manuals

- Handbooks focusing on troubleshooting techniques

Online Resources

- Educational websites offering tutorials and videos

- Forums and communities where enthusiasts share experiences

- Official manufacturer websites with resources and support