When it comes to maintaining a high-performing lawn mower, familiarity with its various elements is essential. Each component plays a crucial role in ensuring the machine operates efficiently and reliably. By comprehending the intricate relationships between these parts, users can enhance their maintenance routines and troubleshoot any issues that may arise.

In this section, we will delve into the intricate layout of the mower’s assembly. With a detailed overview of its mechanisms, you will gain insights into how each section contributes to overall functionality. Recognizing these individual components will empower you to make informed decisions regarding repairs and replacements.

Additionally, understanding the arrangement of the mower’s elements can save time and effort during maintenance tasks. Whether you are an experienced technician or a novice user, this knowledge will serve as a valuable resource. By grasping how each piece fits into the larger system, you can ensure optimal performance and longevity for your equipment.

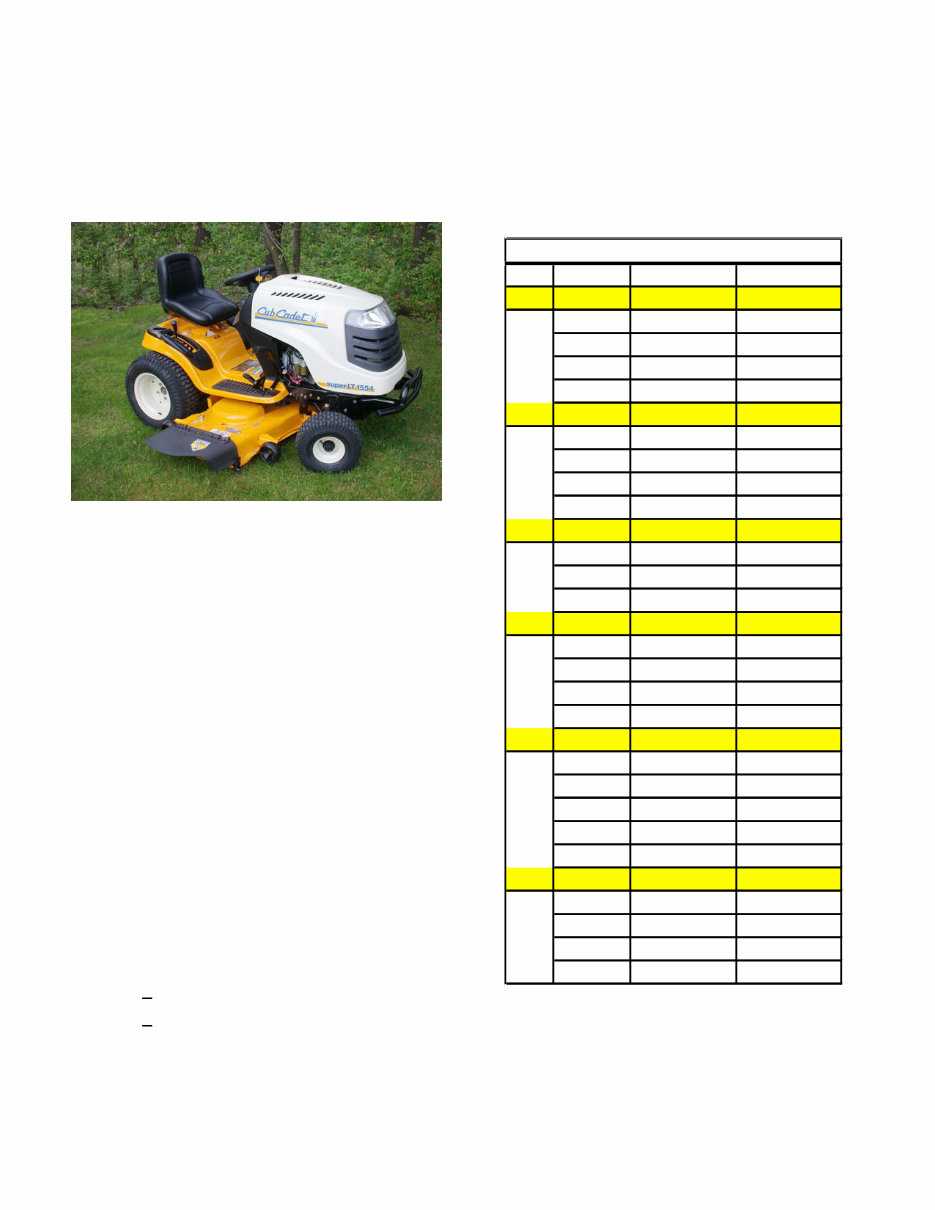

Overview of the Lawn Tractor

This section provides a comprehensive look at a popular model in the lawn care equipment market. Renowned for its reliability and efficiency, this machine is designed for both homeowners and professionals. Its robust features ensure effective grass management and ease of use, making it a favored choice among users.

Key Features

The machine boasts an array of functionalities that enhance its performance. Key attributes include a powerful engine, user-friendly controls, and a durable cutting deck. These features contribute to its reputation as a dependable tool for maintaining expansive lawns.

Specifications

| Feature | Details |

|---|---|

| Engine Type | Single Cylinder, 4-Stroke |

| Cutting Width | 42 inches |

| Transmission | Automatic |

| Fuel Capacity | 1.5 gallons |

Key Features of LT1024 Model

The LT1024 model stands out in its category due to a blend of innovative design and functionality. This machine is engineered to provide an exceptional user experience, combining power and efficiency for a variety of outdoor tasks.

Powerful Engine Performance

Equipped with a robust engine, this model ensures reliable performance even under demanding conditions. The high torque output allows for smooth operation, making it suitable for tackling both large lawns and intricate landscaping projects.

Comfort and Ease of Use

Featuring an ergonomic design, the operator’s comfort is prioritized, allowing for extended use without fatigue. The intuitive controls simplify operation, enabling users of all experience levels to navigate the machine with confidence.

Durability is another hallmark, with quality materials used in construction, ensuring longevity and resistance to wear. This combination of features positions the model as an excellent choice for those seeking efficiency and reliability in their outdoor equipment.

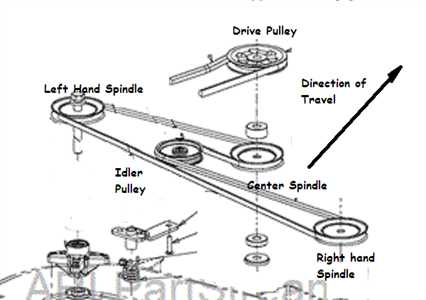

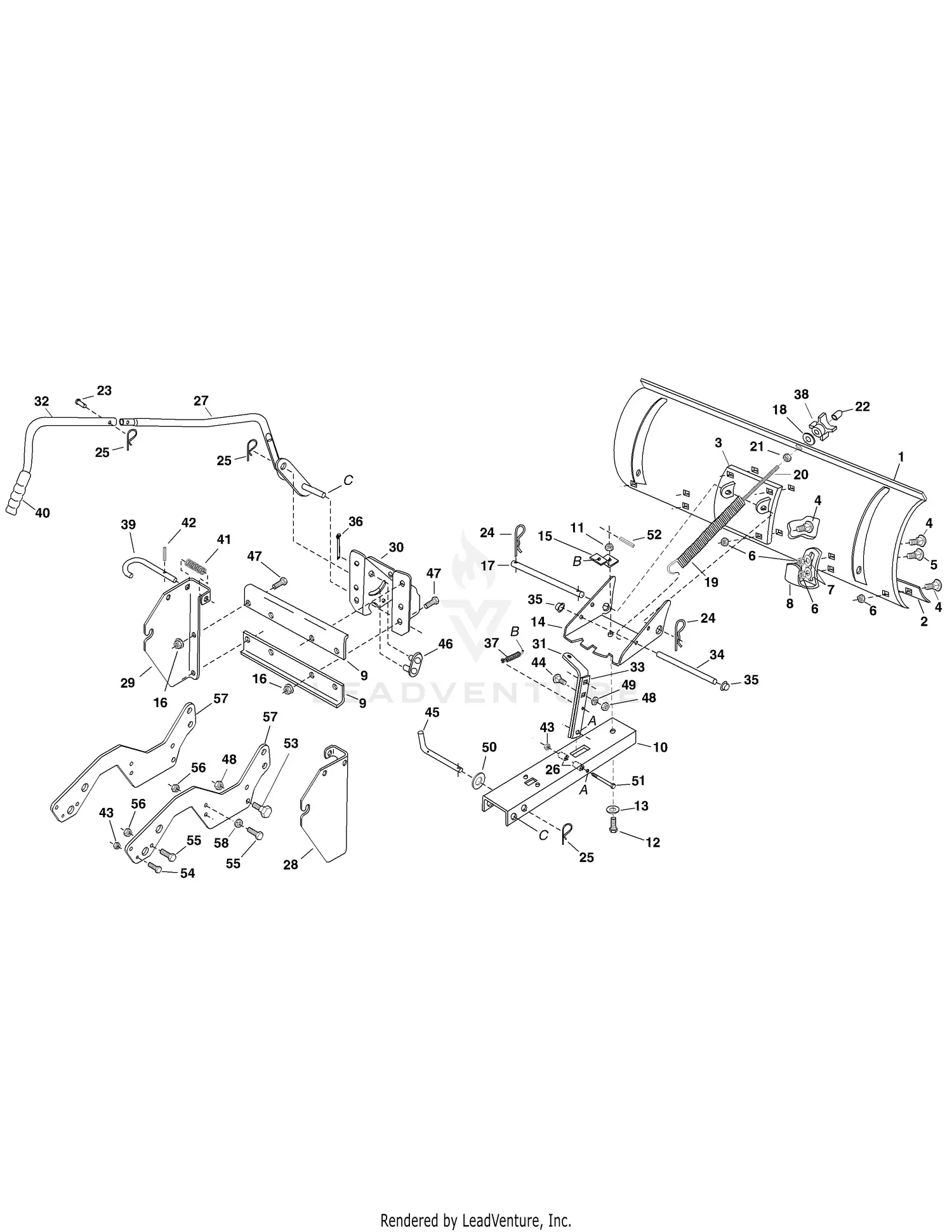

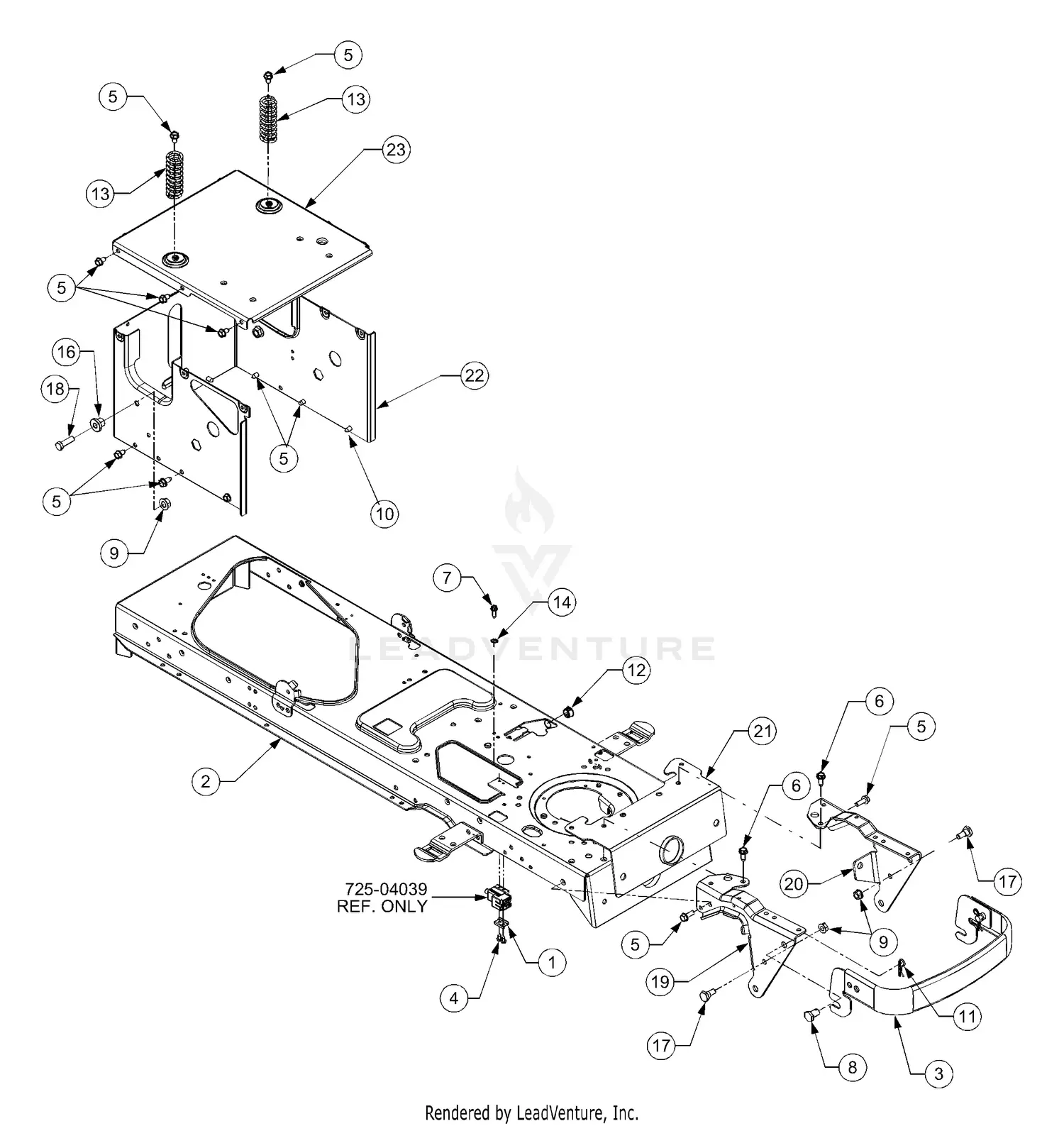

Importance of Parts Diagrams

Understanding the intricate details of machinery components is essential for effective maintenance and repair. Visual representations serve as a valuable resource, allowing users to identify and locate each individual element within a complex system. These illustrations simplify the process of troubleshooting, ensuring that technicians can efficiently address issues and enhance performance.

Benefits of Visual Representations

- Facilitates quick identification of components.

- Enhances understanding of assembly and disassembly procedures.

- Reduces the likelihood of errors during repairs.

- Provides a reference point for ordering replacements.

Practical Applications

- Streamlining maintenance schedules.

- Improving training for new technicians.

- Ensuring compatibility of replacement items.

- Helping in the accurate reassembly of machines.

In summary, these visual aids are indispensable tools that promote efficiency, accuracy, and knowledge in the upkeep of machinery. Their role cannot be overstated in fostering a better understanding of the overall mechanical framework.

Common Parts for LT1024 Maintenance

Regular upkeep of your lawn tractor ensures optimal performance and longevity. Understanding the essential components involved in maintenance helps keep your machine running smoothly and efficiently. This section highlights key elements that are crucial for routine servicing.

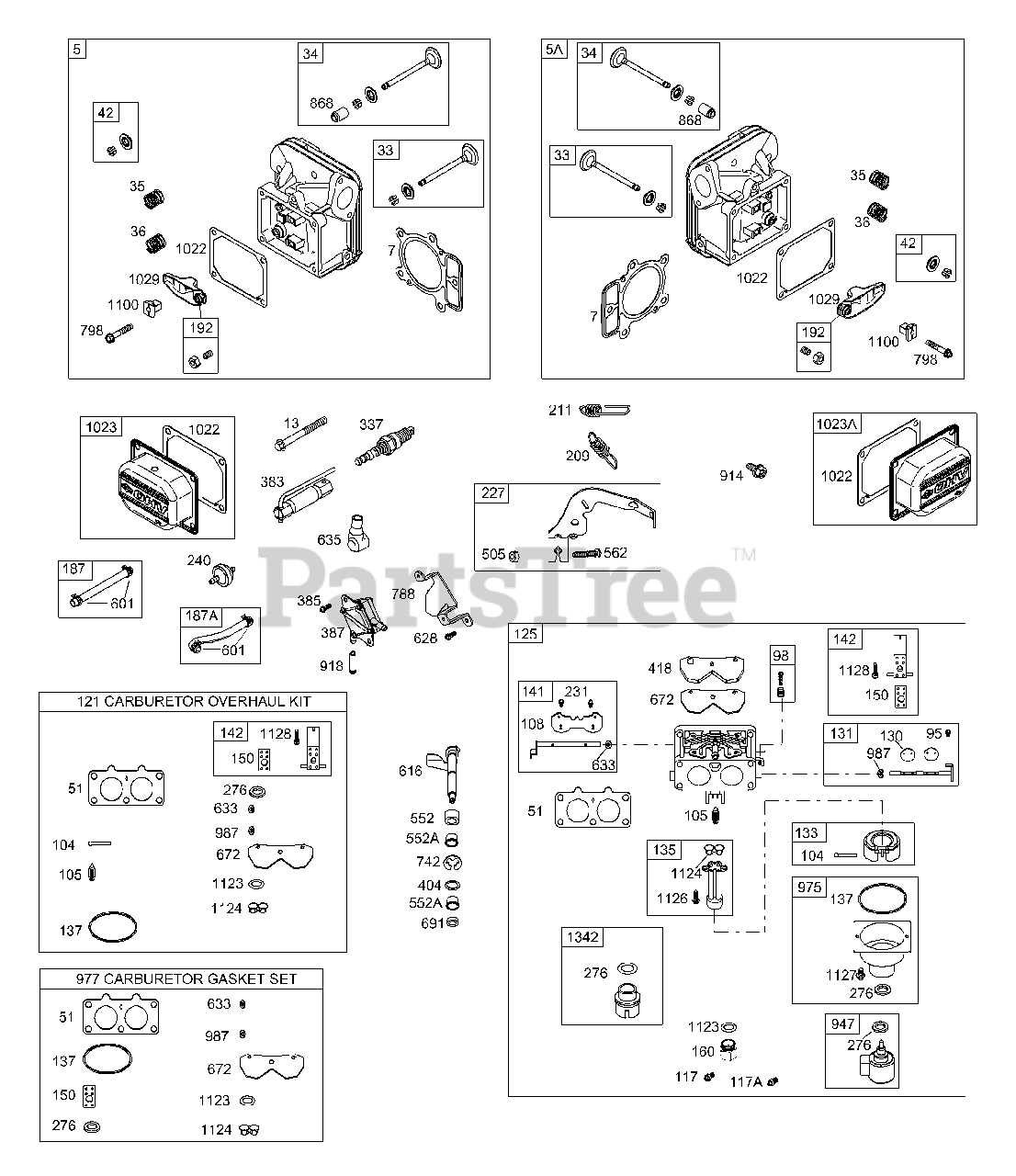

Engine Components

One of the primary areas to focus on is the engine, which requires several vital items. Oil filters and air filters are essential for maintaining proper function, while spark plugs are crucial for ignition efficiency. Regularly checking and replacing these items can significantly enhance performance.

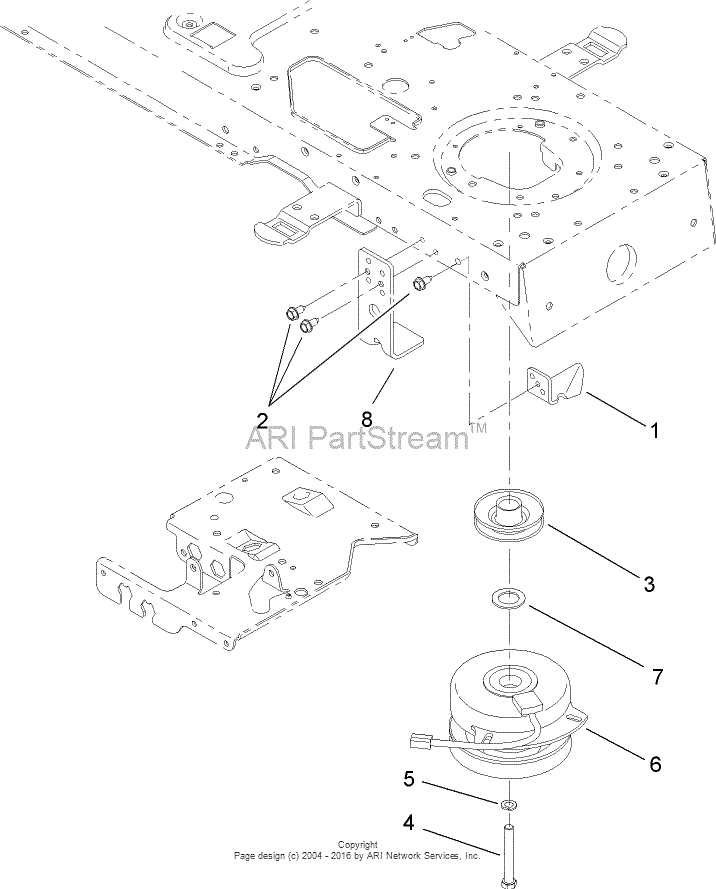

Drive System Essentials

The drive system also warrants attention. Belt replacements are necessary to ensure smooth operation, while wheel bearings play a key role in stability and maneuverability. Ensuring these components are in good condition will improve overall handling and reduce wear over time.

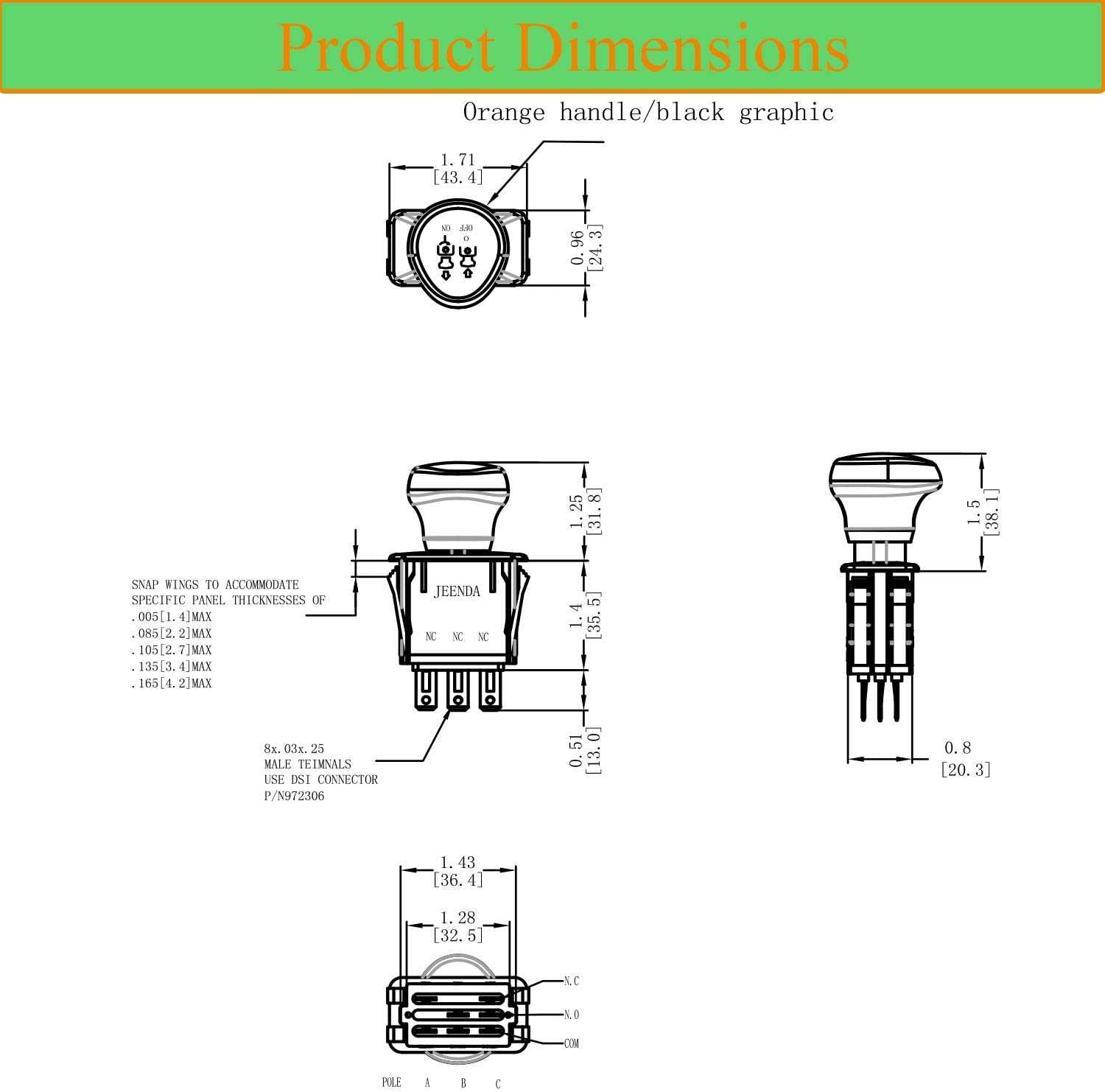

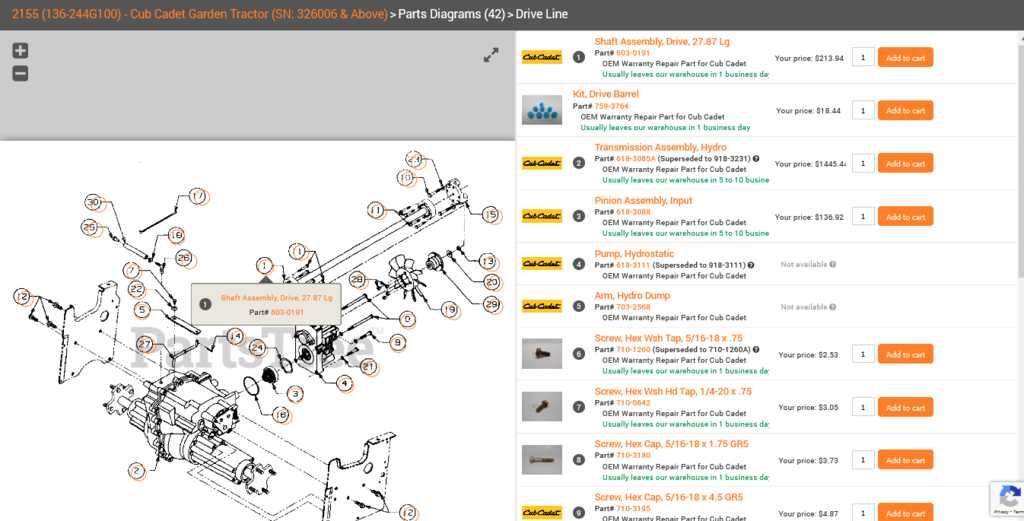

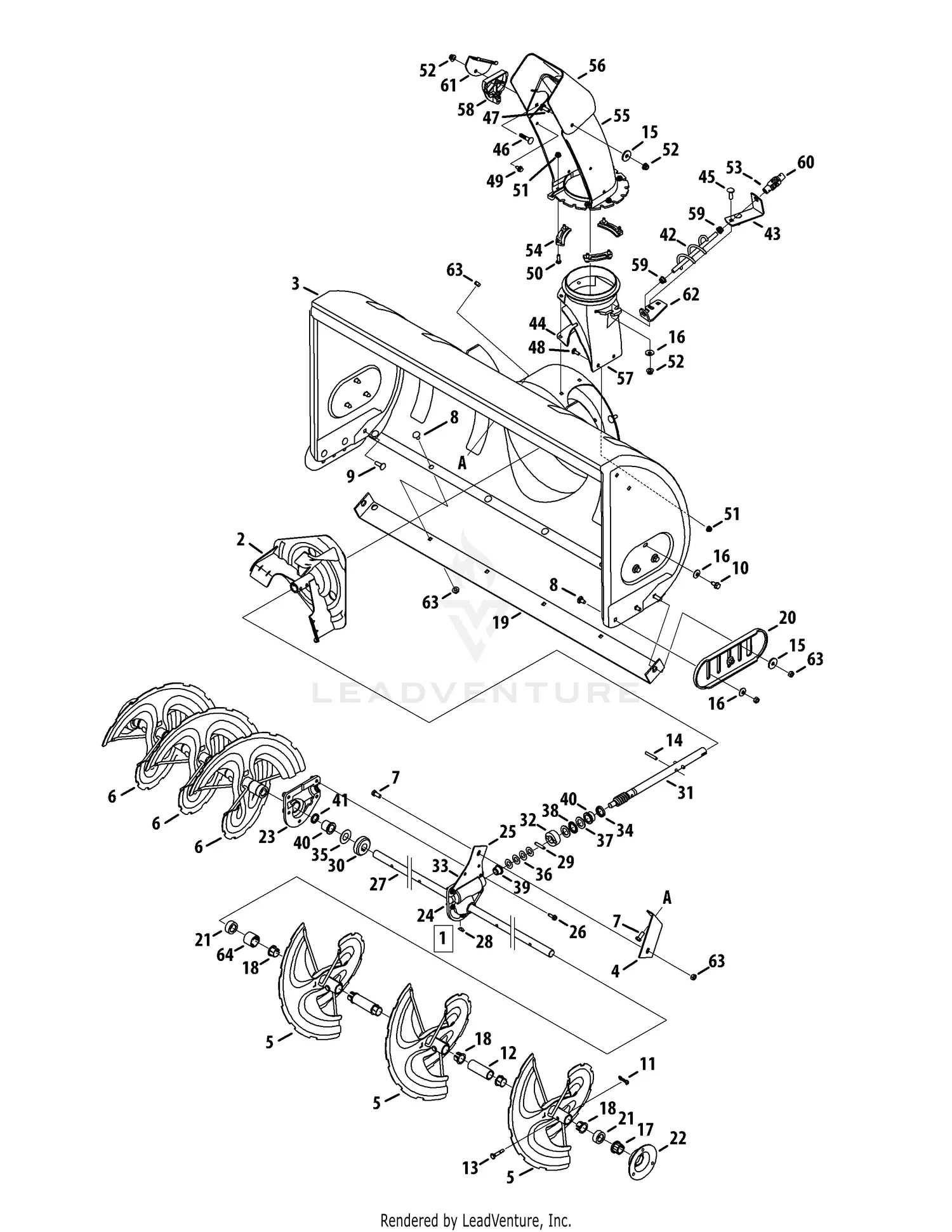

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repairs. These illustrations provide a comprehensive overview of each element’s placement and function, helping users identify what they need to address or replace. Mastering the art of interpreting these visuals can significantly streamline the repair process.

Key Elements to Look For

Start by identifying labels and numbers associated with each piece, as these indicate specific parts and their corresponding references. Pay attention to groupings, which show how various components interact, and note any directional arrows that signify movement or connection points.

Practical Tips for Effective Use

When analyzing the visual, take your time to cross-reference with the accompanying manual. Create a checklist of needed components based on your findings, and highlight any potential issues you spot during your review. This systematic approach will enhance your understanding and facilitate a smoother repair experience.

Identifying Components in Diagrams

Understanding the layout of mechanical illustrations is crucial for effective maintenance and repair. By recognizing the various elements, one can ensure proper functionality and troubleshoot issues more efficiently. This knowledge empowers users to tackle mechanical tasks with confidence and precision.

Common Symbols and Their Meanings

Each illustration typically employs standardized symbols that represent specific parts. Familiarity with these notations allows individuals to quickly discern the roles of each component within the larger assembly. This can significantly streamline the process of identifying potential problems.

Step-by-Step Analysis

Approaching these illustrations methodically enhances comprehension. Begin by isolating each section and cross-referencing it with a parts list if available. This systematic examination reveals connections and dependencies that are essential for effective repairs and maintenance.

Replacement Parts: Where to Buy

Finding quality components for your outdoor equipment can be a challenge, but there are numerous reliable sources to explore. Whether you are looking to restore functionality or enhance performance, knowing where to shop is crucial. Various retailers and online platforms offer a wide selection of alternatives to ensure you can maintain your machinery efficiently.

Online Retailers

Numerous e-commerce websites provide an extensive inventory of components, often at competitive prices. Major platforms such as Amazon and eBay are excellent starting points, where you can find both new and used items. Additionally, specialized websites dedicated to outdoor equipment often carry a comprehensive range of options. Look for customer reviews to help gauge the quality and reliability of the products.

Local Dealerships and Service Centers

Visiting nearby dealerships or service centers can be beneficial, as they usually stock genuine items and can offer expert advice. These establishments often have knowledgeable staff who can assist you in identifying the right components for your specific model. Furthermore, supporting local businesses can enhance your community’s economy while ensuring you receive high-quality goods.

Tools Needed for LT1024 Repairs

Proper maintenance and repair require a selection of essential equipment to ensure efficiency and safety. Having the right tools on hand not only facilitates smoother operations but also enhances the overall quality of the work performed. Familiarity with these instruments can significantly impact the effectiveness of any service or restoration tasks.

Key tools include wrenches for tightening and loosening bolts, screwdrivers for assembling and disassembling components, and pliers for gripping and manipulating parts. A multimeter can be invaluable for diagnosing electrical issues, while a socket set provides versatility for various sizes of fasteners. Safety gear, such as gloves and goggles, is equally important to protect against potential hazards during repairs.

Additionally, specialized tools tailored for specific tasks, such as a torque wrench for ensuring proper fastening or a fuel line tool for managing fuel systems, may also be beneficial. Organizing these tools in a dedicated space will streamline the repair process, making it easier to access what is needed quickly and efficiently.

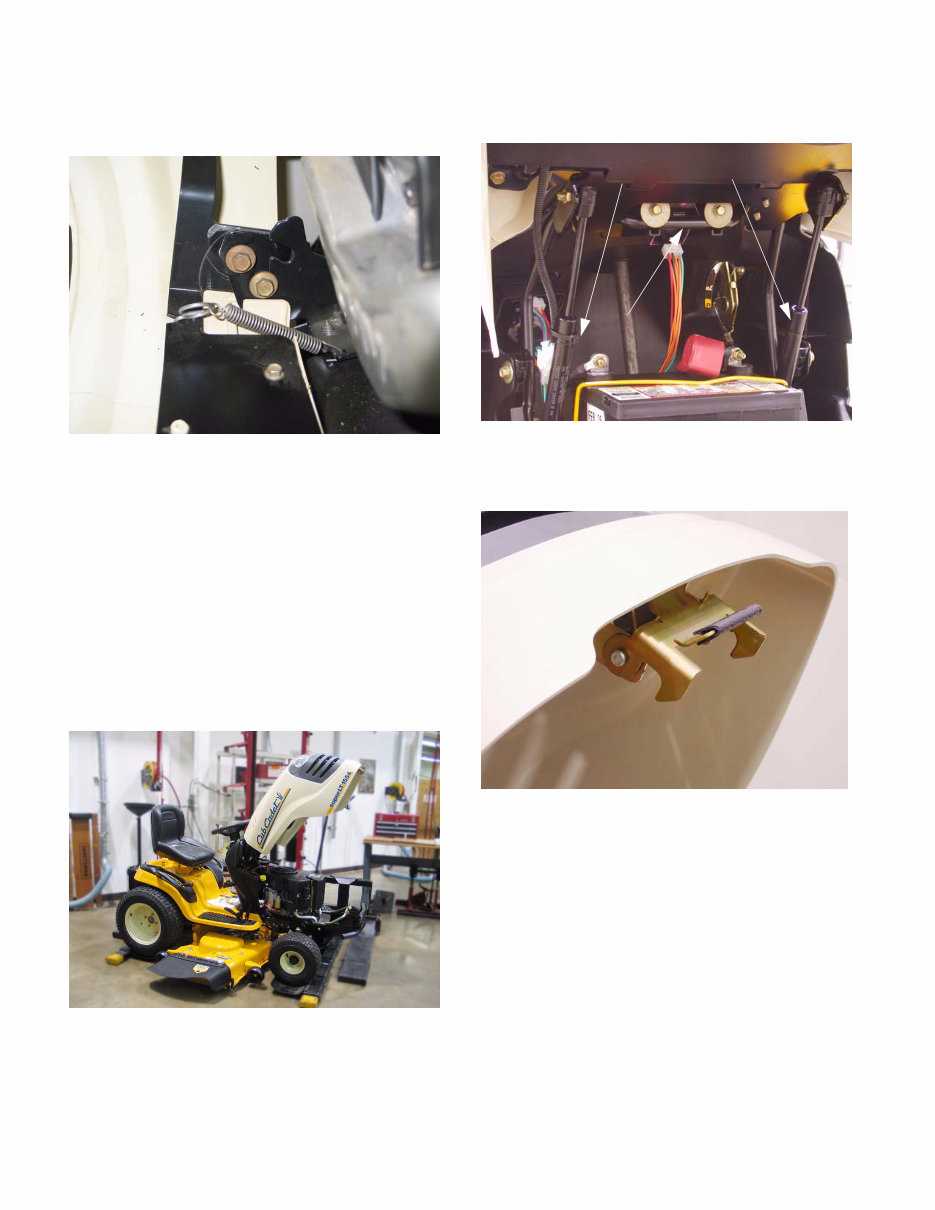

Step-by-Step Repair Process

Repairing machinery can seem daunting, but following a systematic approach can simplify the task significantly. This guide outlines a structured method to address common issues, ensuring each step is clear and manageable. Whether you’re a seasoned technician or a novice, understanding the repair process will empower you to tackle maintenance with confidence.

Step 1: Begin by assessing the problem. Identify the specific issue and gather any necessary tools and components needed for the repair.

Step 2: Next, disassemble the relevant sections carefully. Take notes or photos to remember how everything fits together for easy reassembly.

Step 3: Inspect each part thoroughly for wear and damage. Replace any faulty components as needed, ensuring you choose high-quality replacements.

Step 4: After replacement, reassemble the machinery by reversing the disassembly steps. Refer to your notes or photos to ensure accuracy.

Step 5: Finally, test the equipment to confirm that the repairs were successful and that everything functions smoothly. Regular maintenance checks can help prevent future issues.

Safety Tips for Maintenance

Ensuring safety during maintenance tasks is essential to prevent accidents and injuries. By following specific guidelines, individuals can create a secure environment while working on equipment. This section highlights key practices to enhance safety and minimize risks during upkeep activities.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear. Protective gear helps shield against flying debris, sharp edges, and harmful substances that may be encountered during maintenance. Make sure that your clothing is fitted and not loose to avoid entanglement with moving parts.

Proper Tools and Workspace

Utilize the correct tools for each task, ensuring they are in good condition and suitable for the job. An organized and clutter-free workspace reduces the likelihood of accidents. Before starting any maintenance work, make sure to disconnect power sources and secure any moving components to prevent unintended operation.

Common Issues and Solutions

Maintaining lawn care machinery can present various challenges that require attention. Understanding common malfunctions and their remedies is essential for optimal performance and longevity.

Typical Problems

- Engine Won’t Start

- Uneven Cutting

- Excessive Vibration

- Clogged Deck

Effective Solutions

- Check fuel levels and battery connections for starting issues.

- Adjust the cutting height and inspect blades for sharpness to ensure even cuts.

- Inspect engine mounts and tighten any loose bolts to reduce vibration.

- Clear debris from the deck and ensure the discharge chute is free of obstructions.

Customer Reviews of LT1024 Parts

This section delves into the feedback provided by users regarding various components associated with the model. Customers often share their experiences to highlight the quality, durability, and effectiveness of different elements that enhance the overall functionality of their machines.

Many users express satisfaction with the longevity and performance of replacement items, noting that they have successfully restored their equipment to optimal working condition. Positive remarks frequently emphasize how easy the installation process is, allowing for a seamless transition from old to new components.

On the other hand, some reviews point out challenges related to compatibility and fit. A few customers have encountered discrepancies between their expectations and the actual performance of specific elements. Constructive criticism often focuses on the need for better instructions or clearer specifications to aid in selecting the right replacements.

Overall, user feedback serves as a valuable resource for prospective buyers, helping them make informed decisions while highlighting the importance of quality and reliability in maintenance and repair.

Long-term Care for Your Tractor

Proper maintenance is essential for ensuring the longevity and optimal performance of your agricultural equipment. Regular attention not only enhances efficiency but also prevents costly repairs and prolongs its lifespan.

Essential Maintenance Tasks

- Change the oil and replace filters regularly.

- Check and clean the air filter to ensure proper airflow.

- Inspect the battery and clean terminals to prevent corrosion.

- Examine belts and hoses for wear and replace as necessary.

- Keep tires properly inflated and check for signs of damage.

Seasonal Preparations

- Before winter, store the equipment in a sheltered area and drain fluids.

- In spring, conduct a thorough inspection and tune-up.

- Monitor fuel levels and use stabilizers to prevent degradation.