When it comes to maintaining your lawn equipment, having a clear view of the different elements that make up your machine is essential. Understanding how the various sections work together ensures smoother operation and helps in identifying areas that might require attention over time. Familiarizing yourself with each section will make it easier to manage maintenance and repairs.

In this guide, we’ll explore the essential elements of a popular riding mower model, focusing on the key systems and how they interact. From the cutting mechanism to the drivetrain, every section plays a crucial role in ensuring optimal performance and longevity. Having a good grasp of these systems will help you maintain the equipment effectively and extend its service life.

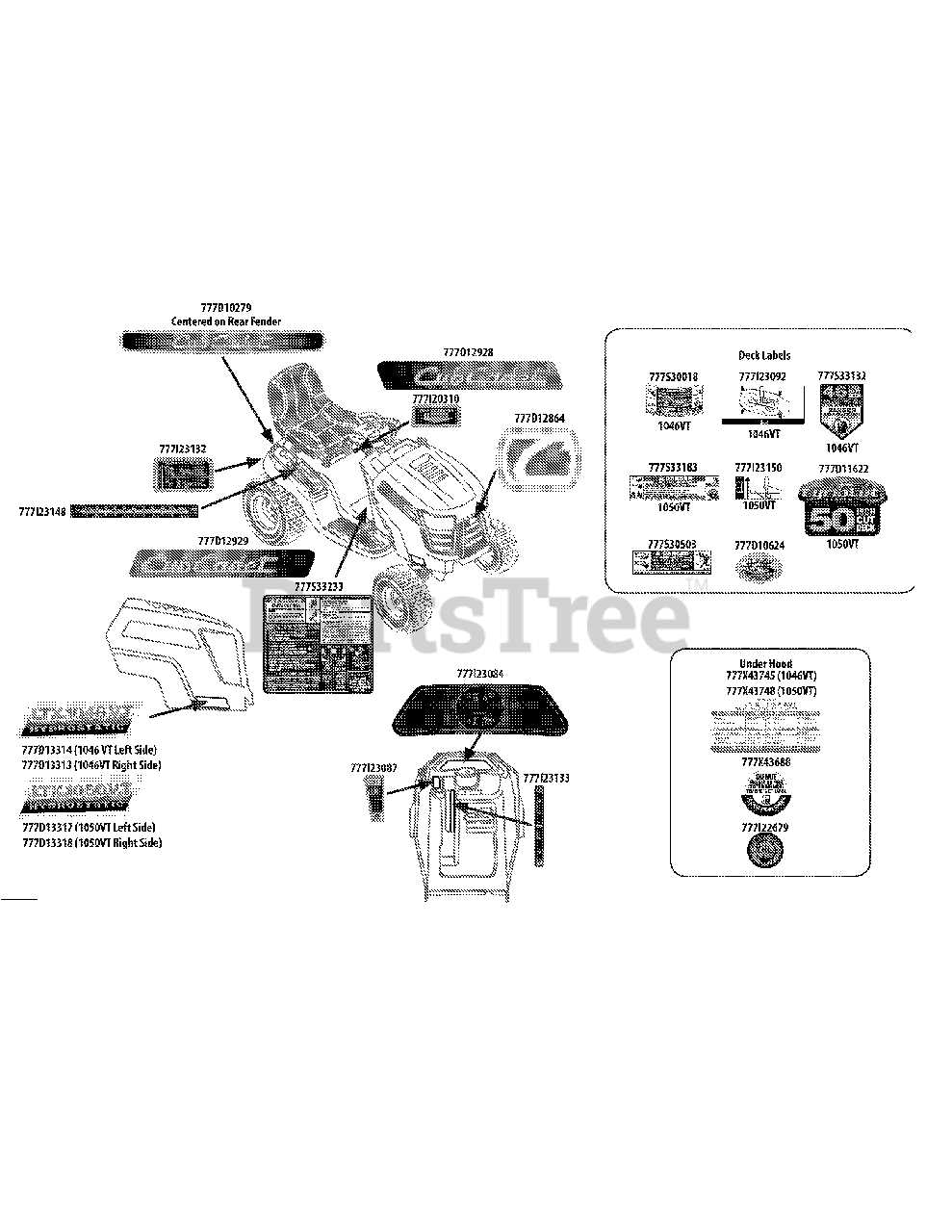

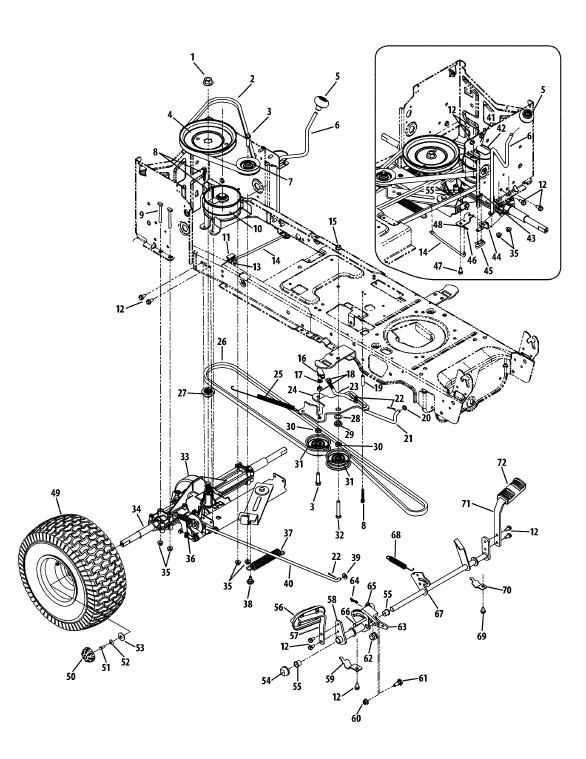

Cub Cadet LTX1046 Parts Overview

The machinery in question is composed of various essential components that ensure its smooth operation and durability. These elements work in harmony, contributing to efficient performance and long-term reliability, which are critical for maintenance and functionality.

Key Mechanical Components

- Engine: The heart of the system, providing the necessary power for all functions.

- Transmission: Transfers power from the engine to the wheels, ensuring smooth movement.

- Cutting Deck: Responsible for precision in grass cutting, adjustable to different heights.

Additional Functional Elements

- Wheels and Tires: Provide stability and mobility across different terrains.

- Steering System: Enables accurate control and maneuverability during operation.

- Blade Assembly:

Key Components of the LTX1046 Mower

The effective performance of a lawn mower relies on several crucial elements that ensure smooth operation and consistent results. Understanding these components helps maintain the machine in top condition, promoting longevity and efficiency. Each part plays a distinct role in the overall function, contributing to a balanced and reliable mowing experience.

One of the most vital parts is the engine, which provides the necessary power to operate the machine. Alongside the engine, the cutting deck is responsible for trimming grass evenly across large areas. The deck’s blades are key in achieving precise cuts, and their condition directly impacts mowing quality.

Transmission systems are another essential element, allowing the user to control speed and direction with ease. The system ensures smooth transitions during operation, whether adjusting for terrain or changing direction. Additionally, wheels and tires provide traction and stability, allowing the mower to navigate different surfaces comfortably.

Other important parts include the steering mechanism, which offers control over the movement of the mower, and the fuel system, responsible for

Understanding the Drive System Mechanism

The drive system in riding lawn equipment is a crucial component responsible for transferring power from the engine to the wheels. Its effective operation ensures smooth movement across different terrains, allowing for efficient and consistent performance. This section delves into the key elements that work together to manage power transmission and how they contribute to the overall functionality of the machine.

Key Components

The drive mechanism consists of various parts that work in unison. The engine generates power, which is then channeled through a transmission system to control the speed and direction of the equipment. A belt-driven system or hydrostatic transmission may be used to optimize power delivery, depending on the model’s design.

How It Works

As the engine runs, power is sent to the transmission, which adjusts based on the user’s input from the throttle or gear shift. The power is t

Blade Assembly and Maintenance Guide

Proper assembly and regular upkeep of cutting blades are essential for efficient performance and longevity. Ensuring that the components are correctly installed and maintained will help prevent wear, reduce the risk of malfunction, and maintain consistent results in various tasks.

Steps for Blade Installation

Before starting, ensure you have all necessary tools and safety equipment. Begin by positioning the blade on the shaft, making sure that it fits securely. Align the mounting holes and use bolts to fasten the blade, tightening them gradually in a cross pattern to ensure balanced tension. Double-check that the blade is properly aligned to avoid any potential issues during use.

Blade Maintenance Tips

Regular inspection and sharpening of the blade are critical for optimal performance. It’s recommended to check the blade for damage or dullness after every use. Sharpening should be done evenly to maintain balance and prevent uneven wear. Additionally, ensure that the bolts and nuts are securely fastened during routine maintenance to avoid loosening.

Maintenance Task Frequency Blade sharpening After every 10-15 hours of use Inspect bolts and nuts Every use Electrical System Diagram for LTX1046

The electrical system of this machine is designed to manage the flow of power throughout various components, ensuring smooth operation. Understanding how the wiring and electrical connections are laid out is crucial for proper maintenance and troubleshooting. In this section, we will explore the layout and connections without diving into technical complexities, focusing instead on the overall structure.

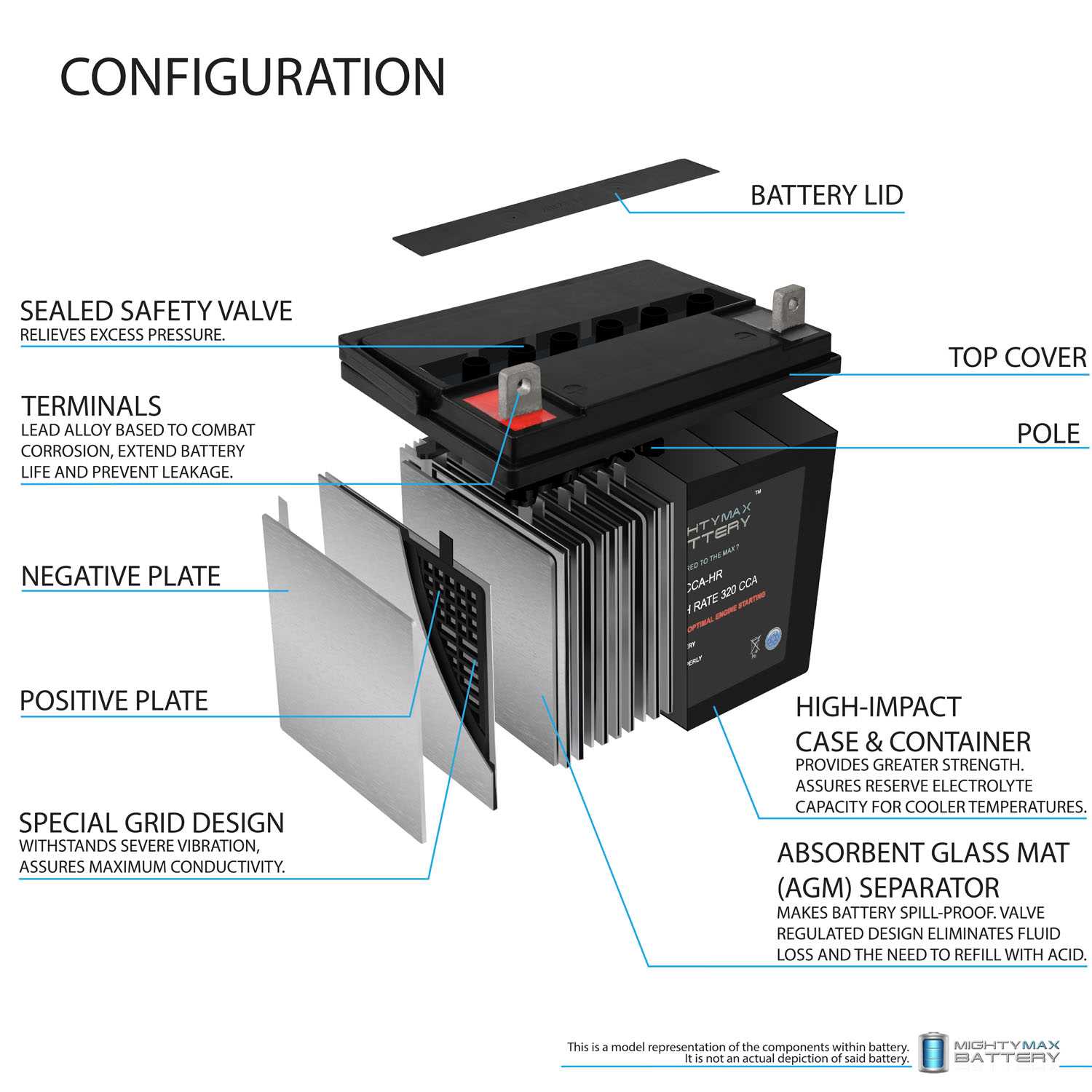

Main Components of the Electrical System

The key elements in the system include the battery, ignition switch, starter motor, and alternator. These parts work together to control power distribution and engine startup. Let’s take a closer look at how these components are interconnected and how they contribute to the overall functioning of the machine.

Component Function Battery Supplies electrical power to the system Ignition Switch Activates the starting process Starter Motor Fuel System Parts and Function

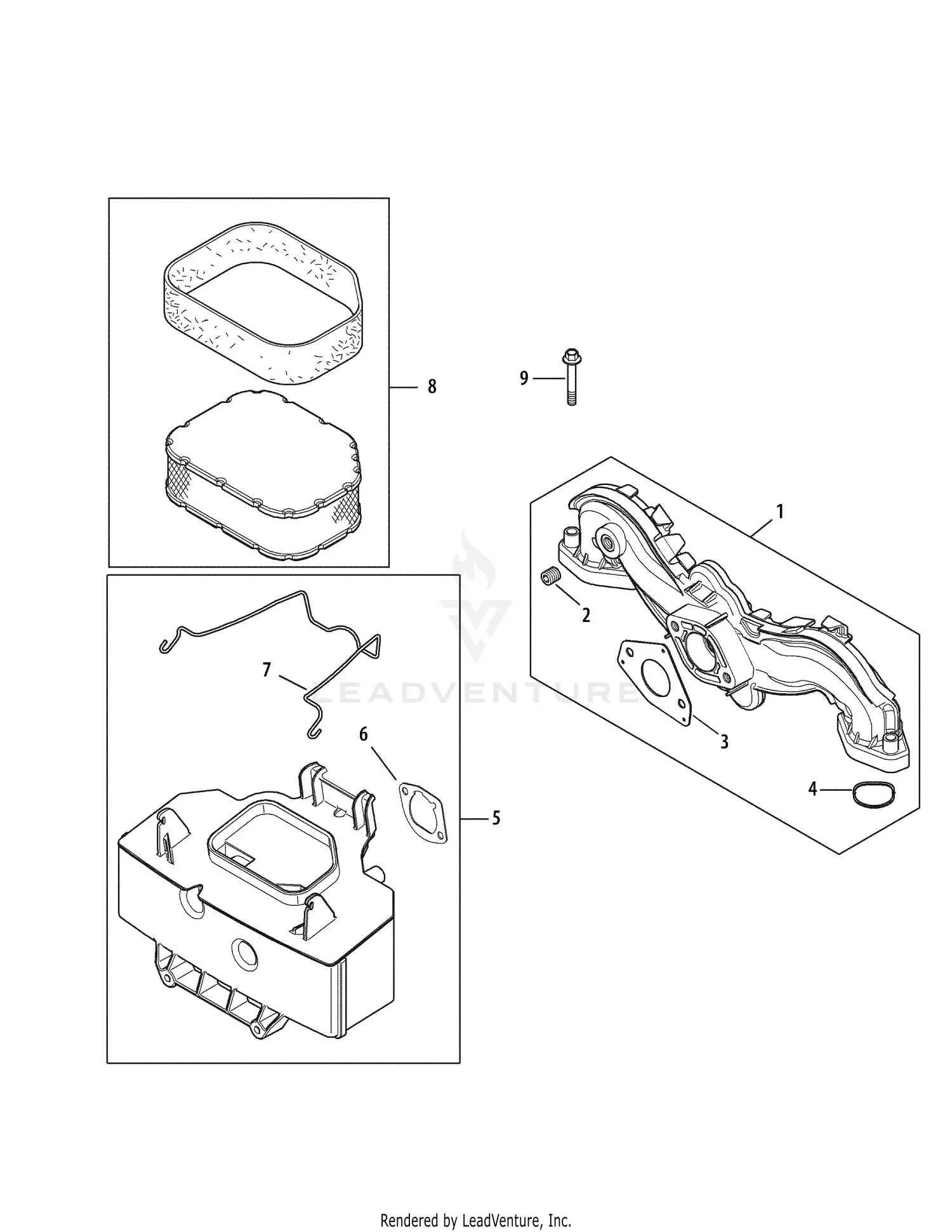

The fuel system plays a crucial role in the operation of outdoor power equipment, ensuring that the engine receives the necessary fuel for combustion. This system includes various components that work together to deliver fuel efficiently, maintaining optimal performance and reliability. Understanding these elements can help users diagnose issues and maintain their equipment effectively.

Key Components

The primary elements of the fuel system include the fuel tank, fuel lines, pump, filter, and carburetor. The fuel tank stores the gasoline, while the fuel lines transport it to the engine. The pump draws fuel from the tank, and the filter ensures that impurities do not reach the engine. Finally, the carburetor mixes the fuel with air to create the combustible mixture necessary for engine operation.

Functionality Overview

Each component has a specific function that contributes to the overall efficiency of the engine. The fuel tank is designed to hold an adequate supply of fuel, while the lines must be durable and leak-free to maintain pressure. The pump is responsible for delivering fuel at the right flow rate, and the filter protects the engine from damage caused by debris. The carburetor’s role is vital, as it ensures the correct fuel-to-air ratio for combustion, affecting engine performance and emissions.

Steering Components and Alignment Tips

Proper functionality of the steering system is crucial for the optimal performance and maneuverability of your machine. Understanding the various components involved and ensuring they are correctly aligned can significantly enhance the user experience and prolong the lifespan of the equipment.

The key components of the steering assembly typically include:

- Steering Wheel: The primary control mechanism for direction.

- Steering Shaft: Connects the steering wheel to the steering gear.

- Steering Gear: Translates the rotational movement of the wheel into lateral movement.

- Linkages: Transfers motion from the steering gear to the wheels.

- Spindles: Pivot points that allow the wheels to turn.

To maintain proper alignment and functionality, consider the following tips:

- Regular Inspection: Frequently check all components for wear and damage.

- Alignment Check: Ensure that the steering linkage is properly aligned to prevent uneven tire wear.

- Lubrication: Keep moving parts well-lubricated to minimize friction and wear.

- Tighten Connections: Regularly inspect and tighten any loose bolts or connections.

- Professional Service: If unsure, consult a professional for alignment adjustments and repairs.

By following these guidelines, you can ensure that your steering system operates smoothly and efficiently, enhancing both performance and safety.

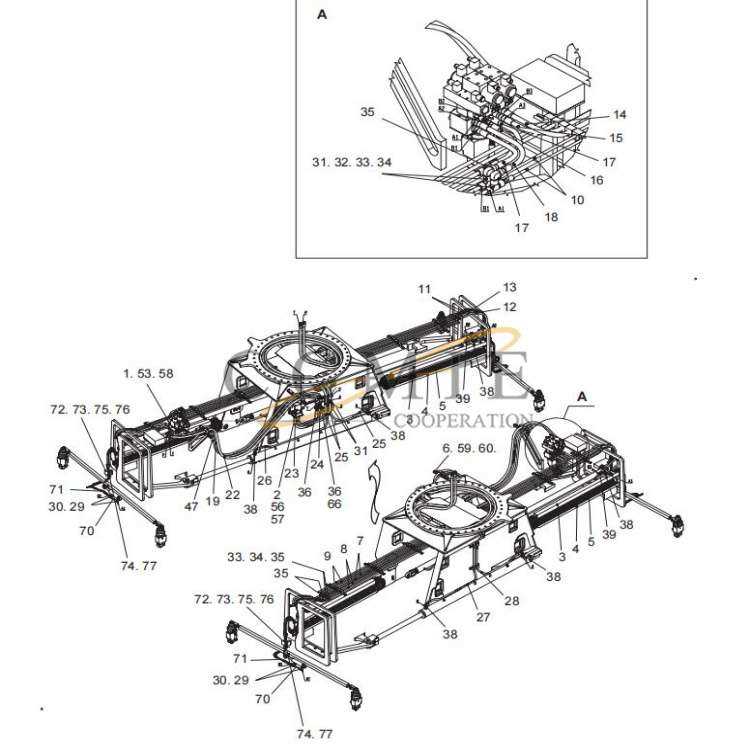

Deck Belt Routing and Adjustment

The proper routing and adjustment of the drive belt are essential for maintaining optimal performance and longevity of your lawn equipment. Ensuring that the belt is correctly aligned and adjusted can prevent unnecessary wear and tear, leading to improved efficiency and functionality.

Routing the Drive Belt: Start by referring to the manufacturer’s guidelines for the specific routing path. Generally, the belt should loop around the drive pulleys and idlers in a specific order to maintain tension and function correctly. Pay close attention to the alignment, ensuring that the belt sits securely in the grooves of each pulley. Any misalignment can lead to slippage or damage over time.

Adjusting Belt Tension: The tension of the drive belt is crucial for effective operation. If the belt is too loose, it may slip, while excessive tension can cause premature wear. To adjust the tension, locate the adjustment mechanism, typically a tensioner or idler pulley. Rotate or reposition this component to achieve the desired tightness, ensuring that the belt maintains a firm grip on the pulleys without excessive pressure.

Regular checks and adjustments of the drive belt are recommended to ensure smooth operation and prolong the life of your machinery. By following these guidelines, you can maintain the efficiency of your equipment and avoid potential issues down the line.

Engine Cooling System Explained

The cooling system of an engine plays a crucial role in maintaining optimal operating temperatures. Efficient temperature regulation is essential to prevent overheating and ensure the engine performs at its best. This system utilizes various components to manage heat and distribute it away from critical areas.

Key components of a typical engine cooling system include:

- Radiator: This component dissipates heat from the coolant that circulates through the engine.

- Water Pump: Responsible for circulating the coolant throughout the system, ensuring even temperature distribution.

- Thermostat: Regulates the flow of coolant based on temperature, allowing for optimal engine warm-up and cooling.

- Cooling Fans: Help increase airflow through the radiator, particularly at low speeds or when the engine is under heavy load.

- Coolant Reservoir: Stores excess coolant, providing a reserve that helps maintain pressure and prevent boiling.

Understanding how these elements work together can enhance maintenance practices and improve the longevity of the engine. Regular checks of coolant levels, the integrity of hoses, and the functioning of the thermostat can prevent overheating and associated damage.

In summary, a well-functioning cooling system is vital for the efficiency and reliability of an engine, and proper attention to its components can lead to smoother operation and prolonged engine life.

Transmission Parts and Troubleshooting

The functionality of any mower relies heavily on its drive system. Understanding the components involved in this mechanism is essential for effective maintenance and troubleshooting. This section will provide insights into the key elements of the transmission system, along with common issues that may arise and how to address them.

Below is a table outlining the primary components of the drive mechanism and their functions:

Component Function Gearbox Transfers power from the engine to the wheels, enabling movement. Drive Belt Connects the engine to the gearbox, transferring rotational force. Chain Links the gearbox to the rear axle for effective power distribution. Clutch Engages and disengages the drive mechanism, allowing for smooth starts and stops. Pulleys Guide the drive belt and adjust the torque delivered to the wheels. Common issues with the drive system include slipping belts, unusual noises, and loss of power. Regular inspection of components, ensuring proper tension and alignment, and replacing worn parts can help maintain optimal performance. By familiarizing yourself with these elements, you can effectively troubleshoot and resolve issues that may arise.

Brake System Components and Repair

The braking system is a crucial element of any machinery, ensuring safety and control during operation. Understanding its components and their functions is essential for effective maintenance and timely repairs. This section provides an overview of the various elements involved in the braking system and common repair practices.

Key Components of the Braking System

- Brake Pads: These components create friction against the brake rotor to slow down or stop the machine.

- Brake Rotors: The surface against which the brake pads press, converting kinetic energy into heat.

- Brake Calipers: These house the brake pads and apply pressure to them against the rotors.

- Brake Lines: Hoses that transfer hydraulic fluid from the master cylinder to the calipers.

- Master Cylinder: Converts the force applied on the brake pedal into hydraulic pressure.

Common Repair Procedures

- Inspection: Regularly check all components for wear and damage. Look for cracks in rotors or pads that are worn thin.

- Replacing Brake Pads: If the pads are worn down, replace them to ensure proper braking performance.

- Bleeding the Brakes: This process removes air bubbles from the brake lines, ensuring consistent hydraulic pressure.

- Rotating or Resurfacing Rotors: Depending on the condition, rotors may need to be resurfaced or replaced for optimal performance.

Chassis and Frame Construction Details

The chassis serves as the foundational structure of the equipment, providing essential support and stability during operation. Its design is critical for ensuring durability and longevity, as it must withstand various stresses encountered in different environments.

The frame is typically crafted from robust materials that can endure heavy loads and impacts. Reinforcements are often strategically placed to enhance strength and reduce flexing, which is vital for maintaining alignment and performance. The configuration of the frame components is also carefully considered to optimize weight distribution, allowing for improved maneuverability and control.

In addition, the assembly process involves precise welding and fastening techniques to ensure all parts fit together securely. This attention to detail not only contributes to the structural integrity but also facilitates ease of maintenance and repair. Understanding these construction details is essential for anyone looking to work on or customize their equipment effectively.

Common Issues with LTX1046 Parts

When maintaining a riding mower, several challenges may arise concerning its components. These problems can stem from wear and tear, improper usage, or lack of regular upkeep. Understanding these common issues can help users troubleshoot and address them effectively, ensuring the longevity and efficiency of the equipment.

Issue Description Solution Worn Blades Over time, blades may become dull or damaged, leading to poor cutting performance. Regularly inspect and sharpen or replace blades as needed. Fuel Leaks Leaks can occur in the fuel system, posing a risk of fire and reducing efficiency. Check for cracks in fuel lines and replace any damaged parts immediately. Battery Issues Problems with the battery can prevent the mower from starting or cause intermittent power loss. Inspect connections, clean terminals, and replace the battery if it shows signs of failure. Transmission Problems Difficulty in shifting gears or slipping can indicate issues with the transmission system. Consult the manual for adjustment procedures or seek professional repair. Overheating Engines may overheat due to inadequate lubrication or blocked cooling fins. Regularly check oil levels and ensure cooling systems are clean and unobstructed.