In the world of outdoor machinery, having a clear understanding of the various components and their configurations is crucial for effective maintenance and repair. A well-structured layout serves as a vital resource for enthusiasts and professionals alike, enabling them to identify individual elements and their respective functions. By examining such arrangements, one can ensure optimal performance and longevity of their equipment.

Knowledge of the intricate design of machinery allows users to tackle challenges more efficiently. Whether it’s for troubleshooting issues or planning upgrades, familiarity with the assembly of parts enhances the overall user experience. This resource serves as a comprehensive guide for anyone looking to delve deeper into the intricacies of their lawn care tools.

Furthermore, having access to a detailed illustration not only aids in the identification of components but also streamlines the process of acquiring replacements when necessary. By comprehensively exploring the layout, users can engage in informed discussions and make educated decisions regarding their machinery. Embracing this knowledge empowers individuals to maintain their equipment in peak condition.

Overview of the Premium Riding Mower

This advanced lawn maintenance machine stands out for its exceptional performance and durability. Designed for professional landscapers and avid gardeners alike, it offers a powerful engine combined with an ergonomic design. Its ability to tackle various terrains makes it an ideal choice for maintaining expansive lawns and gardens.

Key Features

The riding mower boasts a robust engine that delivers impressive power and efficiency. With a high-quality cutting deck, it ensures a clean and precise cut every time. The model also incorporates innovative technology for enhanced maneuverability and ease of use, making it suitable for both seasoned professionals and beginners.

Benefits of Ownership

Investing in this machine means significantly reducing time spent on lawn care. The combination of speed and precision leads to a beautifully maintained outdoor space with minimal effort. Additionally, the sturdy construction promises longevity, providing excellent value over the years.

Key Features of Pro Z 900

This section highlights the distinctive attributes that set this advanced lawn care machine apart from its competitors. With a focus on efficiency, durability, and user comfort, these features are designed to enhance the overall experience of operating the equipment, making it a preferred choice for professionals and enthusiasts alike.

Robust Construction

The equipment is built with high-quality materials that ensure longevity and resilience against various environmental conditions. This sturdy framework allows for consistent performance, minimizing the risk of breakdowns during operation. The heavy-duty design is complemented by a well-engineered chassis, providing stability on uneven terrain.

User-Friendly Controls

Ease of use is a hallmark of this model, featuring intuitive controls that simplify operation. The ergonomic layout minimizes fatigue, allowing users to work for extended periods without discomfort. Additionally, the presence of advanced technological integrations enhances precision, making the mowing process more efficient and effective.

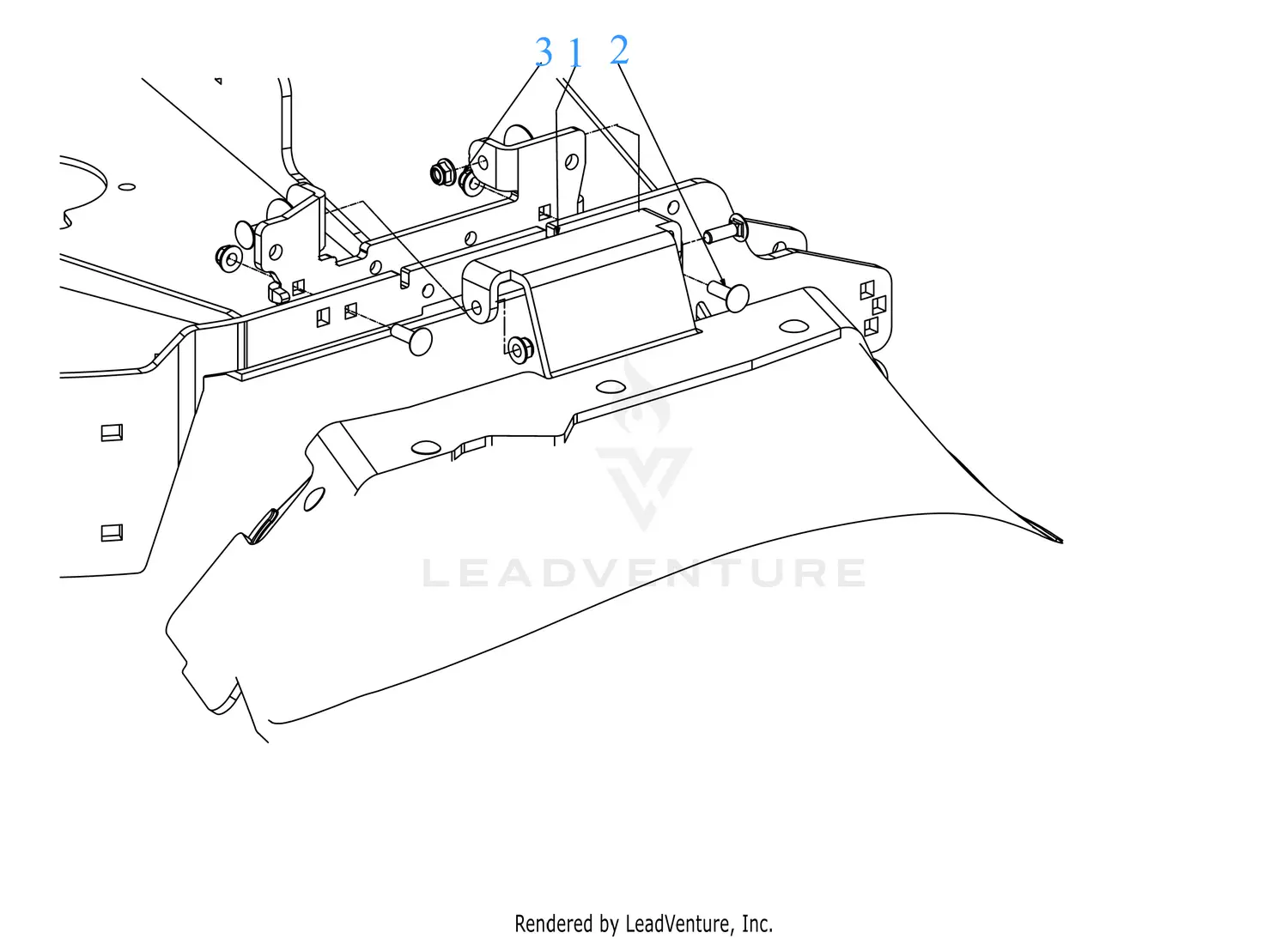

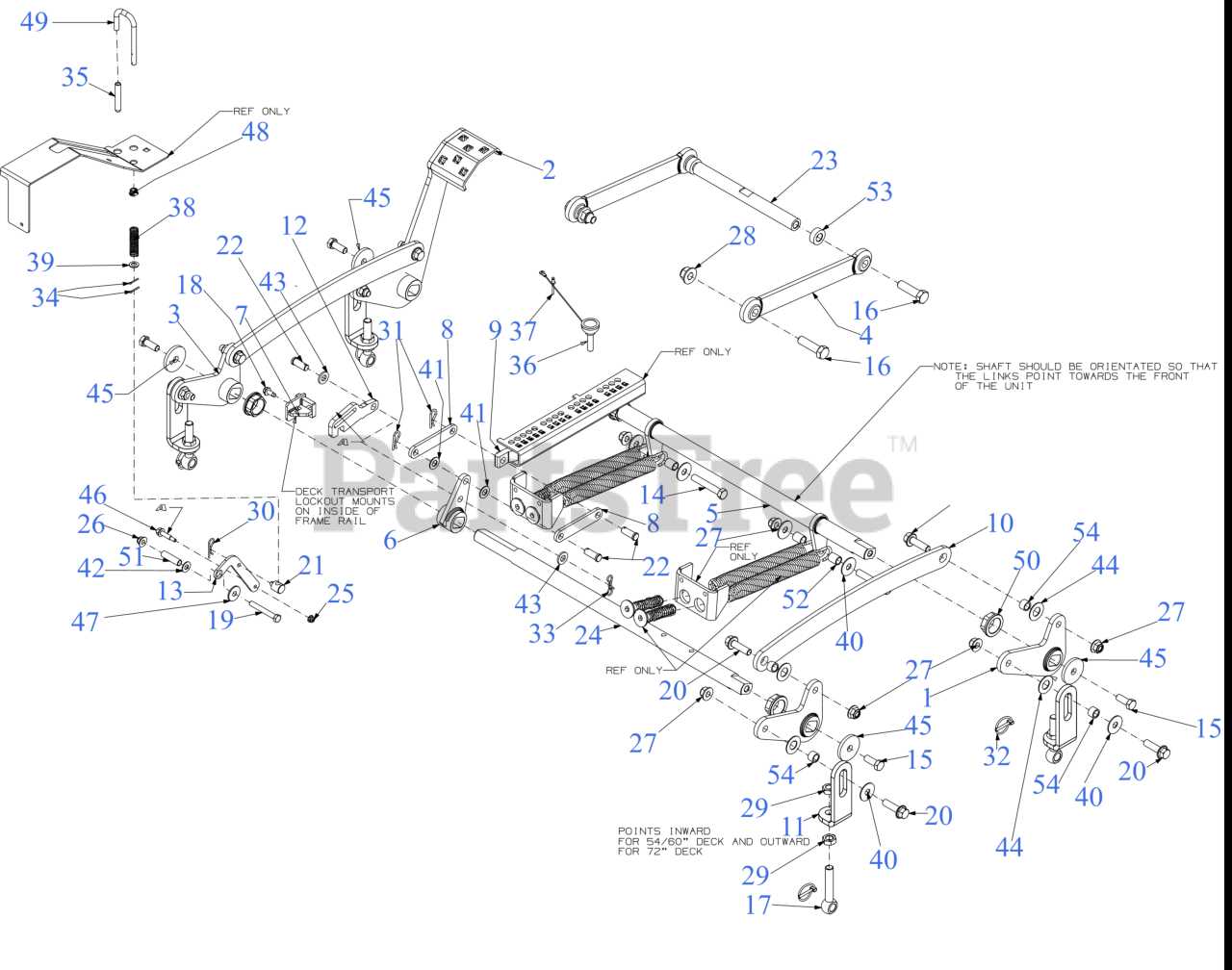

Importance of Parts Diagrams

Understanding the layout and components of any machinery is essential for efficient maintenance and repair. Visual representations of individual elements not only enhance comprehension but also facilitate quicker identification of issues. These illustrations serve as invaluable tools for technicians and enthusiasts alike, simplifying complex structures into more manageable information.

Enhanced Clarity and Communication

Visual aids promote clearer communication between team members. When everyone refers to the same graphical representation, misunderstandings are minimized. This clarity is particularly crucial in collaborative settings, where multiple individuals may work on the same equipment. Moreover, detailed visuals help in training new staff, ensuring they grasp the essential features without extensive verbal explanations.

Streamlined Maintenance Procedures

Having access to a visual breakdown allows for more efficient servicing. Technicians can quickly locate the necessary components, saving valuable time during repairs. This efficiency is not just beneficial for professional mechanics; hobbyists and DIY enthusiasts also gain confidence from having clear references, enabling them to tackle projects that may have otherwise seemed daunting.

Common Issues with Pro Z 900

The operation of high-performance lawn care machines can be hindered by various complications. Users often encounter specific challenges that may impact efficiency and performance. Understanding these issues is crucial for maintaining optimal functionality and ensuring a satisfactory experience with the equipment.

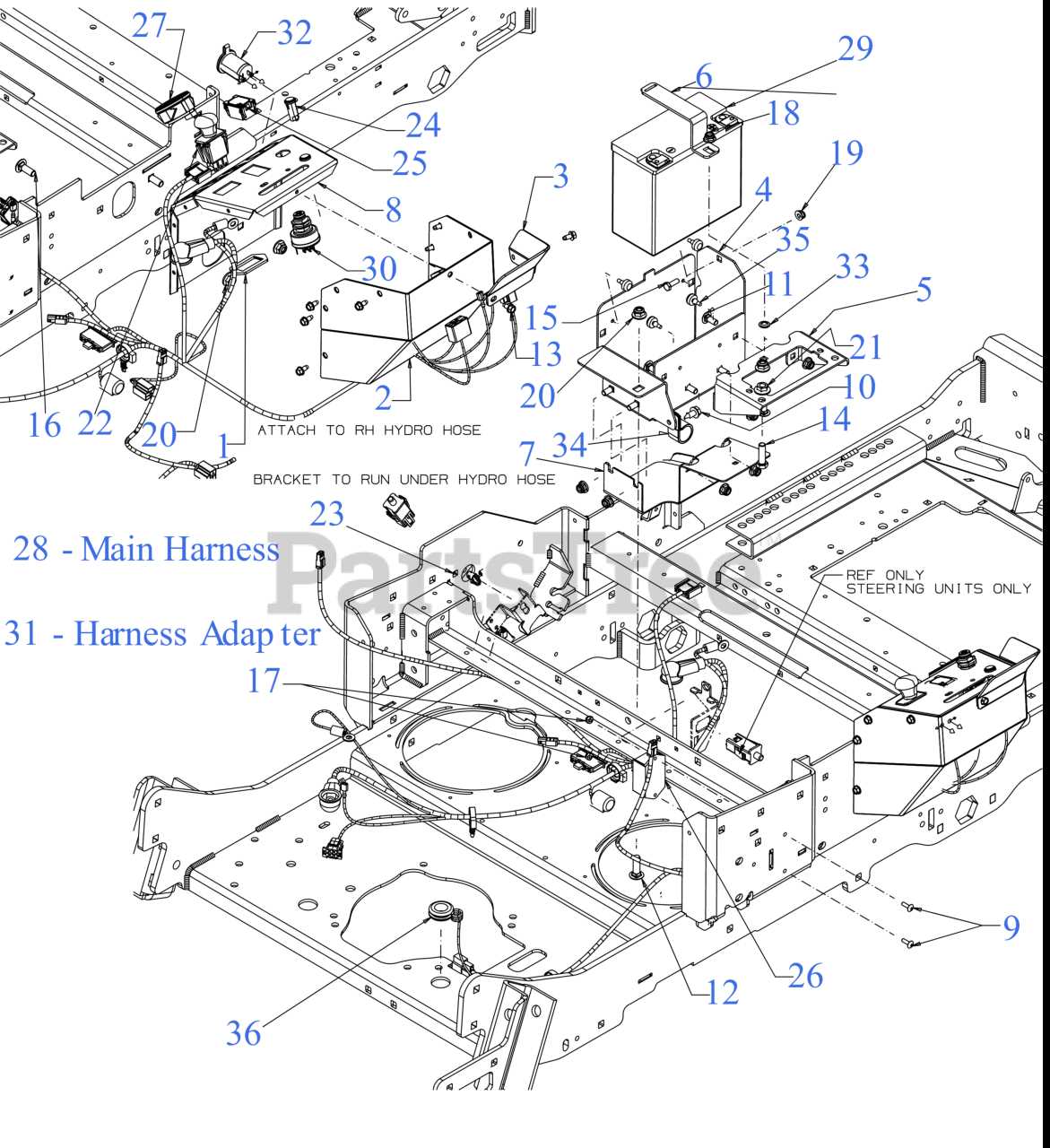

Electrical Problems

One prevalent concern involves electrical systems, which can lead to starting difficulties or erratic behavior during operation. Faulty wiring, corroded connectors, or drained batteries may contribute to these issues. Regular inspection and maintenance of the electrical components are essential to prevent malfunctions.

Engine Performance

Another frequent issue pertains to engine operation. Users may experience reduced power or unusual noises, which could signal underlying problems such as fuel delivery issues or air filter blockages. Timely diagnostics and servicing can help restore the machine’s performance and extend its lifespan.

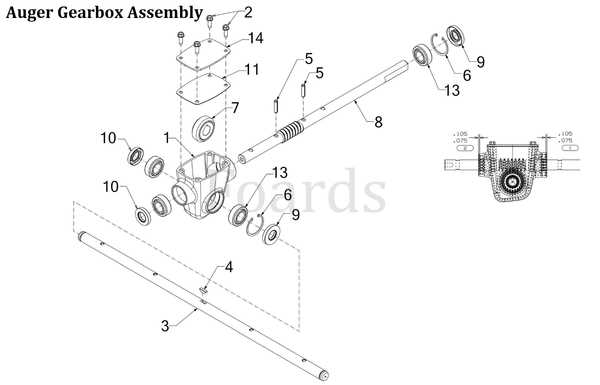

Understanding the Parts List

Grasping the components of machinery is essential for effective maintenance and repair. A well-organized inventory of elements provides insights into functionality and assists users in identifying what is necessary for various tasks. Familiarity with these components not only enhances troubleshooting skills but also ensures that any replacements are suitable and effective.

The Importance of Component Identification

Recognizing each item in the inventory allows for a more systematic approach to upkeep. Knowing specific names and roles of each element can significantly reduce downtime. Additionally, this knowledge empowers operators to make informed decisions when seeking replacements or upgrades.

Navigating the Inventory Effectively

When exploring the list, it is vital to understand how each component interacts with others within the system. Some items may be interconnected, meaning that the failure of one could impact the performance of another. Therefore, a thorough comprehension of their relationships can lead to more efficient repairs and optimizations.

In summary, developing a solid understanding of the components and their functions enhances overall machine reliability and performance. An informed approach to maintenance ultimately saves time and resources.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your outdoor equipment requires a proactive approach to upkeep. Regular maintenance not only enhances functionality but also extends the lifespan of machinery, making it a worthwhile investment for any owner.

1. Routine Inspections: Conduct frequent checks to identify any signs of wear or damage. Pay attention to critical components and replace any that show signs of deterioration.

2. Cleanliness Matters: Keep the equipment free from dirt and debris. Accumulation can lead to mechanical issues. Use a soft brush or compressed air to remove buildup from hard-to-reach areas.

3. Lubrication: Regularly lubricate moving parts to minimize friction and prevent premature wear. Refer to the manufacturer’s guidelines for recommended lubricants and intervals.

4. Fuel Quality: Always use high-quality fuel to prevent engine problems. Stale or contaminated fuel can cause performance issues and damage internal components.

5. Storage Practices: Store the equipment in a dry, sheltered location to protect it from environmental factors. Use covers to shield from dust and moisture when not in use.

6. Follow the Manual: Adhere to the maintenance schedule provided in the owner’s manual. This resource offers essential insights and guidelines tailored to your specific model.

Implementing these strategies will significantly contribute to the longevity and reliability of your machinery, ensuring that it remains in peak condition for years to come.

Where to Find Replacement Parts

Finding high-quality components for your outdoor equipment can be a daunting task. However, with the right approach, you can locate reliable sources that provide the necessary items to keep your machinery running smoothly.

Here are several avenues to explore when searching for suitable components:

- Authorized Dealers: Always check with certified distributors, as they often have a comprehensive selection of genuine items that ensure optimal performance.

- Online Retailers: Numerous e-commerce platforms specialize in outdoor machinery, providing convenience and a wide range of choices. Make sure to read customer reviews to gauge product quality.

- Local Repair Shops: Small businesses that focus on equipment repair may have access to parts directly or can order them for you. They also offer valuable expertise.

- Manufacturer’s Website: Most manufacturers maintain a website where you can find detailed catalogs of components and ordering information.

- Second-Hand Market: Platforms like eBay or local classifieds can be excellent sources for used items, often at a fraction of the original price. Just ensure to check the condition before purchasing.

By considering these options, you can effectively locate the necessary components to maintain and enhance the functionality of your equipment.

Decoding the Diagram Symbols

Understanding the symbols utilized in mechanical schematics is essential for effective maintenance and repair. These visual representations serve as a universal language, allowing users to interpret the intricacies of machinery quickly. Each icon conveys specific information about components, their functions, and interconnections, ensuring that users can efficiently navigate through the intricacies of the equipment.

Below is a table that illustrates common symbols found in mechanical schematics, along with their meanings:

| Symbol | Description |

|---|---|

| ⚙️ | Gear – Indicates a rotating component. |

| Reversible – Signifies a part that can operate in multiple directions. | |

| Connection – Represents electrical or mechanical linkages. | |

| Drive System – Indicates components related to power transmission. | |

| ️ | Adjustment – Points to areas requiring tuning or calibration. |

| ❗ | Warning – Highlights potential hazards or important notes. |

By familiarizing oneself with these symbols, users can gain a clearer understanding of their machinery, leading to more informed decisions during repair and maintenance activities. Proper interpretation of these visual cues not only enhances efficiency but also promotes safety in operational practices.

Step-by-Step Repair Process

This section outlines a systematic approach to diagnosing and fixing issues in your outdoor machinery. Following these steps will help ensure that repairs are thorough and effective, minimizing the risk of recurring problems.

Preparation and Assessment

Before starting any repair work, it’s essential to gather the necessary tools and materials. Begin by assessing the condition of the equipment to identify visible signs of damage or wear. Note any unusual sounds or performance issues that may indicate underlying problems.

| Task | Description |

|---|---|

| Gather Tools | Collect all required tools such as wrenches, screwdrivers, and pliers. |

| Inspect the Equipment | Look for obvious signs of damage or malfunction, including leaks or frayed wires. |

| Document Findings | Take notes on observed issues for future reference and troubleshooting. |

Executing Repairs

Once you have a clear understanding of the problems, proceed with the necessary repairs. Depending on the identified issues, this may involve replacing components, tightening loose fittings, or lubricating moving parts. Always refer to the manufacturer’s guidelines to ensure that repairs are performed correctly.

| Repair Task | Steps |

|---|---|

| Replace Worn Parts | Remove damaged components and install new ones as specified in the manual. |

| Adjust Settings | Make necessary adjustments to settings for optimal performance. |

| Test the Equipment | Run the machine to ensure repairs were successful and everything is functioning properly. |

Tools Needed for Repairs

When it comes to performing maintenance and repairs on outdoor equipment, having the right instruments at your disposal is crucial. A well-equipped toolkit not only streamlines the process but also enhances the overall efficiency of your work. Understanding which tools are essential can significantly reduce downtime and improve the quality of repairs.

Essential Hand Tools

Basic hand tools are the foundation of any repair job. These include screwdrivers, wrenches, and pliers. A set of socket wrenches is particularly useful for tightening and loosening various components. It’s also advisable to have a hammer and a tape measure handy for more precise tasks. Each tool serves a specific purpose, allowing for meticulous adjustments and modifications.

Power Tools and Safety Gear

For more extensive repairs, incorporating power tools can save time and effort. An electric drill or a reciprocating saw can make cutting and fastening much easier. Additionally, safety gear such as gloves, safety glasses, and ear protection should not be overlooked. Prioritizing safety ensures a secure working environment, enabling you to focus on the task at hand without unnecessary risks.

Customer Reviews and Feedback

This section highlights the experiences and insights shared by users regarding the machinery. Feedback from consumers serves as a valuable resource, offering perspectives on performance, durability, and usability. Understanding what users appreciate or dislike can guide potential buyers in making informed decisions.

Overall, users have expressed a wide range of opinions about the equipment. Some appreciate its reliability and ease of use, while others have pointed out areas for improvement. Below is a summary of the most common feedback points:

| Aspect | Positive Feedback | Negative Feedback |

|---|---|---|

| Performance | Reliable in various conditions, efficient cutting | Occasional issues with speed under heavy load |

| Durability | Long-lasting materials, withstands tough usage | Some components require frequent replacement |

| User Experience | Easy to maneuver, intuitive controls | Steeper learning curve for new users |

| Maintenance | Simple maintenance procedures, accessible parts | Limited information on troubleshooting |

In summary, while the machinery has garnered many favorable reviews, potential buyers should consider both the strengths and weaknesses highlighted by existing users. This balanced view can help in selecting the right equipment for their needs.

Comparing Pro Z 900 with Competitors

When evaluating high-performance lawn care equipment, it’s essential to analyze various models to determine which offers the best features and functionality for users. In this segment, we will delve into the similarities and differences between a leading contender and its closest rivals in the market, focusing on performance, durability, and user experience.

Performance Overview

Performance is a critical factor for any professional-grade mower. Here are some aspects to consider:

- Engine power and efficiency

- Cutting speed and quality

- Terrain adaptability

- Fuel consumption rates

Our model stands out with its powerful engine and exceptional cutting precision, making it a favorite among landscape professionals. Competitors may offer similar engine specs, but often fall short in delivering consistent results across varied terrains.

Durability and Build Quality

Longevity of equipment is crucial for cost-effectiveness. Key points of comparison include:

- Frame construction materials

- Deck design and protection

- Maintenance requirements

This mower boasts robust construction that withstands rigorous use, while many competitors utilize lighter materials that may not endure prolonged exposure to demanding conditions. Additionally, the ease of maintenance in our model enhances its appeal, allowing users to minimize downtime and maximize productivity.

In conclusion, while several options are available in the market, this particular mower excels in both performance and durability, making it a top choice for professionals seeking reliable equipment for their landscaping needs.

Warranty Information and Support

This section aims to provide essential details regarding the coverage and assistance available for your equipment. Understanding the warranty terms and support options ensures you can effectively maintain and protect your investment over time.

Warranty Coverage

The warranty typically includes protection against defects in materials and workmanship. Here are the key elements you should know:

- Duration: Most warranties offer coverage for a specific period from the date of purchase.

- Exclusions: Damage due to misuse, neglect, or unauthorized repairs may void the warranty.

- Transferability: Some warranties may be transferable if the equipment changes ownership.

Support Services

Access to reliable support services can enhance your ownership experience. Consider the following options:

- Customer Service: Reach out to the dedicated team for assistance with any issues you encounter.

- Authorized Dealers: Seek help from certified dealers for repairs and maintenance to ensure quality service.

- Online Resources: Utilize official websites for manuals, troubleshooting guides, and FAQs to address common concerns.