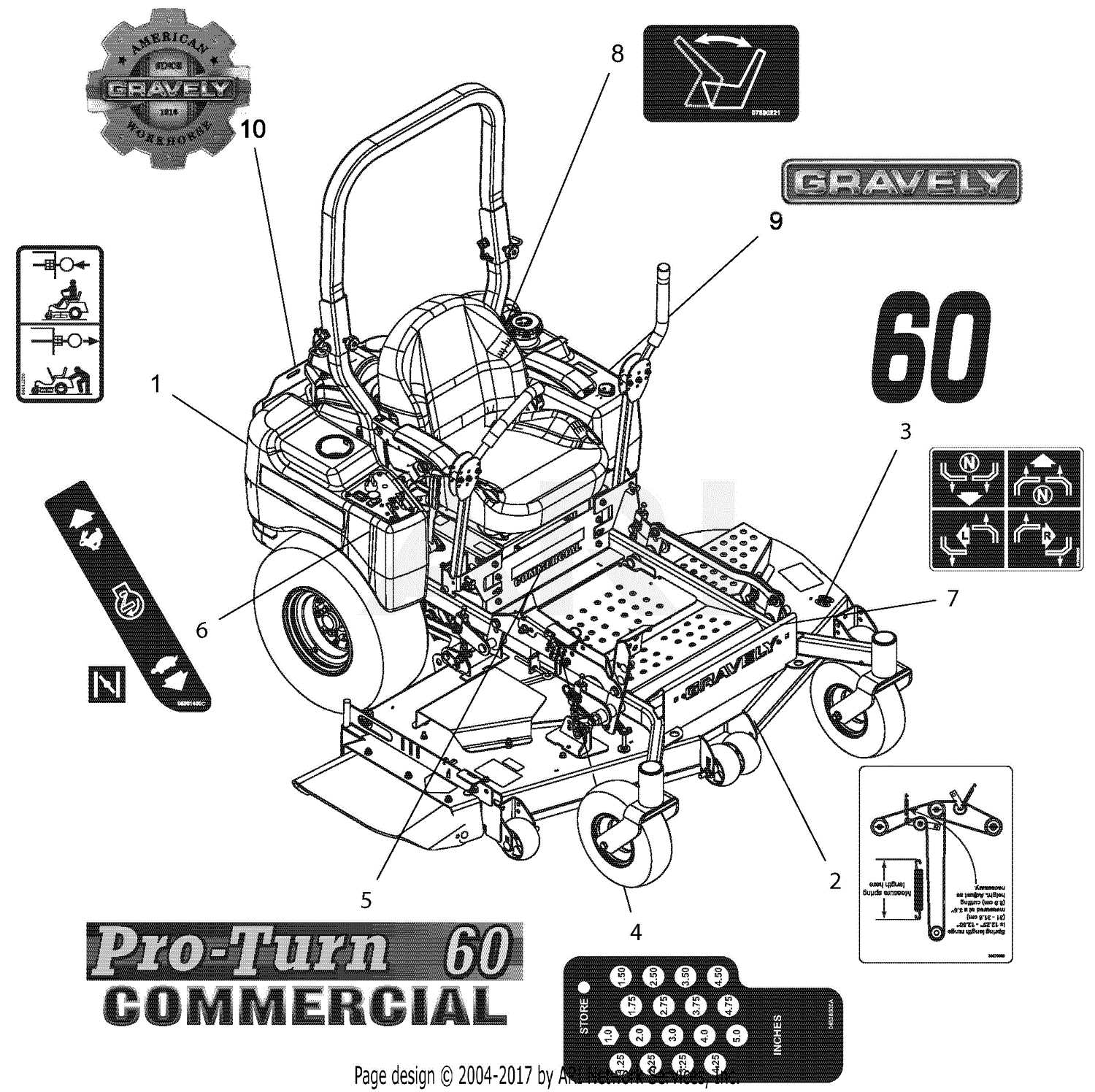

Understanding the intricacies of mechanical systems requires detailed insights into how various components interact within a machine. These blueprints serve as a guide, helping users identify and comprehend the arrangement and function of each element. By studying the layout, one can easily locate specific areas that require maintenance or replacement.

Visual breakdowns of machinery are essential for ensuring the longevity and efficiency of operations. Whether it’s for routine check-ups or troubleshooting issues, having access to a clear structural reference is invaluable. Such diagrams not only simplify complex assemblies but also streamline repairs, making it easier to navigate the inner workings of the equipment.

Efficiency and accuracy in maintaining mechanical devices depend heavily on these well-organized schematics. They provide a reliable source of information for users, enabling them to follow step-by-step procedures with confidence. From identifying the correct components to understanding their placement, these visual aids are key to effective maintenance practices.

Understanding the Main Components

Every piece of machinery is made up of essential parts that work together to ensure smooth operation. Familiarizing yourself with these elements is key to maintaining and troubleshooting the system effectively. The components play specific roles, and understanding their functions helps in identifying any issues that may arise.

Engine and Power System

The engine serves as the heart of the machine, providing the power necessary for operation. It drives other mechanical systems, ensuring the movement and performance of key functions. Regular maintenance of this unit is essential to keep the entire machine running efficiently.

Control Mechanism

The control system allows the operator to manage the machine’s performance. This includes levers or pedals that direct movement, speed, and precision. Keeping these controls in good condition ensures smooth and responsive handling during operation.

How the Cutting System Works

The cutting mechanism operates by rotating sharp blades at high speed to slice through grass and other vegetation. These blades are mounted on spindles and are powered by an engine that transfers energy through belts or other transmission systems. The blades move horizontally across the surface, creating a uniform cut as the machine moves forward.

Blade Rotation and Speed

The rotation of the blades is crucial for the effectiveness of the cutting system. By spinning at a high velocity, the blades create enough force to cut through thick grass. The speed of rotation can be adjusted based on the height of the grass and the desired cutting result, allowing for both rough and fine mowing.

Deck and Airflow

The deck, which houses the blades, is designed to enhance airflow around the cutting area. This airflow helps lift the grass blades, making it easier for the cutting edges to produce a clean, even cut. The design of the deck also directs clippings either to a collection system or back onto the ground for mulching, depending on the configuration.

Engine Parts and Their Functions

Understanding the key components of the engine and their respective roles is essential for maintaining optimal performance. Each element has a specific job, and together they form a system that powers the machine efficiently.

- Pistons: These components move up and down within the cylinders, converting the energy from fuel combustion into mechanical power.

- Cylinders: The chambers where fuel combustion occurs. The number and size of cylinders directly affect the engine’s power output.

- Crankshaft: Converts the linear motion of the pistons into rotational energy, driving the wheels or other parts of the machinery.

- Camshaft: Controls the opening and closing of the valves, ensuring the correct timing for fuel intake and exhaust release.

- Valves: Allow air and fuel into the cylinders and let exhaust gases escape after combustion. They open and close in precise timing with the engine’s cycle.

- Fuel Injectors: Deliver the right amount of fuel into the combustion chambers at the correct intervals, ensuring efficient burning of the fuel.

- Cooling System: Prevents the engine from overheating by circulating

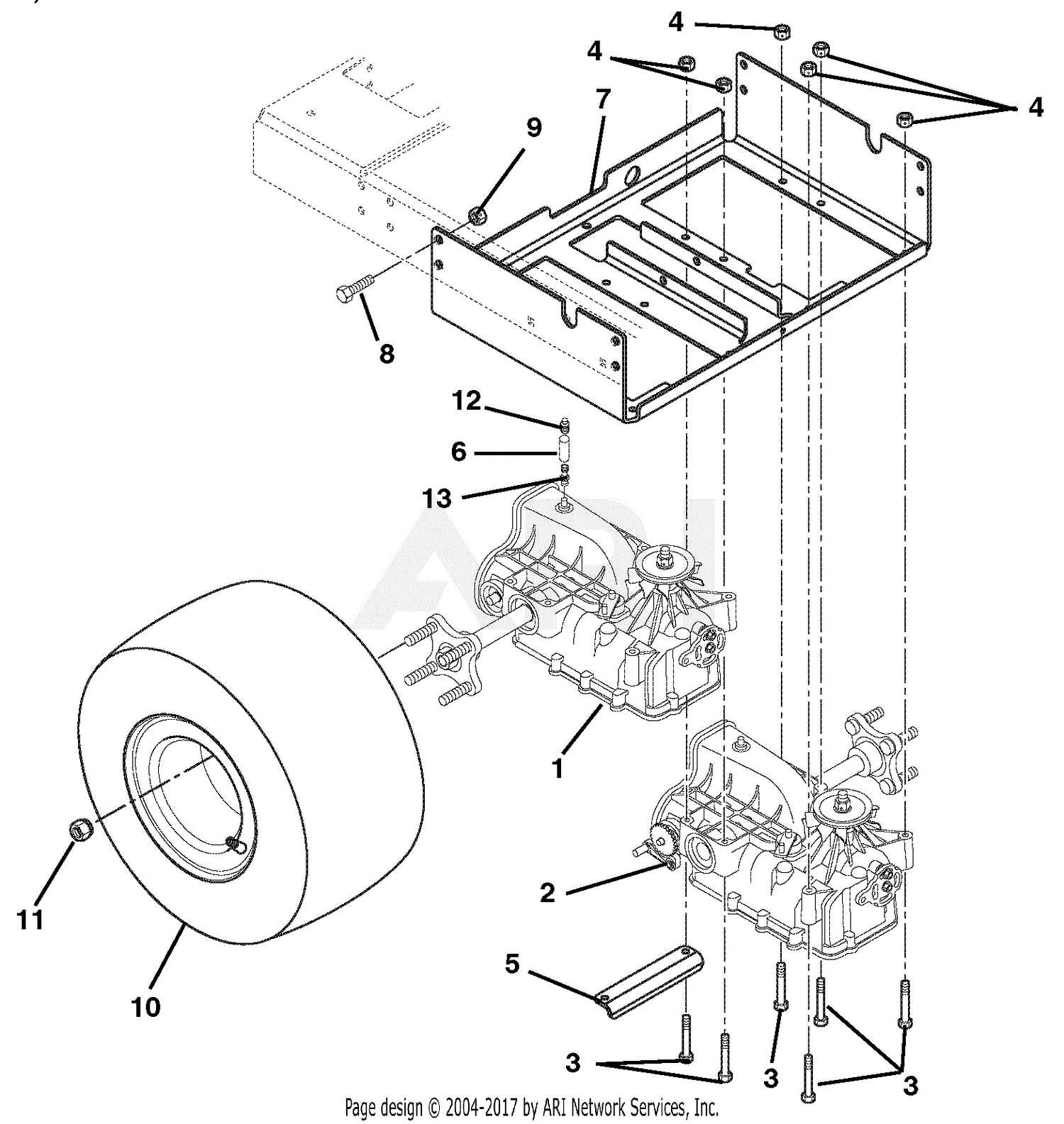

Hydraulic System Overview

The hydraulic system powers various components by transmitting fluid under pressure, enabling smooth and efficient operation of the machinery. It ensures precise control of movement, making it a key element for performance and stability.

Below are the main features of the hydraulic system:

- High-pressure fluid transmission for consistent power delivery.

- Pumps that generate the necessary fluid flow to the actuators.

- Valves that regulate fluid direction and pressure.

- Filters to ensure clean fluid and prevent system damage.

- Reservoirs for storing hydraulic fluid at the required levels.

These components work together to maintain operational control, preventing overloads and ensuring responsive actions.

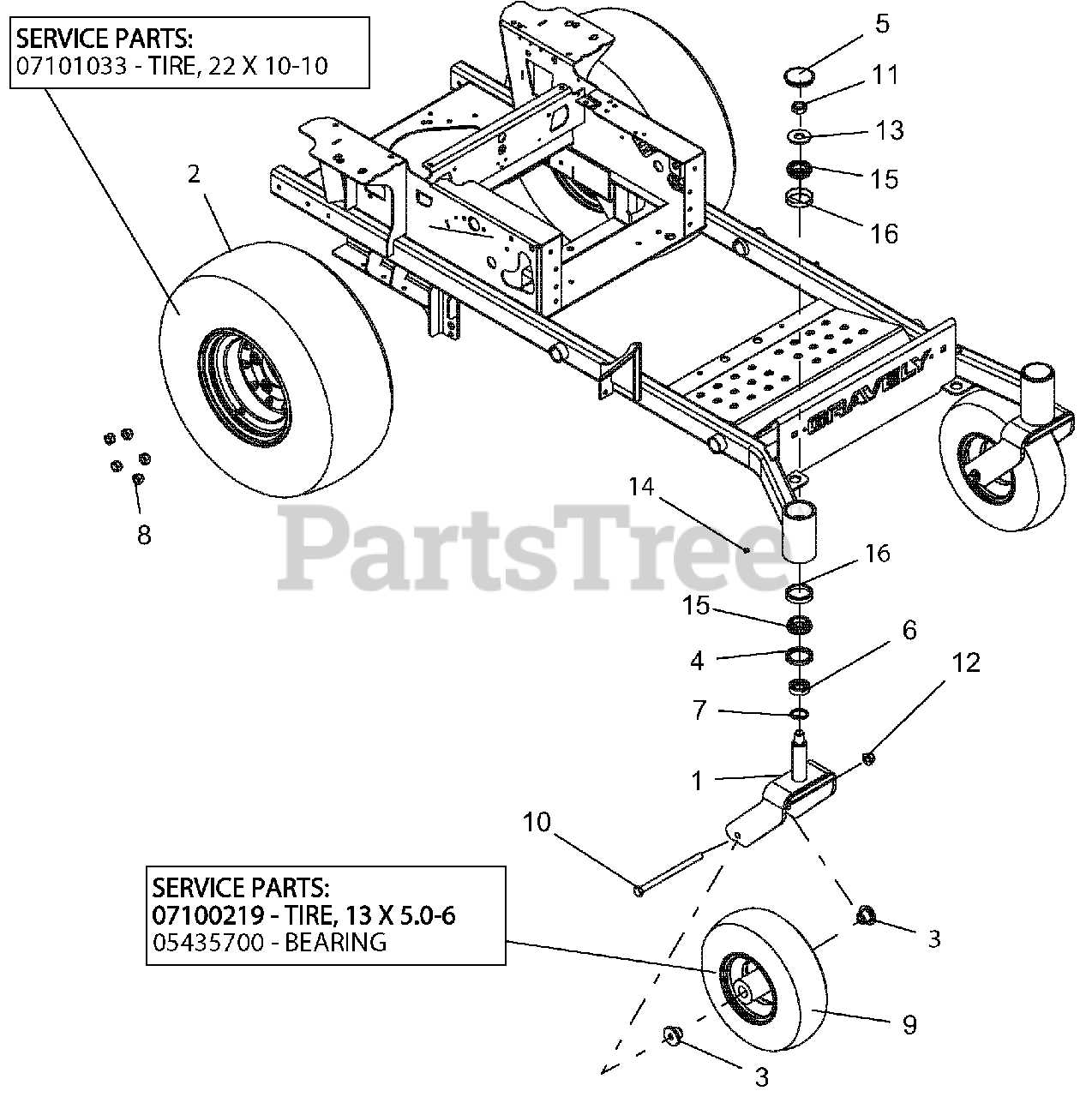

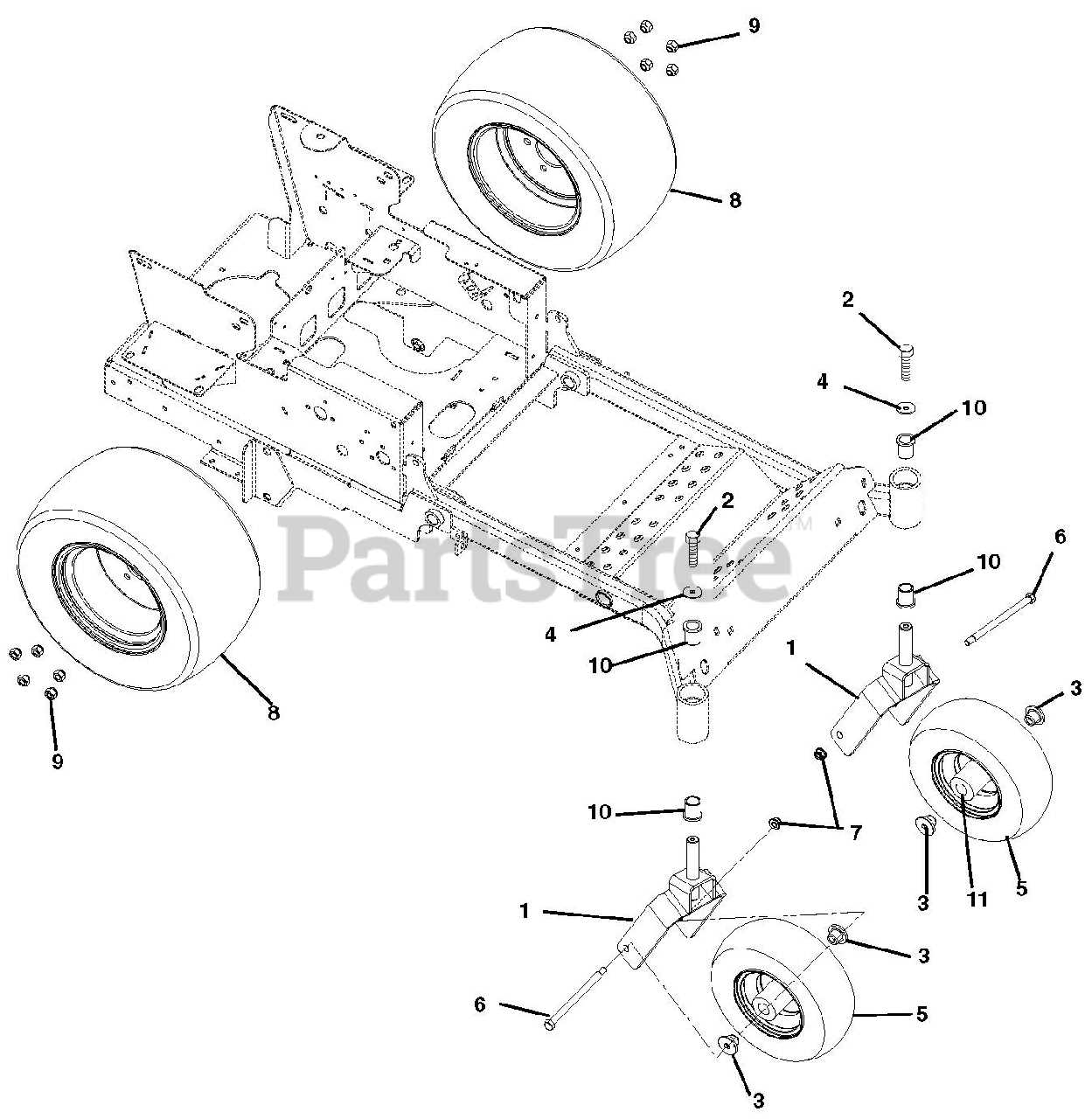

Understanding the Steering Mechanism

The steering mechanism of a riding machine operates through a system of levers and hydraulic controls, designed to ensure precise direction and smooth movement. This system is key for controlling the motion, allowing the operator to maneuver effectively in different conditions.

At its core, the mechanism relies on the balance between two independent drive systems, which can be adjusted individually to control the speed and direction of the machine. This approach provides excellent maneuverability and makes tight navigation possible without much physical effort from the operator.

Another critical aspect is the hydraulic component that responds to steering inputs, distributing power efficiently to the wheels. Proper understanding of how these hydraulic controls interact with the steering ensures smoother operation and reduces wear over time.

Maintenance of this system is essential, as regular checks of the hydraulic fluid and adjustments to the lever sensitivity will extend the machine’s lifespan and improve overall performance.

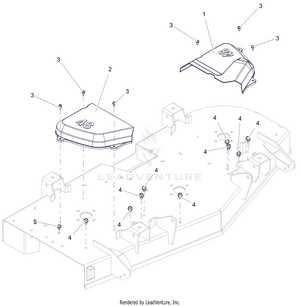

Deck and Blade Assembly Details

This section provides an overview of the assembly components related to the cutting deck and blades, crucial for maintaining optimal performance in lawn care equipment. Understanding these elements can help users ensure efficient operation and extend the lifespan of their machinery.

Components of the Cutting Deck

- Chassis: The main structure that supports all other components.

- Deck Shell: The outer casing that protects and houses the blades.

- Spindles: These rotating parts hold the blades and allow them to spin freely.

- Blade Mounts: Connectors that attach blades to the spindles securely.

- Adjustment Mechanism: A system that enables height adjustments for different mowing conditions.

Blade Specifications

- Material: Typically made from high-strength steel for durability.

- Length: Varies depending on the model, usually measured in inches.

- Design: May include mulching features or standard cutting edges.

- Sharpening: Regular maintenance required to maintain cutting efficiency.

Electrical System Breakdown

The electrical system in lawn maintenance equipment plays a crucial role in its overall functionality and performance. Understanding its components and how they interact is essential for efficient troubleshooting and maintenance.

Main Components: The core elements include the battery, ignition system, wiring harness, and various switches. Each part must function properly to ensure reliable operation.

Common Issues: Problems often arise from faulty connections, worn-out switches, or battery failures. Regular inspection can prevent unexpected breakdowns and extend the lifespan of the machinery.

Maintenance Tips: Keeping connections clean, ensuring secure fittings, and checking for signs of wear can significantly enhance the reliability of the electrical system. Additionally, replacing components at the first sign of trouble can save time and resources.

Fuel System Components Explained

The fuel system in a lawn care machine plays a crucial role in ensuring efficient operation and performance. Understanding the various elements involved in this system can help users maintain their equipment effectively and troubleshoot issues that may arise.

Component Function Fuel Tank Stores fuel required for operation. Fuel Pump Delivers fuel from the tank to the engine. Fuel Filter Removes impurities and debris from the fuel. Fuel Lines Convey fuel between the tank, pump, and engine. Carburetor Mixes air and fuel for optimal combustion. Troubleshooting Common Wear and Tear

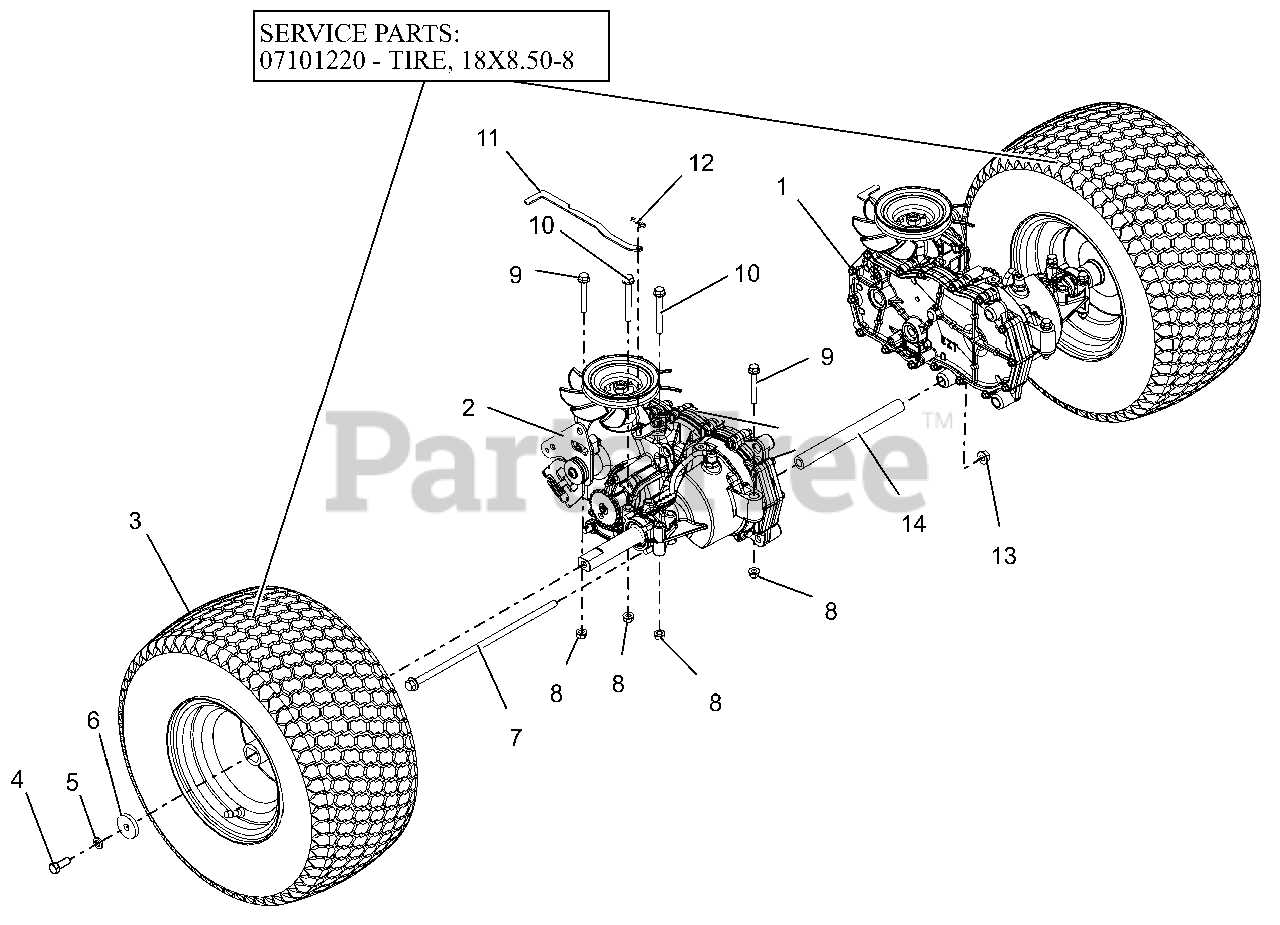

Understanding the typical signs of deterioration in machinery is essential for maintaining optimal performance. Regular inspection can help identify issues before they escalate, ensuring longevity and efficiency. This section focuses on recognizing common problems that arise from regular use and how to address them effectively.

Identifying Signs of Damage

Routine checks should include examining belts, blades, and wheel assemblies for any visible signs of wear. Cracks, fraying, or unusual sounds during operation can indicate underlying issues. Early detection is crucial for preventing further damage and costly repairs.

Effective Solutions for Repair

When issues are identified, replacing worn components or tightening loose fittings can often resolve the problem. Regular maintenance routines, including lubrication and cleaning, will also help extend the lifespan of your equipment. Implementing these practices ensures your machinery remains in peak condition.

Maintenance Tips for Key Parts

Proper upkeep of essential components is crucial for ensuring the longevity and efficiency of your equipment. Regular attention can prevent common issues and enhance performance.

Regular Inspections

- Conduct routine checks to identify wear and tear.

- Examine belts and blades for any signs of damage.

- Ensure all connections are secure to avoid operational disruptions.

Cleaning and Lubrication

- Clean debris and dirt from all surfaces to prevent buildup.

- Apply lubricant to moving parts regularly to reduce friction.

- Replace filters as needed to maintain air quality and efficiency.

Upgrading Essential Machine Parts

Enhancing crucial components of your equipment can significantly improve its performance and longevity. By focusing on key areas such as cutting blades, engines, and transmissions, you can optimize efficiency and ensure smoother operation. Regularly assessing these elements allows for timely upgrades that prevent larger issues down the line.

Investing in high-quality replacements or advanced alternatives not only boosts functionality but also enhances safety and reliability. Whether it’s upgrading to a more robust engine or choosing precision-engineered components, each enhancement contributes to a better overall user experience. Prioritize regular maintenance checks to identify areas for improvement, ensuring your machine operates at its best.