Understanding the placement and structure of mechanical assemblies is essential for keeping equipment in top condition. A clear overview of how various elements connect allows for quick troubleshooting and smooth servicing, minimizing downtime and ensuring consistent operation.

This section provides a detailed look at how key elements are organized within a widely used model. By examining individual components and their interconnections, users can better comprehend the overall structure, identify potential issues, and replace worn-out items efficiently.

Whether you are a seasoned technician or a newcomer, having a reliable reference that outlines essential connections and configurations ensures that every maintenance step is taken with precision and confidence.

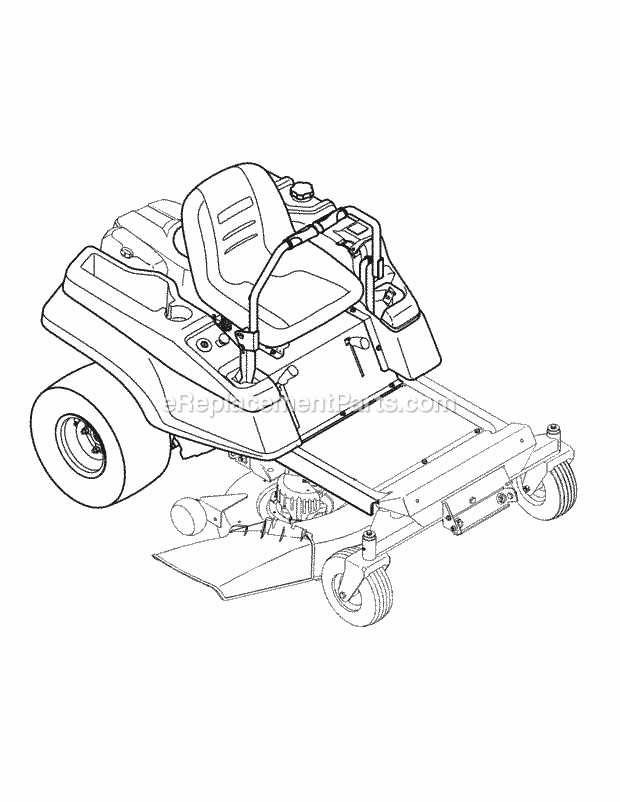

Key Components of Riding Equipment

Understanding the essential elements of powered lawn tools ensures smooth operation and longevity. Each mechanism plays a vital role in maintaining performance, supporting seamless motion, and ensuring safety during use.

- Power Unit: This section drives the machine, converting fuel or electrical energy into mechanical force for movement and operation.

- Transmission System: Responsible for transferring power from the engine to the wheels, enabling controlled acceleration and speed adjustments.

- Steering Mechanism: Allows precise control over direction, ensuring stability and maneuverability, even in tight spaces.

- Cutting Assembly: Designed for efficient grass trimming, it includes blades and housing to facilitate consistent results.

- Drive Wheels and Tires: Provide traction and stability on various terrains, improving control and safety during movement.

- Control Interface: A set of levers, pedals, or switches that allow the operator to manage speed, direction, and other essential functions.

- Frame and Chassis: The structural base that supports all components, ensuring durability and proper weight distribution.

By recognizing these core elements, users can better maintain their equipment, ensuring optimal functionality and extended service life.

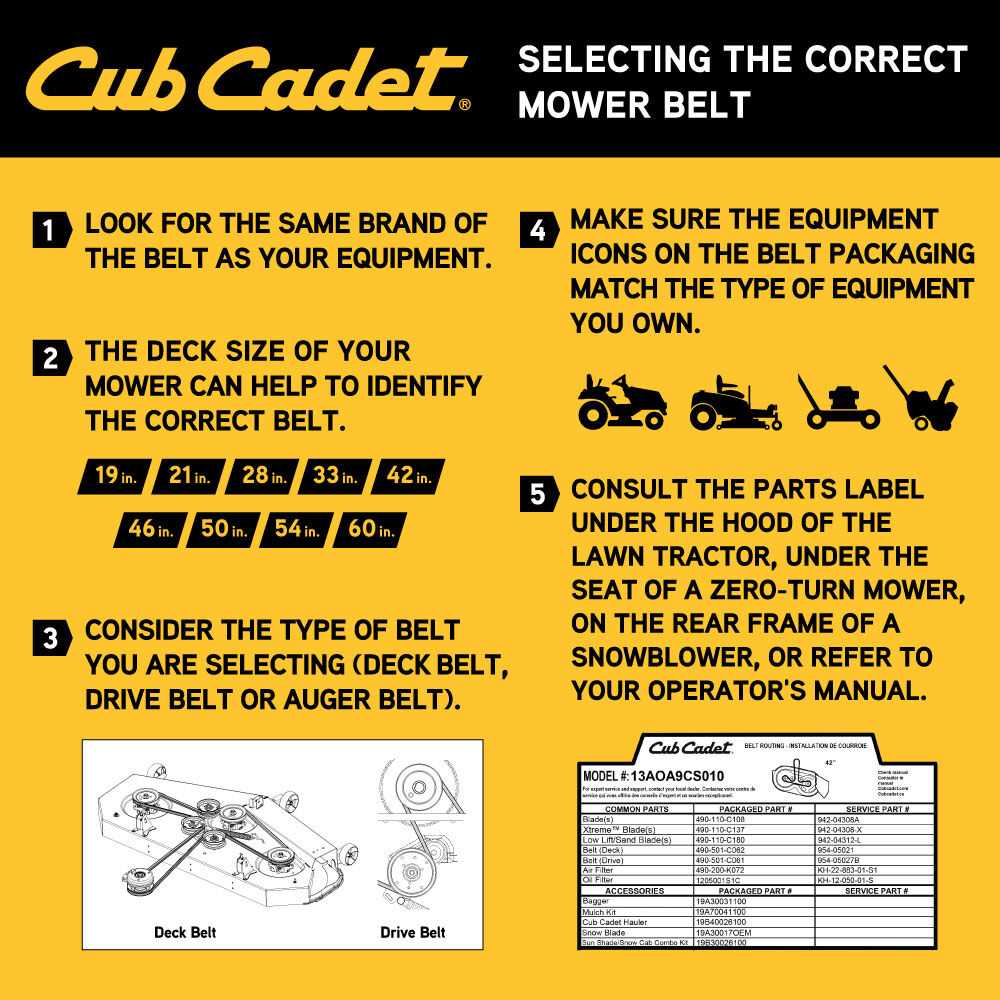

Understanding Deck Assembly Layout

The layout of the deck is an essential aspect to ensure optimal performance and functionality of any machine designed for cutting operations. The arrangement of various components influences not only the efficiency but also the durability and ease of maintenance. A clear understanding of the structure helps in identifying key sections that require attention during assembly or troubleshooting.

Key Components Overview

Several critical elements contribute to the overall functionality of the deck. These include the positioning of the blades, the belt configuration, and the mounting system. Each part plays a specific role, and their alignment ensures smooth and effective operation. Understanding how these components interact is crucial for maintaining peak performance.

Importance of Proper Alignment

Maintaining proper alignment of the deck’s elements is vital for achieving an even cut and avoiding unnecessary wear. Misalignment can lead to uneven performance and reduce the machine’s lifespan. Regular checks of the blade height and tension of the belts are essential steps in ensuring everything functions as intended.

Wheels and Tires for Smooth Operation

Maintaining the right balance between traction and movement ensures optimal performance. The rotating components at the base are crucial for efficient handling, whether on uneven surfaces or flat terrains. Their design and condition directly affect stability and control, making regular inspection essential.

Choosing the right material can enhance grip and reduce wear over time. Pneumatic options offer better cushioning for rougher areas, while solid alternatives are preferred for durability and minimal maintenance. Selecting the appropriate type ensures better maneuverability and efficiency in different working conditions.

Periodic maintenance, such as checking for air pressure and monitoring surface wear, helps prevent issues during operation. Timely replacements not only extend the lifespan of these essential components but also ensure smoother rides and reduced vibration during use.

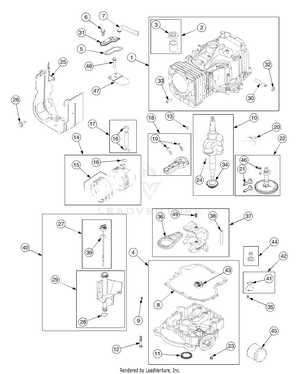

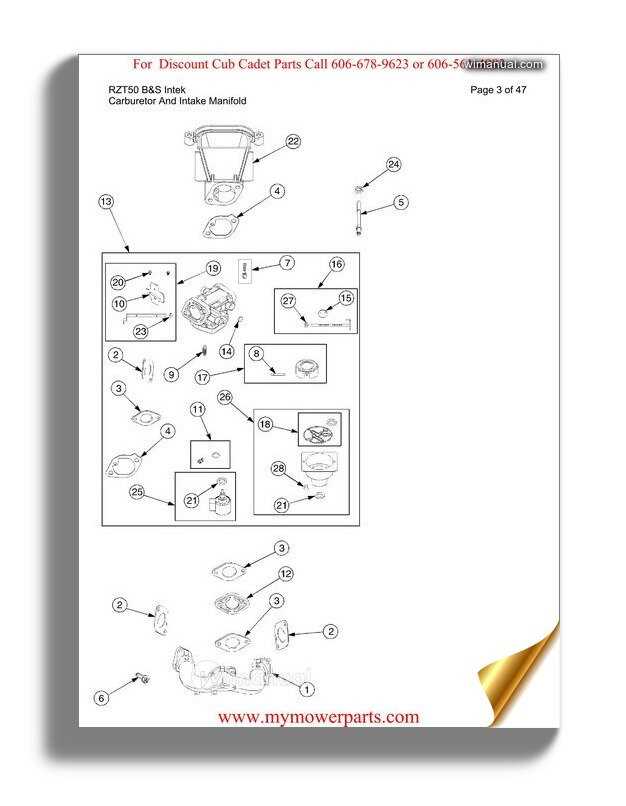

Identifying Engine Section Elements

This section explores the key mechanical components found in the power unit, highlighting essential elements responsible for performance and operation. Understanding the configuration and function of these elements ensures smoother troubleshooting and effective maintenance.

- Ignition System: Initiates combustion within the chamber by generating the necessary spark at the right moment.

- Air Intake: Draws in and regulates the airflow required for proper combustion, affecting fuel efficiency.

- Fuel Delivery: Supplies the engine with the precise amount of fuel for optimal operation, ensuring energy is converted efficiently.

- Cooling Mechanism: Maintains temperature balance by dissipating excess heat, preventing overheating during operation.

- Exhaust Outlet: Expels gases produced during combustion, keeping emissions under control and maintaining performance.

Each element plays a vital role in ensuring the engine runs smoothly, with proper synchronization between these systems being crucial for sustained efficiency and durability.

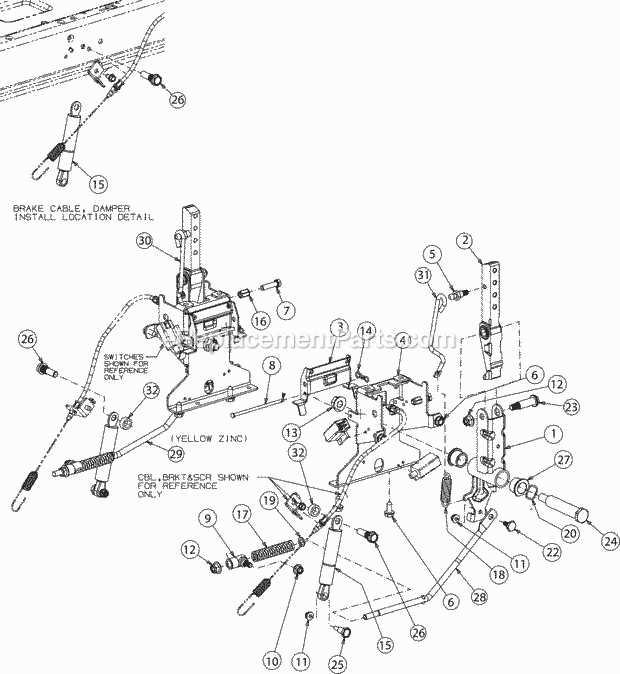

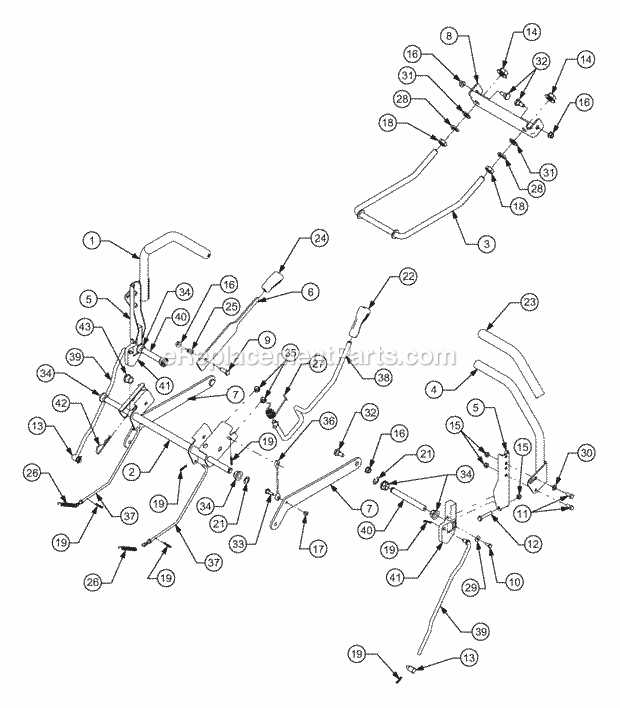

Steering Mechanism Overview and Design

The steering system plays a crucial role in maintaining smooth control and precise handling. It ensures that directional changes are executed efficiently, allowing for stable movement across various terrains. This section delves into the underlying structure and functional components responsible for managing directional input.

- Control Linkages: Connect the steering wheel to mechanical components, translating rotational input into movement of the wheels.

- Pivots and Bearings: Facilitate smooth rotation and reduce friction, ensuring that turning efforts are minimized during operation.

- Tie Rods: Maintain alignment between the front wheels, ensuring synchronized motion and reducing uneven tire wear.

- Adjustable Components: Enable fine-tuning to correct alignment issues and improve stability over time.

The design also emphasizes durability and ease of maintenance. With robust materials and a modular layout, it ensures that individual elements can be inspected and replaced without disassembling the entire system. This approach simplifies upkeep and extends the overall lifespan of the equipment.

Transmission System: Functions and Structure

The transmission system plays a crucial role in the overall functionality of a machine, facilitating the transfer of power from the engine to the wheels. This complex assembly is designed to ensure smooth operation and effective control, allowing for the seamless movement of the vehicle. Understanding its components and their respective roles is essential for maintaining optimal performance and longevity.

Key Functions

One of the primary functions of the transmission system is to convert the engine’s rotational force into usable torque for propulsion. This is achieved through a series of gears that adjust the output based on the speed and load conditions. Additionally, the system provides the ability to change speeds, enabling the operator to navigate various terrains and conditions effectively.

Structural Components

The structure of the transmission system comprises several integral components, including the gearbox, driveshaft, and differential. Each part works in harmony to transmit power while minimizing energy loss. The gearbox houses multiple gears that engage and disengage as needed, while the driveshaft transfers the power to the wheels. The differential allows for the distribution of power to the wheels, ensuring stability and traction during movement.

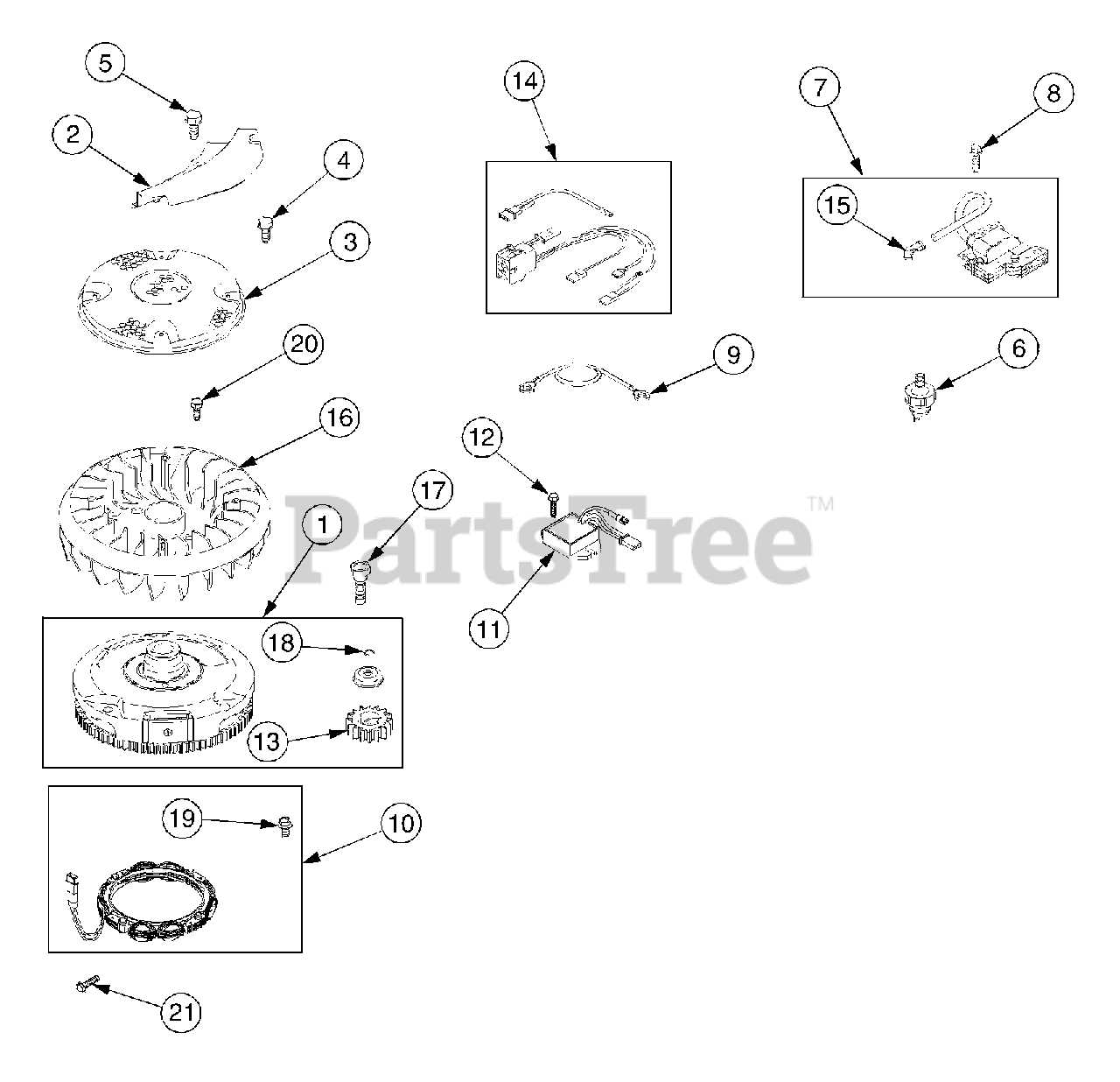

Electrical Connections and Circuit Routes

This section explores the fundamental aspects of electrical linkages and pathways within the machinery. Understanding these connections is crucial for ensuring optimal functionality and reliability of the device. Each circuit route plays a vital role in the seamless operation of various components, and a comprehensive grasp of their layout facilitates effective troubleshooting and maintenance.

Key Components of Electrical Systems

- Wiring Harness: The network of wires that transmits power and signals.

- Connectors: Junction points that allow for easy assembly and disassembly of components.

- Switches: Devices that control the flow of electricity within the system.

- Fuses: Safety devices that protect circuits from overloads.

Understanding Circuit Pathways

- Power Supply: The origin of electrical energy for the system.

- Distribution: How power is routed to various components.

- Grounding: Ensuring safety and preventing electrical faults.

- Signal Flow: Pathways for data transmission between parts.

By familiarizing oneself with these elements, one can ensure that electrical operations run smoothly and efficiently, thereby enhancing overall performance and longevity.

Blade Mechanism and Cutting Performance

The efficiency of a mowing apparatus relies heavily on the design and functionality of its cutting components. Understanding how these elements work together can greatly enhance the overall performance and longevity of the equipment.

At the core of this system is the cutting assembly, which consists of various interconnected elements that ensure a precise and effective grass trimming experience. Key features include:

- Blade Design: The shape and sharpness of the blades play a crucial role in how effectively they slice through grass, affecting the quality of the cut.

- Rotation Mechanism: The way blades are rotated can influence cutting efficiency. A higher rotational speed typically leads to a cleaner and more uniform cut.

- Height Adjustment: The ability to modify the height at which the blades operate allows for customization based on grass type and desired length.

- Material Quality: Durable materials used in blade construction can prevent wear and tear, ensuring sustained performance over time.

Proper maintenance of these components is vital. Regular sharpening of the blades, along with inspection of the rotation system, can prevent issues such as uneven cutting or damage to the grass. Additionally, understanding how the cutting mechanism interacts with the terrain can lead to better mowing results, contributing to the overall health and appearance of the lawn.

Maintenance Points and Service Recommendations

Regular upkeep is essential to ensure optimal performance and longevity of your equipment. By adhering to a structured maintenance schedule, you can prevent potential issues and enhance the efficiency of your machinery. This section outlines key maintenance practices and service recommendations that will keep your system running smoothly.

It is advisable to perform routine inspections and servicing, focusing on various components that require attention. Below is a table summarizing important maintenance tasks and their recommended frequency:

| Maintenance Task | Frequency |

|---|---|

| Check and replace the air filter | Every 25 hours of operation |

| Inspect the blades for wear | Every 50 hours of operation |

| Change the engine oil | Every 50 hours or annually |

| Examine tire pressure | Monthly |

| Clean the fuel system | Every 100 hours of operation |

| Check battery connections and terminals | Every season |

In addition to these tasks, always refer to the manufacturer’s manual for specific guidance and adhere to safety protocols during maintenance activities. Regular service not only ensures effective operation but also helps in identifying minor issues before they escalate into major problems.

Seat and Operator Controls Placement

The arrangement of seating and control elements is crucial for ensuring operator comfort and effective machine handling. A well-designed layout facilitates easy access to essential functions while maintaining a safe driving position. This section will explore the optimal positioning of the seat and various control mechanisms, highlighting their roles in enhancing user experience.

Typically, the seat should be positioned to provide clear visibility of the working area and controls. It is vital that the operator can reach all levers, buttons, and pedals without stretching or straining. Adjustable features can further personalize the setup, accommodating operators of varying heights and preferences.

The placement of controls plays a significant role in operational efficiency. Controls should be logically arranged to allow intuitive use, minimizing the need for the operator to divert attention from the task at hand. For instance, throttle and speed adjustment controls are often located near the operator’s right hand for quick access.

Additionally, incorporating safety features, such as seat switches that ensure the operator is seated while the machine is in operation, contributes to the overall safety of the system. Thoughtful integration of seating and controls can greatly improve both functionality and comfort, ultimately leading to better performance and satisfaction.

Chassis Design for Stability and Safety

The framework of a vehicle plays a crucial role in ensuring both balance and security during operation. A well-engineered structure not only supports various components but also enhances the overall performance by minimizing vibrations and maintaining a low center of gravity. This design principle is essential for achieving optimal handling and rider confidence, particularly in challenging terrains.

Key Elements of a Stable Framework

Several factors contribute to a robust framework, including material selection, geometric configuration, and weight distribution. Utilizing high-strength materials allows for a lighter yet durable assembly, reducing the risk of structural failure. Moreover, an optimized layout that evenly distributes weight across the vehicle enhances stability, ensuring that the machine can navigate inclines and uneven surfaces with ease.

Safety Features Integrated into the Structure

Incorporating safety mechanisms into the framework is vital for protecting the operator and preventing accidents. Features such as roll bars and reinforced sections provide additional protection in the event of a tip-over or collision. Furthermore, a thoughtfully designed chassis layout facilitates easy access to maintenance points, allowing for timely inspections and repairs that contribute to long-term safety and reliability.

Fuel System Components and Layout

The efficient operation of any small engine heavily relies on its fuel delivery system. Understanding the various elements and their arrangement is crucial for maintenance and troubleshooting. This section explores the key components involved in the fuel supply mechanism, ensuring optimal performance of the machinery.

- Fuel Tank: The reservoir for storing the fuel, typically made from durable materials to withstand environmental conditions.

- Fuel Lines: Hoses that transport fuel from the tank to the engine, designed to handle the necessary pressure without leaking.

- Fuel Filter: A critical component that removes impurities from the fuel before it reaches the engine, helping to prevent damage.

- Fuel Pump: Responsible for drawing fuel from the tank and delivering it to the engine, ensuring a steady supply during operation.

- Carburetor: This device mixes air and fuel in the correct ratio for combustion, playing a vital role in engine efficiency and performance.

The arrangement of these components is designed to facilitate a smooth flow of fuel, minimizing disruptions and ensuring the engine operates effectively. Regular checks and maintenance of each part contribute to the overall reliability of the system.

Brake and Safety Mechanism Insights

Understanding the intricacies of braking and safety systems is essential for ensuring optimal performance and reliability in various machinery. These components play a pivotal role in maintaining operational control and preventing accidents during use. By examining these mechanisms, operators can enhance their awareness of the essential features that contribute to safety and efficiency.

One critical aspect of these systems involves the integration of various elements designed to prevent unintended movement and provide responsive braking. Below is a brief overview of some fundamental components commonly found in these systems:

| Component | Description |

|---|---|

| Brake Lever | Engages the braking system to slow down or stop the machinery effectively. |

| Safety Switch | Automatically disengages the engine when the operator leaves the seat, enhancing safety. |

| Foot Pedal | Allows the operator to apply brakes with ease while maintaining control over the machine’s speed. |

| Parking Brake | Holds the machine stationary when not in operation, preventing accidental movement. |

Incorporating these elements effectively contributes to a comprehensive safety framework, safeguarding users while optimizing functionality.