For anyone maintaining a high-performance lawn care machine, it’s essential to be familiar with the various components and their arrangement. Whether you are looking to replace a specific element or perform routine upkeep, knowing how each part works in harmony is key to keeping your equipment in top shape.

In this guide, we’ll delve into the structure of this well-known zero-turn mower model. By examining the layout of key elements, you will gain a clearer understanding of how everything is interconnected, making both troubleshooting and maintenance more straightforward.

As we explore the detailed arrangement of each component, you’ll find tips on how to manage upkeep, what to look for when certain elements need replacement, and how to ensure the machine continues to operate efficiently. Whether you’re a professional or a weekend gardener, this guide will serve as a helpful resource for maintaining

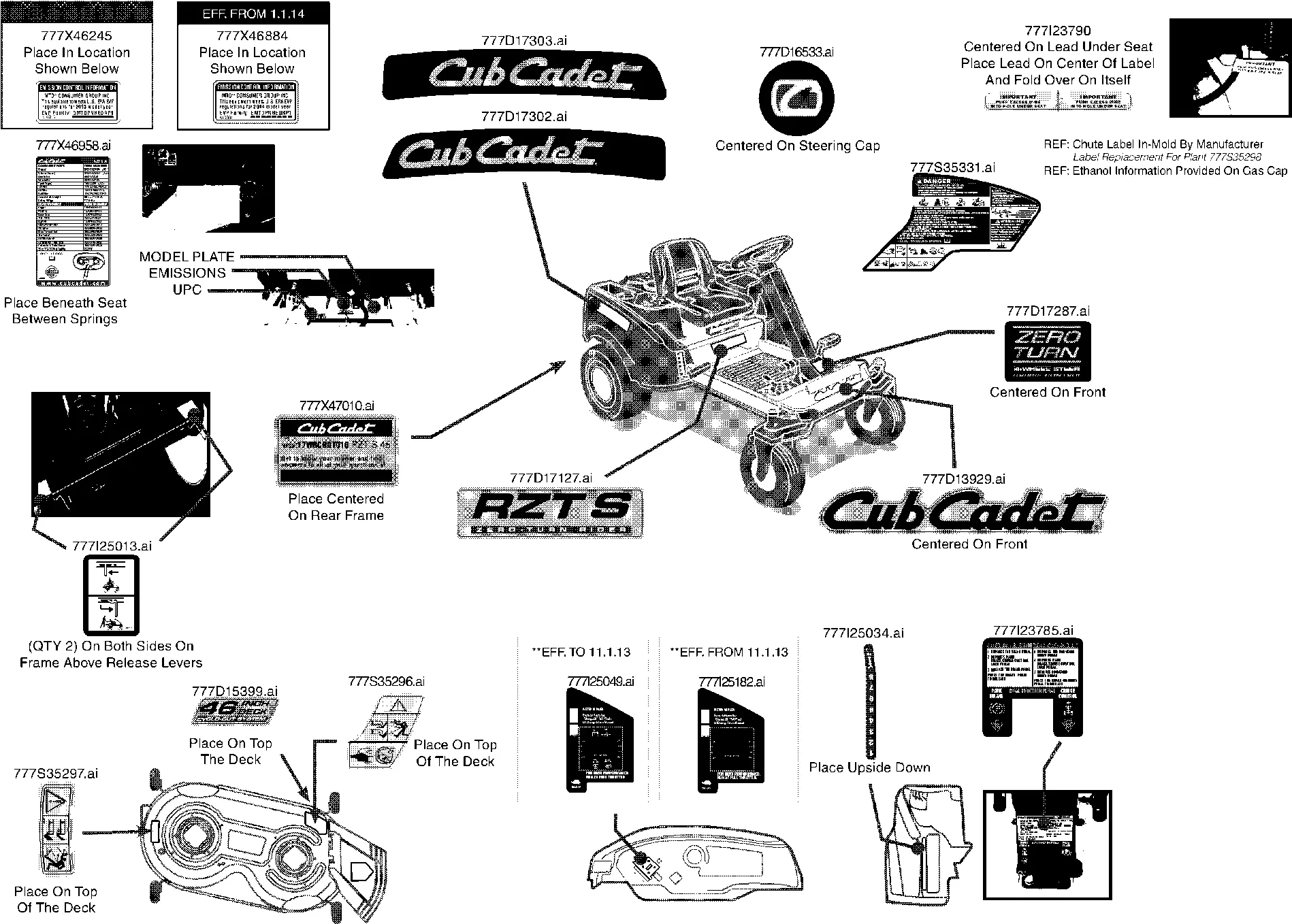

Overview of Cub Cadet RZT Parts

Maintaining your equipment requires understanding the essential components that make it function effectively. These elements work together to ensure smooth operation and long-term reliability. A well-structured system allows for optimal performance, reducing downtime and the need for frequent repairs.

Key Mechanical Elements

Each section of the equipment is built with precision to handle specific tasks. From the engine to the transmission system, these critical components are designed to withstand rigorous conditions. Proper care and timely maintenance are essential to ensure the longevity of these parts, ensuring a seamless experience when in use.

Functional Assemblies and Systems

The operational systems are composed of various mechanical and electrical assemblies that synchronize to deliver efficient results. Understanding how these assemblies interact can help in identifying potential issues early, allowing you to address them before they

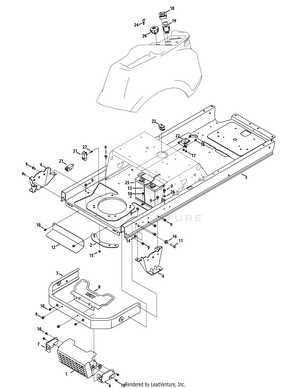

Understanding the RZT Mower Structure

The construction of a zero-turn mower is designed to provide efficient and precise lawn care. Its framework combines various elements, each with a specific purpose, allowing for optimal performance on different terrains. By understanding the individual components and how they interact, one can maintain and operate the mower more effectively.

Frame and Chassis

The frame forms the backbone of the machine, providing structural integrity and support for all its mechanical and electrical systems. A robust chassis ensures durability and stability, allowing the mower to handle

Key Components of the Riding Mower

The riding mower is built with essential elements that work together to provide efficient and smooth performance. Understanding these fundamental parts helps to ensure proper maintenance and optimize the functionality of the machine.

Engine: The heart of the machine, responsible for powering the entire system. Regular upkeep of this component is crucial for sustained performance.

Transmission System: This mechanism controls the movement and speed, ensuring smooth transitions

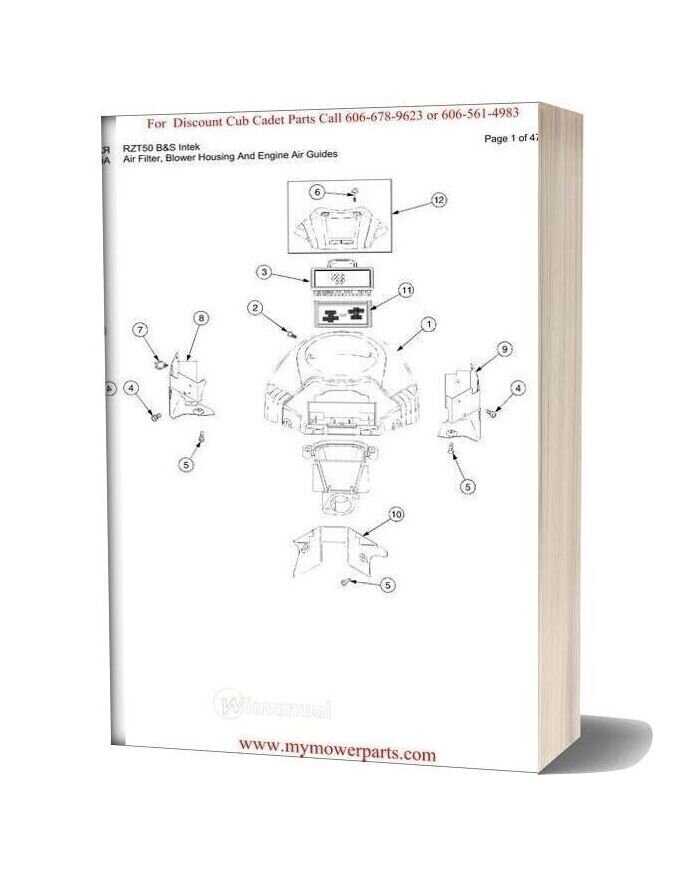

Engine Parts Breakdown for RZT Mowers

Understanding the key components of a mower’s motor is essential for maintaining its performance and ensuring longevity. This section offers a detailed overview of the essential elements, explaining how each part contributes to the efficient operation of the machine. By familiarizing yourself with the individual components, you can better diagnose issues and perform necessary maintenance or replacements.

Main Engine Components

- Cylinder Block – The foundation of the motor, housing various internal parts responsible for the combustion process.

- Crankshaft – Converts the linear motion from the pistons into rotational energy, which drives the mower forward.

- Pistons – Move up and down within the cylinder to compress fuel and air, initiating the combustion process.

- Valves – Regulate the flow of

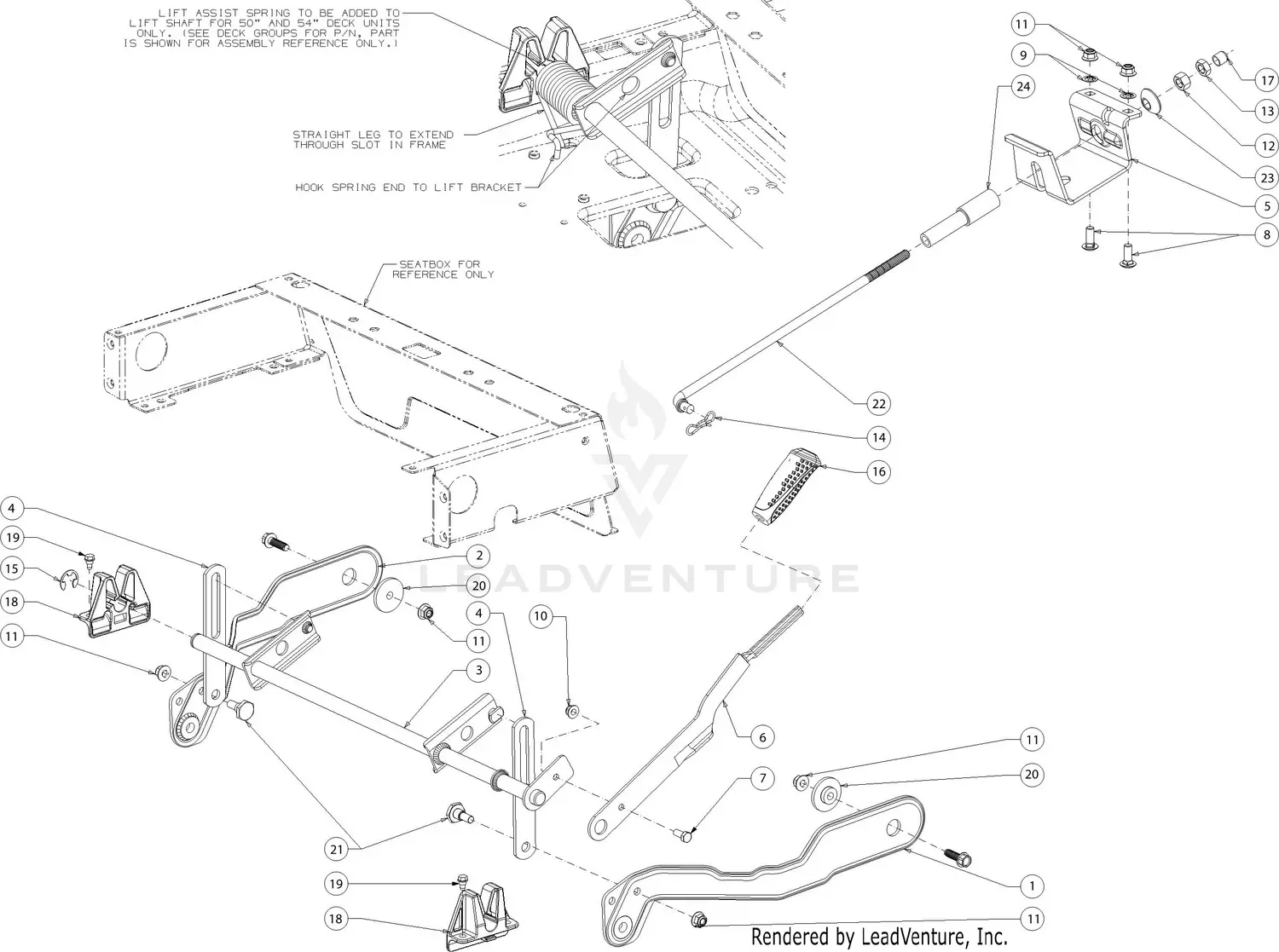

Steering Mechanism Parts and Function

The steering system is crucial for the precise control and maneuverability of any vehicle. It allows the operator to direct the vehicle smoothly, ensuring that turns and adjustments are made with minimal effort. A well-functioning steering system provides stability and safety, making it easier to navigate through different terrains.

Understanding the key components of the steering mechanism and their individual roles is essential for maintaining optimal performance. Below is a breakdown of the main elements and their functions within the steering system:

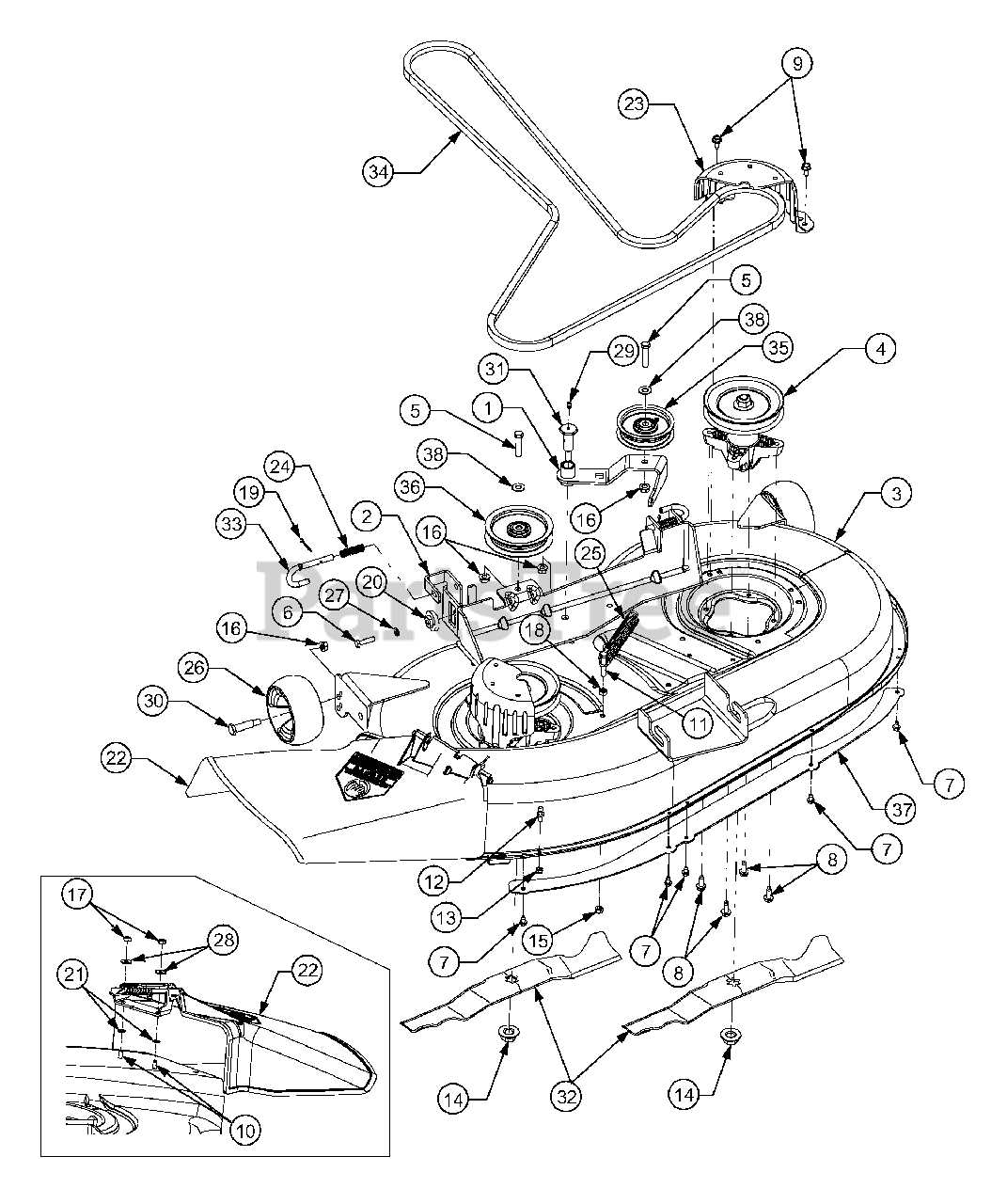

Component Function Steering Wheel Provides the input force to initiate directional changes, allowing the operator to control the direction of the vehicle. Steering Column Connects the Deck Assembly and Cutting Blades

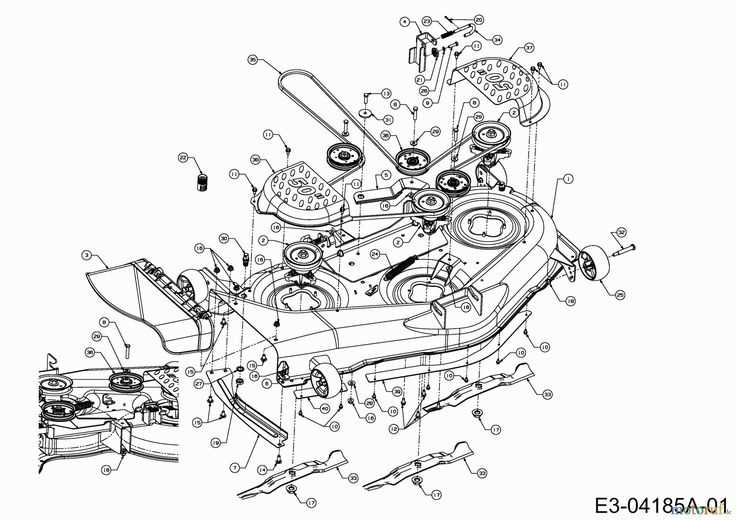

The assembly of the mowing deck and the cutting elements plays a crucial role in ensuring optimal performance and efficiency of your lawn maintenance equipment. Proper installation and maintenance of these components contribute significantly to achieving a clean and even cut, enhancing the overall quality of your lawn care routine.

Components of the Mowing Deck

- Deck Shell: The main structure that houses the cutting blades and provides protection.

- Spindle Assemblies: These house the cutting blades and allow for their rotation, facilitating effective grass trimming.

- Adjustable Hangers: These components enable height adjustments for the deck, allowing for customization based on grass type and terrain.

- Anti-Scalp Wheels: These prevent the deck from digging into the ground, ensuring a smooth mowing experience.

Cutting Blades Maintenance

Maintaining the cutting blades is essential for achieving the best results. Regular inspection and sharpening of the blades can prevent tearing of the grass, promoting healthier growth. Follow these steps for effective blade care:

- Check blades for wear and damage.

- Sharpen blades regularly to maintain a clean cutting edge.

- Replace dull or damaged blades to ensure optimal performance.

- Clean the underside of the deck to remove grass clippings and debris.

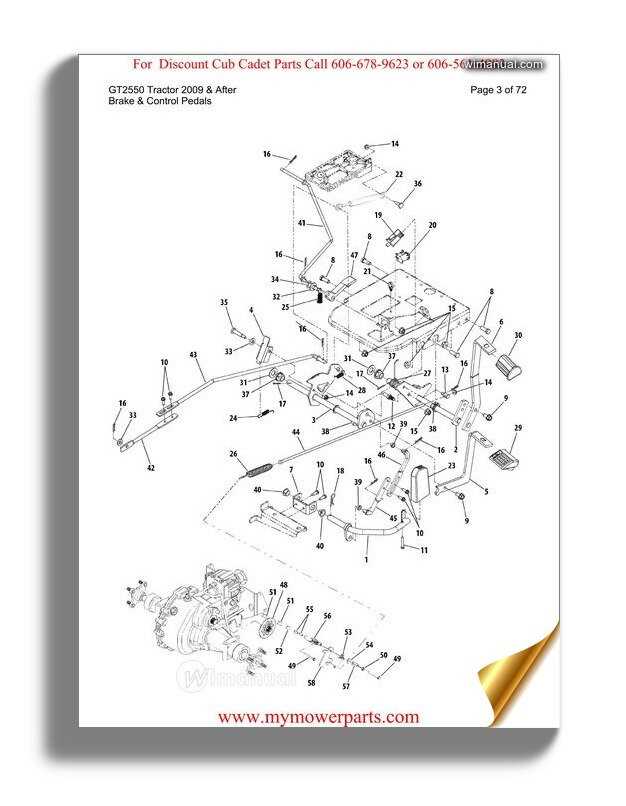

Transmission System and Drive Components

The transmission system plays a vital role in the efficient operation of various machinery, ensuring that power generated by the engine is effectively transferred to the wheels. This system encompasses several components that work in harmony to provide optimal performance, enabling the equipment to navigate various terrains and handle diverse tasks.

Key elements of the transmission system include:

- Gearbox: The gearbox adjusts the torque and speed delivered to the wheels, allowing for efficient movement across different surfaces.

- Driveshaft: This component connects the gearbox to the axles, transmitting power while allowing flexibility during operation.

- Clutch: The clutch facilitates smooth engagement and disengagement of the engine from the transmission, allowing for controlled acceleration and deceleration.

- Brakes: Essential for stopping and controlling the speed of the machinery, brakes are integral to the safety and functionality of the system.

Regular maintenance of these components is crucial for ensuring longevity and peak performance. Routine checks can help identify wear and tear, allowing for timely replacements or repairs. By understanding the intricacies of the transmission system and its associated drive elements, users can optimize their machinery’s performance and extend its lifespan.

Electrical System Overview for the RZT

The electrical system of a riding mower is a vital component that ensures the proper functioning of various features, from ignition to lighting. Understanding the intricacies of this system can enhance maintenance practices and troubleshooting efforts. This section will provide insights into the essential elements and functions of the electrical system.

- Battery: The heart of the electrical system, supplying power to all components.

- Ignition Switch: Controls the starting and stopping of the engine, ensuring safety and convenience.

- Wiring Harness: A network of cables that connects all electrical parts, facilitating communication between them.

- Fuses: Safety devices that protect the electrical system from overloads and short circuits.

- Starter Motor: Engages the engine, converting electrical energy into mechanical power to initiate operation.

Regular inspections of the electrical components are crucial for maintaining optimal performance. Identifying worn or damaged parts early can prevent more significant issues and extend the lifespan of the equipment. Additionally, understanding the role of each element can simplify repairs and upgrades, allowing for a more efficient operation.

Fuel System Components and Maintenance

The fuel system is essential for the efficient operation of any outdoor power equipment, as it ensures that the engine receives the proper amount of fuel for optimal performance. Understanding the various elements involved in this system and their maintenance requirements can significantly enhance the longevity and reliability of the machine.

Key components of the fuel system include:

- Fuel Tank: This is where the fuel is stored before being delivered to the engine.

- Fuel Filter: It removes impurities and contaminants from the fuel to prevent engine damage.

- Fuel Pump: Responsible for transporting fuel from the tank to the engine.

- Fuel Lines: These are the hoses that carry fuel between the tank, pump, and engine.

- Carburetor or Fuel Injector: This component mixes air and fuel for combustion.

Regular maintenance of the fuel system is crucial for ensuring optimal performance and preventing potential issues. Recommended maintenance practices include:

- Regularly check and clean the fuel filter to ensure proper fuel flow.

- Inspect fuel lines for leaks, cracks, or wear, replacing them as necessary.

- Keep the fuel tank clean and free from debris to avoid contamination.

- Use fresh fuel to minimize the risk of engine starting issues and performance degradation.

- Periodically clean the carburetor or check the fuel injectors for optimal fuel mixing.

By following these maintenance tips, operators can enhance the performance and extend the lifespan of their outdoor equipment, ensuring reliable operation for years to come.

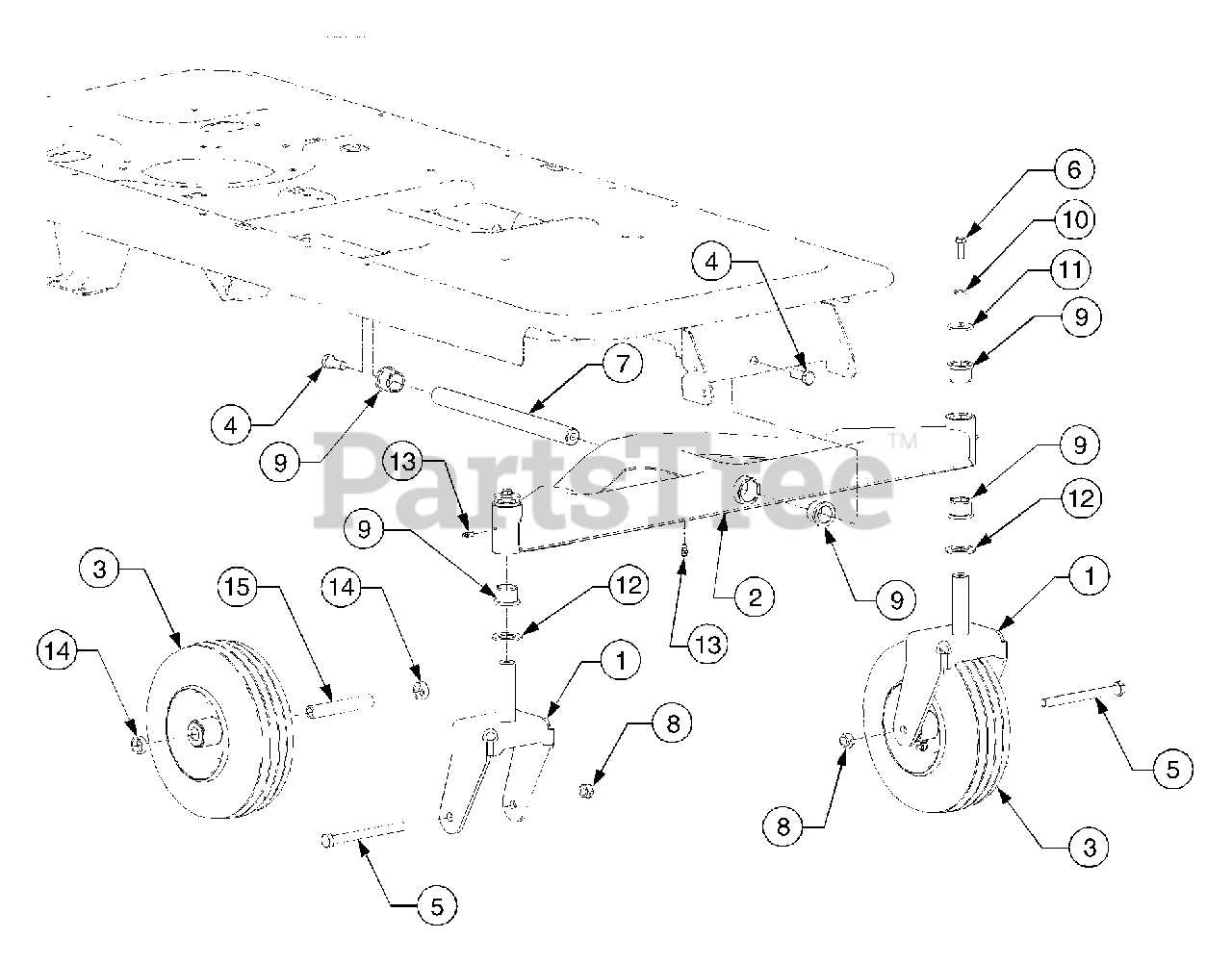

Suspension and Wheel Assembly Details

The suspension and wheel assembly play a critical role in the overall performance and stability of any outdoor equipment. These components work together to provide a smooth ride, ensuring that the machine can effectively navigate various terrains while maintaining user comfort. Understanding the intricacies of these assemblies is essential for proper maintenance and optimal functionality.

Components of the Suspension System

The suspension system consists of several key elements, including springs, shock absorbers, and linkages. Springs absorb shocks from uneven surfaces, enhancing ride quality and stability. Shock absorbers control the oscillation of the springs, preventing excessive bouncing and ensuring better traction. Additionally, the linkages connect the different parts of the suspension, allowing for coordinated movement during operation.

Wheel Assembly Mechanics

The wheel assembly is composed of various parts that contribute to the overall mobility of the equipment. Key components include the wheel rims, tires, and hubs. The wheel rims provide structural support for the tires, while the hubs serve as the central connection point, allowing the wheels to rotate freely. Proper maintenance of these components is vital to ensure efficient movement and prevent premature wear.

Seat and Comfort Accessories Breakdown

Understanding the components related to seating and comfort can significantly enhance the user experience. This section delves into the various features and accessories designed to improve seating functionality, adjustability, and overall comfort. By identifying these elements, users can better appreciate the enhancements available for their equipment, ensuring a more enjoyable operation.

Key Features of Seating Accessories

Seating accessories encompass a range of functionalities aimed at providing support and convenience. These features may include adjustable armrests, cushioned seats, and ergonomic designs that promote proper posture. Each element is designed to contribute to the overall comfort and usability of the machine.

Comfort Enhancements Overview

In addition to basic seating features, several comfort enhancements can be integrated to further improve the user experience. These may involve additional padding, lumbar support, and heating elements. Such enhancements are particularly beneficial during extended use, as they help reduce fatigue and improve productivity.

Accessory Type Description Benefits Adjustable Armrests Supports arms while driving, customizable height and angle. Improved arm comfort, reduced strain. Cushioned Seat Soft padding for enhanced seating comfort. Increased comfort during long periods of use. Lumbar Support Supportive feature that promotes proper spine alignment. Reduces back discomfort, enhances posture. Heating Elements Built-in warmth feature for cold weather operation. Increased comfort during colder conditions. Replacement Parts for Common Wear

Every machine has components that experience wear and tear over time. Understanding which elements are prone to deterioration can help users maintain optimal performance and prolong the lifespan of their equipment. This section will explore essential replacements that can enhance efficiency and ensure smooth operation.

Commonly Affected Components

- Belts: Often subject to fraying and stretching, leading to reduced functionality.

- Blades: Regular use can dull cutting edges, requiring timely sharpening or replacement.

- Batteries: Performance diminishes with age, impacting the reliability of the equipment.

- Filters: Clogged filters can hinder airflow and reduce engine efficiency.

- Tires: Wear on treads can affect traction and handling on various terrains.

Maintenance Tips

- Regularly inspect components for signs of wear.

- Keep a maintenance schedule to replace parts proactively.

- Utilize high-quality replacements to ensure compatibility and durability.

- Consult the manufacturer’s guidelines for specific recommendations on replacements.

Troubleshooting with Cub Cadet RZT Diagrams

Effective problem-solving in machinery often relies on detailed illustrations that highlight various components and their interconnections. These visuals serve as valuable resources for identifying issues and ensuring optimal performance. By analyzing these schematics, users can pinpoint malfunctions, streamline repairs, and enhance the longevity of their equipment.

When encountering difficulties, consider the following steps to effectively utilize the provided illustrations:

- Identify the Issue: Begin by observing the symptoms of the malfunction. Is the engine not starting? Are there unusual noises? Document these issues clearly.

- Consult the Visuals: Reference the appropriate schematics to locate the components associated with the identified problem. Pay close attention to connections and wiring.

- Trace the Circuit: Follow the flow of energy through the machine, using the diagrams to understand how each part interacts. This can reveal areas where the problem may reside.

- Perform Systematic Checks: Create a checklist of components to examine based on the visual references. This should include both mechanical and electrical parts.

- Document Findings: Keep a record of any anomalies discovered during the inspection. This can help in diagnosing the root cause more efficiently.

By adhering to these steps and utilizing the provided illustrations, users can effectively diagnose and rectify issues, ensuring their machinery operates at peak efficiency.