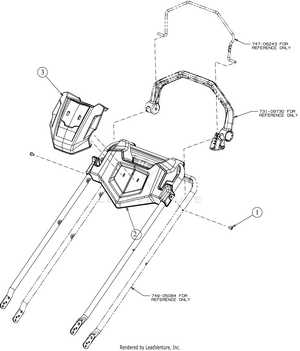

When maintaining your lawn equipment, knowing the structure and arrangement of its essential elements is crucial for proper upkeep and repair. Whether you’re replacing a worn-out piece or troubleshooting an issue, having a clear view of how everything fits together helps streamline the process and ensures smooth operation.

In this guide, we’ll explore the layout and configuration of the key elements that make your outdoor machine function efficiently. From the engine assembly to the cutting mechanisms, understanding how these parts work together can save time and effort during maintenance.

By diving into the specifics of the equipment’s layout, you’ll gain valuable insights into each component’s role, allowing you to handle repairs or replacements with confidence. This knowledge will not only improve your machine’s performance but also extend its lifespan.

Understanding the Structure of Cub Cadet SC500Z

Exploring the design and layout of this advanced lawn machine reveals how various components are arranged to ensure smooth and efficient operation. By understanding the placement and function of different elements, you can better maintain and optimize the equipment for long-term use. This section will provide insight into the main features and their roles within the machine.

| Component | Description | |||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine Assembly | The core power source that drives the machine, delivering the necessary force for movement and blade rotation. | |||||||||||||||||||||||||||||||||||||||||||||

| Cutting Deck | The area where the blades are housed, designed to cut grass at various heights with precision and efficiency. | |||||||||||||||||||||||||||||||||||||||||||||

| Drive System |

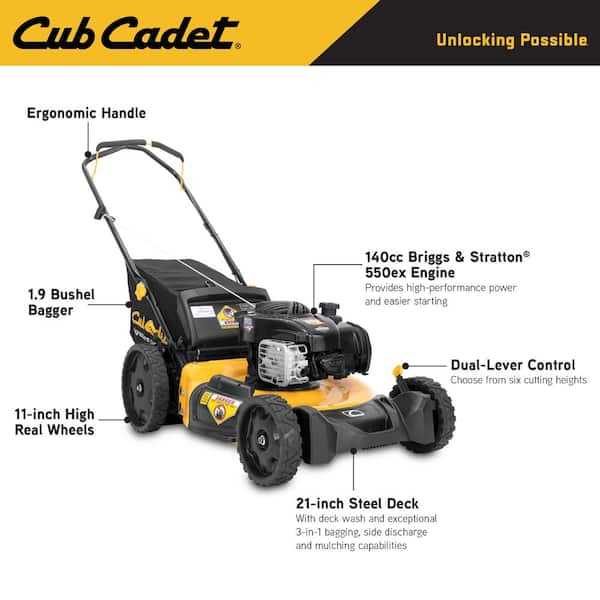

Key Components of the MowerThe mower consists of several essential elements that work together to ensure smooth operation and efficient grass cutting. Each component plays a crucial role in maintaining performance, from propulsion to cutting mechanisms, offering a reliable tool for lawn care. Engine: The heart of the machine, the engine powers the entire system, providing the necessary energy for both movement and blade rotation. It ensures the mower can handle various terrains and cutting conditions with ease. Cutting Deck: This section houses the blades and is responsible for determining the width of the grass cut. A well-designed cutting deck ensures uniform trimming and helps manage the clippings effectively. Drive System: The drive system controls the movement of the mower, allowing users to guide it smoothly across different surfaces. Whether it’s self-propelled or manually operated, the drive system is key to making mowing more manageable. Wheels Engine Parts and Their FunctionsUnderstanding the components that make up the internal structure of a motor is essential for maintaining and optimizing its performance. Each element plays a critical role in ensuring smooth operation and overall efficiency, contributing to the power and reliability of the machine. In this section, we’ll explore some of the most crucial elements, their roles, and how they contribute to the functionality of the system. Key ComponentsOne of the most important elements is the cylinder, which acts as the central chamber where the fuel is ignited, generating power. The piston, situated inside the cylinder, moves up and down, converting the energy from the fuel into mechanical motion. Both the cylinder and piston must work in harmony for the engine to perform effectively. Supportive Elements

Another vital component is the crankshaft Blades and Cutting System OverviewThe cutting system is designed to deliver precise and efficient grass trimming, ensuring a clean and consistent result. By focusing on the alignment and sharpness of the blades, the system allows for a smooth operation, reducing the time spent on maintenance while enhancing overall performance. This section will explore the key elements of this system, providing a closer look at its functionality and components. Key Features of the Cutting MechanismThe cutting mechanism includes specially designed blades that rotate at optimal speeds, slicing through grass with precision. The shape and material of the blades are crucial for durability, minimizing wear even in challenging conditions. The efficient design also reduces clogging, allowing the system to work continuously without interruptions. Maintaining the Blades for Optimal PerformanceRegular inspection and sharpening of the blades are essential to maintain peak performance. Keeping the blades sharp ensures they can cut through grass evenly, reducing stress Fuel System Diagram BreakdownThe fuel delivery mechanism plays a crucial role in the proper functioning of an engine, ensuring that fuel is supplied efficiently and consistently. This section will delve into the various components involved in the system, highlighting their individual purposes and how they interact to keep the engine running smoothly. Key Components of the Fuel SystemAt the core of the system is the fuel tank, which serves as the storage unit for the gasoline or other fuel type. The fuel lines transport the fuel from the tank to the engine, while a fuel filter ensures that impurities are removed before reaching critical parts. A pump is responsible for moving the fuel through these lines at the necessary pressure. Understanding the Flow Process

Once the fuel has passed through the filtering stage, it enters the carburetor or injectors, depending on the engine type, where it’s mixed with air for combustion. This balanced mix is then ignited in the engine Wheel Assembly and Traction ControlThe wheel assembly plays a crucial role in ensuring optimal maneuverability and stability for lawn care equipment. A well-designed system enhances the overall performance and safety of the machine, allowing it to traverse various terrains with ease. Understanding the components involved in the wheel assembly and their functions is essential for proper maintenance and troubleshooting. Components of the Wheel Assembly

Traction Control Mechanisms

Effective traction control is vital for maintaining grip on different surfaces. Several mechanisms contribute to this function:

Regular inspection and maintenance of the wheel assembly and traction control features can prolong the lifespan of the equipment and enhance its performance. Drive System Components AnalysisThe efficiency of a lawn maintenance machine relies heavily on its propulsion mechanism. Understanding the various elements that contribute to this system is essential for optimal performance. Each component plays a specific role in ensuring that the machine operates smoothly and effectively across different terrains. The primary elements of the propulsion system include the transmission, which facilitates power transfer from the engine to the wheels, and the drive belts that connect these components. These belts are crucial for maintaining proper tension and ensuring that the power is efficiently conveyed. Additionally, the wheels’ design and tread pattern influence traction and maneuverability, enabling the equipment to navigate various surfaces with ease. Regular inspection and maintenance of these components can prevent potential issues and prolong the lifespan of the equipment. Identifying wear and tear early can save time and reduce costs associated with repairs. By understanding the functionality and interconnections of the drive system elements, users can enhance their machine’s operational effectiveness and reliability. Deck Parts and Adjustments GuideThis section focuses on the essential components of the cutting platform and the necessary modifications to ensure optimal performance. Proper understanding and maintenance of these elements are crucial for achieving efficient operation and excellent results. Regular inspections and adjustments contribute significantly to the longevity and effectiveness of the cutting system. Below is a comprehensive overview of the main components along with their respective functions:

Regularly inspecting and adjusting these components will ensure a smooth mowing experience and improve overall performance. Proper care and timely adjustments are essential for optimal functionality. Handle and Control Panel LayoutThe arrangement of the handle and control interface is crucial for ensuring efficient operation and user comfort. Understanding the components and their positions aids in effective manipulation and maintenance of the equipment. Key elements typically found in this layout include:

Each of these components plays a vital role in enhancing usability and safety, making it essential for users to familiarize themselves with their locations and functions. For optimal performance, regular checks and maintenance of these elements are recommended. Proper alignment and functionality ensure a smoother experience and prolong the life of the equipment. Throttle and Choke Cable ConnectionsThe proper integration of control cables is crucial for the efficient operation of outdoor machinery. Understanding the connection points and layout of these cables ensures that the operator can effectively manage engine performance and air intake, leading to optimal functionality. Understanding Cable Functions

Throttle and choke cables serve distinct purposes in machinery. The throttle cable regulates engine speed, while the choke cable controls air intake during engine start-up. Correctly identifying and connecting these cables is essential for reliable performance. Connection Points OverviewBelow is a summary of the connection points for both the throttle and choke cables:

Transmission and Speed Control DetailsThe mechanism responsible for managing motion and adjusting pace plays a vital role in ensuring optimal performance of the equipment. Understanding the elements involved in this system can enhance the overall efficiency and responsiveness of the machine during operation. Transmission Components: The transmission consists of various parts that work together to facilitate power transfer from the engine to the wheels. Key elements include gears, belts, and pulleys that synchronize to enable smooth shifts in speed and direction. Speed Adjustment Mechanism: This feature allows operators to customize the speed based on specific tasks or terrain conditions. By manipulating levers or controls, users can select different speed settings, providing versatility for various applications. Maintenance Considerations: Regular upkeep of the transmission and speed control system is essential for longevity. Checking fluid levels, inspecting for wear and tear, and ensuring proper alignment of components are crucial steps to prevent operational issues and enhance performance. Safety Features and Related PartsEnsuring a safe operating environment is paramount when using outdoor machinery. Various elements are designed to enhance user protection and minimize risks during operation. Understanding these features and their components can significantly contribute to the overall safety and effectiveness of the equipment. The following components play a crucial role in maintaining safety standards:

To enhance the effectiveness of these safety mechanisms, regular maintenance is vital. Checking and replacing worn or damaged components ensures that all safety features function correctly. Adopting a proactive approach to equipment care not only enhances safety but also prolongs the lifespan of the machine. Maintenance Points and Spare Parts GuideThis section provides essential insights into upkeep and essential components for optimal performance. Regular servicing is crucial to ensure longevity and efficiency, making it vital to be aware of specific areas that require attention and the corresponding replacements necessary for smooth operation. Proper maintenance not only enhances functionality but also minimizes unexpected breakdowns. Familiarity with key elements to monitor and replace is fundamental for maintaining the equipment’s reliability and performance over time.

|