Maintaining your lawn tractor in optimal condition is essential for achieving a pristine lawn. An effective way to ensure proper upkeep is to familiarize yourself with the various components that make up this essential machine. Recognizing the different parts and their functions can significantly enhance your maintenance routine, allowing you to address issues before they escalate.

Visual representations of the various elements can serve as invaluable resources for both novice and experienced users. By examining these schematics, you can gain insights into how each component interacts within the system, facilitating a more informed approach to repairs and replacements. This knowledge empowers you to troubleshoot common problems and undertake maintenance tasks with confidence.

Moreover, understanding the layout and functionality of each part can lead to more efficient lawn care practices. Whether you’re seeking to enhance performance or prolong the lifespan of your equipment, a thorough comprehension of its inner workings is key. Dive into the intricacies of your machine and discover how each section contributes to its overall efficacy.

Understanding the LT1050 Cub Cadet

This section explores a specific model of garden machinery that has gained recognition for its efficiency and performance. By examining its components and functionality, users can enhance their maintenance skills and ensure optimal operation.

Key Features:

- Powerful engine capabilities

- User-friendly controls

- Durable construction materials

Benefits of Maintenance:

- Prolongs the lifespan of the equipment

- Improves performance and efficiency

- Reduces the risk of costly repairs

For effective upkeep, understanding the layout and mechanics is crucial. This knowledge not only aids in repairs but also enhances the overall user experience.

Overview of Lawn Tractor Components

Lawn tractors are essential machines for maintaining grassy areas, offering a blend of functionality and efficiency. Understanding their various elements is crucial for optimal performance and longevity.

Key Components

- Engine: Powers the machine and determines its overall capabilities.

- Transmission: Facilitates speed adjustments and power transfer to the wheels.

- Deck: Houses the cutting blades, crucial for achieving a precise cut.

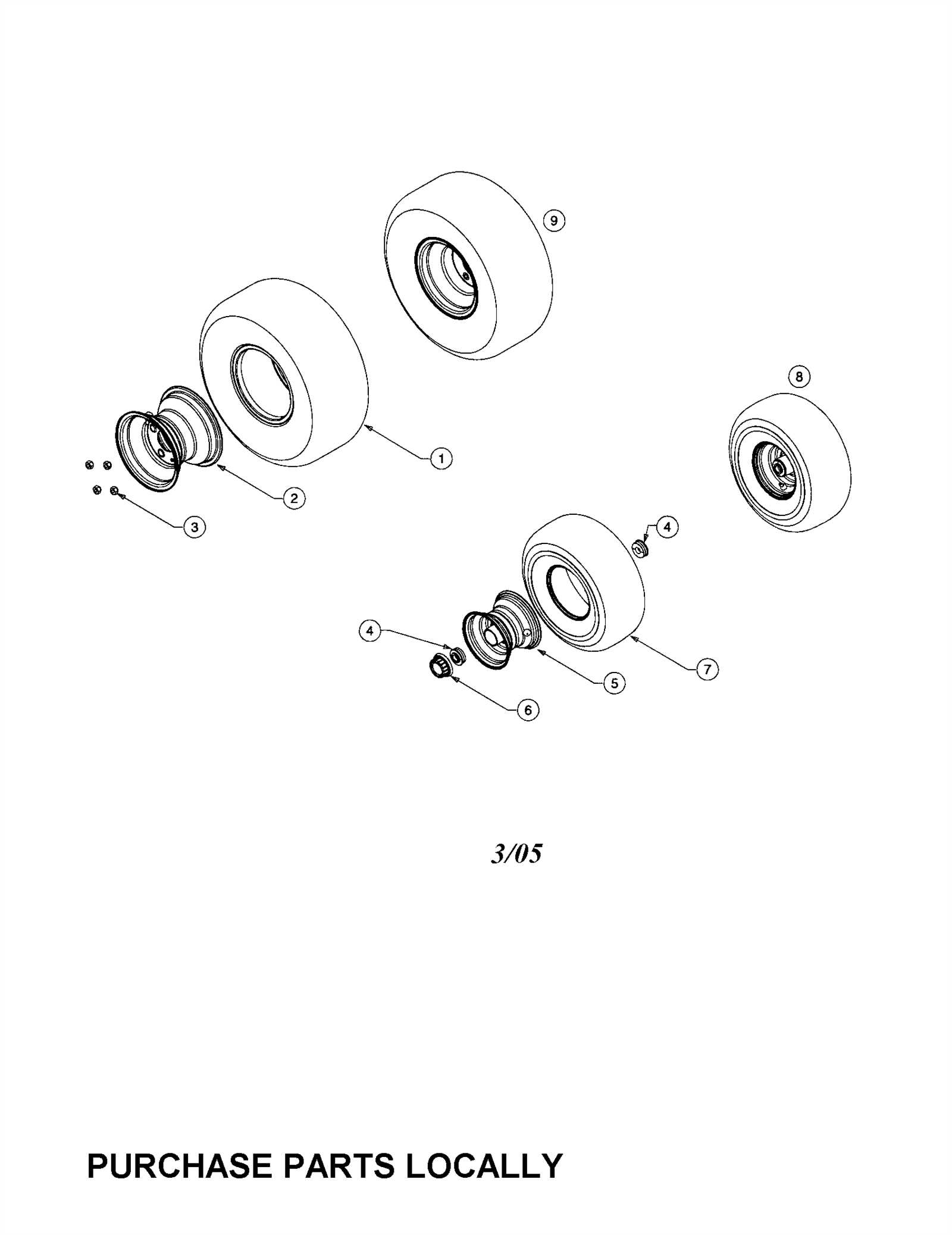

- Wheels: Support maneuverability and stability across different terrains.

Additional Features

- Steering System: Provides control and direction during operation.

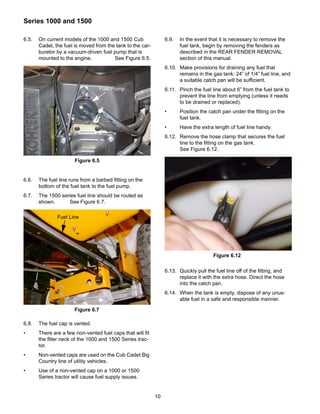

- Fuel System: Stores and delivers fuel to the engine efficiently.

- Battery: Supplies electrical power for starting and operating lights.

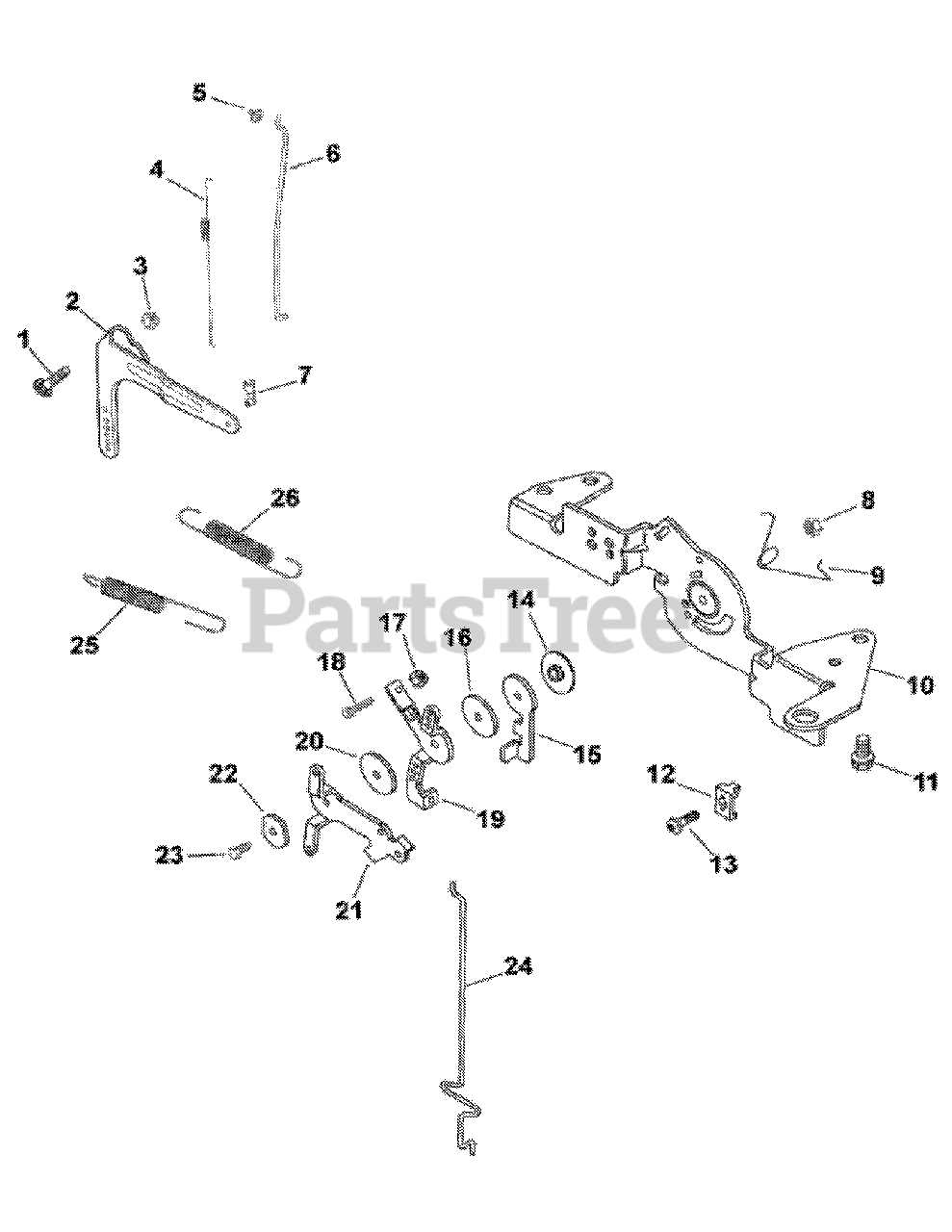

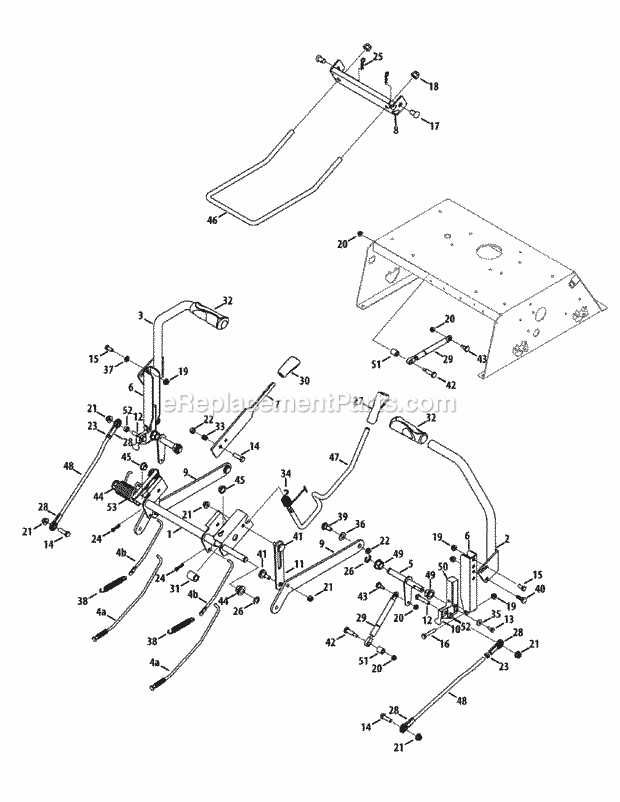

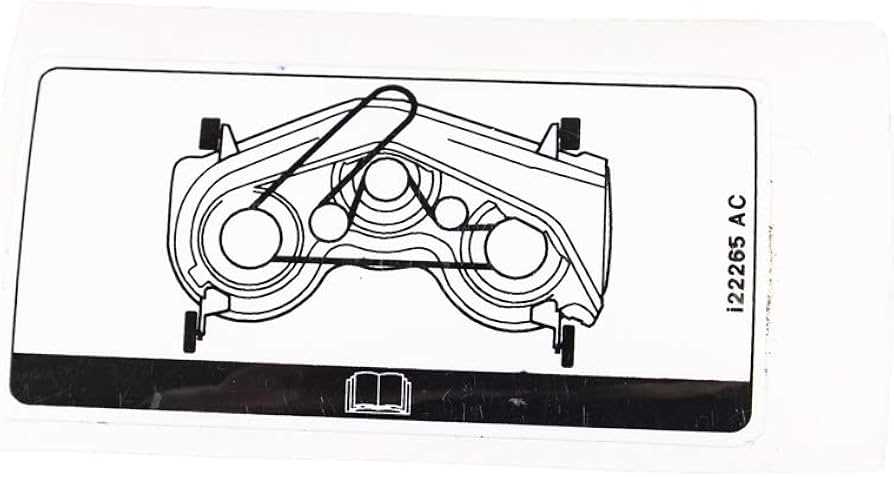

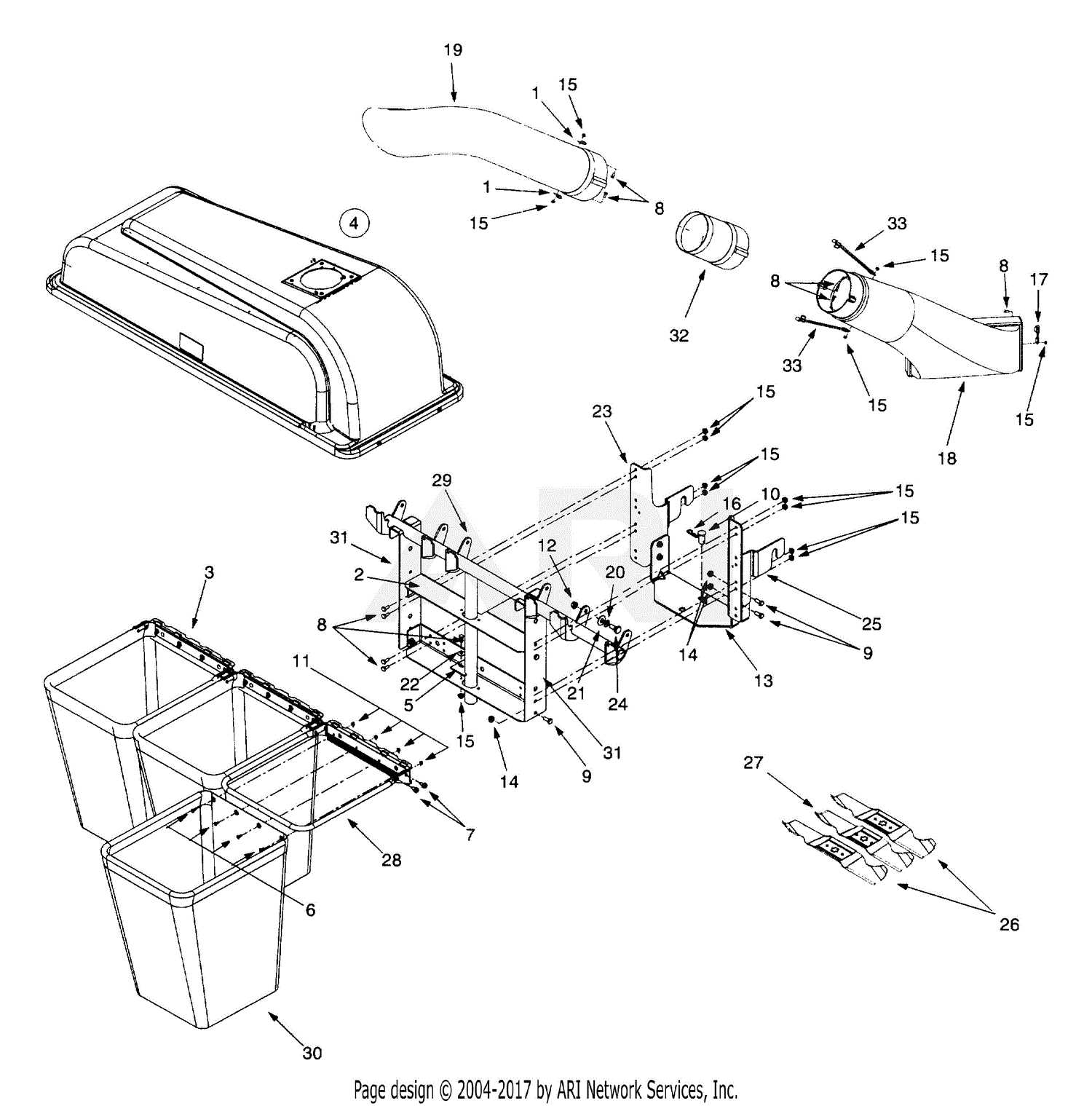

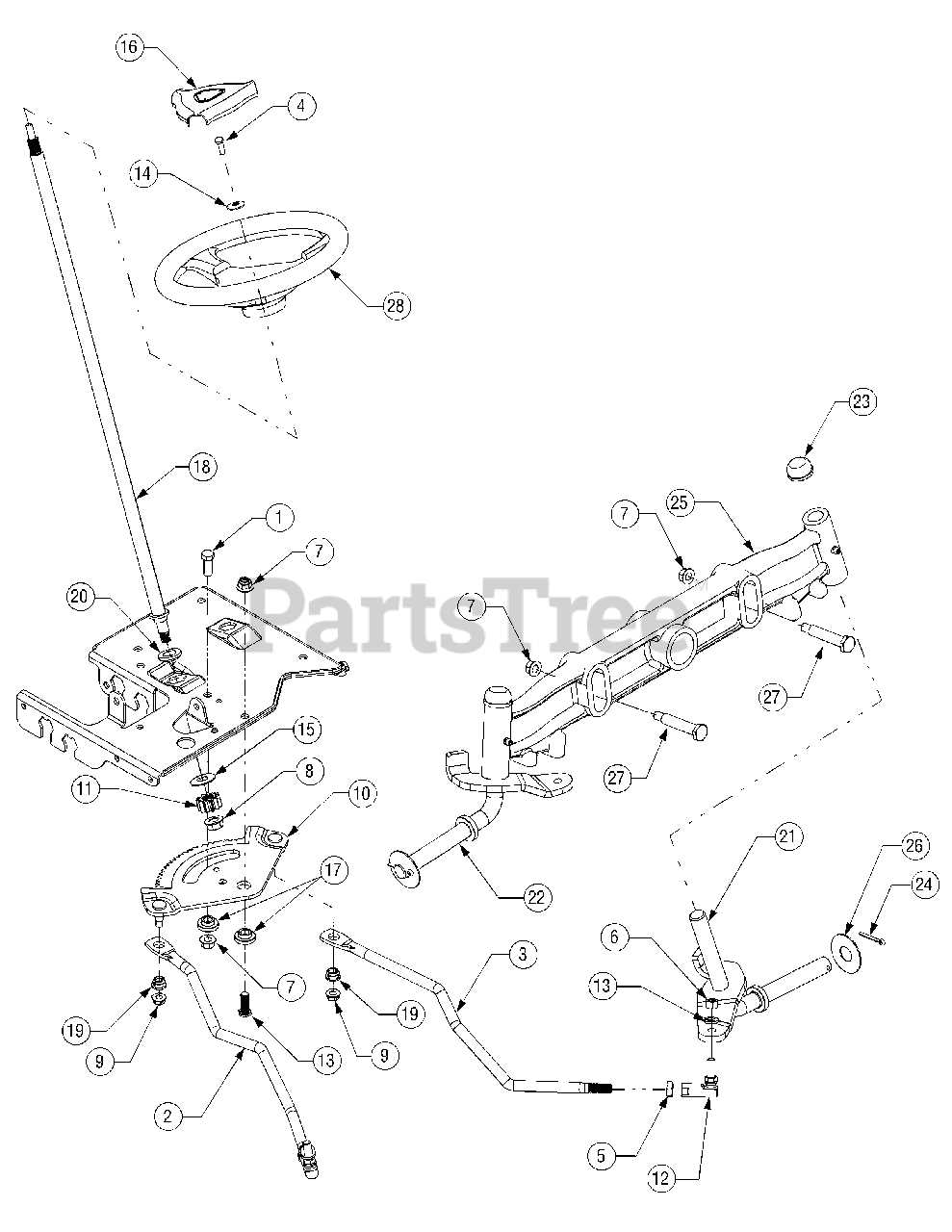

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations enhance the clarity of these elements, enabling users to quickly identify what is needed.

- Facilitates efficient troubleshooting.

- Reduces the likelihood of errors during assembly.

- Streamlines the ordering process for replacements.

- Enhances overall understanding of the equipment.

Ultimately, having a clear visual reference saves time and improves the longevity of the machine.

Key Features of LT1050 Model

The model stands out in its category, offering a range of attributes designed for efficiency and ease of use. These features collectively enhance performance, making it a preferred choice for homeowners and professionals alike.

One of the most notable aspects is its powerful engine, which delivers reliable performance across various terrains. Coupled with a user-friendly control system, operators can navigate with precision, ensuring effective operation during lawn maintenance.

The cutting deck is engineered for optimal grass handling, allowing for clean, even cuts while reducing the need for frequent passes. This feature not only saves time but also promotes a healthier lawn.

Additionally, the model includes a comfortable seating arrangement, designed to support long hours of use without compromising user comfort. Ergonomic controls further enhance the experience, making it accessible for individuals of all experience levels.

Durability is another key trait, with a robust build that withstands the rigors of regular use. This ensures longevity, making it a sound investment for those looking for reliable equipment.

Where to Find Parts Diagrams

When seeking visual references for machinery components, it’s essential to know the best resources available. These illustrations provide clarity on assembly and functionality, helping users understand each element’s role.

Online Platforms: Various websites specialize in providing detailed schematics. Manufacturer sites often host comprehensive resources, while forums and dedicated repair sites may offer user-generated content that can be invaluable.

Manuals: Printed or digital guides frequently include these visuals. Checking the official documentation that comes with your equipment can yield helpful diagrams for reference.

Local Dealers: Authorized retailers and repair shops may have physical copies of these visuals or can direct you to the right resources. Their expertise often includes insights into common repairs and replacements.

Community Resources: Online communities and social media groups dedicated to machinery maintenance can be excellent places to seek advice. Enthusiasts often share their findings and can guide you to useful diagrams.

Common Replacement Parts for LT1050

Maintaining the performance of your lawn tractor is essential for efficient operation and longevity. Certain components may require replacement over time due to wear and tear. Understanding these frequently needed items can help you keep your machine running smoothly.

Essential Components

Among the most commonly replaced items are the blades, which play a crucial role in cutting grass effectively. Dull or damaged blades can lead to uneven mowing results. Regularly checking and replacing them ensures optimal performance.

Other Frequently Needed Items

Additionally, filters such as air and oil filters are vital for maintaining engine health. Clogged filters can restrict airflow and oil flow, potentially causing engine issues. It’s recommended to replace these components at regular intervals. Belts also experience wear and should be inspected regularly, as they are integral for power transmission throughout the machine.

How to Use the Diagram Effectively

Understanding the layout of components can greatly enhance your maintenance and repair efforts. A visual reference serves as a guide, helping you identify each element with clarity and precision.

- Begin by familiarizing yourself with the overall structure. This will provide a solid foundation for recognizing individual parts.

- Identify key sections relevant to your current project. Focus on those areas to streamline your efforts.

- Cross-reference with the user manual to ensure accuracy in part identification and functionality.

By leveraging this visual tool, you can enhance your efficiency and reduce the risk of errors during maintenance tasks.

Troubleshooting with Parts Diagrams

Understanding mechanical systems can often be a complex task, but utilizing visual representations of components can greatly simplify the troubleshooting process. These illustrations provide a clear overview of each element’s function and relationship, making it easier to identify issues and devise effective solutions.

When facing problems with your equipment, referencing these visuals allows you to pinpoint the exact location of a malfunction or wear. It enhances your ability to assess whether a component needs repair or replacement. Additionally, having a clear visual guide aids in ensuring that all parts are correctly assembled and functioning as intended.

| Common Issues | Possible Causes | Recommended Actions |

|---|---|---|

| Engine won’t start | Fuel blockage, battery failure | Check fuel lines, test battery voltage |

| Unusual noises | Loose components, worn bearings | Tighten bolts, inspect bearings |

| Poor cutting performance | Dull blades, misalignment | Sharpen or replace blades, adjust alignment |

| Excessive vibration | Imbalanced parts, damaged mounts | Inspect for damage, replace or realign |

In conclusion, leveraging visual guides enhances your ability to troubleshoot effectively, leading to quicker repairs and improved performance. This approach not only saves time but also helps maintain the longevity of your machinery.

Benefits of OEM vs Aftermarket Parts

When it comes to maintaining machinery, choosing the right components is crucial for performance and longevity. Understanding the differences between original manufacturer offerings and third-party alternatives can greatly influence the effectiveness and reliability of your equipment.

Original components are designed specifically for the equipment, ensuring perfect compatibility and adherence to quality standards. This can lead to improved performance, reduced risk of malfunction, and often comes with a warranty that guarantees peace of mind.

On the other hand, third-party options may offer lower prices, appealing to budget-conscious users. While some aftermarket solutions can deliver satisfactory performance, the variability in quality can pose risks, such as increased wear and potential damage over time.

Ultimately, the choice between these options should consider factors like cost, reliability, and the intended use of the machinery. A well-informed decision can significantly impact the overall maintenance experience and operational efficiency.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended lifespan of your outdoor machinery. By implementing a few strategic practices, you can enhance performance and reliability, minimizing the risk of unexpected breakdowns.

Routine Inspections

Conduct frequent checks of vital components such as the engine, belts, and filters. Identifying wear and tear early can prevent larger issues. Always refer to the manufacturer’s guidelines for specific maintenance schedules.

Cleaning and Lubrication

Keep all parts clean and well-lubricated. Dirt accumulation can lead to mechanical failures, while proper lubrication reduces friction. Investing time in these tasks can significantly boost the efficiency of your equipment.

Identifying Wear and Tear Signs

Recognizing the signs of deterioration in machinery is crucial for maintaining optimal performance. Regular inspections can reveal issues before they escalate, ensuring longevity and efficiency. Understanding common indicators of wear helps operators take timely action and prevent costly repairs.

Common Indicators

Look for unusual noises, vibrations, or changes in performance. These symptoms can suggest problems with components such as belts, bearings, or engines. Additionally, inspect for visible signs like cracks, rust, or fraying, which often indicate the need for immediate attention.

Preventive Measures

Implementing a routine maintenance schedule can significantly reduce wear and extend the lifespan of your equipment. Regular lubrication, cleaning, and component checks are essential practices that help in identifying issues early and maintaining optimal functionality.

Step-by-Step Repair Guide

This section provides a comprehensive guide to effectively troubleshoot and repair your machinery. By following a systematic approach, you can identify issues and implement solutions efficiently.

- Identify the Problem:

- Observe the symptoms.

- Consult the manual for common issues.

- Gather Tools and Supplies:

- Ensure you have the necessary tools.

- Stock up on replacement components as needed.

- Disassemble Carefully:

- Follow the sequence outlined in the manual.

- Keep screws and small parts organized.

- Inspect Components:

- Look for wear and tear.

- Check for any signs of damage.

- Replace or Repair:

- Use new parts for replacements.

- Follow repair techniques for damaged items.

- Reassemble:

- Carefully put all parts back together.

- Ensure everything is secure and in place.

- Test the Equipment:

- Run the machinery to check for proper function.

- Monitor for any irregularities.

Resources for LT1050 Owners

Maintaining and enhancing the performance of your lawn care equipment can significantly extend its lifespan and improve efficiency. For owners seeking support and valuable information, a range of resources is available to help navigate repairs, maintenance, and upgrades. These resources include manuals, online forums, and specialized retailers that cater specifically to your needs.

Manuals and Guides

Accessing the correct manuals is crucial for understanding the operation and upkeep of your machine. Many manufacturers offer downloadable guides that provide detailed instructions on maintenance tasks, troubleshooting, and specifications.

| Resource Type | Description | Link |

|---|---|---|

| Owner’s Manual | Comprehensive guide covering operation and care | Download here |

| Maintenance Schedule | Recommended timelines for routine tasks | View schedule |

| Troubleshooting Guide | Step-by-step solutions for common issues | Access guide |

Online Communities and Forums

Joining online communities can provide invaluable insights and support from fellow enthusiasts. These platforms allow you to ask questions, share experiences, and find advice on specific issues or enhancements.