In the realm of heavy machinery, a comprehensive grasp of various elements is essential for effective operation and maintenance. When working with robust construction equipment, familiarizing oneself with the intricate assembly of its components can significantly enhance performance and longevity. This knowledge not only aids in troubleshooting but also empowers operators and technicians to make informed decisions regarding repairs and upgrades.

Examining the structure of these formidable machines reveals a complex network of mechanisms that work in harmony. Each segment plays a pivotal role in ensuring the functionality and efficiency of the overall system. Recognizing how these parts interconnect fosters a deeper appreciation for the engineering behind such powerful equipment, allowing for more effective handling in various tasks.

Moreover, understanding the specific arrangements and functions of these essential components can streamline maintenance procedures. A well-organized overview serves as a valuable reference for professionals in the field, facilitating quick identification of issues and ensuring that the machinery operates at peak capacity. By exploring this intricate web of parts, one can significantly contribute to the successful operation of these vital tools in the construction industry.

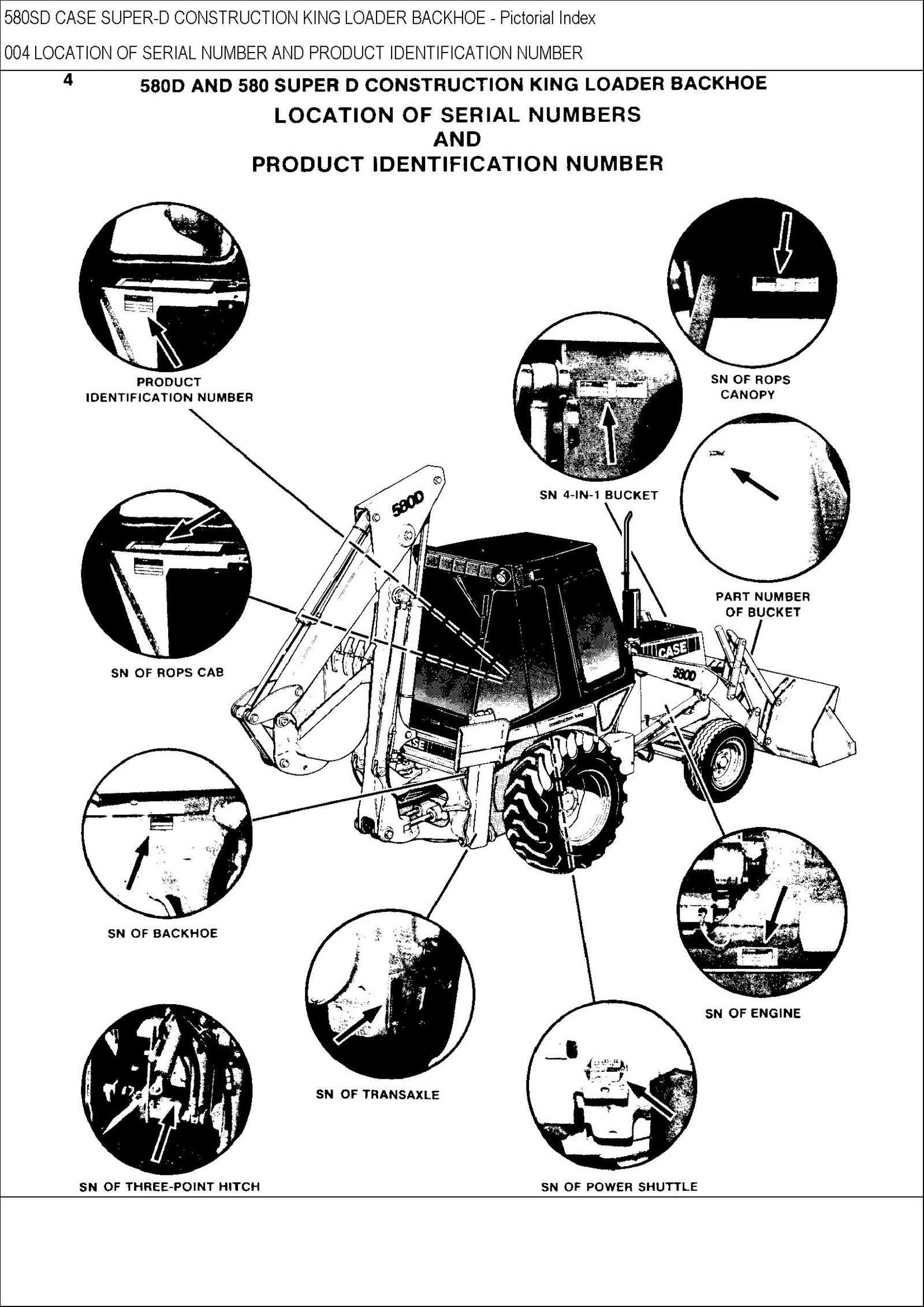

Understanding Case 580 Backhoe Overview

This section provides a comprehensive look at a versatile construction machine widely utilized in various industries. Known for its efficiency and adaptability, this equipment is essential for tasks ranging from excavation to material handling. Understanding its components and functionality is crucial for effective operation and maintenance.

| Feature | Description |

|---|---|

| Engine | Powerful unit that drives the machine’s operations. |

| Loader | Front attachment for lifting and moving materials. |

| Excavator | Rear tool for digging and trenching tasks. |

| Hydraulics | System that powers various attachments and functions. |

| Cab | Operator’s area designed for comfort and visibility. |

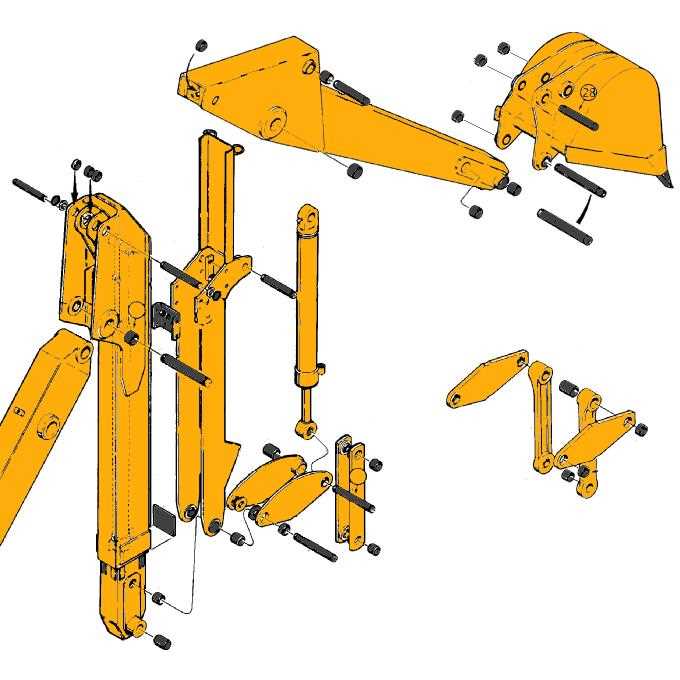

Key Components of the Backhoe

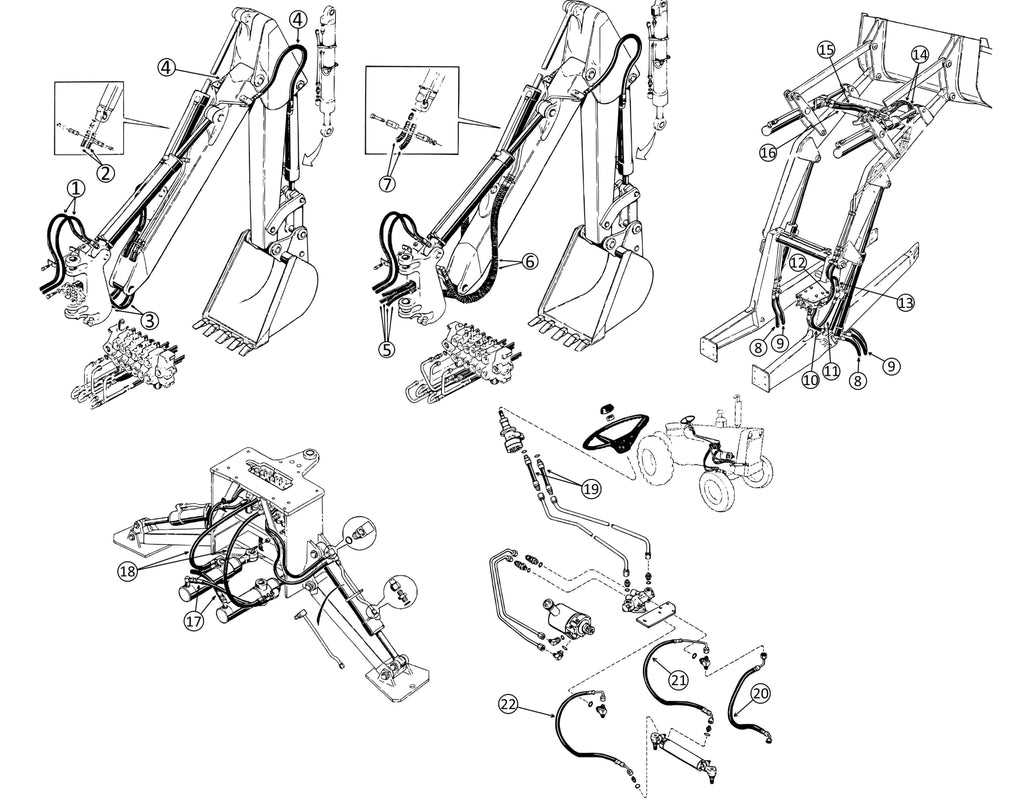

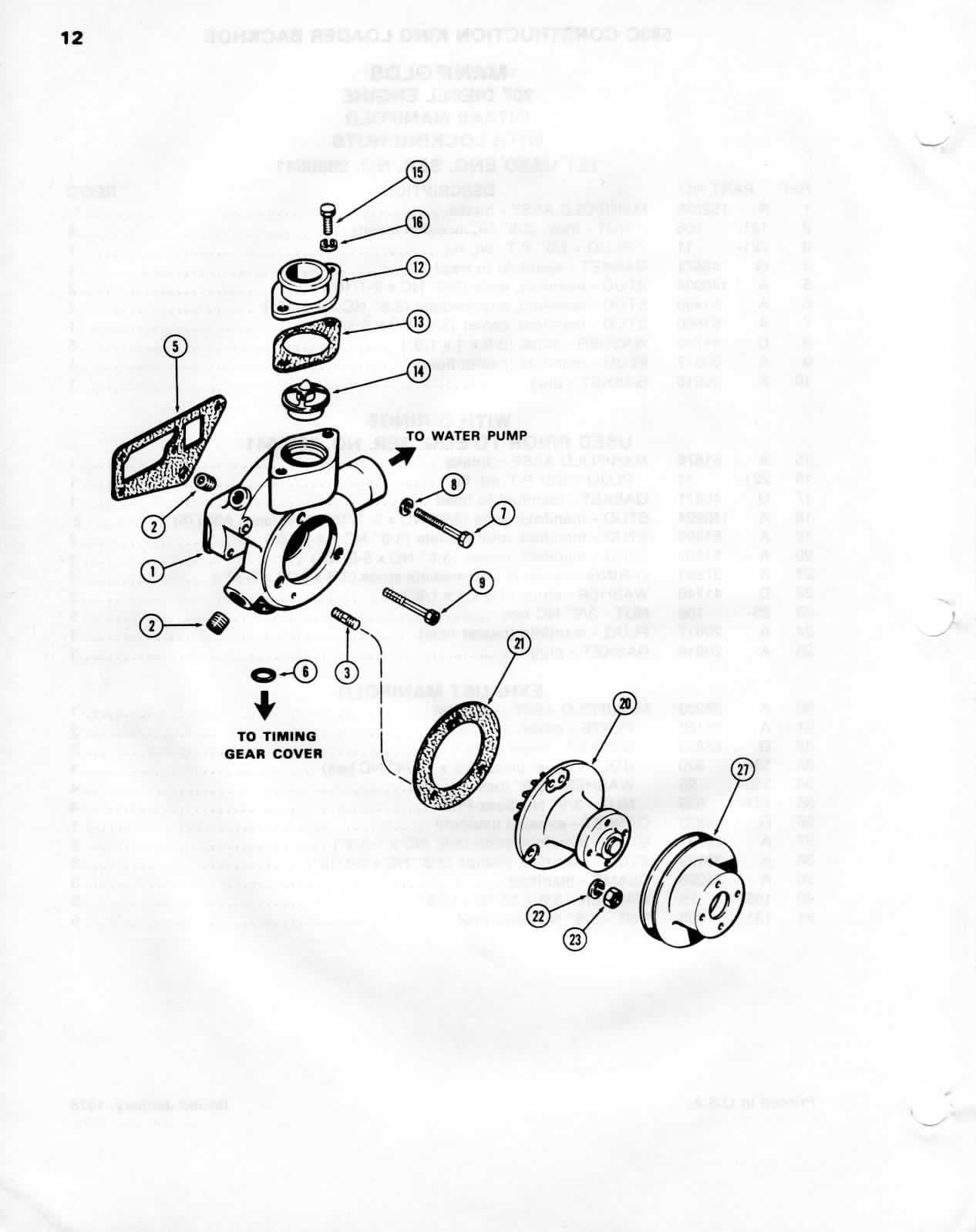

The efficient operation of any excavation machinery relies on a variety of essential elements that work in harmony. Understanding these components is crucial for effective maintenance and troubleshooting. Each part plays a specific role in enhancing the machine’s overall performance and functionality.

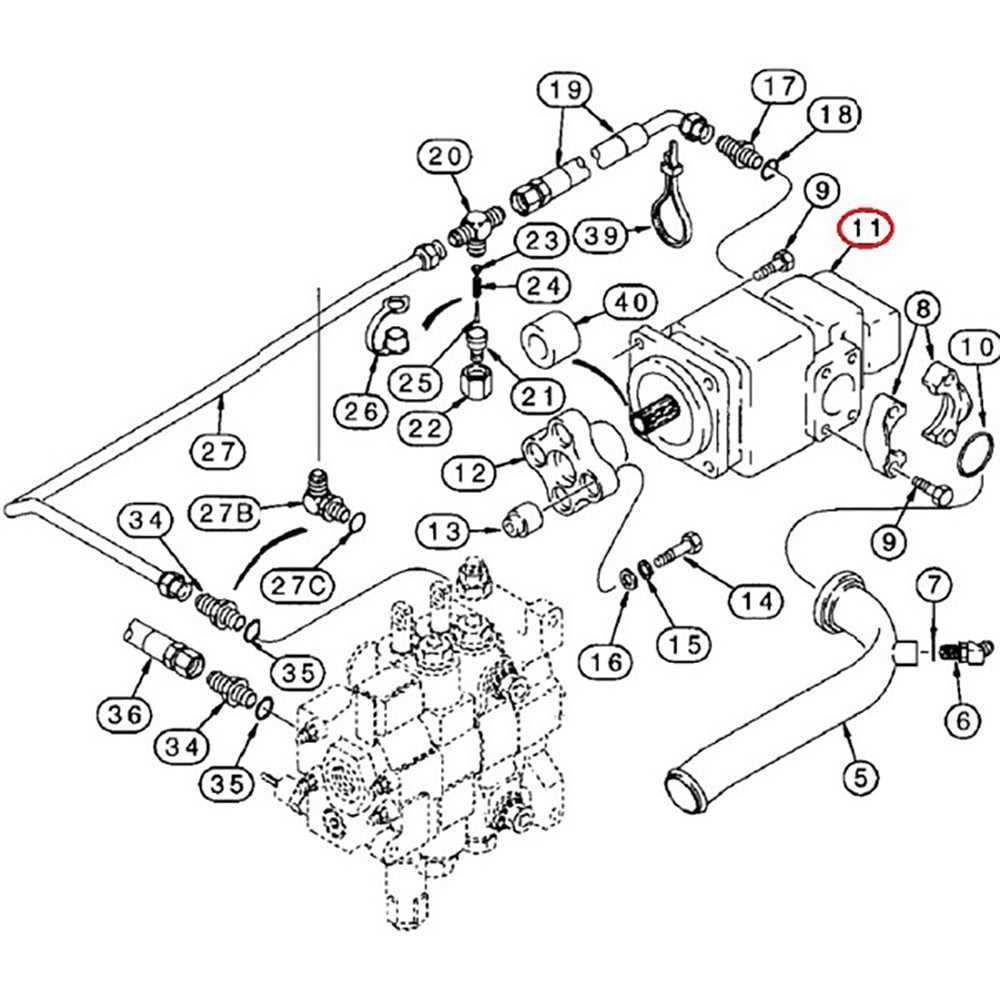

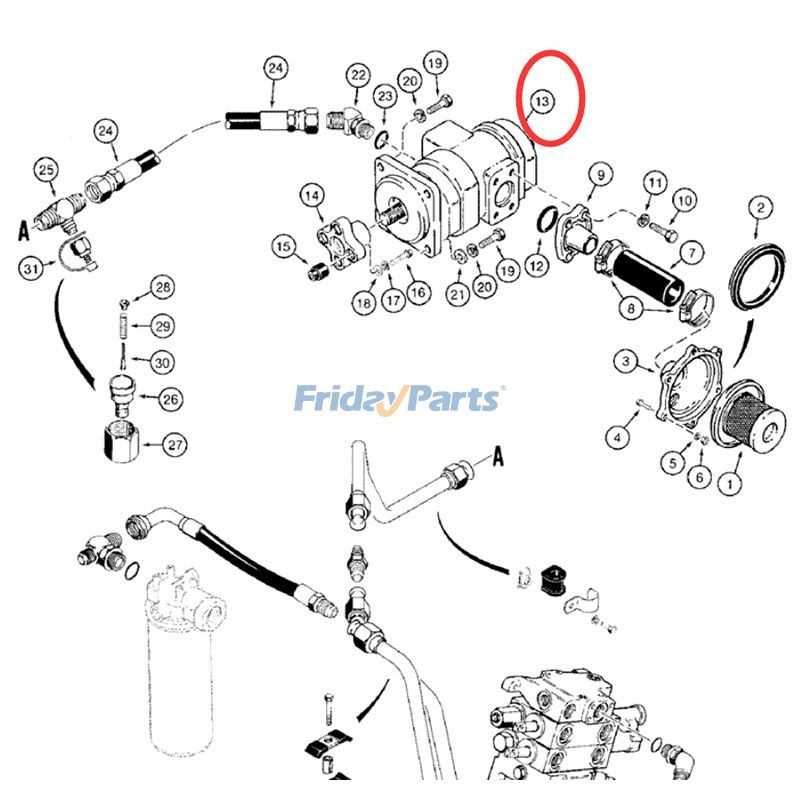

Hydraulic System

At the heart of any excavation equipment lies the hydraulic system, responsible for powering various movements and functions. This intricate network of pumps, hoses, and cylinders enables the machine to lift, dig, and maneuver with precision. Regular checks and maintenance of this system are vital to ensure optimal performance and to prevent costly breakdowns.

Frame and Chassis

The frame serves as the backbone of the machinery, providing structural integrity and support. It is designed to withstand the stresses of heavy loads and rough terrain. Analyzing the condition of the frame and chassis can reveal potential issues that may affect stability and safety during operation. Regular inspections are recommended to identify wear or damage early on.

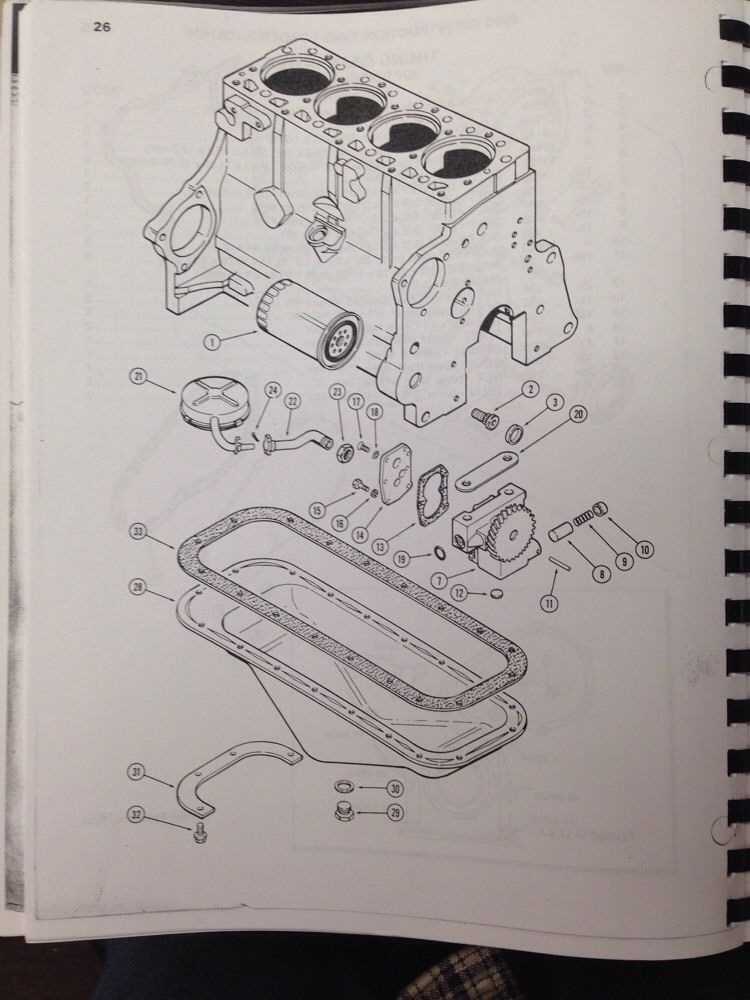

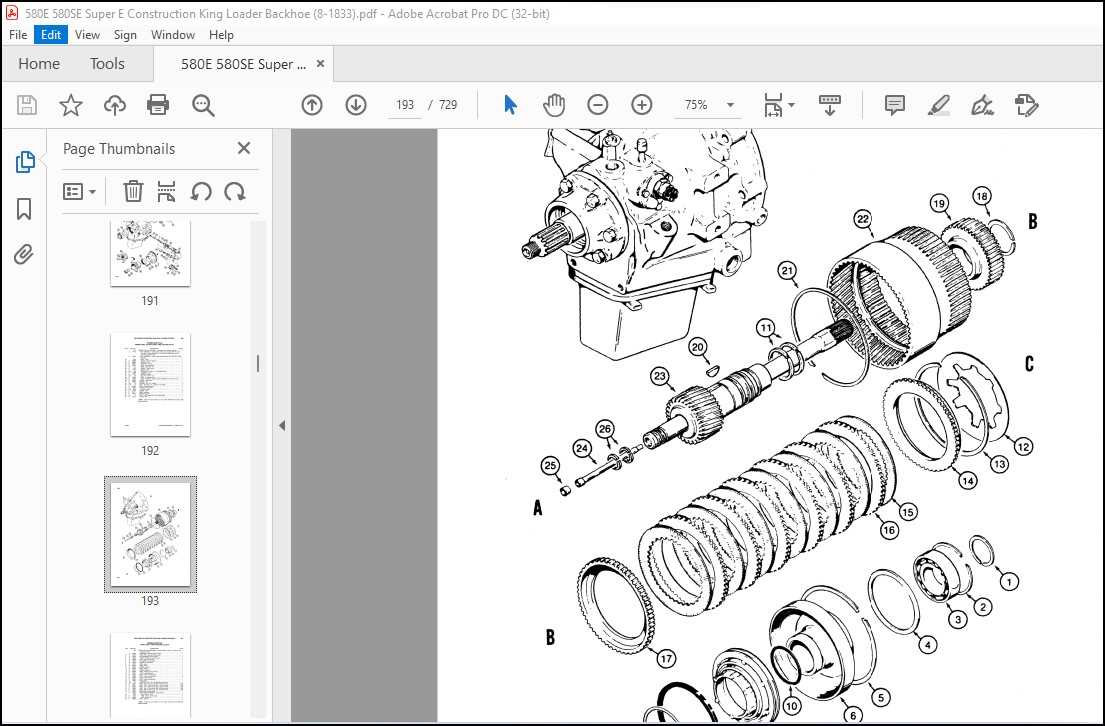

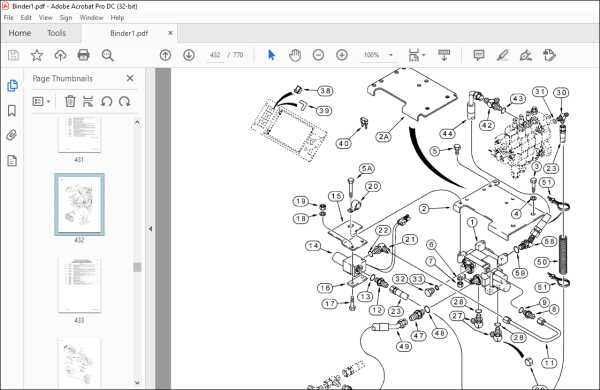

Importance of Parts Diagrams

Understanding the components of machinery is crucial for maintenance and repair. Visual representations allow users to identify individual elements, facilitating efficient troubleshooting and restoration processes. These illustrations serve as a roadmap, ensuring that each piece is correctly positioned and functioning optimally.

Enhanced Troubleshooting

When issues arise, having a clear visual guide can significantly streamline the diagnostic process. Technicians can quickly pinpoint the source of a malfunction, reducing downtime and minimizing frustration.

Effective Communication

Diagrams foster better collaboration among team members. By providing a common reference point, everyone involved can discuss repairs and upgrades more effectively, leading to improved outcomes and shared understanding.

How to Read the Diagram

Understanding a technical illustration is crucial for effective maintenance and repairs. This guide will provide you with the necessary skills to interpret these visual representations accurately.

Key Components to Identify

- Symbols: Recognize various symbols used to denote specific elements.

- Labels: Pay attention to any textual annotations that clarify functions.

- Connections: Note how different parts interact with each other.

Steps to Analyze the Illustration

- Familiarize yourself with the layout and organization.

- Identify the main sections and their respective functions.

- Follow the flow of operations as indicated by arrows or lines.

- Cross-reference with a list of components for clarification.

Common Parts for Replacement

In the world of heavy machinery, certain components frequently require attention due to wear and tear. Understanding which elements are most susceptible to damage can help operators maintain optimal performance and extend the lifespan of their equipment.

| Component | Common Issues | Replacement Frequency |

|---|---|---|

| Hydraulic Pump | Leakage, reduced efficiency | Every 1,500 hours |

| Bucket Teeth | Worn down, broken | As needed |

| Filters | Clogging, reduced flow | Every 500 hours |

| Seals and Gaskets | Fluid leaks | Every 1,000 hours |

| Brake Linings | Wear, reduced stopping power | As needed |

Tools Needed for Repairs

When undertaking maintenance or repair tasks, having the right tools is crucial for efficiency and effectiveness. The selection of instruments can significantly impact the outcome of your project, ensuring that each step is executed smoothly and accurately.

Essential Instruments

- Wrenches

- Screwdrivers

- Socket sets

- Pliers

- Impact tools

Additional Equipment

- Torque wrench

- Jack stands

- Measuring tape

- Safety goggles

- Gloves

Maintenance Tips for Longevity

Regular upkeep is essential for enhancing the lifespan of your machinery. By implementing a consistent maintenance routine, you ensure optimal performance and reduce the likelihood of costly repairs. This not only saves time but also increases overall efficiency.

1. Regular Inspections: Conduct frequent checks on all components to identify wear and tear before it becomes a major issue. Look for any signs of damage or unusual noises.

2. Fluid Changes: Ensure that hydraulic fluids and oils are changed at recommended intervals. This keeps systems running smoothly and prevents overheating.

3. Cleanliness: Keep your equipment clean from dirt and debris. A clean machine operates better and is easier to inspect for potential issues.

4. Proper Storage: When not in use, store your machinery in a sheltered environment to protect it from the elements. This helps prevent rust and corrosion.

5. Operator Training: Ensure that all users are properly trained on operation and safety. Well-informed operators tend to use equipment more efficiently, reducing wear.

By following these tips, you can delve into a routine that promotes the ultimate durability and reliability of your machinery, ensuring it serves you well for years to come.

Identifying Part Numbers Effectively

Recognizing and locating specific component identifiers is crucial for maintenance and repairs. Understanding how to efficiently determine these codes can save time and resources while ensuring the right items are selected for any task.

Tips for Efficient Identification

To streamline the identification process, consider the following strategies:

- Utilize online resources and databases for cross-referencing.

- Consult user manuals and technical documents for detailed information.

- Engage with community forums for shared insights and experiences.

Common Identifier Formats

| Format Type | Description |

|---|---|

| Alpha-Numeric | Combination of letters and numbers, often used for specificity. |

| Sequential | Series of numbers that indicate the order of production. |

| Standardized | Pre-defined codes that follow industry norms for easier recognition. |

Aftermarket vs. OEM Parts

When it comes to maintaining and repairing machinery, the choice between original equipment manufacturer components and alternative solutions often arises. Each option presents distinct advantages and considerations, influencing not only performance but also budgetary factors.

Benefits of OEM Components

Original manufacturer components are designed specifically for a particular machine model, ensuring compatibility and reliability. These items often come with warranties, reflecting the manufacturer’s confidence in their durability and performance. Additionally, using OEM solutions can preserve resale value by maintaining the integrity of the equipment.

Advantages of Aftermarket Solutions

On the other hand, alternative options frequently offer cost savings and a wider range of choices. Many aftermarket manufacturers produce components that meet or exceed the specifications of the original products, often at a reduced price. This can be particularly beneficial for older machinery, where OEM components may be scarce or prohibitively expensive.

| Criteria | OEM Components | Aftermarket Solutions |

|---|---|---|

| Compatibility | Perfect fit for specific models | Varies, but often good |

| Cost | Generally higher | Typically lower |

| Warranty | Often includes warranty | Varies by manufacturer |

| Availability | Limited to manufacturer stock | Widely available |

Ordering Parts Online Safely

When it comes to acquiring components for machinery, ensuring a secure transaction process is paramount. With the increasing prevalence of online marketplaces, buyers must be vigilant to avoid potential pitfalls. This section provides essential tips for navigating the digital landscape with confidence and safeguarding your investments.

Key Considerations for Online Purchases

Before finalizing any online acquisition, it’s vital to assess several factors that contribute to a safe buying experience:

| Factor | Description |

|---|---|

| Reputable Sellers | Always choose established vendors with positive customer feedback to minimize risks. |

| Return Policies | Check the return and warranty policies to ensure you can resolve issues post-purchase. |

| Secure Payment Methods | Utilize secure payment options, such as credit cards or trusted payment gateways. |

| Detailed Descriptions | Examine product descriptions and specifications thoroughly to confirm compatibility. |

Final Tips for Safe Transactions

Always perform a quick online search for reviews or ratings about the seller. Engaging with forums or communities can also provide valuable insights. Remember, staying informed is the best defense against fraudulent activities in the online marketplace.

Expert Recommendations for Usage

When operating heavy machinery, following expert advice is crucial for ensuring efficiency and safety. Understanding the appropriate methods and techniques can significantly enhance performance and prolong the lifespan of the equipment.

Best Practices for Operation

- Always conduct a pre-use inspection to identify any potential issues.

- Familiarize yourself with the operator’s manual and safety protocols.

- Utilize proper techniques for loading and unloading materials.

Maintenance Tips

- Regularly check fluid levels and replace filters as needed.

- Inspect and tighten all bolts and connections to prevent wear.

- Schedule routine maintenance with qualified technicians for optimal performance.

Common Issues and Troubleshooting

Understanding typical malfunctions and their solutions is crucial for maintaining optimal performance of heavy machinery. Addressing these problems promptly can prevent costly repairs and downtime.

Engine Overheating: This issue often arises due to coolant leaks or a malfunctioning thermostat. Regularly check fluid levels and ensure the radiator is clean to enhance cooling efficiency.

Hydraulic System Failures: Symptoms include sluggish operation or complete lack of movement. Inspect hoses for leaks and ensure the hydraulic fluid is at the correct level and free from contamination.

Electrical Problems: Flickering lights or unresponsive controls may indicate battery issues or faulty wiring. Conduct routine inspections and test connections to maintain a reliable electrical system.

Transmission Issues: Difficulty shifting gears can signal low fluid levels or worn components. Regular maintenance of the transmission system is essential to prevent significant breakdowns.

By being proactive and addressing these common issues, operators can ensure their equipment remains in peak condition, enhancing both efficiency and safety on the job site.

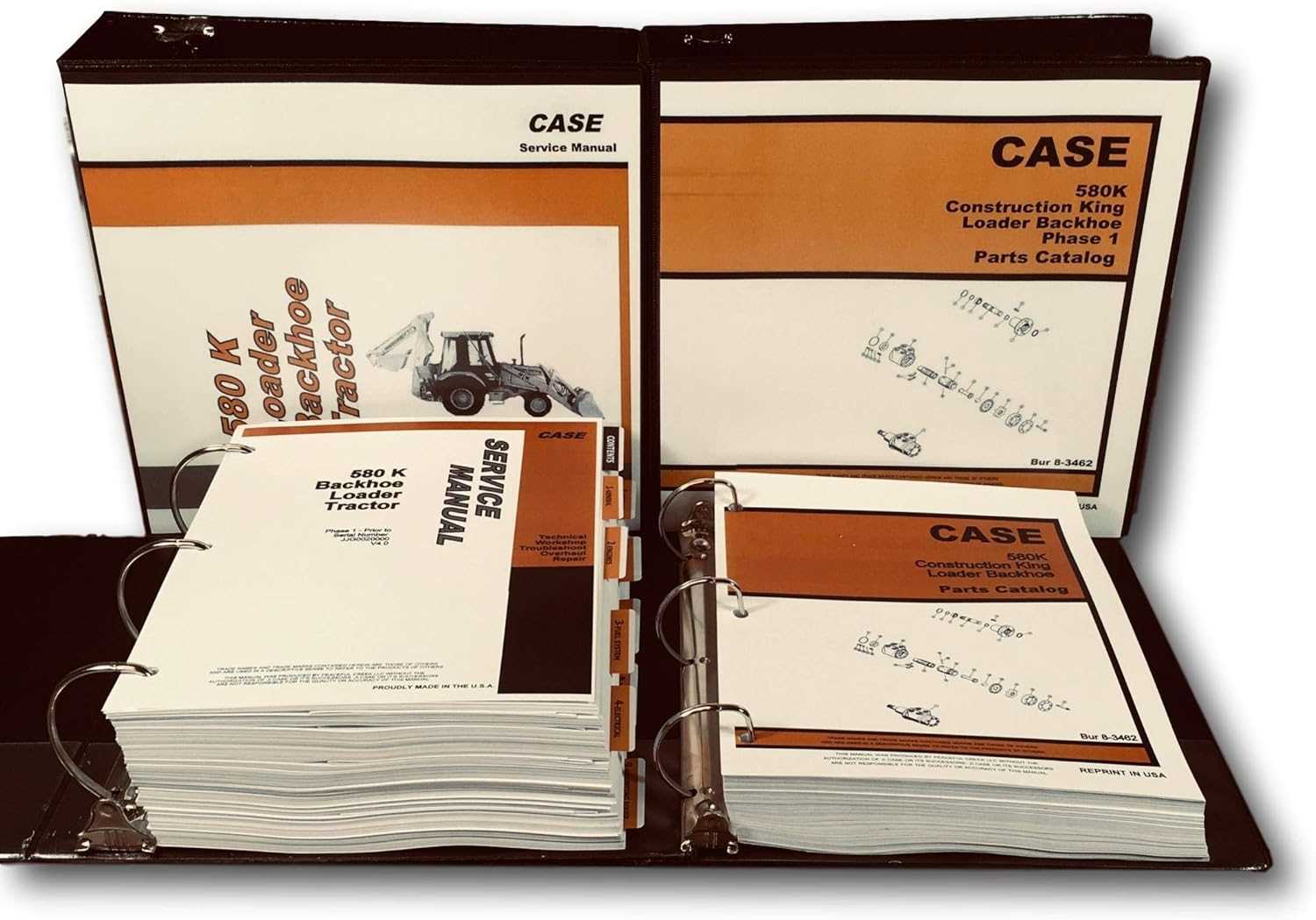

Resources for Further Learning

Expanding your knowledge in the field of heavy machinery and its components is crucial for both enthusiasts and professionals. A variety of resources are available that provide in-depth information, instructional content, and visual aids to enhance your understanding. Whether you’re looking for technical manuals, instructional videos, or online forums, these materials can significantly aid in your learning journey.

Online Platforms

Numerous websites offer comprehensive guides and tutorials. Platforms like YouTube host countless videos demonstrating maintenance procedures and troubleshooting techniques. Additionally, dedicated forums and communities allow users to share experiences and advice, making them valuable for practical insights.

Books and Manuals

Printed materials, such as technical manuals and instructional books, serve as excellent references. These resources often provide detailed schematics and step-by-step procedures that are beneficial for hands-on learning. Libraries and online bookstores typically have a variety of titles available, catering to different skill levels and interests.