The intricacies of industrial machinery can often be daunting, but a thorough comprehension of their structural layouts is essential for effective maintenance and operation. In this section, we will explore how visual representations can enhance your understanding of these complex systems.

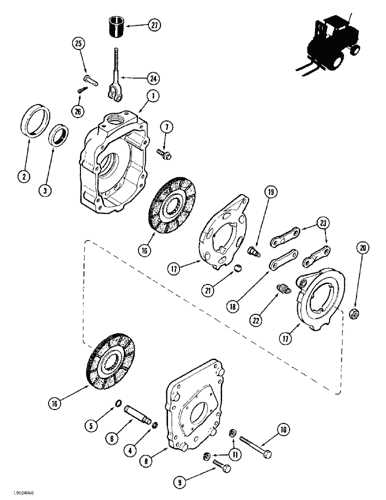

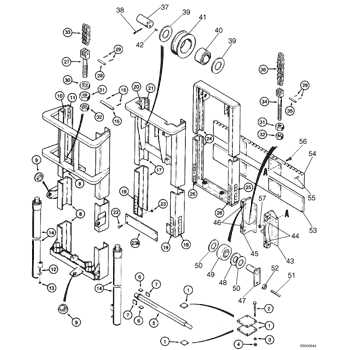

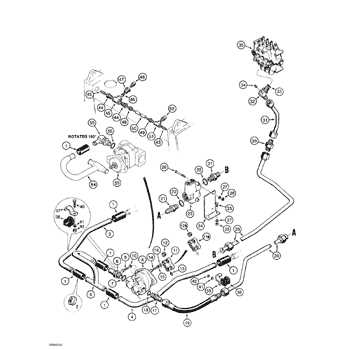

Identifying key elements is crucial when navigating the various components that make up heavy equipment. By examining detailed illustrations, operators and technicians alike can easily pinpoint specific sections and understand their interconnections.

Furthermore, the ultimate goal is to facilitate better repairs and optimizations, ensuring machinery operates at peak efficiency. Delving into these schematics can provide valuable insights, ultimately leading to improved performance and longevity of the equipment.

Understanding Case 586E Forklift Parts

Grasping the components of heavy machinery is essential for optimal performance and longevity. Each element plays a critical role in the overall function, contributing to efficiency and safety. By familiarizing yourself with these key elements, you can ensure proper maintenance and reduce downtime.

Key Components: The primary structures include the chassis, hydraulic systems, and engine. Each of these systems is intricately linked, allowing the machinery to perform various tasks effectively.

Maintenance Considerations: Regular inspections and replacements are vital to keep the equipment running smoothly. Understanding how each component interacts can help identify potential issues before they escalate.

By delving into the specifics of these elements, operators can make informed decisions about repairs and upgrades, ultimately enhancing the machine’s performance and reliability.

Key Components of the Forklift

Understanding the essential elements of heavy machinery is crucial for effective operation and maintenance. Each part plays a significant role in ensuring optimal performance, safety, and efficiency. Familiarity with these components helps users troubleshoot issues and enhance longevity.

| Component | Description |

|---|---|

| Chassis | The main framework that supports the entire structure. |

| Power Source | The engine or motor that provides the necessary energy for operation. |

| Hydraulic System | A system that controls the lifting and lowering mechanisms. |

| Lift Mechanism | Components that raise and lower the load, ensuring stability. |

| Steering System | Enables maneuverability and control during operation. |

| Safety Features | Includes elements like seat belts and alarms for operator protection. |

Importance of Parts Diagrams

Understanding the intricate components of machinery is crucial for maintenance and repair. Visual representations serve as invaluable tools, providing clarity and guidance when addressing mechanical issues. By illustrating how various elements fit together, these schematics facilitate efficient troubleshooting and assembly processes.

Such representations not only enhance comprehension for technicians but also streamline communication among team members. When everyone has access to a clear illustration, the likelihood of errors decreases significantly, leading to smoother operations. Furthermore, these visuals aid in the identification of replacement components, ensuring that the right parts are acquired for repairs.

Ultimately, relying on detailed schematics fosters a more organized approach to maintenance, allowing for timely interventions that prolong the lifespan of equipment. In a field where precision is paramount, having access to well-crafted visuals can make all the difference in achieving optimal performance.

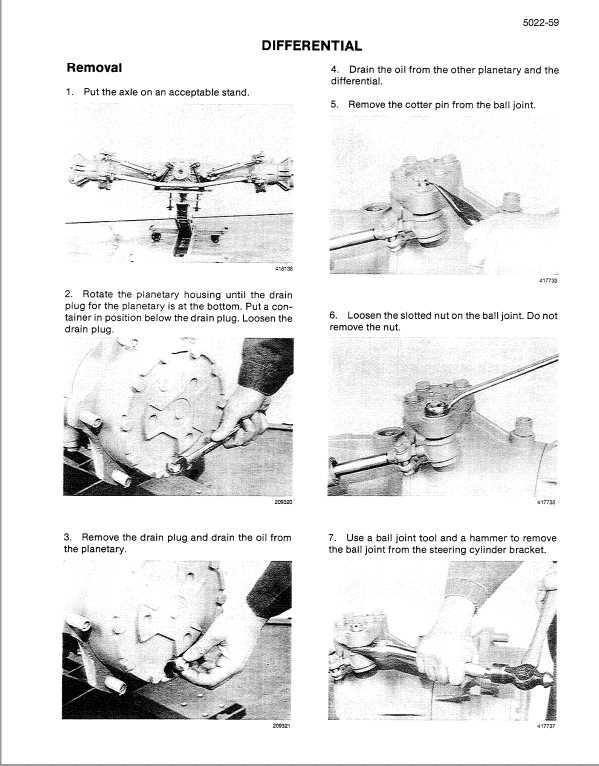

How to Read a Parts Diagram

Understanding a schematic representation of components is crucial for effective maintenance and repair. These illustrations serve as a visual guide, allowing users to identify various elements and their interconnections. By mastering the interpretation of these visuals, one can enhance efficiency and ensure accurate reassembly.

Start by familiarizing yourself with the layout of the illustration. Typically, the components are organized systematically, often grouped by function or location. This arrangement aids in locating specific items quickly.

Next, pay attention to labels and accompanying numbers. Each symbol or drawing will usually correspond to a reference number in the legend, which provides detailed descriptions of the items. Understanding these labels is key to proper identification.

Finally, practice cross-referencing the schematic with actual equipment. This hands-on approach reinforces learning and helps visualize how components fit together in the real world. With time, this skill will lead to a more intuitive understanding of mechanical assemblies.

Common Replacement Parts Overview

In the realm of industrial machinery, regular maintenance and timely exchanges of essential components play a crucial role in ensuring optimal performance and longevity. Understanding the typical items that may require replacement helps operators maintain operational efficiency and reduce downtime.

Key Components That Often Need Replacement

- Hydraulic Cylinders: Vital for lifting and lowering mechanisms, these elements can wear out over time and may require timely replacement.

- Filters: Air and hydraulic filters ensure clean operation; regular changes are necessary to prevent contamination and maintain system efficiency.

- Tires: Wear and tear from constant movement necessitates frequent inspection and replacement to ensure safety and stability.

- Battery: As a power source, maintaining a reliable battery is critical, and replacement may be needed due to aging or capacity loss.

Signs of Wear and When to Replace

- Frequent leaks or drops in hydraulic pressure can indicate failing cylinders.

- Unusual noises or vibrations during operation may signal the need for tire replacement.

- Low battery performance, such as slow starting or frequent recharging, is a clear indicator that a new battery is needed.

- Clogging or reduced efficiency in filters may affect overall functionality, suggesting a timely change.

Being proactive about replacing these crucial components can significantly enhance productivity and extend the lifespan of the machinery.

Maintenance Tips for Forklift Parts

Regular upkeep is essential for ensuring optimal performance and longevity of your machinery. Proper care can prevent costly repairs and enhance efficiency, allowing for seamless operations in various environments. Implementing a few strategic practices can significantly extend the lifespan of crucial components.

Routine Inspections

Conduct frequent assessments of key components to identify wear and tear. Look for signs of damage, leaks, or unusual sounds. Addressing issues early can save time and resources in the long run.

Lubrication and Cleaning

Maintaining cleanliness and proper lubrication of moving parts is vital. Regularly apply suitable lubricants and remove dirt or debris that can hinder performance. This simple step can dramatically improve functionality and prevent premature failures.

Identifying Issues with Your Forklift

Recognizing problems with your lifting equipment is crucial for ensuring safe and efficient operation. Timely identification of faults can prevent further damage and enhance productivity.

Common Signs of Trouble

Look out for unusual noises, vibrations, or changes in performance. These indicators often signal that something is amiss and requires immediate attention.

Regular Maintenance Checks

Implementing a routine inspection schedule can help delve into potential issues before they escalate. Regular upkeep not only prolongs the life of your machinery but also ensures optimal functionality.

Where to Find OEM Parts

Locating original equipment manufacturer components is crucial for ensuring optimal performance and longevity of your machinery. These authentic items are designed specifically to meet the standards set by the original maker, providing reliability and efficiency.

Authorized Dealers

One of the most reliable sources for genuine components is through authorized dealers. They not only guarantee authenticity but often provide expert advice on installation and maintenance, ensuring you get the most out of your equipment.

Online Marketplaces

Another effective way to find original components is by exploring reputable online marketplaces. Websites that specialize in industrial equipment typically offer a wide selection, along with user reviews that can help you make informed decisions.

Aftermarket Parts vs. OEM Parts

The choice between alternative components and original manufacturer components is a crucial consideration for many operators. Each option offers distinct advantages and drawbacks that can significantly impact performance and reliability.

Advantages of Aftermarket Components

- Cost-effectiveness: Typically lower prices can lead to significant savings.

- Variety: A wider selection often allows for tailored solutions to specific needs.

- Innovation: Some alternative options may incorporate newer technologies or enhancements.

Benefits of OEM Components

- Compatibility: Designed to fit seamlessly with specific equipment.

- Quality assurance: Often subjected to rigorous testing and quality control.

- Warranty support: Usually comes with manufacturer guarantees that protect your investment.

Ordering Parts Efficiently

Acquiring components for machinery can be streamlined through a structured approach. Understanding the layout of the necessary items and their specific functions enhances the efficiency of the ordering process. This section explores effective strategies to ensure timely procurement while minimizing downtime.

Understanding Component Requirements

Before placing an order, it’s essential to accurately identify the components needed for maintenance or repair. Utilizing a well-organized list that details each item and its specifications can significantly improve accuracy. Cross-referencing with service manuals or guides aids in preventing errors and ensuring that the correct items are sourced.

Utilizing Reliable Suppliers

Building relationships with trusted suppliers is vital. Researching and selecting vendors with a solid reputation can lead to better pricing, faster delivery times, and quality assurance. Establishing clear communication regarding needs and expectations can further enhance the ordering experience, ensuring that all necessary components arrive promptly.

Benefits of Regular Maintenance

Routine upkeep of heavy machinery plays a crucial role in ensuring optimal performance and longevity. Consistent attention to maintenance can significantly reduce the risk of unexpected breakdowns, enhance safety, and improve overall efficiency. This section highlights the key advantages of adhering to a regular maintenance schedule.

Improved Performance

Regular servicing allows equipment to operate at peak efficiency. It ensures that all components are functioning correctly and that any minor issues are addressed before they escalate into major problems. This proactive approach helps maintain the reliability of the machinery, allowing it to perform tasks more effectively.

Cost Savings

Investing in consistent maintenance can lead to substantial cost savings in the long run. By preventing severe malfunctions, businesses can avoid expensive repairs and unplanned downtime. Additionally, well-maintained equipment is often more fuel-efficient, further reducing operational costs.

| Benefit | Description |

|---|---|

| Enhanced Safety | Regular checks reduce the risk of accidents caused by equipment failure. |

| Increased Lifespan | Proper care extends the working life of machinery, maximizing investment. |

| Higher Resale Value | Well-maintained equipment retains better value over time. |

Resources for Forklift Owners

Owning heavy machinery comes with the responsibility of proper maintenance and management. Access to reliable resources can enhance the longevity and efficiency of your equipment. From technical manuals to community forums, these tools are essential for maximizing performance and ensuring safety.

Online platforms offer a wealth of information, including maintenance tips, troubleshooting guides, and user forums where owners share experiences and advice. Additionally, manufacturers often provide detailed manuals and support services to assist in understanding specific models and their unique needs.

Local dealerships and repair shops can also be invaluable, offering not only parts but expert insights into upkeep and repairs. Networking with other operators can provide practical knowledge and help identify common challenges faced in daily operations.

Lastly, attending workshops and training sessions can deepen your understanding of machinery handling and safety practices, empowering you to make informed decisions regarding your equipment.