The intricate world of heavy machinery involves a multitude of elements working in harmony to achieve optimal performance. A comprehensive overview of these components is essential for anyone looking to maintain or repair such equipment effectively. Each segment plays a vital role in the overall functionality, and recognizing their arrangement is crucial for successful operation.

In this exploration, we will delve into the various segments that comprise these robust machines, illustrating their connections and functions. By examining the layout and organization of these crucial elements, operators and technicians can gain valuable insights into troubleshooting and enhancing machine efficiency.

Furthermore, understanding the relationships between different components allows for more informed decision-making when it comes to upgrades or replacements. This knowledge not only aids in immediate repairs but also contributes to long-term maintenance strategies, ensuring that machinery continues to perform at its best.

Understanding Case 885 Machinery

This section explores the intricacies of a well-known agricultural machine, highlighting its essential components and functionality. By examining how these elements work together, one can appreciate the design and engineering that contribute to its efficiency and reliability in various farming tasks.

The machinery operates through a harmonious blend of mechanical systems, each fulfilling a specific role. Understanding these roles allows operators to optimize performance and ensure proper maintenance. Delving into the mechanisms reveals the ultimate synergy between power and precision, crucial for achieving desired outcomes in the field.

Maintenance is a key aspect that influences the longevity and productivity of the equipment. Regular checks and servicing not only enhance performance but also prevent unexpected breakdowns. Knowledge of the inner workings empowers users to make informed decisions, ensuring the machinery remains in peak condition throughout its operational lifespan.

Overview of Case 885 Features

This section provides a comprehensive look at the key characteristics of a well-regarded agricultural machine known for its reliability and performance. Users can expect a blend of innovative design and practical functionality that enhances productivity in various tasks.

- Powerful Engine: Designed for optimal performance, ensuring efficient operation in the field.

- Durable Build: Constructed with robust materials to withstand harsh conditions and heavy use.

- User-Friendly Controls: Intuitive layout that simplifies operation for both new and experienced users.

- Versatile Attachments: Compatible with a wide range of implements for diverse agricultural applications.

- Efficient Fuel Consumption: Engineered for better fuel efficiency, reducing overall operational costs.

In summary, this machine exemplifies the ultimate balance between strength and efficiency, making it a valuable asset for agricultural operations.

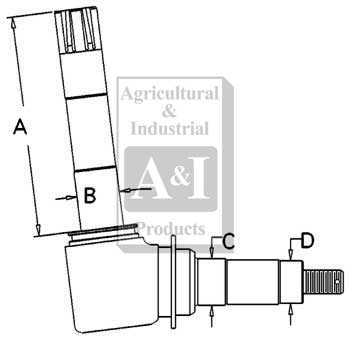

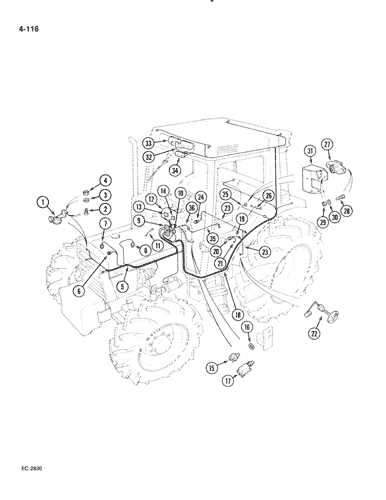

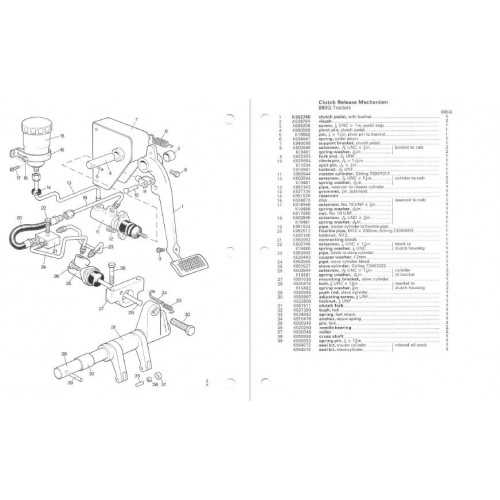

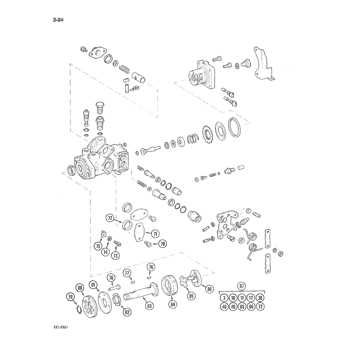

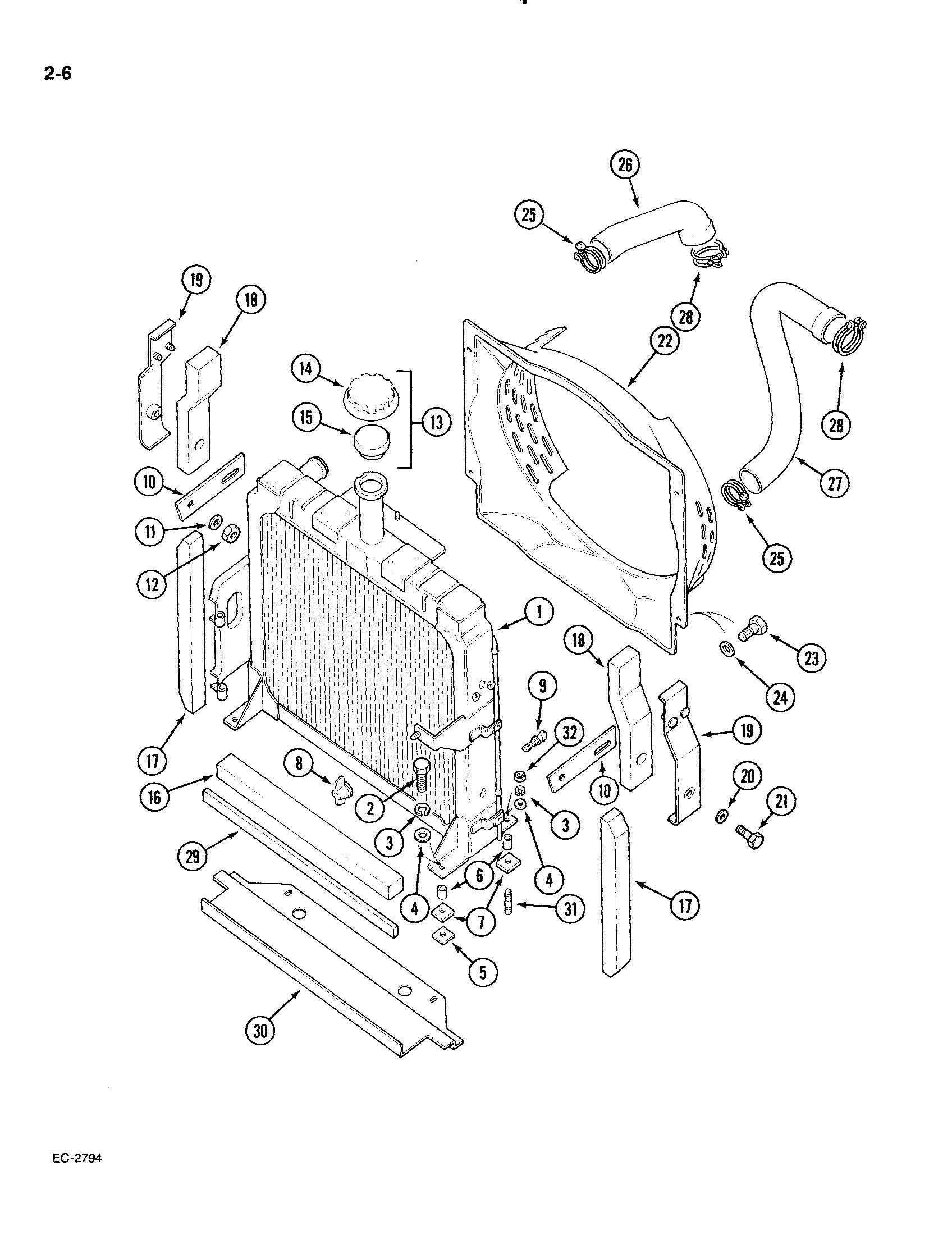

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. They offer a clear overview, helping users understand the relationship between various elements and their functions. Such illustrations serve as essential references for both professionals and enthusiasts, ensuring accurate assembly and disassembly processes.

By utilizing these schematics, individuals can quickly identify specific pieces, reducing the risk of errors during repairs. This not only enhances efficiency but also prolongs the lifespan of equipment. Furthermore, detailed visuals facilitate effective communication among team members, allowing for a smoother workflow and collaboration.

In addition, these resources are invaluable for training new personnel, providing them with a comprehensive understanding of the machinery’s structure. They enable learners to visualize complex systems, making it easier to grasp intricate concepts. Overall, having access to well-crafted visual guides significantly improves both individual and collective performance in maintenance tasks.

Identifying Key Components

Understanding the essential elements of a mechanical assembly is crucial for effective maintenance and repair. Each component plays a specific role, contributing to the overall functionality and efficiency of the machine. By recognizing these vital parts, users can ensure optimal performance and longevity.

Core Elements

Among the most important elements are the engine, transmission, and hydraulic systems. The engine serves as the powerhouse, generating the necessary energy for operation. Meanwhile, the transmission facilitates the transfer of power to various mechanisms, enabling movement and functionality. Lastly, the hydraulic system is responsible for managing fluid power, crucial for many operational tasks.

Supportive Features

In addition to the primary components, various supportive features enhance performance and reliability. Elements such as filters, sensors, and electrical systems play a critical role in monitoring and maintaining the efficiency of operations. Filters ensure clean fluid circulation, while sensors provide real-time data on the machine’s status. The electrical system manages power distribution, ensuring all parts function harmoniously.

How to Read Diagrams Effectively

Understanding visual representations requires a clear strategy to grasp the information they convey. By familiarizing yourself with the symbols and layout, you can better interpret the relationships and functions illustrated. This guide aims to provide essential tips for navigating complex visuals with confidence.

Familiarize Yourself with Symbols

Before diving into the details, take a moment to identify common icons and notations used in the representation. Knowing what each symbol represents will help you quickly connect the dots and understand the overall structure.

Follow the Flow

Pay attention to the direction of lines and connections, as they often indicate the sequence of operations or relationships. By tracing these paths, you can uncover the underlying logic and enhance your comprehension of the entire layout.

Common Issues in Case 885 Parts

When dealing with heavy machinery components, several common challenges may arise that can impact performance and efficiency. Understanding these issues is crucial for maintaining optimal functionality and ensuring longevity. Users often encounter problems related to wear, compatibility, and assembly that can lead to significant operational disruptions.

Wear and Tear: One of the most frequent concerns is the deterioration of various elements over time. Factors such as heavy use, environmental conditions, and maintenance practices can accelerate this process. Regular inspections are essential to identify worn components before they fail.

Compatibility: Ensuring that replacement elements are compatible with existing machinery is another common challenge. Mismatched components can lead to inefficiencies, increased wear, and potential damage. It is vital to verify specifications and compatibility before making any replacements.

Assembly Issues: Proper installation is critical for optimal operation. Users may face difficulties during assembly, leading to misalignment or improper fitting. These issues can affect performance and may require additional adjustments or professional assistance.

Addressing these challenges proactively can significantly enhance the reliability and efficiency of your machinery, minimizing downtime and ensuring smooth operations.

Replacement Parts Availability

Ensuring the accessibility of components is crucial for the maintenance and longevity of machinery. A reliable supply chain for these essential items can significantly enhance operational efficiency and reduce downtime. Availability is often influenced by factors such as demand, production schedules, and distribution networks.

When seeking replacements, it is vital to consider multiple sources, including authorized dealers, aftermarket suppliers, and online marketplaces. Each option may offer varying levels of quality, pricing, and delivery times. Researching these alternatives can provide users with the best solutions tailored to their specific needs.

Additionally, staying informed about the latest updates from manufacturers can lead to better procurement strategies. Regularly checking for new releases or inventory changes ensures that users can swiftly obtain the required components when necessary. Ultimately, proactive planning and awareness are key to maintaining operational integrity.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of machinery. Implementing regular care routines can prevent unnecessary wear and ensure optimal performance. Here are some effective strategies to consider.

Regular Inspections

- Conduct frequent checks for signs of wear and tear.

- Inspect fluid levels and top up as needed.

- Look for leaks and address them promptly.

Routine Cleaning

- Remove dirt and debris from surfaces to avoid corrosion.

- Clean filters regularly to maintain airflow and efficiency.

- Use appropriate cleaning agents to prevent damage.

Tools Needed for Repairs

To ensure successful maintenance and restoration of machinery, having the right implements is essential. A well-equipped toolbox not only facilitates the repair process but also enhances efficiency and safety during tasks.

Basic hand tools such as wrenches, screwdrivers, and pliers are fundamental for tackling a variety of issues. Additionally, specialized equipment like torque wrenches and hydraulic jacks may be necessary for more complex repairs. Investing in quality tools can significantly impact the longevity and performance of the equipment.

Furthermore, safety gear such as gloves and goggles should not be overlooked, as they protect against potential hazards. Ultimately, the right combination of tools and safety equipment is crucial for effective and secure repairs.

Comparative Analysis with Similar Models

In this section, we delve into a detailed examination of a specific model alongside its counterparts within the same category. By evaluating various attributes and performance metrics, we aim to uncover the strengths and weaknesses that distinguish these machines from one another. This approach not only highlights the unique features of our model but also provides insights into the broader landscape of similar equipment.

Performance Metrics

When assessing operational efficiency, factors such as power output, fuel consumption, and load capacity come into play. Our model exhibits exceptional performance in terms of fuel efficiency compared to its nearest rivals, which often require more energy to achieve comparable results. This efficiency can translate into significant cost savings for users over time.

Durability and Build Quality

The construction materials and overall design significantly impact longevity and maintenance needs. A comparative review reveals that our model is built with superior materials, providing enhanced durability. In contrast, some competitors might prioritize initial cost savings, leading to compromised longevity and higher maintenance frequencies.

User Experience

Another critical aspect is the ease of use and operator comfort. User feedback indicates that our model offers a more intuitive interface and ergonomic design, making it more accessible for operators of varying experience levels. This can greatly influence productivity on the job site, as ease of operation often correlates with efficiency.

Market Position

Finally, an analysis of market positioning reveals that our model is competitively priced while offering superior features. In contrast, other models may present lower upfront costs but often lack essential capabilities that can enhance overall productivity and user satisfaction.

This comparative analysis underscores the importance of considering various factors when choosing equipment. By understanding the nuances of each model, potential users can make informed decisions that align with their operational needs and budgetary constraints.

Owner Experiences and Feedback

This section aims to share insights and testimonials from individuals who have utilized the machinery in various capacities. The feedback gathered offers valuable perspectives on performance, reliability, and overall satisfaction, allowing potential users to make informed decisions based on real-world experiences.

Common Themes in User Feedback

- Durability and Longevity: Many users highlight the robust construction that withstands rigorous tasks.

- Efficiency: Operators frequently mention the enhanced productivity achieved during operation.

- Maintenance: A recurring point is the ease of upkeep, making it manageable for users to maintain optimal performance.

Notable User Testimonials

- “The machine has consistently exceeded my expectations in heavy-duty applications.”

- “I appreciate how straightforward it is to access components for servicing.”

- “The efficiency gains have significantly reduced my operational costs.”

Overall, the consensus reflects a high level of satisfaction, underscoring the reliability and effectiveness of the equipment in various operational environments.

Resources for Further Learning

This section aims to provide valuable materials and references for individuals interested in deepening their understanding of machinery components and their functionalities. Exploring these resources can enhance both theoretical knowledge and practical skills in the field.

Recommended Books

| Title | Author | Publication Year |

|---|---|---|

| Understanding Machine Mechanics | John Smith | 2018 |

| Advanced Components and Systems | Emily Johnson | 2020 |

Online Courses

| Course Title | Platform | Duration |

|---|---|---|

| Introduction to Mechanical Systems | Coursera | 6 weeks |

| Components and Their Applications | edX | 4 weeks |