When it comes to the efficiency and durability of farming machinery, it’s crucial to have a clear understanding of how each element works together. Knowing how the individual elements are connected and function is key to maintaining and optimizing your equipment for various field operations. This section will help you grasp the overall structure, so you can easily identify essential connections and perform regular maintenance tasks.

In modern agriculture, ensuring the longevity of machinery involves more than just regular use. It’s about recognizing when and where certain elements require attention. By familiarizing yourself with the arrangement of components, you can avoid unexpected breakdowns, saving both time and resources. Detailed insights into the structural organization will empower you to better manage repairs and replacements as necessary.

Understanding the layout of these essential elements also enables better customization for specific farming tasks. Whether you need to adjust settings or replace a specific part, having knowledge of the overall framework makes the process smoother and more efficient.

Understanding the Main Components

The machinery used for field preparation consists of several key elements, each contributing to the overall efficiency and performance. By familiarizing yourself with these crucial parts, you’ll be better equipped to maintain and optimize the equipment for maximum productivity.

- Blades and Discs: These are responsible for cutting through the soil, ensuring it is properly turned and mixed. Their sharpness and positioning are essential for effective operation.

- Frame Structure: The backbone of the equipment, supporting all other components and providing the necessary durability for challenging field conditions.

- Hydraulic System: Controls the movement and adjustments of the tool, allowing for smooth operation and adaptation to different soil types and terrains.

- Wheels and Tires: Offer mobility and stability, ensuring the equipment moves smoothly across the field, even in uneven or rough conditions.

- Depth Control Mechanism: Regulates the working depth, which is critical for achieving the desired soil preparation results, depending on the

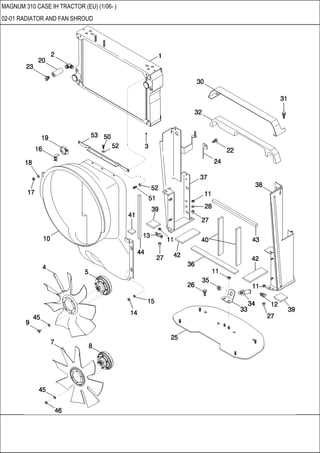

Exploring the Frame Structure

The framework of agricultural equipment plays a crucial role in ensuring durability and stability during operation. This section delves into the essential components that make up the supporting structure, providing a solid foundation for other mechanical elements. Understanding how these components interconnect allows for better performance and extended lifespan of the machine.

Reinforced Materials and Design: Modern agricultural frames are constructed from high-strength materials that can withstand significant stress and pressure. These materials not only provide stability but also ensure that the structure maintains integrity over time, even under demanding conditions.

Optimized Weight Distribution: One of the key aspects of frame design is the balanced distribution of weight. A well-structured frame helps in reducing strain on specific areas, allowing for smoother operation and reducing wear on critical parts. This balance also contributes to greater fuel efficiency and maneuverability.

Component Integration: The frame acts as a central hub for various attachments and systems. Proper alignment and secure connections between components are essential to ensure consistent performance. This

Tillage Blades and Their Functions

Tillage blades play a critical role in preparing the soil for planting by influencing how the ground is broken up, aerated, and mixed. These components are specifically designed to handle various tasks during soil preparation, ensuring optimal conditions for crop growth. Understanding the types of blades and their roles can help improve the efficiency of soil management.

- Disc Blades: These blades are curved and are commonly used for slicing through soil and residue. They help in breaking up clods and improving soil structure.

- Chisel Blades: Designed for deep soil penetration, chisel blades work to loosen compacted layers and allow for better water infiltration.

- Sweep Blades: These wide blades are used for shallow tillage, helping to cut weeds and mix surface materials without disturbing the deeper soil layers.

- Spike Blades: Spike blades are ideal for aeration and soil loosening, making them effective in enhancing root penetration and water absorption

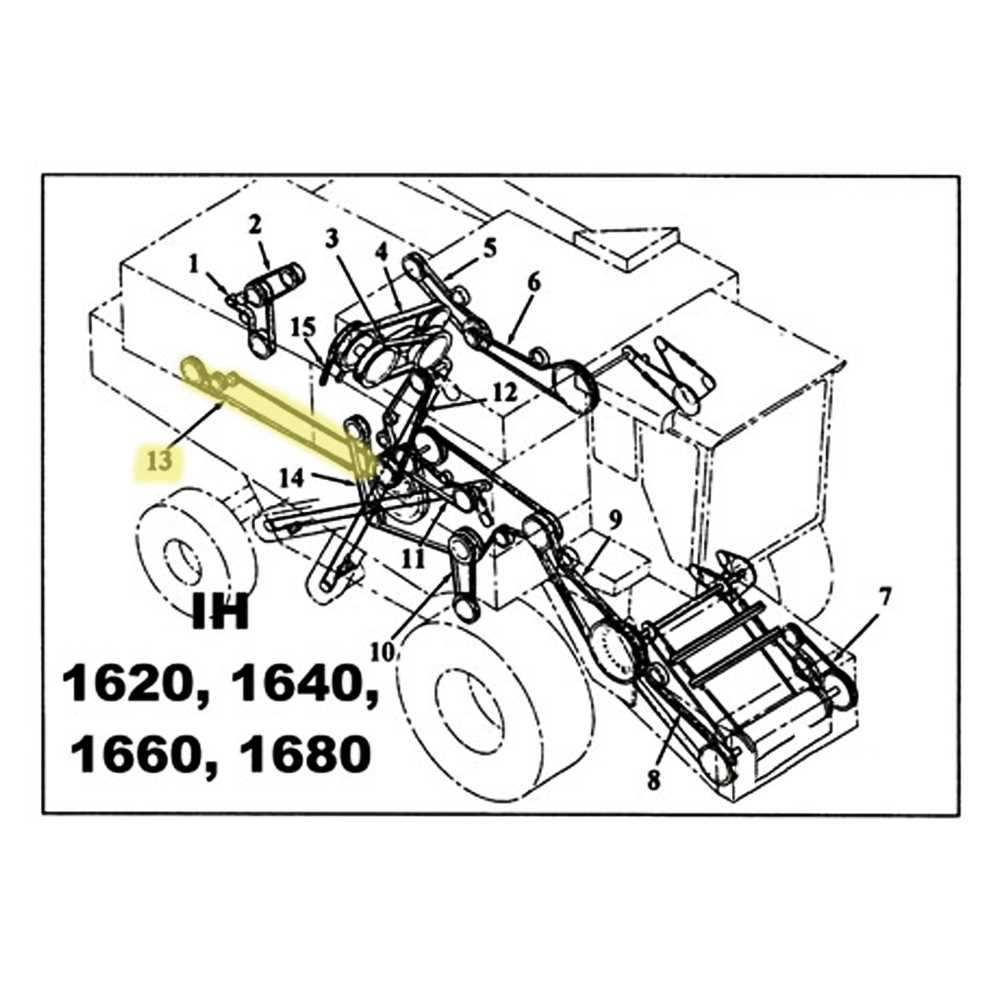

Hydraulic System Breakdown

The hydraulic system plays a crucial role in managing the overall operation and efficiency of modern machinery. It ensures that various mechanical components receive the necessary pressure and fluid control, allowing for precise movements and smooth functionality. Understanding the way this system is structured is essential for troubleshooting and maintaining performance in challenging conditions.

Key elements within the system include the pumps, valves, and cylinders, all working together to create a seamless transfer of energy. Fluid dynamics and pressure regulation are core aspects of this system, and their balance is critical for avoiding failures. Proper maintenance and timely inspections can prevent issues that may lead to larger mechanical problems.

Each section of the hydraulic network must be monitored for wear, leaks, and performance inefficiencies. By keeping the system in

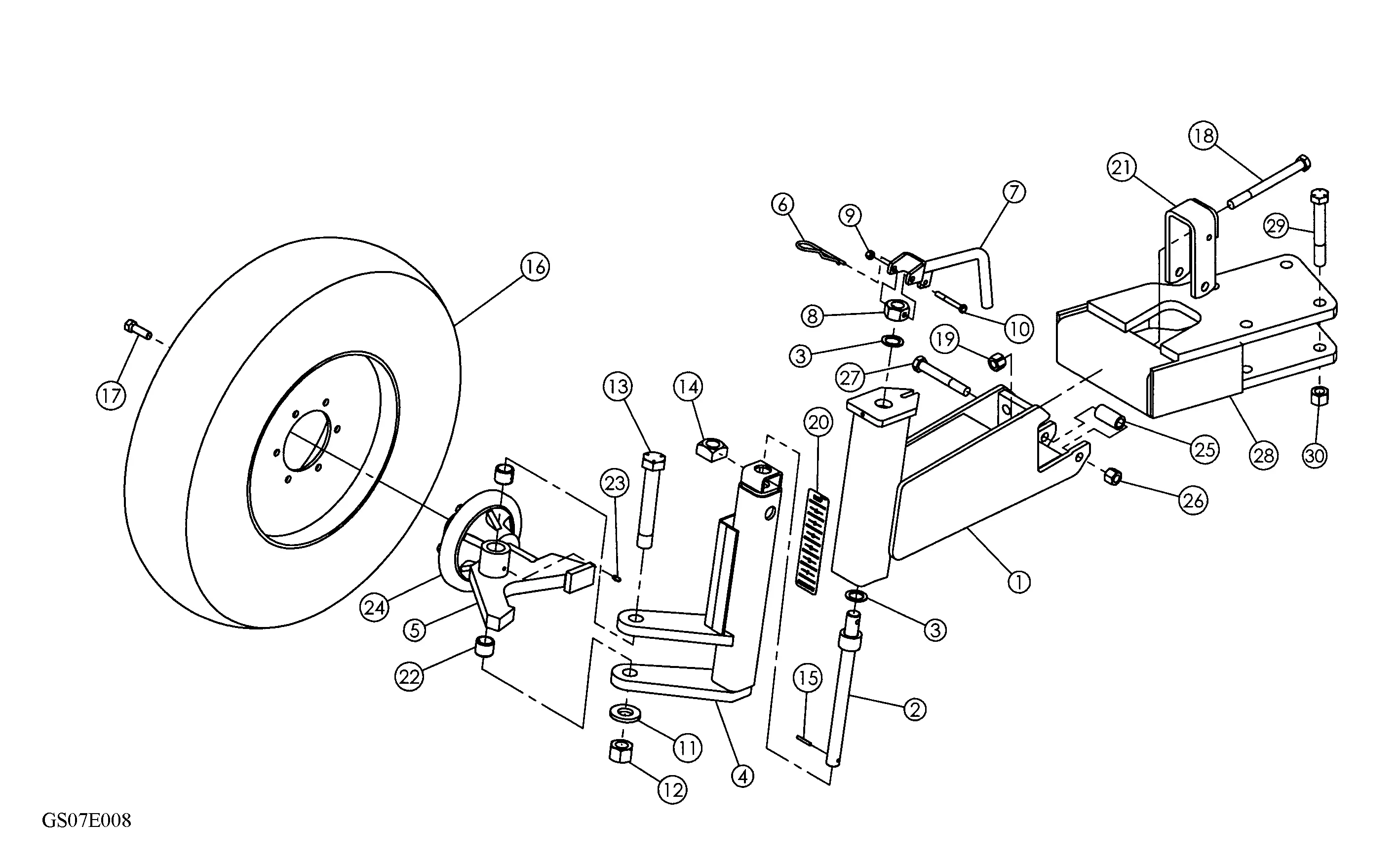

Wheels and Tire Configurations

The structure and layout of wheels and tires play a crucial role in ensuring optimal performance and durability. Proper alignment, tire types, and size compatibility are all factors that influence the efficiency and stability of machinery during operation. Understanding how these components work together is essential for maintaining equipment in peak condition.

- Tire Size: Choosing the right tire size ensures smooth movement and prevents wear on the machinery. It is important to match the tire size with the weight and the surface it operates on.

- Tread Pattern: Different tread designs are suited for varying soil conditions. Aggressive patterns provide better traction in loose ground, while smoother treads offer stability on firmer terrain.

- Wheel Alignment: Proper wheel alignment is key to reducing uneven tire wear and ensuring the machine moves straight and efficiently

Disc Adjustment Mechanisms

The process of modifying the position and angle of discs is crucial for optimizing soil cultivation. Proper adjustments enhance the efficiency of soil mixing and ensure uniformity in the tillage process. Various mechanisms are employed to facilitate these adjustments, allowing operators to tailor the equipment to specific agricultural requirements.

Key aspects of disc adjustment mechanisms include:

- Angle Adjustment: Altering the angle of the discs can influence how deeply they penetrate the soil. This can be adjusted based on soil type and moisture levels.

- Depth Control: Mechanisms that regulate the depth of disc operation are essential for achieving desired tillage results. This can involve hydraulic systems or manual settings.

- Spacing Configuration: The distance between discs affects coverage and efficiency. Adjustable spacing allows for customization based on crop type and field conditions.

- Resistance Settings: Some systems include features to modify the resistance of the discs against soil. This adjustment can help in managing power requirements and wear on the equipment.

Understanding these mechanisms enables operators to maximize the effectiveness of their cultivation efforts, ultimately contributing to better crop yields and soil health.

Maintenance Guide for Bearings

Proper upkeep of rotational components is essential for ensuring optimal performance and longevity. Regular attention to these elements can prevent costly breakdowns and enhance overall efficiency. This section outlines key practices for maintaining these crucial parts, focusing on inspection, lubrication, and replacement.

Inspection: Regular checks are vital to identify any signs of wear or damage. Look for unusual noises, vibrations, or heating, which may indicate that a component is failing. Additionally, inspect for any discoloration or surface irregularities that may suggest deterioration.

Lubrication: Adequate lubrication is crucial for reducing friction and heat. Utilize the manufacturer’s recommendations for the type and frequency of lubricant to ensure optimal operation. Over-lubrication can lead to excess pressure and potential failure, while under-lubrication may result in insufficient protection.

Replacement: If inspection reveals significant wear, timely replacement is necessary. Be sure to use components that meet specified standards to maintain system integrity. Following the correct installation procedures will also enhance performance and reliability.

By adhering to these maintenance guidelines, users can significantly extend the life of rotational components and maintain the efficiency of their machinery.

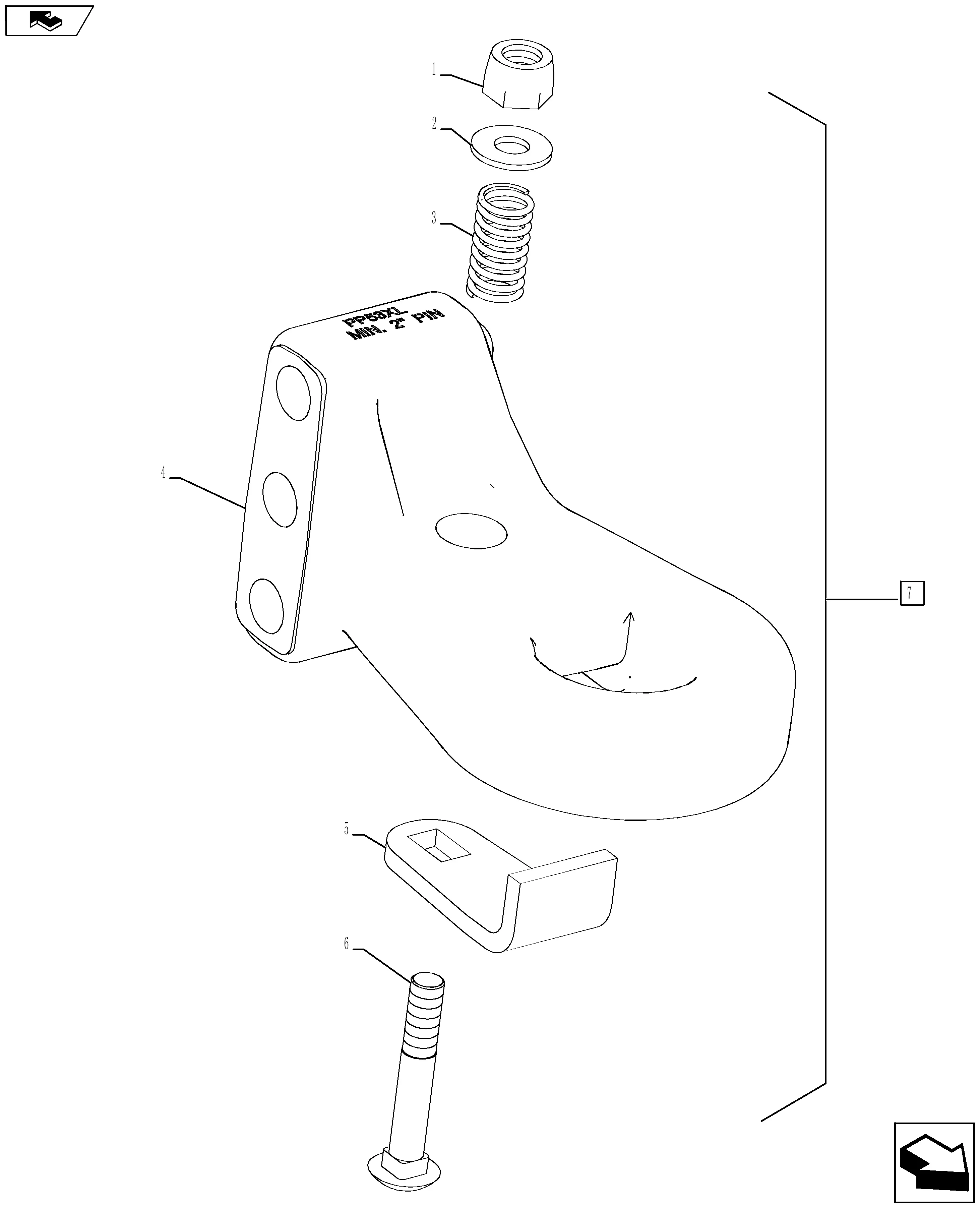

Spring Tensioning System Overview

The tensioning mechanism plays a crucial role in ensuring optimal performance and longevity of agricultural machinery. This system is designed to maintain appropriate pressure on various components, facilitating seamless operation and reducing wear over time.

Key Functions

- Maintains consistent pressure on attachments and implements.

- Reduces vibrations and impacts during operation.

- Enhances overall stability of the machinery.

Components of the Tensioning Mechanism

- Springs: Provide the necessary force to maintain tension.

- Adjustment Mechanism: Allows for fine-tuning of the tension based on operational needs.

- Mounting Brackets: Secure the system in place, ensuring durability and reliability.

Safety Features and Precautions

Ensuring user safety during operation is paramount for agricultural machinery. Various measures and mechanisms are incorporated into the design to protect operators and bystanders. Understanding these features and adhering to recommended precautions can significantly minimize the risk of accidents and injuries.

It is essential to familiarize oneself with the equipment’s safety guidelines before commencing work. This includes recognizing warning labels and understanding the operational controls designed for safe handling.

Feature Description Emergency Stop Quickly halts all operations to prevent further movement in hazardous situations. Safety Guards Protect moving parts, reducing the risk of entanglement or contact during operation. Operator Presence Control Automatically shuts down machinery if the operator leaves the designated area. Warning Lights Indicate when the equipment is in operation or if there are potential issues. By adhering to these safety measures and maintaining vigilance while using the equipment, operators can ensure a safer working environment. Regular maintenance checks and compliance with operational protocols further enhance safety standards.

Identifying Key Wear Parts

Understanding the essential components that experience significant wear is crucial for maintaining optimal performance. These elements play a vital role in the overall functionality and efficiency of the equipment. Recognizing which parts are prone to deterioration can help in planning timely replacements and ensuring uninterrupted operation.

Key components that typically face substantial wear include those involved in soil interaction and movement. These may consist of blades, tines, and other mechanisms that directly engage with the ground. Regular inspections and assessments of these items can reveal signs of damage or excessive wear, allowing for proactive maintenance strategies.

Moreover, monitoring the condition of wear-prone elements not only extends the lifespan of the machinery but also enhances productivity. Identifying early indicators of wear can lead to better decision-making regarding repairs and replacements, ultimately contributing to improved efficiency in agricultural practices.

Lubrication Points and Care

Proper maintenance is essential for the longevity and efficiency of agricultural machinery. Ensuring that all moving parts are adequately lubricated reduces friction, minimizes wear, and prevents potential breakdowns. Identifying key areas that require regular attention will help in preserving the equipment’s functionality.

Key Areas for Lubrication

Focus on critical components such as bearings, joints, and pivot points. These areas are prone to wear and benefit significantly from consistent lubrication. Utilizing high-quality lubricants tailored for heavy machinery will enhance performance and extend service life.

Maintenance Routine

Establish a routine for inspecting and applying lubricant to the designated spots. Regular checks should be part of the maintenance schedule, especially before and after intensive use. Keeping a record of lubrication activities can aid in tracking the maintenance history and ensuring nothing is overlooked.

Replacement and Installation Instructions

This section provides essential guidance for the substitution and setup of components in agricultural machinery. Following the proper procedures ensures optimal performance and longevity of the equipment. Adhering to these guidelines will facilitate a smooth transition during the replacement process.

Preparation Steps

Before beginning the replacement, it is crucial to gather all necessary tools and components. Ensure that the work area is clean and organized to prevent any mishaps. Review the following checklist to confirm that you have everything you need:

Item Description Tools Wrenches, screwdrivers, and pliers Components New parts for replacement Safety Gear Gloves and protective eyewear Installation Process

Once you have gathered all necessary items, proceed with the installation as follows:

- Begin by disconnecting the power source to ensure safety.

- Remove the old component carefully, taking note of how it is secured.

- Install the new component in the same orientation as the previous one, securing it properly.

- Reconnect the power source and perform a functionality check to ensure proper installation.