In the world of modern farming, the efficiency and reliability of machinery play a crucial role in ensuring productive harvests. Understanding the intricate systems that make up these machines is essential for operators and technicians alike. By familiarizing oneself with the essential elements, one can optimize performance and extend the lifespan of the equipment.

Every piece of agricultural machinery consists of numerous interconnected components, each designed to perform specific functions. A comprehensive overview of these elements allows users to identify potential issues and carry out necessary maintenance with confidence. This knowledge not only improves the functionality of the equipment but also enhances overall operational efficiency.

Furthermore, gaining insight into the layout and function of each component aids in troubleshooting and repairs. By knowing how different sections interact and support one another, individuals can address problems more effectively, leading to minimized downtime. This understanding is invaluable for anyone involved in the operation or upkeep of farming machinery.

Understanding the Case IH 8420 Baler

This section explores the essential aspects of a popular agricultural machine known for its efficiency in handling various types of forage. Gaining insight into its functionality and design can significantly enhance operational effectiveness and maintenance practices.

Key Features and Functions

The machine is equipped with advanced technology that optimizes the process of creating compact, manageable bundles of hay or straw. Its robust build ensures durability while its innovative features facilitate ease of use, making it a valuable asset for farmers.

Maintenance and Care

Regular upkeep is vital to prolonging the lifespan of this equipment. Understanding the core components and their functions allows operators to identify potential issues early, ensuring optimal performance throughout its operational life.

Key Features of the 8420 Model

This model is designed with a range of innovative attributes that enhance its efficiency and productivity in the field. By focusing on advanced technology and robust construction, it caters to the needs of modern agricultural practices, ensuring that users can achieve optimal results with ease.

Advanced Technology Integration

The incorporation of cutting-edge systems allows for seamless operation, making it easier for operators to manage tasks. Features such as automated adjustments and real-time monitoring contribute to improved performance and consistency, ultimately leading to higher yields.

Durable Construction and Reliability

Built with high-quality materials, this equipment offers exceptional durability. The design emphasizes longevity, ensuring that it can withstand the rigors of frequent use in challenging environments. This reliability is essential for farmers who depend on their machinery for day-to-day operations.

In conclusion, the combination of technological advancements and sturdy design makes this model a valuable asset in any agricultural setting.

Importance of Regular Maintenance

Consistent upkeep of agricultural machinery is crucial for ensuring optimal performance and longevity. Regular inspections and servicing not only help in identifying potential issues before they escalate but also contribute to enhanced efficiency and productivity. This proactive approach minimizes unexpected breakdowns, reducing downtime during critical operational periods.

Enhancing Performance

Routine maintenance directly impacts the functionality of equipment. By adhering to a scheduled maintenance plan, operators can ensure that all components are working harmoniously. This leads to smoother operations and improved output, ultimately benefiting overall farm productivity.

Cost Efficiency

Investing time and resources in regular care can lead to significant savings in the long run. By preventing major repairs through timely maintenance, operators can avoid costly downtime and repairs. Furthermore, well-maintained equipment often operates more efficiently, resulting in lower fuel and operational costs.

Common Parts and Their Functions

This section explores various essential components found in agricultural machinery designed for efficient hay and straw handling. Understanding these elements enhances operational efficiency and maintenance practices.

Feed Roller: This component is responsible for directing the material into the compression chamber, ensuring a consistent flow for optimal baling.

Chamber: The area where the material is compacted into bundles, featuring adjustable mechanisms to accommodate different sizes and densities.

Twine and Netting System: Vital for securing the finished bundles, this system applies twine or netting around the compacted material, ensuring it holds together during transport.

PTO Shaft: This connection transfers power from the tractor to the machinery, allowing it to operate efficiently and effectively in the field.

Wheel Assembly: This part supports mobility and stability, enabling easy maneuvering across various terrains while maintaining balance during operation.

Hydraulic System: Facilitates the automatic adjustments of components, allowing for seamless transitions between different operational settings for enhanced efficiency.

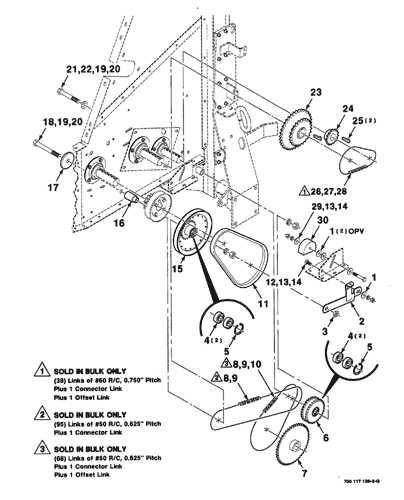

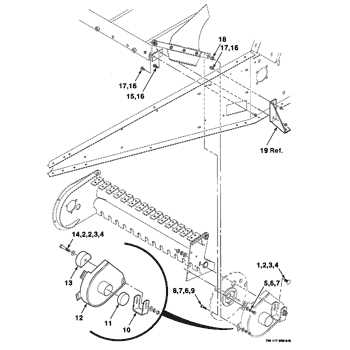

How to Read the Parts Diagram

Understanding a component schematic is crucial for effective maintenance and repairs of agricultural machinery. This visual representation provides detailed insights into each element’s function and location, facilitating the identification of any faulty parts that may need attention.

Familiarizing with the Layout

The first step is to recognize the overall structure of the schematic. Typically, components are arranged logically, often grouped by their function. Familiarize yourself with the key sections and how they interrelate. Each segment usually includes numbered labels that correspond to a list, offering descriptions and specifications of each part.

Interpreting Symbols and Labels

Next, pay attention to the symbols used throughout the schematic. Different shapes and lines can indicate various types of components or connections. Emphasize the importance of these symbols, as they provide vital information regarding the assembly and functionality of the machine. Additionally, cross-reference the labels with the accompanying list to gain a complete understanding of the components’ roles.

By mastering these aspects, you will enhance your ability to troubleshoot and maintain your equipment efficiently.

Identifying Worn Components

Recognizing degraded elements in machinery is crucial for maintaining efficiency and longevity. By monitoring specific indicators, operators can ensure that performance remains optimal, minimizing downtime and costly repairs.

Key Indicators of Wear

- Unusual noises during operation

- Decreased output quality

- Visible signs of cracking or fraying

- Inconsistent operation or responsiveness

Steps for Inspection

- Perform regular visual checks of components.

- Listen for abnormal sounds while the machine is in use.

- Measure the performance against standard benchmarks.

- Replace any identified parts before they lead to failure.

Where to Find Replacement Parts

Locating suitable components for your machinery can significantly enhance its performance and longevity. Numerous resources are available to help you identify the right items to ensure seamless operation.

Online Retailers

Numerous e-commerce platforms specialize in agricultural equipment components. Websites often feature extensive catalogs, allowing you to search by model or type. Customer reviews can provide valuable insights into product quality and seller reliability.

Local Dealerships and Distributors

Visiting nearby dealerships is another effective strategy. Knowledgeable staff can assist you in identifying the specific items needed. Additionally, they may offer genuine replacements that guarantee compatibility and performance.

Tools Needed for Repairs

When undertaking maintenance or restoration tasks, having the right equipment is crucial for efficiency and safety. Proper tools not only facilitate the process but also ensure that repairs are performed to a high standard, minimizing future issues.

Essential items include:

- Wrenches – for tightening and loosening bolts.

- Screwdrivers – necessary for various fastening applications.

- Pliers – useful for gripping and manipulating components.

- Socket sets – ideal for working with different sizes of nuts and bolts.

- Torque wrenches – to ensure fasteners are tightened to the correct specifications.

- Cutting tools – for any necessary modifications or replacements.

- Safety gear – including gloves and goggles to protect against injuries.

By assembling these tools, individuals can confidently tackle repairs, leading to optimal performance and longevity of the equipment.

Tips for Efficient Baler Operation

Maximizing productivity while minimizing wear and tear is essential for any harvesting machine. Understanding key operational strategies can significantly enhance performance and longevity, ensuring that the equipment functions at its best throughout the season.

1. Regular Maintenance: Keeping your equipment in top shape requires routine checks and timely repairs. Regularly inspect components such as belts and rollers to prevent unexpected breakdowns.

2. Optimal Settings: Adjusting settings based on material type and moisture content can lead to improved efficiency. Ensure that the compression settings are suited for the specific crop to achieve desired bale density.

3. Proper Speed: Maintaining an appropriate operational speed is crucial. Too fast can lead to inadequate compaction, while too slow may reduce throughput.

4. Monitor Conditions: Be aware of weather and ground conditions. Wet or overly dry materials can affect the quality of the output. Aim to work under optimal conditions for the best results.

5. Operator Training: Ensure that all operators are well-trained and understand the machine’s features and functions. Proper knowledge can prevent mistakes that lead to inefficiencies or damage.

Common Issues and Troubleshooting

In the realm of agricultural machinery, encountering operational challenges is not uncommon. Understanding potential malfunctions and having a systematic approach to address them can significantly enhance efficiency and reduce downtime. This section outlines frequent problems that may arise, along with effective troubleshooting methods to resolve them.

1. Unusual Noises: If you notice any unexpected sounds during operation, it could indicate wear or misalignment of components. Check for loose parts or damaged bearings. Lubricating moving parts may also help alleviate these issues.

2. Inconsistent Bale Formation: When bales are not forming uniformly, inspect the tension settings and ensure that the feeding system is clear of debris. Adjustments to the pickup height may also improve consistency.

3. Jamming: Frequent jamming can disrupt workflow. Examine the feed system for blockages, and ensure that the machine is not overloaded. Regular maintenance and cleaning can prevent this issue.

4. Hydraulic Problems: If you experience sluggish movements or a complete loss of hydraulic function, check fluid levels and look for leaks in hoses and connections. Replacing damaged components can restore proper operation.

5. Electrical Issues: Malfunctions in the control system may arise from faulty wiring or blown fuses. Inspect all electrical connections and replace any damaged wires to ensure reliable functionality.

By proactively identifying and addressing these common challenges, operators can maintain optimal performance and extend the lifespan of their machinery.

Upgrades and Enhancements Available

When it comes to optimizing performance and efficiency in agricultural machinery, several enhancements can be implemented. These modifications not only improve functionality but also extend the lifespan of the equipment. By investing in various upgrades, operators can significantly enhance productivity and achieve better results in their operations.

| Upgrade Type | Description | Benefits |

|---|---|---|

| Enhanced Feed System | Improvements to the feeding mechanism for smoother material intake. | Increased efficiency and reduced blockages. |

| Advanced Control Systems | Integration of modern electronic controls for better precision. | Improved accuracy and automation in operations. |

| Durable Wear Parts | High-quality components designed to withstand harsh conditions. | Longer lifespan and reduced maintenance costs. |

| Performance Monitoring Tools | Systems that track performance metrics in real-time. | Data-driven decisions for enhanced operational efficiency. |

| Customized Attachments | Additional tools tailored to specific tasks and crops. | Versatility and improved task handling. |

Incorporating these upgrades can lead to substantial improvements in the overall functionality of your equipment, making it more efficient and capable of meeting diverse agricultural needs.

Resources for Further Information

Exploring additional materials is essential for a comprehensive understanding of agricultural machinery maintenance and repair. Numerous resources can provide valuable insights into components, functionality, and troubleshooting techniques.

Online Forums: Engaging in community discussions can offer practical advice and firsthand experiences from other users.

Manufacturer Websites: Official sites often have detailed guides, manuals, and FAQs that can help clarify operational issues.

Instructional Videos: Platforms like YouTube feature tutorials that visually demonstrate repairs and maintenance tasks.

Technical Manuals: Acquiring specific manuals can be invaluable for in-depth knowledge of machinery specifications and service procedures.

Industry Publications: Magazines and journals focused on agriculture frequently publish articles that cover the latest innovations and maintenance tips.

By utilizing these resources, one can delve deeper into the intricacies of equipment care, ensuring optimal performance and longevity.