In any powerful cutting device, the correct functioning of various elements plays a crucial role in ensuring smooth operation and efficiency. These machines, designed for heavy-duty tasks, require a combination of different mechanical parts to perform at their best.

Each element has a specific role, whether it’s controlling speed, directing energy, or ensuring safety during operation. Understanding how these various components work together can help improve maintenance and extend the life of your equipment.

By gaining insight into how the tool is constructed and identifying the key components, users can better handle repairs and adjustments, ultimately keeping their tools in top condition.

Understanding the essential elements of a mechanical cutting tool is key to ensuring it operates smoothly. Each component plays a vital role in its function, and knowing how these pieces fit together can help maintain efficiency and prolong the tool’s life.

Main Components

- Power Source

- Cutting Mechanism

- Chain Tensioner

- Safety Features

Importance of Regular Maintenance

Regular upkeep is crucial for optimal performance. Routine checks ensure that each part is functioning as expected, preventing potential issues and ensuring the longevity of the tool.

Understanding Chainsaw Components

The functionality of a cutting tool relies on its various elements working in harmony. Each component plays a vital role in ensuring efficiency and safety during operation. A comprehensive grasp of these parts enhances maintenance practices and optimizes performance.

Power Source is fundamental, providing the energy necessary for the tool’s operation. This can be electric or fueled by gas, each with its own advantages and considerations regarding usability and maintenance.

Bar and Chain work together to perform the actual cutting. The bar serves as a guide, while the chain, equipped with sharp teeth, moves around it to slice through materials. Regular inspection of these components is crucial to maintain cutting efficiency and safety.

Drive Mechanism is responsible for moving the chain. This can involve various systems that convert the power source’s energy into motion. Understanding how this mechanism functions allows users to troubleshoot performance issues more effectively.

Safety Features are designed to protect the operator. Components such as chain brakes and protective guards reduce the risk of accidents, making it imperative to ensure they are in proper working order.

Lastly, Maintenance Tools and accessories enhance the longevity of the equipment. Regular upkeep, including cleaning and lubrication, keeps all parts functioning optimally and prolongs the lifespan of the device.

Grasping the roles and interconnections of these elements contributes significantly to effective usage and maintenance, ensuring that the equipment operates smoothly and safely.

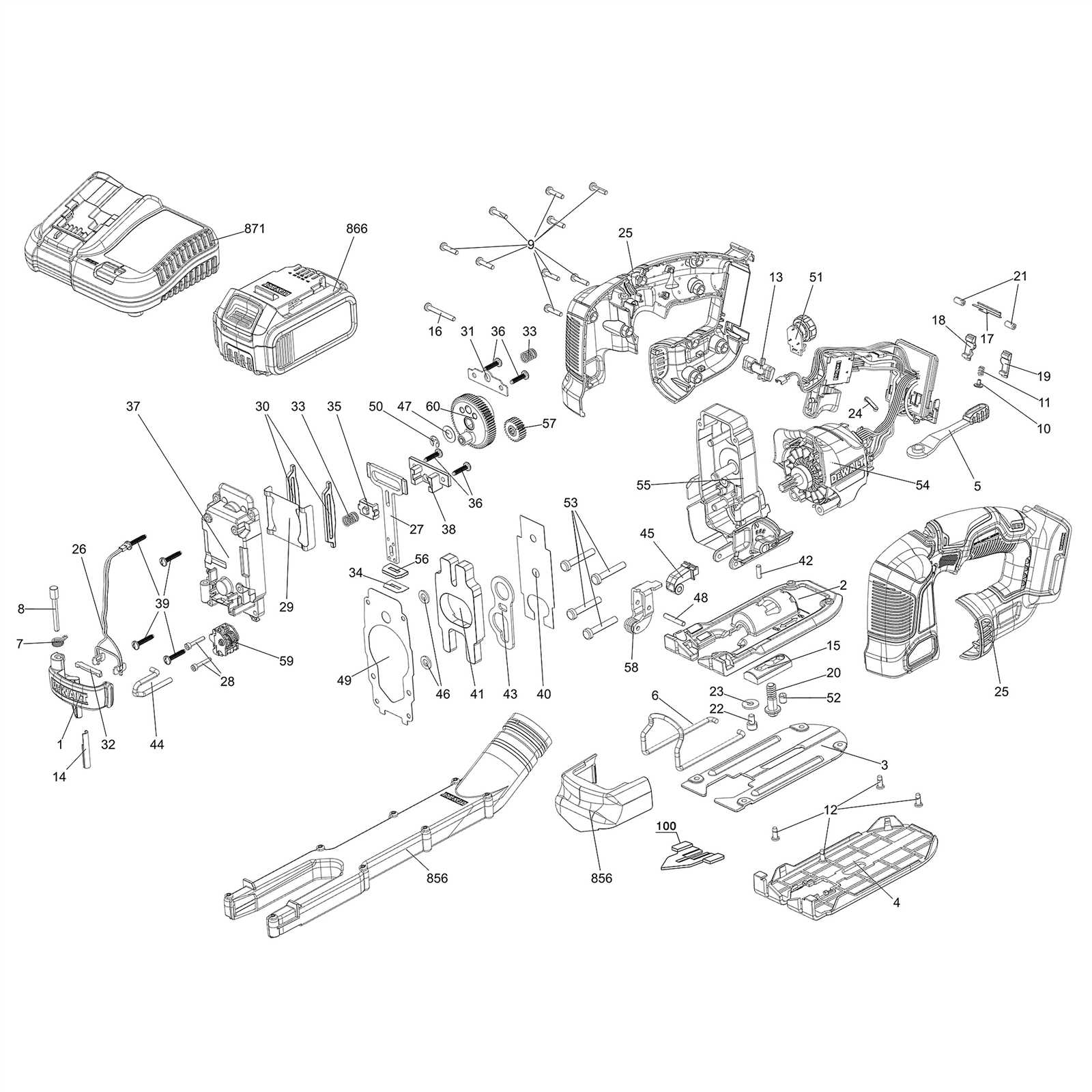

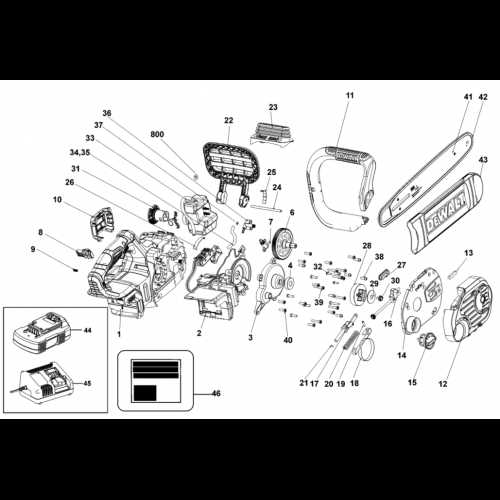

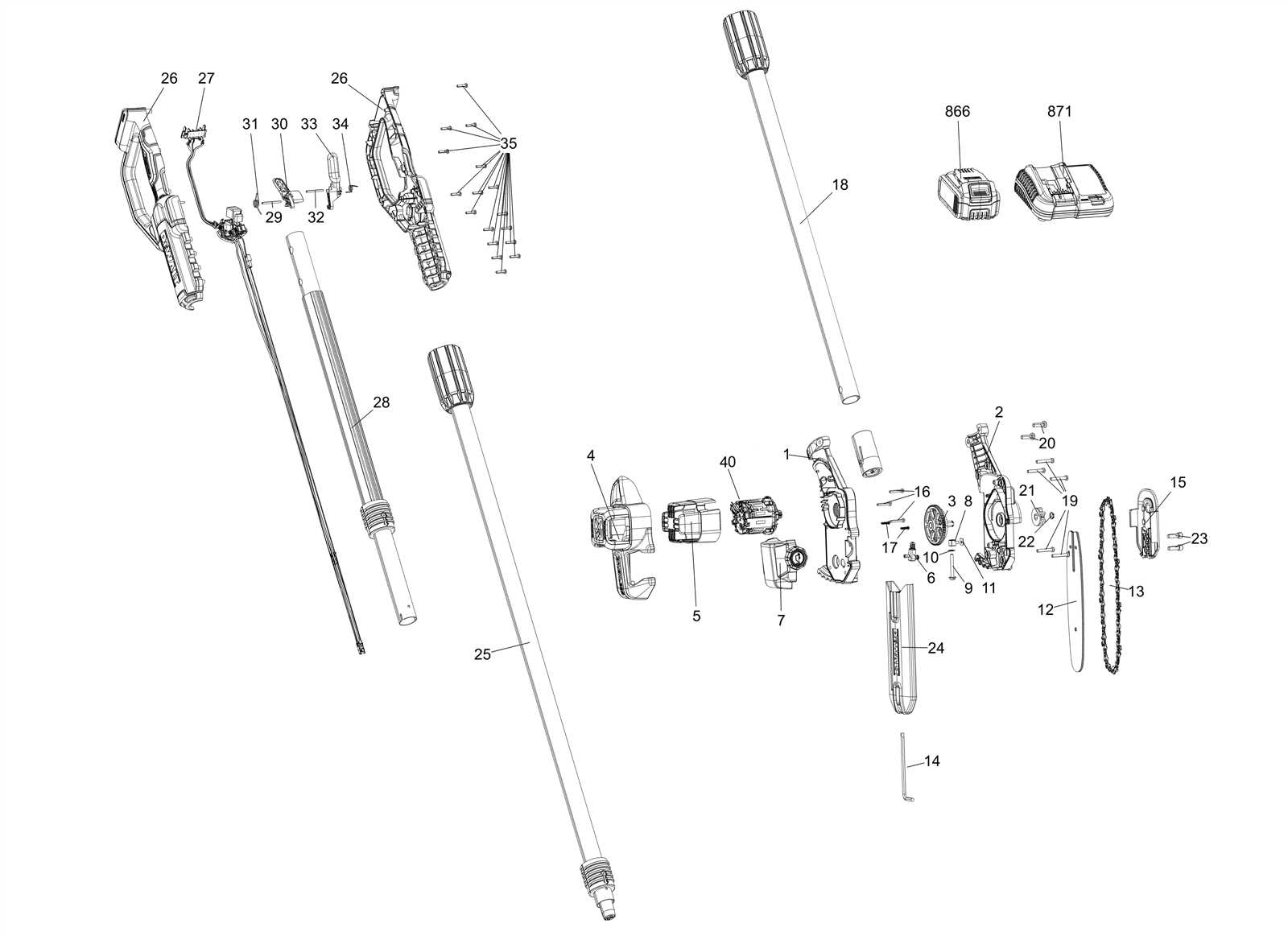

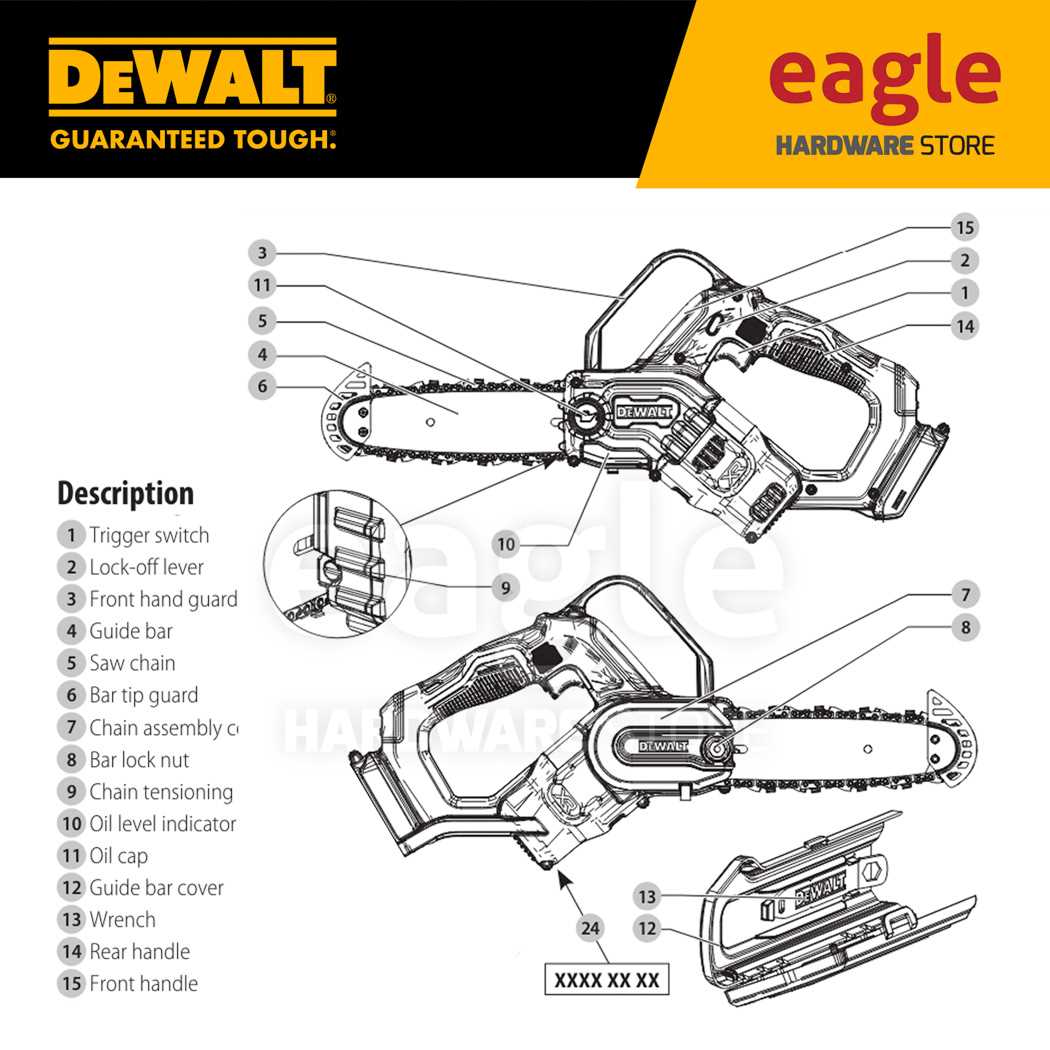

Key Parts of Dewalt Chainsaws

Understanding the essential components of a power cutting tool is crucial for effective maintenance and operation. Each element plays a significant role in ensuring performance, safety, and longevity. Familiarity with these features can enhance both usability and troubleshooting capabilities.

1. Motor: The heart of the tool, the motor generates the necessary power to drive the cutting mechanism. A robust motor contributes to efficient operation and reduces the risk of stalling during heavy use.

2. Cutting Bar: This elongated piece is vital for guiding the chain during operation. The length of the cutting bar can affect the tool’s reach and the size of the material that can be handled.

3. Chain: The moving element that actually performs the cutting. A well-maintained chain ensures clean cuts and optimal performance, while regular sharpening is essential for effectiveness.

4. Guide Plate: Located at the front, this component aids in directing the chain and maintaining alignment during cutting. It plays a crucial role in enhancing accuracy and control.

5. Tensioning Mechanism: This system allows users to adjust the tightness of the chain, ensuring it remains secure during operation. Proper tension is necessary to prevent slippage and improve cutting efficiency.

6. Safety Features: Including chain brakes and protective covers, these elements are designed to reduce the risk of accidents. Understanding their function is key to safe operation.

By gaining insight into these fundamental elements, users can better appreciate the craftsmanship behind their tool and maintain it effectively for years to come.

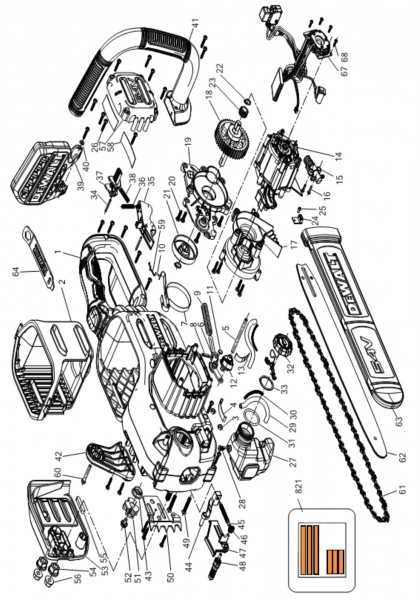

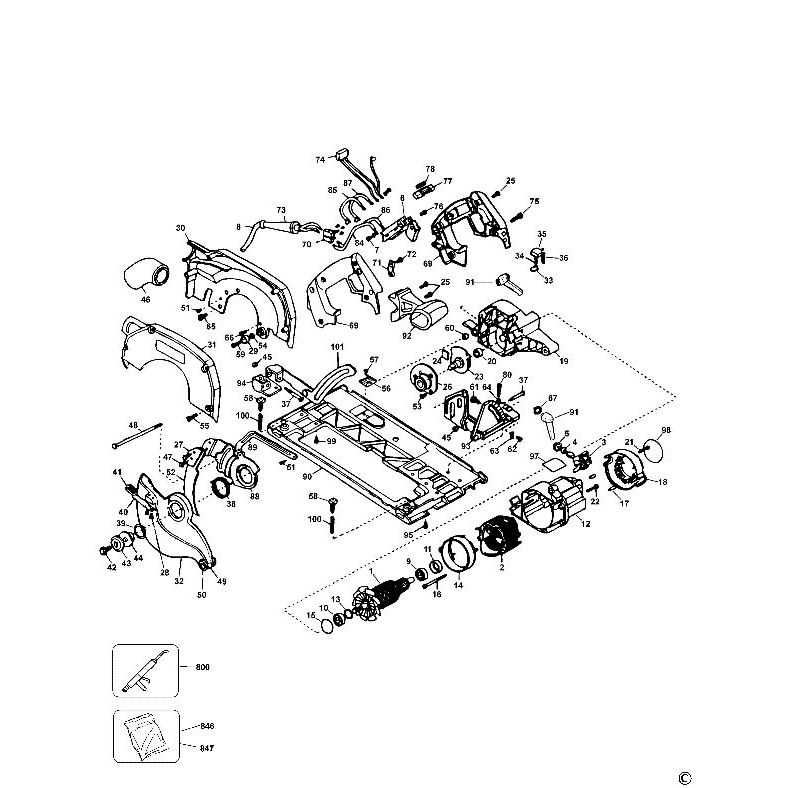

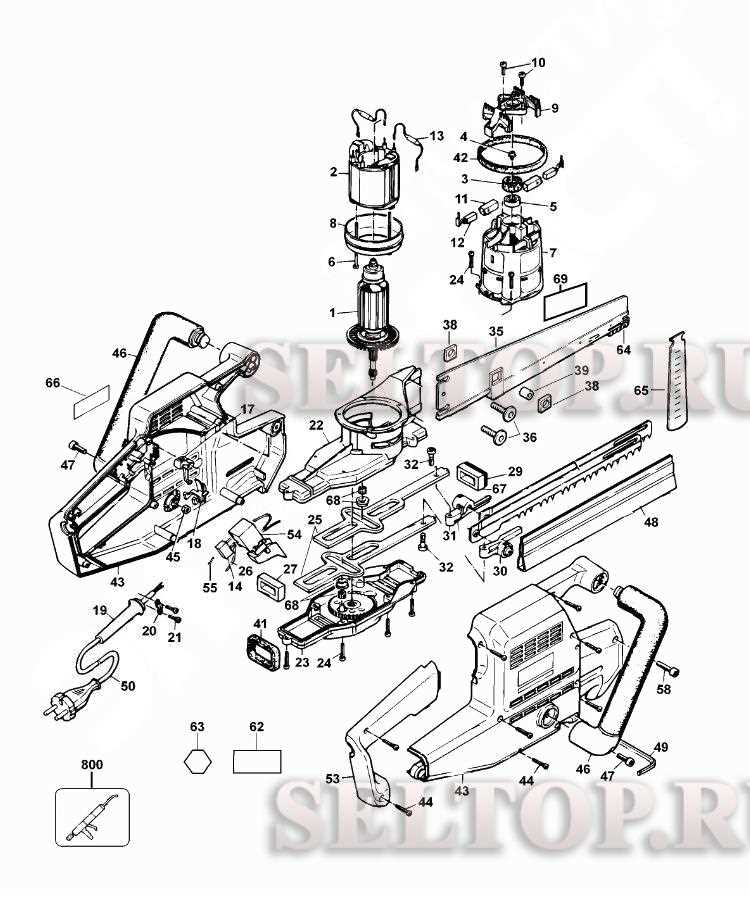

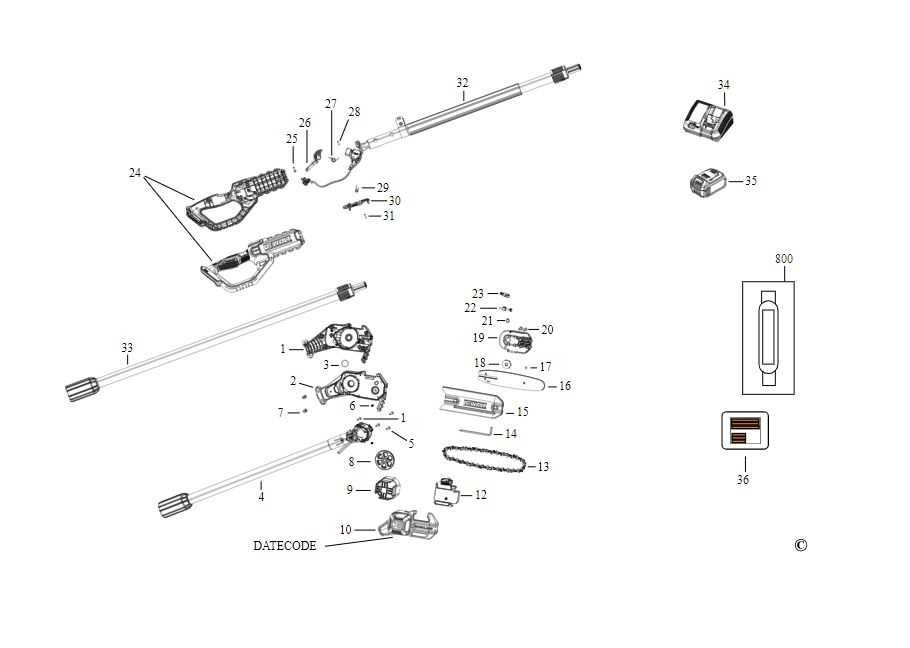

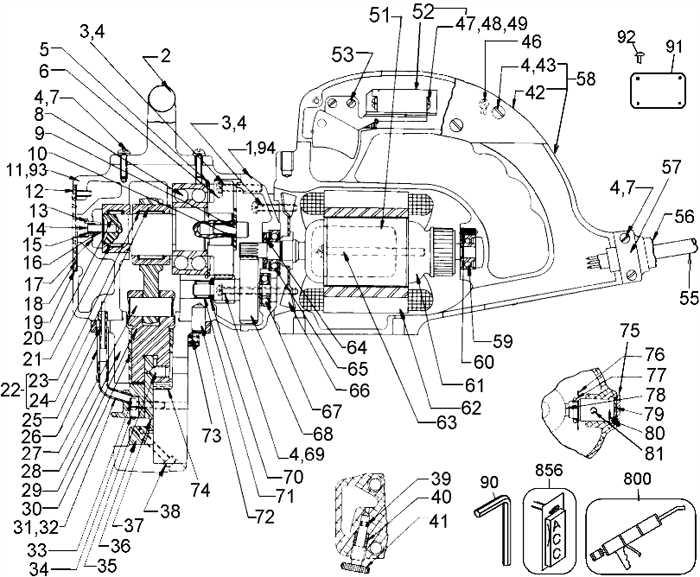

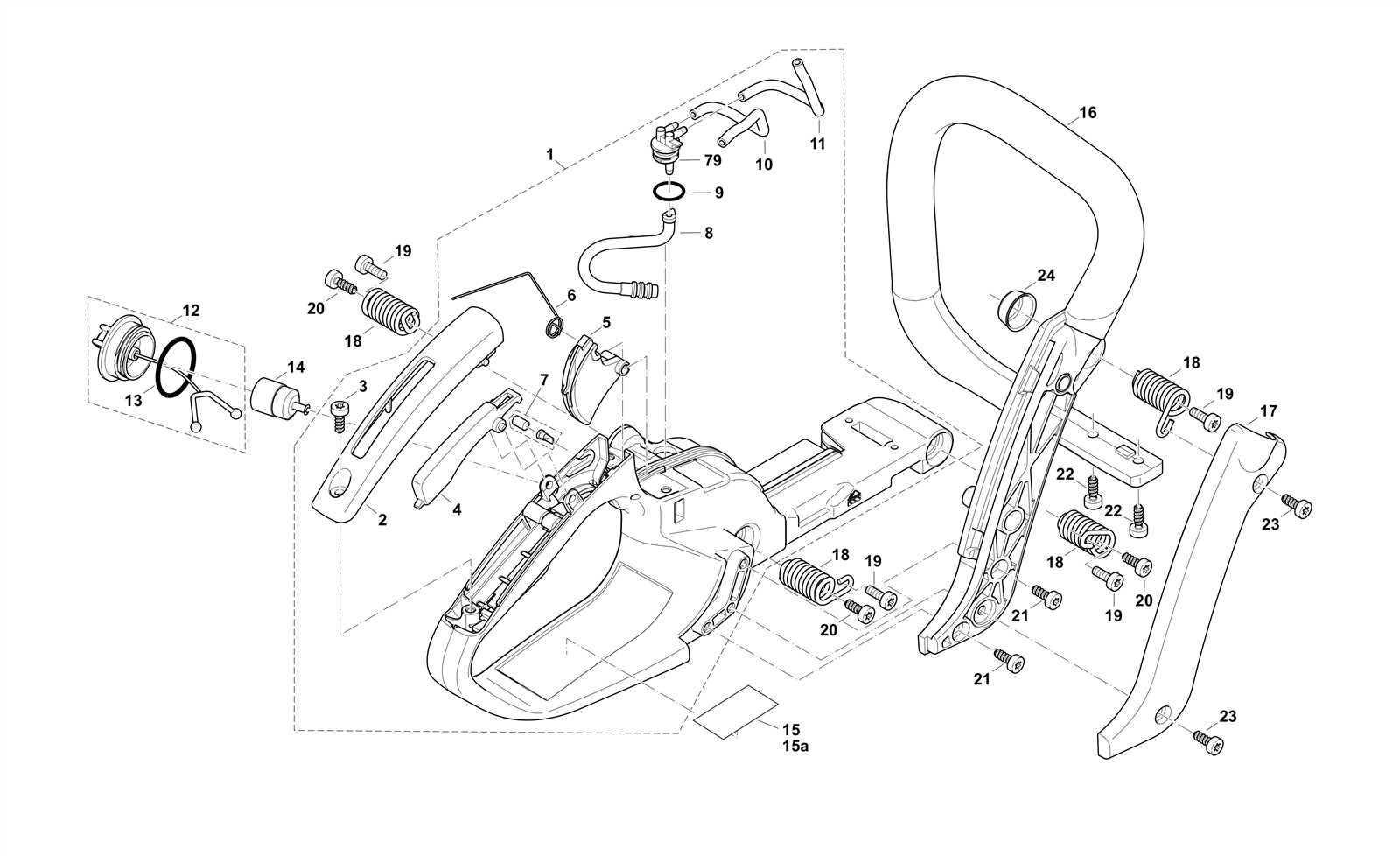

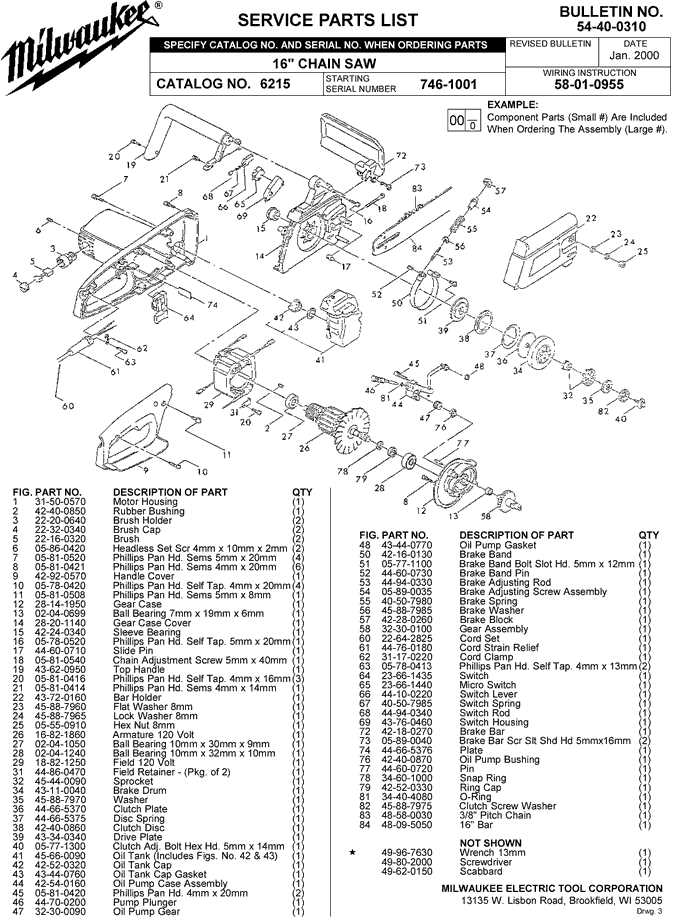

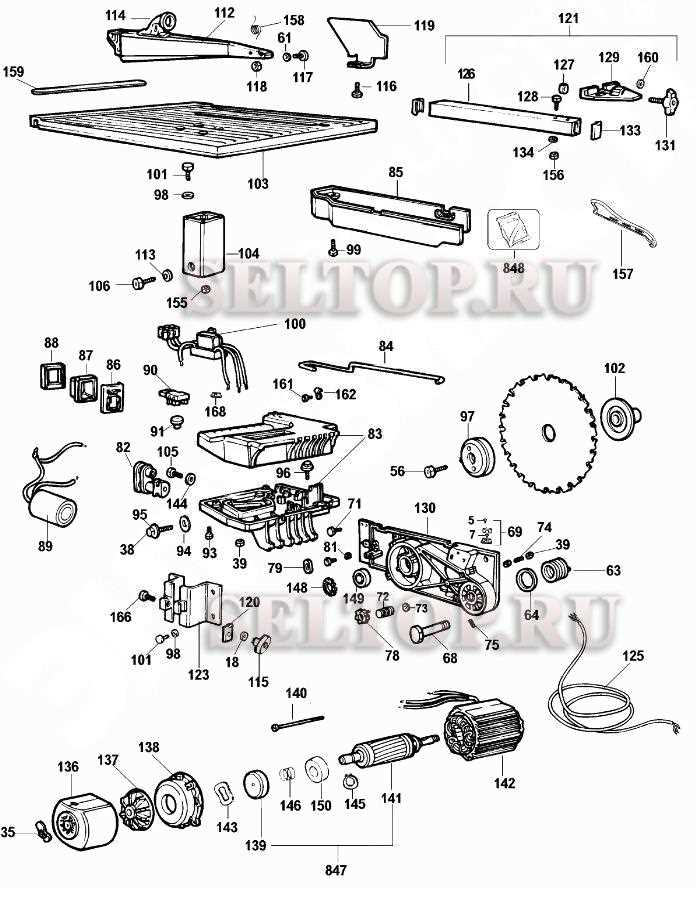

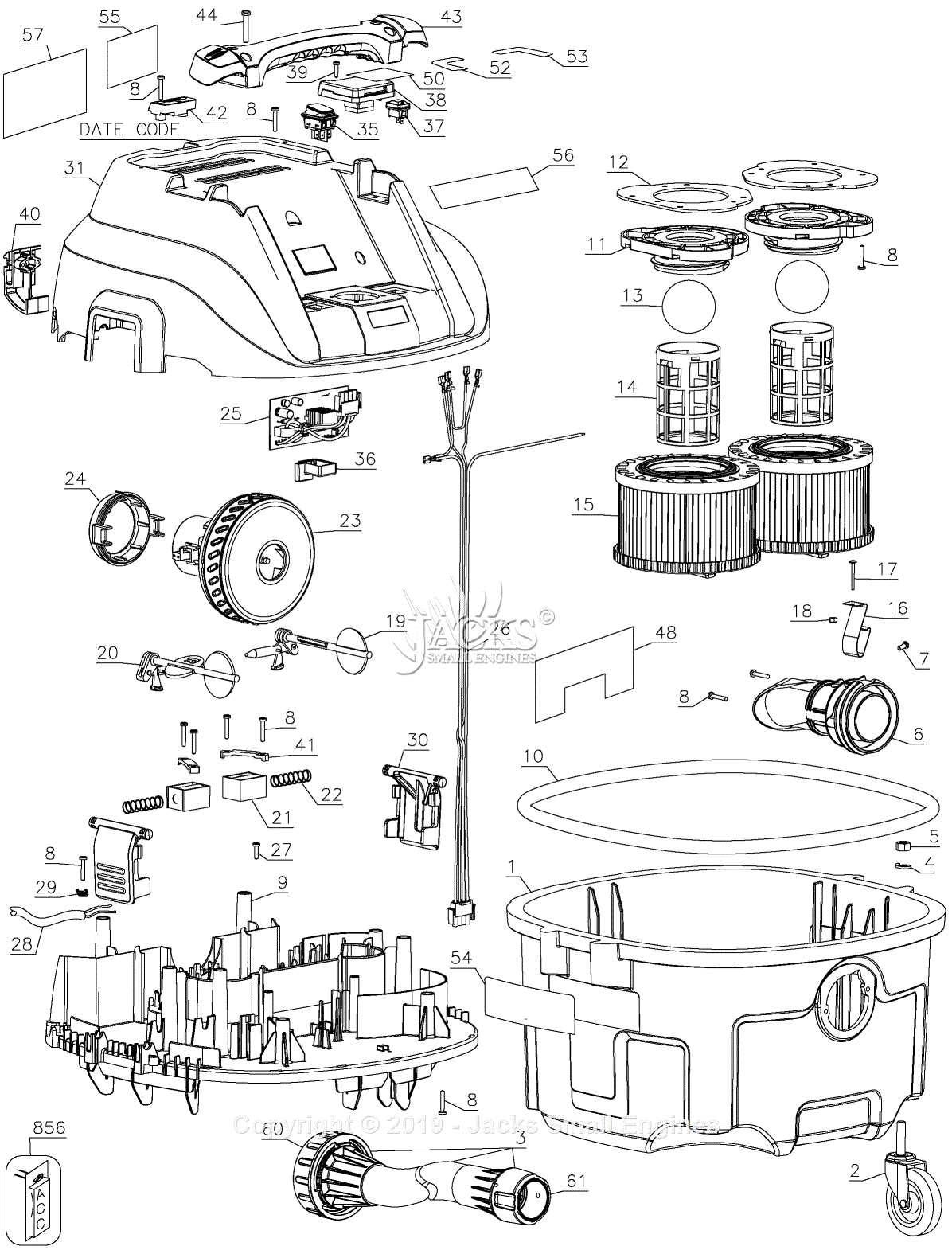

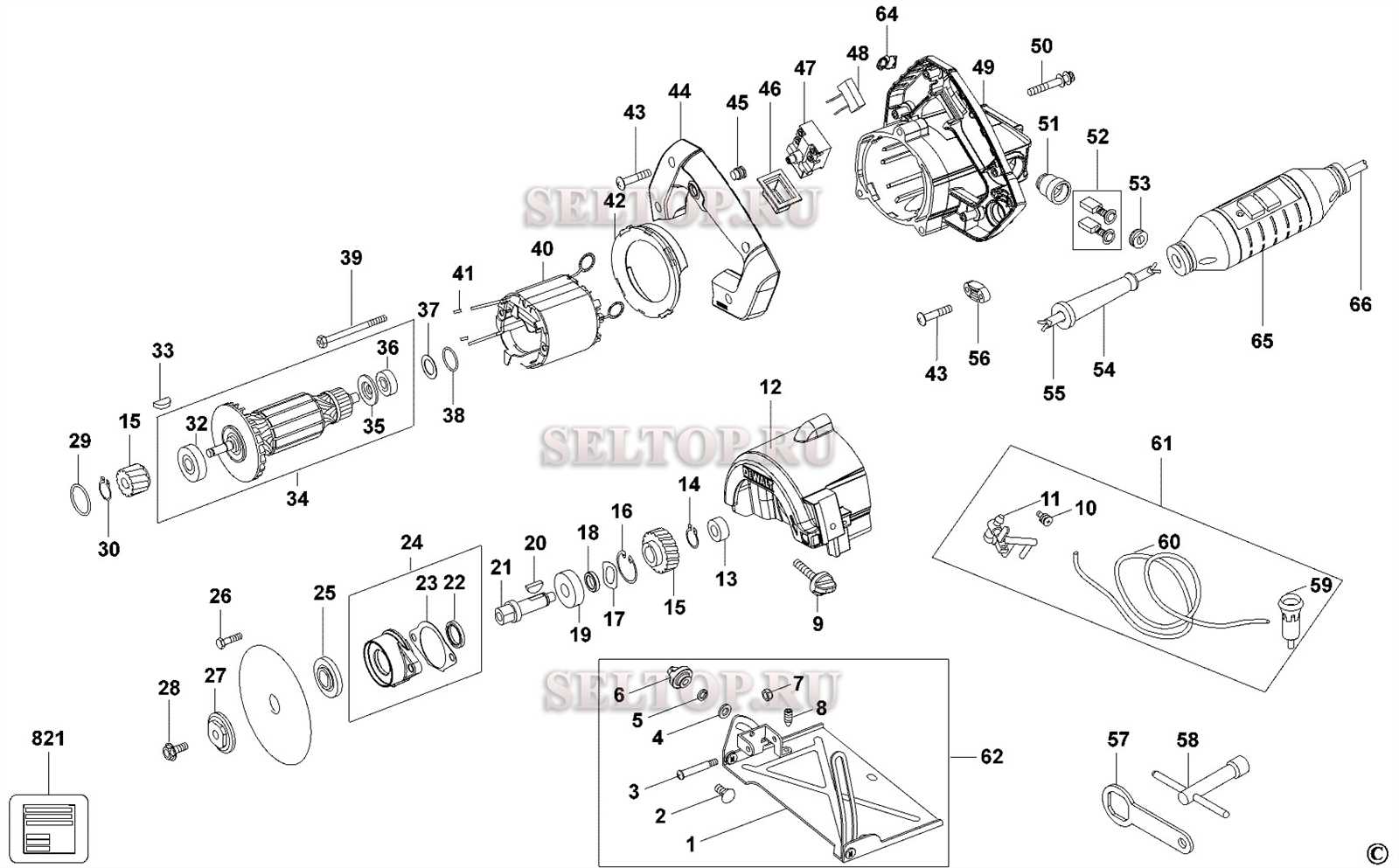

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and functionality of complex tools. They serve as essential guides for users, helping to streamline maintenance and repairs. Such illustrations enhance clarity, making it easier to identify individual elements and their interconnections.

- Facilitates troubleshooting by highlighting each component’s role.

- Enables efficient repairs, reducing downtime and costs.

- Aids in identifying missing or damaged elements quickly.

- Supports proper reassembly, ensuring tools function correctly post-service.

Moreover, these visual aids foster a deeper comprehension of the device’s mechanics, empowering users with the knowledge needed for effective handling. By utilizing these illustrations, individuals can enhance their skills and confidence in managing equipment.

- Improve user knowledge and proficiency.

- Enhance safety during repairs by ensuring correct assembly.

- Provide a reference for ordering replacement elements.

In conclusion, visual representations of components are invaluable resources that contribute significantly to the longevity and performance of tools. They not only aid in the immediate tasks but also enhance overall user experience and competence.

How to Read a Parts Diagram

Understanding the layout of components is crucial for effective maintenance and repair tasks. By familiarizing yourself with the visual representation of each element, you can identify individual pieces and their relationships to one another. This knowledge enables efficient troubleshooting and reassembly.

Identifying Key Sections

Typically, these visual aids are divided into sections that group similar elements together. Familiarize yourself with how the parts are categorized. For example, you may find sections dedicated to the engine, cutting mechanism, or safety features. Each grouping aids in isolating issues based on the area of concern.

Understanding Symbols and Labels

In addition to visual groupings, you’ll encounter various symbols and labels that provide crucial information. Pay attention to these annotations, as they often indicate part numbers, specifications, and instructions for assembly or disassembly. Recognizing these markers will streamline your repair process and ensure you acquire the correct replacements when necessary.

Common Issues with Chainsaw Parts

When operating a cutting tool, understanding potential challenges with its components is crucial for optimal performance and longevity. Various factors can lead to malfunctions, impacting efficiency and safety. Identifying these common issues can help in timely maintenance and repairs.

- Wear and Tear: Over time, frequent usage can cause components to degrade, leading to decreased efficiency.

- Fuel System Problems: Issues with fuel flow, such as clogged filters or lines, can hinder operation.

- Electrical Failures: Malfunctions in the ignition or battery systems can prevent the device from starting.

- Bar and Chain Deterioration: Regular inspection is necessary to ensure proper alignment and tension, as misalignment can lead to excessive wear.

- Lubrication Deficiencies: Insufficient oiling can result in overheating and damage to critical moving parts.

By being aware of these common complications, users can take proactive measures to maintain their equipment effectively and ensure safe operation.

Maintenance Tips for Chainsaw Parts

Regular upkeep of your cutting tool is essential for optimal performance and longevity. By adhering to a few straightforward guidelines, you can ensure that each component functions effectively, reducing wear and enhancing safety.

- Cleanliness: Keep all elements free of debris and oil buildup. Use a soft brush or cloth to wipe down surfaces regularly.

- Lubrication: Apply the appropriate lubricant to moving parts as recommended by the manufacturer. This minimizes friction and prevents premature wear.

- Inspection: Regularly check for signs of damage, such as cracks or rust. Replace any compromised components promptly to maintain safety and performance.

- Sharpening: Keep cutting edges sharp for efficient operation. Use a proper sharpening tool and follow guidelines for angle and technique.

- Storage: Store your tool in a dry place, away from moisture and extreme temperatures. Use protective covers to shield it from dust and environmental factors.

Following these maintenance tips can greatly enhance the lifespan and functionality of your equipment, ensuring reliable performance whenever needed.

Finding Replacement Parts Easily

Locating the necessary components for your tools can often feel overwhelming, especially when faced with various options and resources. However, with the right approach and a bit of guidance, you can streamline the process and ensure you obtain the correct items without unnecessary hassle.

One effective method is to utilize online resources that provide detailed breakdowns of your equipment. By accessing these visuals, you can identify each element clearly, making it simpler to pinpoint what you need. Below is a summary of useful strategies for finding components efficiently:

| Strategy | Description |

|---|---|

| Online Catalogs | Visit manufacturer websites for extensive listings and specifications of available items. |

| Forums and Communities | Engage with online groups where users share their experiences and recommendations. |

| Local Retailers | Check with nearby hardware stores that may carry the required components or can order them for you. |

| Instruction Manuals | Refer to the original manuals for detailed information on compatible items and installation tips. |

By employing these strategies, you can simplify your search and ensure that your equipment remains in optimal working condition, ready for use when you need it most.

Identifying Parts by Model Number

Understanding the components of your equipment is crucial for effective maintenance and repair. By using the model number, you can accurately pinpoint the specific elements that are compatible with your device, ensuring optimal performance and longevity.

Why Model Numbers Matter

Model numbers serve as unique identifiers that provide essential information about your machine’s specifications and design. They help in locating the right components, avoiding mismatches, and streamlining the repair process. Each model is tailored for certain functionalities, making the identification of relevant elements straightforward and efficient.

How to Find and Use the Model Number

To begin, locate the model number, which is typically found on the body of the device or in the user manual. Once you have it, refer to the manufacturer’s resources or online databases to access detailed listings of compatible elements. This ensures that you obtain the correct replacements or enhancements for your equipment. Utilizing the model number simplifies the search, reducing the chances of errors and improving the overall repair experience.

Tools Needed for Parts Replacement

When it comes to maintaining and repairing equipment, having the right tools at your disposal is essential for a successful outcome. This section outlines the necessary implements to effectively swap out components, ensuring both efficiency and safety during the process.

1. Screwdrivers: A set of various sizes, including flathead and Phillips, will allow you to tackle a range of screws found in your machinery. It’s crucial to choose the appropriate type to avoid damaging the fasteners.

2. Wrenches: Adjustable or socket wrenches are indispensable for loosening or tightening nuts and bolts. Having a variety of sizes on hand will help accommodate different fittings.

3. Pliers: Needle-nose and standard pliers are useful for gripping, twisting, and cutting wires or small components. They offer added control when working in tight spaces.

4. Safety Gear: Always prioritize safety by wearing gloves and goggles. Protective equipment minimizes the risk of injury while handling sharp or heavy items.

5. Cleaning Tools: Brushes and cloths are necessary for cleaning parts before installation. Keeping components free of debris ensures optimal functionality.

Equipped with these essentials, you will be prepared to carry out repairs effectively, promoting longevity and performance in your equipment.

Visual Reference for Dewalt Chainsaws

This section serves as a comprehensive guide to understanding the components of your cutting tool. A visual representation allows users to familiarize themselves with each element, enhancing both maintenance and operational efficiency. Recognizing individual parts contributes to smoother functionality and informed troubleshooting.

Importance of Component Identification

Identifying each component is crucial for ensuring optimal performance. Knowing how various pieces fit together helps in performing repairs and replacements accurately. This knowledge not only extends the lifespan of the equipment but also enhances user safety.

How to Utilize Visual Aids

Using visual aids can simplify complex tasks. By referencing diagrams, users can follow step-by-step instructions more effectively. Incorporating these tools into your maintenance routine will empower you to tackle challenges confidently. Remember, a well-informed operator is a safer operator.

Benefits of Using OEM Parts

When it comes to maintaining tools and equipment, opting for original components can significantly enhance performance and longevity. These authentic items are specifically designed to fit perfectly, ensuring optimal functionality and reducing the risk of failure. Below are some key advantages of choosing original manufacturing components.

Quality Assurance

Original components typically undergo rigorous testing and quality control processes, providing users with reliable and durable options. Here are some reasons why quality matters:

- Consistent performance over time

- Enhanced safety during operation

- Reduced likelihood of malfunctions

Compatibility and Support

Using original components ensures compatibility with your equipment, leading to smoother operation. Consider these points:

- Exact fit minimizes installation issues

- Manufacturer support is readily available for guidance

- Warranty coverage often applies, protecting your investment

In summary, choosing original manufacturing components can lead to superior performance, peace of mind, and a more efficient maintenance experience.

Frequently Asked Questions about Chainsaws

This section addresses common inquiries regarding cutting tools, focusing on their components, maintenance, and operation. Understanding these aspects can enhance user experience and ensure safety while working with these powerful machines.

- What are the main components of a cutting tool?

- Motor

- Bar

- Chain

- Oil reservoir

- Handle

- How often should I perform maintenance?

- Regularly check the chain tension.

- Clean the air filter monthly.

- Inspect the bar and chain for wear.

- Change the oil regularly.

- What safety gear is recommended?

- Protective eyewear

- Gloves

- Ear protection

- Sturdy footwear

- Helmet

- How do I choose the right tool for my needs?

- Consider the type of tasks you’ll be performing.

- Evaluate the power source–electric or gas.

- Assess the weight and ease of use.

- Check for features like automatic oiling or anti-vibration systems.

- What should I do if the tool is not functioning properly?

- Check the power source.

- Inspect the chain for damage.

- Ensure proper tensioning.

- Consult the user manual for troubleshooting tips.