The intricate design of a powerful cutting instrument comprises various essential elements that work harmoniously to deliver optimal performance. Recognizing each segment’s function not only enhances efficiency but also simplifies maintenance and repairs. A thorough comprehension of these components can significantly improve the user experience and longevity of the equipment.

As enthusiasts and professionals alike engage in tasks ranging from simple yard work to complex woodworking, familiarity with the structure of these tools becomes paramount. Whether it’s the mechanisms that drive motion or the attachments that facilitate cutting, each piece plays a critical role in achieving the ultimate results.

In this section, we will delve into the various segments that constitute this cutting apparatus, highlighting their importance and interconnections. By exploring these intricacies, users can better appreciate the craftsmanship behind their tools and ensure they operate at peak efficiency.

Understanding Dolmar Chainsaw Components

Exploring the intricate elements of a power cutting tool reveals a complex assembly designed for efficiency and precision. Each component plays a vital role in ensuring optimal performance and safety during operation. Recognizing how these pieces work together enhances the user’s experience and prolongs the life of the equipment.

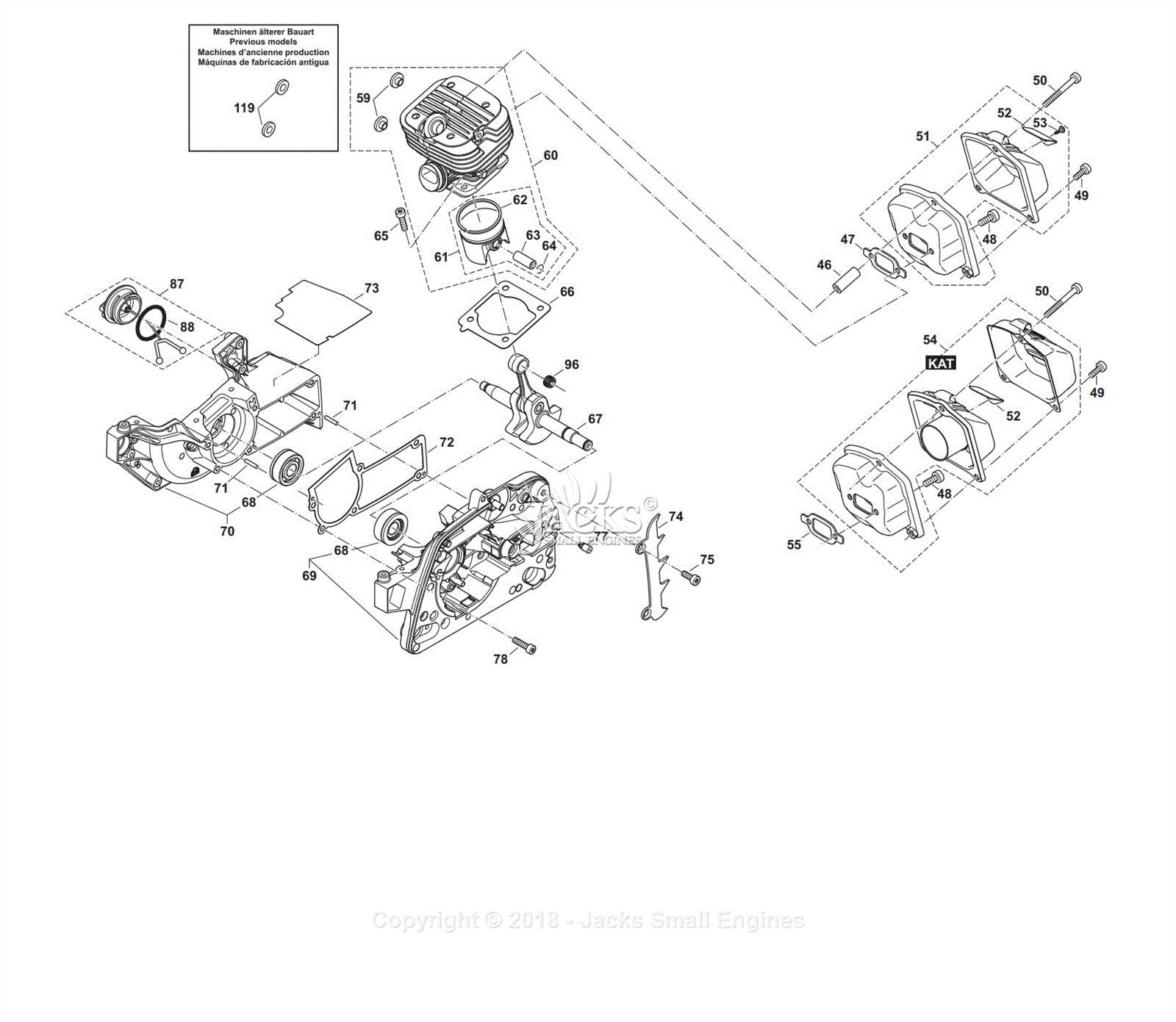

The Engine and Power Mechanism

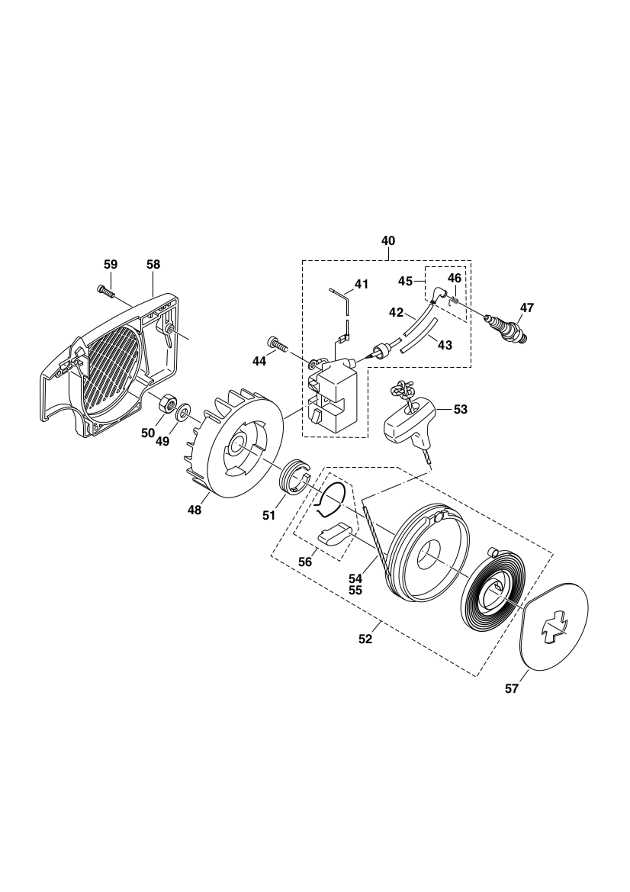

The core of any cutting apparatus is its motor, which converts fuel into mechanical energy. This energy is transmitted through a system of gears and shafts, facilitating the rapid motion necessary for effective cutting. Regular maintenance of the engine is crucial; it ensures that the power delivery remains consistent, preventing unexpected breakdowns during use.

Cutting Equipment and Safety Features

At the forefront of any cutting operation is the blade assembly, designed for sharpness and durability. Proper alignment and tension of the blade are essential for achieving clean cuts while minimizing the risk of kickback. Additionally, safety features such as chain brakes and protective guards serve to protect the user, emphasizing the importance of understanding how to operate the tool safely.

Key Parts of Dolmar Chainsaws

Understanding the essential components of these powerful tools is crucial for maintenance and efficient operation. Each element plays a significant role in the overall functionality, ensuring that tasks are completed effectively.

Essential Components

- Engine: Provides the necessary power to operate.

- Bar: The cutting surface that guides the chain.

- Chain: The loop that performs the cutting action.

- Handle: Ensures control and comfort during use.

- Fuel Tank: Holds the mixture for operation.

Maintenance Elements

- Air Filter: Keeps dirt out of the engine.

- Chain Brake: Enhances safety by stopping the chain quickly.

- Lubrication System: Ensures the chain and bar remain well-oiled.

- Spark Plug: Ignites the fuel mixture for combustion.

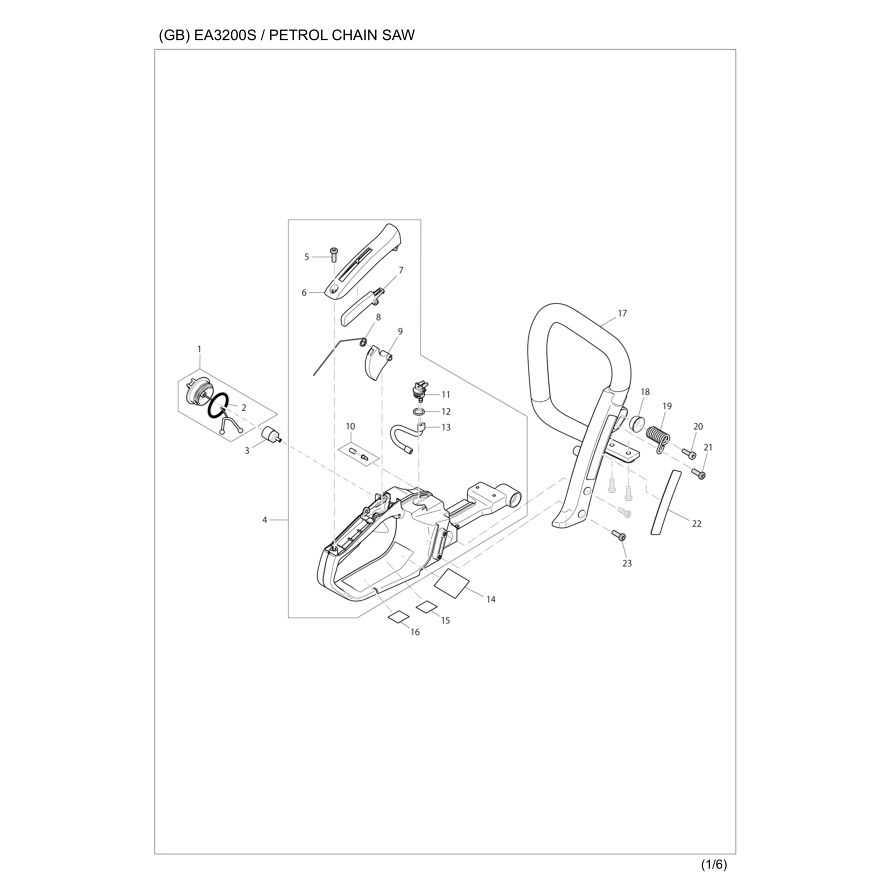

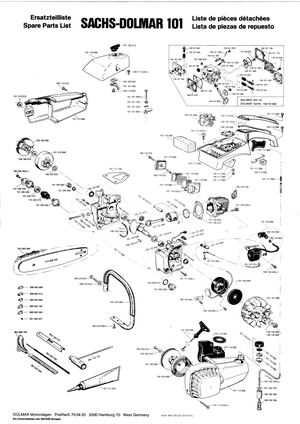

How to Read Parts Diagrams

Understanding illustrations that depict components can significantly enhance your ability to identify and locate individual items within a mechanism. These visuals serve as essential guides, allowing users to grasp how various elements fit together and function collectively.

When examining such visuals, it’s important to recognize common symbols and notations that represent different elements. Here are some key aspects to consider:

| Symbol/Notation | Meaning |

|---|---|

| Solid Lines | Indicate visible components |

| Dotted Lines | Represent hidden elements |

| Numbers | Refer to specific item references |

| Arrows | Show movement or direction |

By familiarizing yourself with these conventions, you can delve into the intricate details of the assembly, making it easier to source replacements or perform maintenance. This knowledge is ultimately invaluable for effective repair and upkeep.

Common Dolmar Chainsaw Issues

Many users encounter typical challenges with their cutting tools, affecting performance and reliability. Understanding these common problems can help in timely maintenance and enhance the longevity of the equipment.

Engine Performance Problems

One of the most frequent issues is related to engine functionality. Symptoms such as difficulty starting or stalling during operation may indicate fuel system malfunctions or air filter blockages. Regular inspection of the fuel lines and filters can prevent these complications.

Bar and Chain Wear

Another prevalent concern is the wear and tear of the guide and cutting elements. Users often notice uneven cuts or excessive vibration. Keeping the bar properly lubricated and ensuring the chain is sharp can significantly mitigate these issues, ensuring smooth and efficient operation.

Replacing Worn-Out Components

Ensuring the longevity and efficiency of your equipment involves timely replacement of aged or damaged elements. This process not only enhances performance but also contributes to safety during operation. Recognizing signs of wear and understanding the components that require attention is essential for maintaining optimal functionality.

Identifying Signs of Wear

Common indicators of component degradation include unusual noises, decreased performance, and visible damage. Regular inspections can help in spotting these issues early, allowing for proactive replacements.

Replacement Process

When proceeding with the replacement, it is vital to follow the correct procedures to avoid further complications. Referencing a detailed schematic can guide you through the steps effectively.

| Component | Signs of Wear | Replacement Frequency |

|---|---|---|

| Blade | Dullness, chips | After 20 hours of use |

| Fuel Filter | Clogs, reduced flow | Every season |

| Air Filter | Dirt accumulation | Monthly |

Maintenance Tips for Longevity

Ensuring the extended life of your outdoor power equipment requires regular care and attention. By following a few essential practices, you can maintain peak performance and avoid costly repairs. These guidelines will help you keep your tools in optimal condition, enhancing both their efficiency and durability.

Regular Cleaning: After each use, remove debris and residues from the machine. This prevents build-up that can lead to corrosion and other issues. Pay special attention to the air filter and cooling fins, as they are crucial for maintaining proper airflow and function.

Lubrication: Properly lubricate moving components to minimize friction and wear. Use the recommended oils for specific parts, ensuring smooth operation. Regular lubrication not only extends the life of components but also improves overall performance.

Inspect Components: Regularly check all essential elements for signs of wear or damage. Look for cracks, looseness, or any abnormal conditions. Early detection of issues allows for timely repairs, preventing further damage.

Sharpening Blades: Keep cutting edges sharp for efficient performance. Dull blades require more power and can strain the equipment. Regular sharpening reduces wear on the motor and enhances cutting precision.

Storage Practices: Store equipment in a dry, cool location to prevent rust and deterioration. Use protective covers and remove fuel to avoid degradation during long periods of inactivity. Proper storage extends the longevity of your tools significantly.

Implementing these maintenance tips will not only enhance the performance of your equipment but also ensure it serves you well for many years to come.

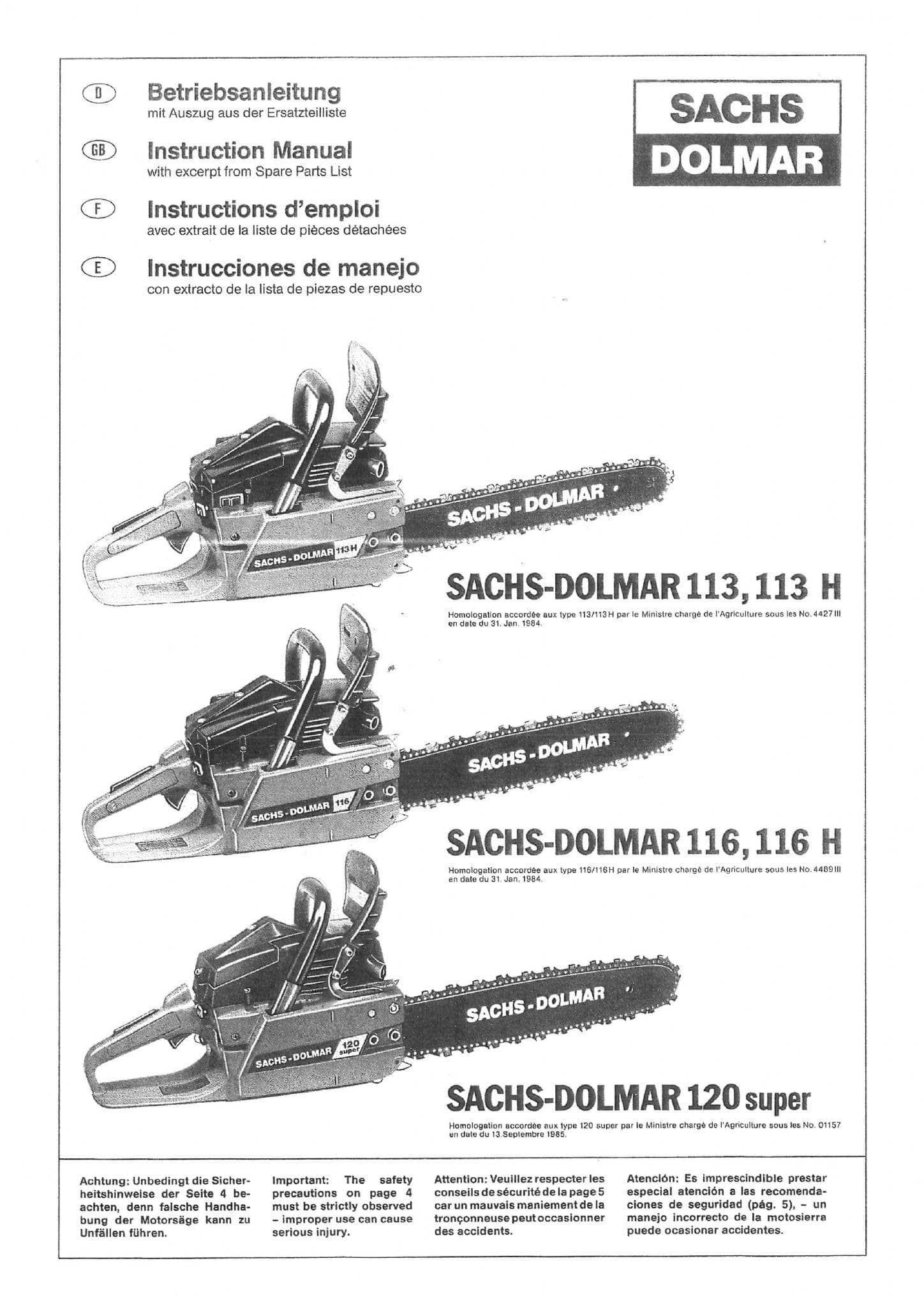

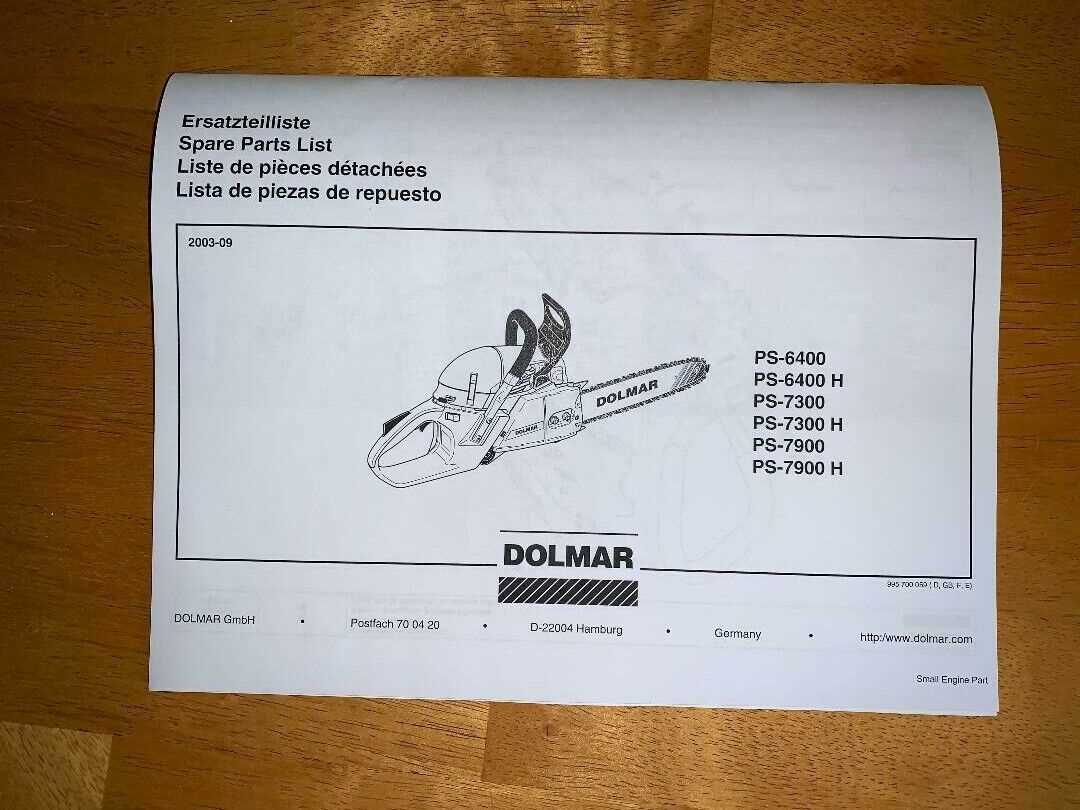

Identifying Specific Parts by Model

Understanding the components of a power tool is essential for maintenance and repair. Each model typically has unique elements that serve specific functions, and recognizing these components can streamline the troubleshooting process. This section will guide you through the identification of essential parts based on the model number, ensuring you have the right information for efficient service.

Key Features to Consider

- Model Number: Always start with the model number, as it provides crucial details about the specifications and compatible components.

- Component Location: Familiarize yourself with where each part is located, as this can aid in quick identification.

- Visual Characteristics: Pay attention to color, shape, and size variations that distinguish similar components.

Steps for Identification

- Locate the model number on the tool.

- Refer to a comprehensive list or guide associated with that model.

- Compare visual attributes of the components you need to identify.

- Consult manufacturer resources for specific descriptions if needed.

By following these guidelines, you can effectively pinpoint the necessary elements required for repairs or replacements, ultimately enhancing the longevity and performance of your equipment.

Benefits of Using Original Parts

Utilizing authentic components in your equipment ensures optimal performance and longevity. These elements are specifically designed to meet the exact specifications of the machinery, promoting seamless integration and functionality. When original items are used, users can experience enhanced reliability and reduced risk of malfunctions.

One significant advantage is the assurance of quality. Genuine components are manufactured under strict guidelines, resulting in superior durability and effectiveness compared to generic alternatives. This means less frequent replacements and maintenance, ultimately saving time and money in the long run.

Additionally, employing original elements often comes with the benefit of warranties and customer support. Manufacturers typically back their products, providing peace of mind and assistance if issues arise. This level of support is often absent with third-party items.

Moreover, using authentic components helps maintain the equipment’s resale value. Buyers are more likely to trust machines that have been kept in original condition, as they associate this with better upkeep and reliability. Thus, investing in genuine parts not only enhances performance but also secures future value.

Where to Buy Replacement Parts

Finding the right components for your equipment can be a challenging task, but it is essential for maintaining performance and longevity. Whether you need to replace worn-out items or upgrade certain features, knowing where to look can make the process much smoother.

Online Retailers

Shopping online offers convenience and a vast selection. Here are some popular platforms:

- Amazon: A wide variety of options, often with user reviews to guide your choice.

- eBay: Ideal for finding both new and used components at competitive prices.

- Specialty Websites: Sites dedicated to outdoor equipment often provide quality items and expert advice.

Local Stores

Visiting a physical store can provide immediate solutions and the opportunity to consult with knowledgeable staff. Consider these options:

- Hardware Stores: Most carry essential supplies and may have the specific items you need.

- Garden Centers: Often stocked with tools and accessories suitable for outdoor maintenance.

- Authorized Dealers: They can offer genuine components and specialized support.

Tools Needed for Repairs

When it comes to maintaining and fixing outdoor power equipment, having the right tools on hand is essential. Proper instruments not only make the job easier but also ensure safety and efficiency during the repair process. Understanding which tools are necessary can significantly enhance your repair experience.

Essential Tools

- Wrenches: A set of adjustable and fixed wrenches will help you loosen or tighten various components.

- Screwdrivers: Both flathead and Phillips screwdrivers are crucial for accessing screws and fasteners.

- Pliers: Needle-nose and standard pliers are useful for gripping and manipulating small parts.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Socket Set: A comprehensive socket set allows for easier handling of nuts and bolts.

Additional Equipment

- Safety Gear: Always wear gloves and goggles to protect yourself during repairs.

- Workbench: A sturdy work surface is vital for organizing tools and parts.

- Cleaning Supplies: Keep a cloth and cleaning solution handy for maintaining components.

- Measuring Tools: Calipers or tape measures can be beneficial for precise measurements.

Equipped with these tools, you’ll be well-prepared to tackle any repair task with confidence and ease.

Safety Precautions During Maintenance

Ensuring safety during the upkeep of equipment is paramount to prevent accidents and injuries. Proper precautions not only protect the individual performing maintenance but also extend the lifespan of the machinery. Following guidelines helps create a secure environment where maintenance can be conducted effectively.

Essential Safety Measures

Before beginning any maintenance work, it is crucial to wear appropriate personal protective equipment (PPE). This includes items such as gloves, goggles, and sturdy footwear. Additionally, ensuring that the workspace is clear of obstacles and potential hazards will contribute to a safer maintenance experience.

Steps to Ensure a Safe Environment

| Step | Description |

|---|---|

| 1. Disconnect Power | Always disconnect the power source to prevent accidental startup during maintenance. |

| 2. Use Proper Tools | Utilize the right tools for the job to avoid mishandling and injuries. |

| 3. Follow Manufacturer Guidelines | Refer to the manufacturer’s instructions for specific maintenance procedures and safety tips. |

| 4. Keep Work Area Clean | A tidy workspace minimizes the risk of accidents and allows for efficient work. |

| 5. Dispose of Waste Properly | Ensure that any waste or debris is disposed of in accordance with local regulations to avoid environmental hazards. |