Maintaining the efficiency of any outdoor power equipment relies heavily on understanding its internal structure. By familiarizing yourself with the individual elements that contribute to its performance, you can ensure a longer lifespan and optimal functionality. This knowledge empowers users to tackle repairs and replacements with confidence, enhancing their overall experience.

Each model features a unique assembly, comprising various components that work together seamlessly. Recognizing how these pieces interact is crucial for troubleshooting and enhancing performance. A comprehensive overview of these elements can serve as an invaluable resource for both seasoned users and newcomers.

In this section, we will explore a detailed representation of the essential components of this specific outdoor device. By examining their arrangement and function, you will gain insights that can aid in maintenance and repairs, ultimately leading to more effective usage and greater satisfaction.

Understanding Husqvarna 359 Chainsaw Parts

Exploring the components of a powerful cutting tool is essential for both maintenance and effective operation. Each element plays a vital role in ensuring optimal performance, making it crucial to familiarize oneself with their functions and interconnections.

Key Components and Their Functions

Engine: The heart of the tool, responsible for converting fuel into power. Understanding its mechanics can enhance efficiency and longevity.

Bar and Chain: These elements work in tandem to deliver precision cuts. Regular inspection and upkeep are necessary to prevent wear and ensure safety.

Maintenance Tips

Regular cleaning and lubrication of moving parts can significantly extend the lifespan of the equipment. Additionally, knowing how to replace worn components promptly will contribute to a smoother operation and better results.

Overview of Chainsaw Components

This section provides a comprehensive understanding of the key elements that make up a cutting tool. Each component plays a vital role in ensuring optimal performance and efficiency during operation.

- Engine: Powers the device and drives the cutting mechanism.

- Guide Bar: The elongated metal part that supports the cutting chain.

- Cutting Chain: The loop of sharp teeth that performs the cutting action.

- Clutch: Engages and disengages the cutting mechanism based on the user’s input.

- Throttle Trigger: Controls the speed and power of the engine.

Understanding these components can help users maintain and operate their tools effectively, enhancing their overall experience.

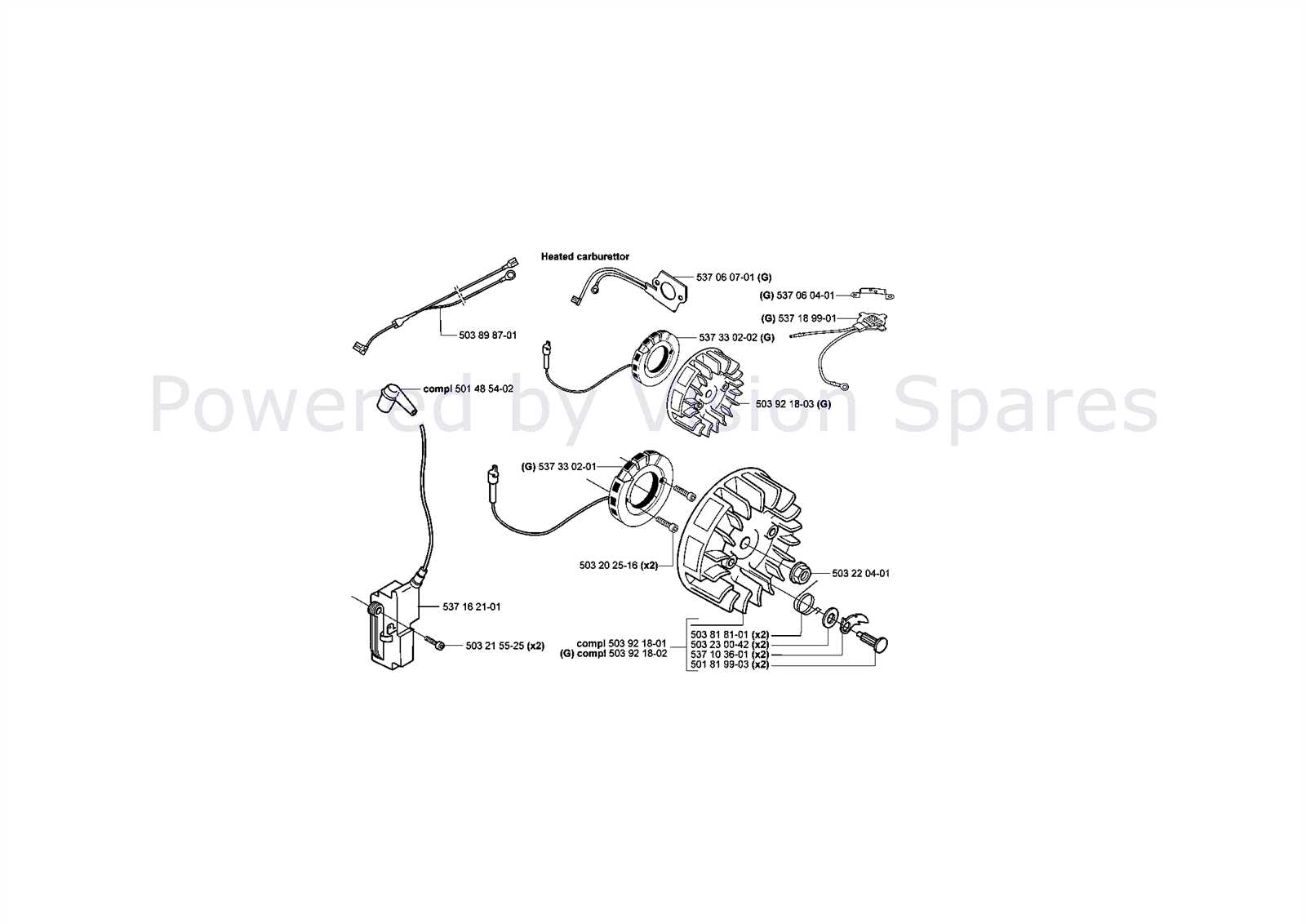

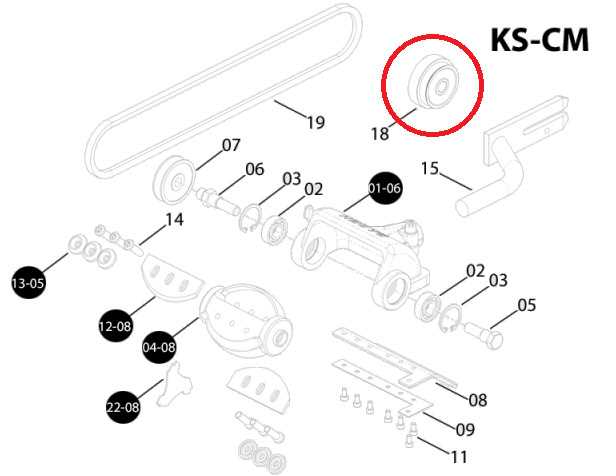

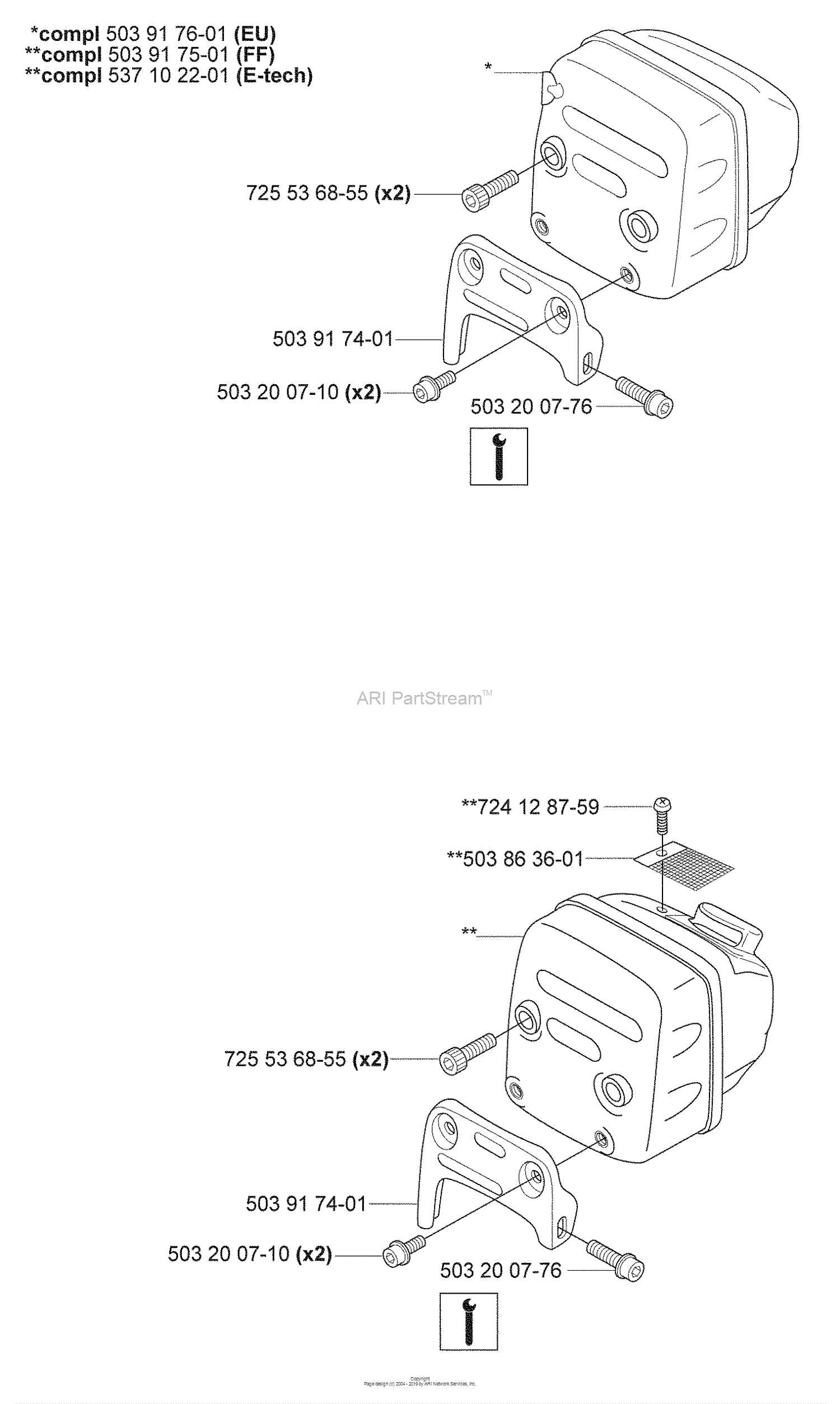

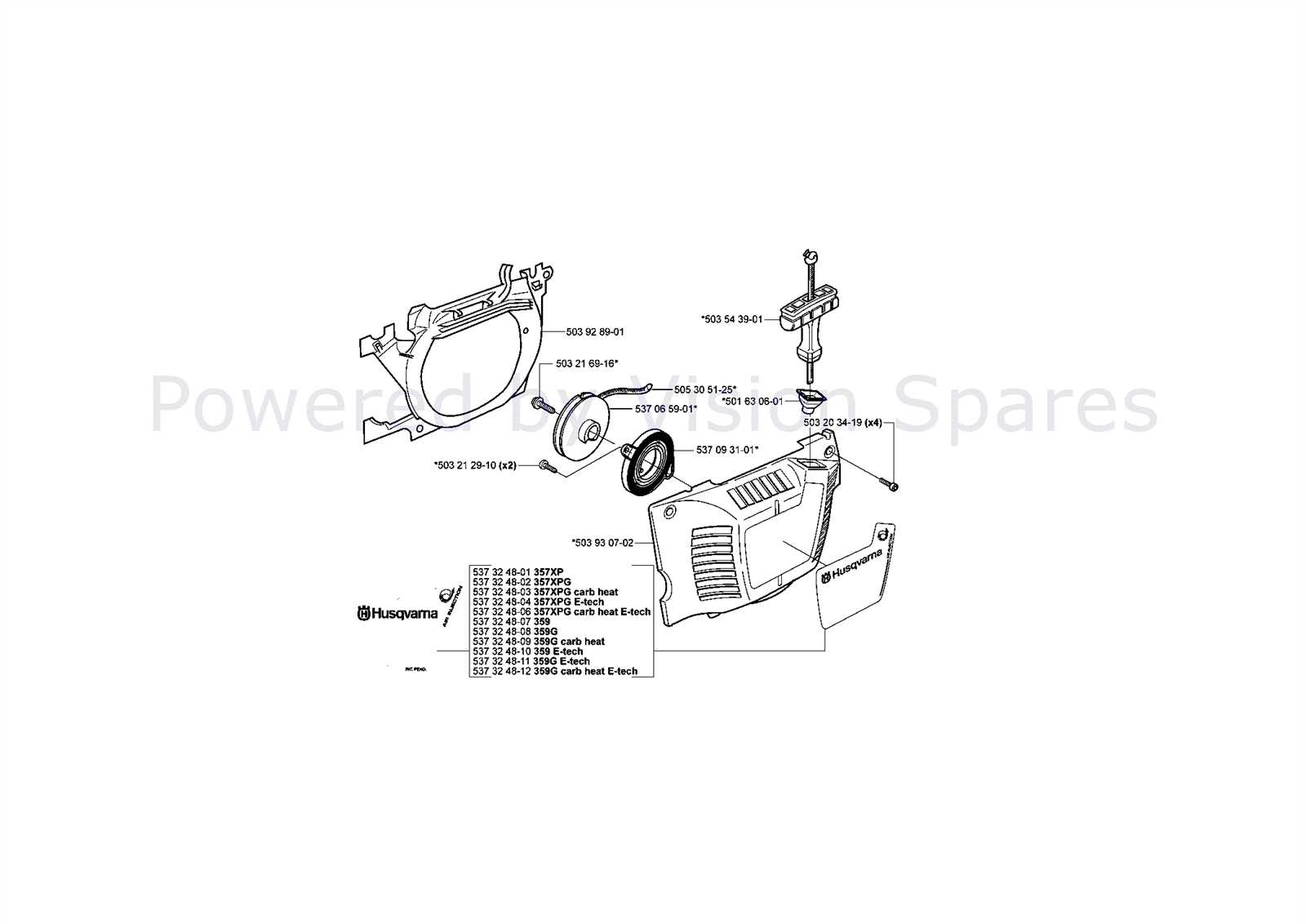

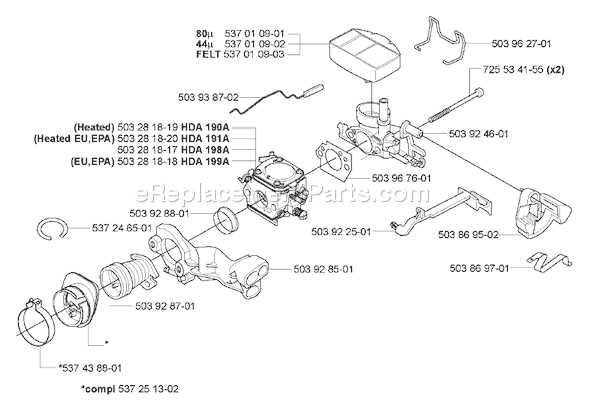

Detailed Parts Diagram Explanation

This section provides a comprehensive overview of the intricate assembly of a specific cutting tool, emphasizing the relationships between its various components. Understanding how each piece functions within the larger mechanism is essential for effective maintenance and troubleshooting.

Component Relationships

The relationship between the different elements is crucial for the overall performance of the device. Each part, from the engine to the cutting mechanism, works in harmony to ensure efficient operation. Recognizing how these components interact can help users diagnose issues more effectively and perform necessary repairs.

Maintenance and Repair Insights

Familiarity with the arrangement and function of each section not only aids in routine upkeep but also enhances safety during operation. Knowledge of how to access specific pieces for replacement or adjustment can prevent damage and prolong the lifespan of the equipment. Proper care, based on a thorough understanding of the assembly, is vital for optimal performance.

Common Issues with Chainsaw Parts

Understanding the frequent complications associated with cutting tools can greatly enhance their longevity and efficiency. Identifying these common issues allows users to maintain their equipment better, ensuring optimal performance and safety during operation.

Wear and Tear

Over time, components may experience deterioration due to regular use. This can lead to reduced efficiency, making it essential to monitor for signs of wear, such as dull blades or compromised safety features.

Fuel System Problems

Fuel-related issues are prevalent, often stemming from clogging or contamination. Ensuring that the fuel system remains clean and properly maintained is crucial to prevent starting difficulties and performance declines.

How to Identify Genuine Parts

Ensuring the authenticity of components is crucial for optimal performance and longevity of your equipment. Recognizing original items can prevent potential issues related to compatibility and reliability.

| Feature | Genuine Component | Counterfeit Component |

|---|---|---|

| Packaging | Branded, high-quality packaging | Generic or poor-quality packaging |

| Labeling | Clear, accurate labeling with a serial number | Missing or unclear labels |

| Quality | Durable materials and precise fit | Flimsy materials and poor fit |

| Pricing | Consistent pricing with official sources | Significantly lower prices |

By examining these aspects, you can confidently select authentic components that contribute to the ultimate performance of your machinery.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring optimal performance and extending the lifespan of your equipment. Regular maintenance not only enhances efficiency but also prevents costly repairs down the line.

- Regular Cleaning: Keep the exterior free of debris and dirt to avoid overheating.

- Inspect Components: Check all parts for wear and tear, replacing any damaged items promptly.

- Lubrication: Ensure that moving parts are adequately lubricated to reduce friction.

- Fuel Quality: Use fresh, high-quality fuel to maintain engine performance.

- Sharpen Blades: Regularly sharpen cutting tools for efficient operation.

By following these tips, you can ensure that your machinery remains reliable and performs at its best for years to come.

Tools Required for Parts Replacement

When it comes to maintaining outdoor power equipment, having the right tools is essential for successful component swaps. Properly equipped, you can ensure efficiency and safety during the replacement process, ultimately prolonging the life of your device.

Essential Tools

- Socket Wrench Set

- Screwdrivers (Flathead and Phillips)

- Torque Wrench

- Replacement Components

Additional Items

- Pliers

- Cleaning Brush

- Lubricant

- Safety Gear (Gloves and Goggles)

By gathering these essential tools, you will be well-prepared to handle any necessary maintenance and repairs with confidence and care.

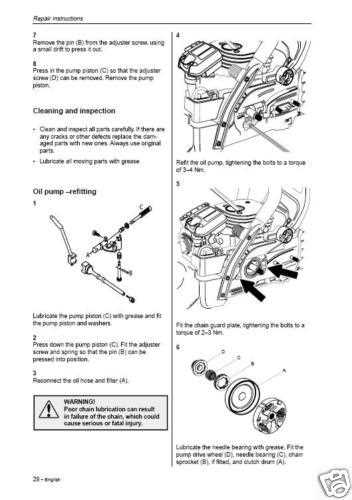

Assembly and Disassembly Guide

This section provides essential instructions for the careful assembly and disassembly of your tool. Understanding the process is crucial for maintenance and repairs, ensuring optimal performance and longevity. Proper handling of components prevents damage and ensures safety during usage.

Disassembly Steps:

Begin by gathering the necessary tools, such as a screwdriver and wrench. Disconnect the power source to eliminate any risk of accidental operation. Carefully remove the casing by unscrewing the designated screws. As you take apart each component, organize them systematically to facilitate reassembly. Take note of the arrangement of parts, as this will aid in reinstallation.

Assembly Steps:

Once all components are laid out, begin reassembling by following the reverse order of disassembly. Ensure that each part fits snugly and securely, avoiding overtightening that may cause damage. Reconnect the power source only after verifying that everything is in place and functioning correctly. Conduct a thorough inspection to confirm that all screws and fittings are secure before testing the tool.

Following these guidelines will help maintain your equipment in peak condition, making future maintenance tasks simpler and more efficient.

Aftermarket vs. OEM Components

When it comes to replacing essential components of outdoor power equipment, users often face the choice between original manufacturer parts and alternative options. Each category offers distinct advantages and considerations that can impact performance, durability, and cost. Understanding these differences is crucial for making informed decisions that align with individual needs and preferences.

Quality and Performance

Original components are typically designed specifically for the equipment, ensuring a precise fit and reliable operation. They undergo rigorous testing to meet manufacturer standards, which can translate to longer life and better performance. Conversely, alternative options may vary significantly in quality. While some aftermarket products can provide excellent performance at a lower price, others may compromise on reliability, potentially leading to issues down the line.

Cost Considerations

Price is often a decisive factor when choosing between original and alternative components. Original parts tend to be more expensive due to their guaranteed compatibility and quality assurance. On the other hand, aftermarket options often present a budget-friendly alternative. However, the initial savings may be offset by potential maintenance costs or reduced longevity, making it essential to weigh the long-term implications of each choice.

Safety Precautions During Repairs

When undertaking maintenance on power tools, it is essential to prioritize safety to prevent accidents and injuries. Proper precautions ensure that the repair process is not only effective but also secure for the technician involved.

Always wear appropriate protective gear, such as gloves, goggles, and ear protection, to shield yourself from potential hazards. Additionally, ensure that your workspace is well-lit and organized to minimize risks associated with clutter.

Before starting any repair work, disconnect the power source to eliminate the chance of accidental activation. It is also wise to familiarize yourself with the equipment’s manual, as it provides crucial safety information and repair guidelines.

Lastly, never hesitate to ask for assistance or consult a professional if you are unsure about any aspect of the repair. Taking the time to ensure safety can ultimately save you from serious injury.

Where to Purchase Replacement Parts

Finding the right components for your equipment can greatly enhance its performance and longevity. Whether you are a professional or a hobbyist, knowing where to source quality replacements is essential for maintaining your tools effectively.

One of the best options is to visit authorized dealers, who offer genuine items that meet the manufacturer’s standards. These retailers often have knowledgeable staff who can assist with specific inquiries and provide recommendations tailored to your needs.

Another valuable source is online marketplaces. Websites dedicated to outdoor equipment frequently feature a wide selection of components, often at competitive prices. Be sure to check customer reviews and seller ratings to ensure a reliable transaction.

Local hardware stores can also be a convenient choice, especially for common items. They may carry a selection of parts or be able to order what you need quickly.

Lastly, consider exploring specialty online forums and communities where enthusiasts share insights and resources. Members often exchange tips on where to find hard-to-locate items or even offer them for sale directly.

By utilizing these various channels, you can confidently find the right replacements to keep your tools in peak condition.

Benefits of Understanding Your Chainsaw

Gaining a solid comprehension of your cutting tool enhances not only its performance but also your safety and efficiency. Familiarity with its components and mechanics allows for better maintenance and troubleshooting, ultimately leading to a more satisfying experience during use.

Improved Safety

Understanding your equipment significantly contributes to safe operation. Here are some key safety benefits:

- Identifying potential hazards associated with improper use.

- Recognizing the importance of safety gear and protocols.

- Knowing how to react in case of malfunctions or accidents.

Enhanced Performance

Knowledge of your tool’s functions can lead to improved efficiency and longevity. Consider the following advantages:

- Regular maintenance becomes more straightforward, preventing breakdowns.

- Improved cutting efficiency by using the right techniques.

- Informed decisions about upgrades or replacements can be made.

Ultimately, a deeper understanding of your equipment empowers you to operate with confidence and skill, making your tasks easier and more enjoyable.